Checking Solder Joints With Multimeter . By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. A multimeter can measure continuity, resistance,. In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. Additionally, check for cold solder joints with a dull or grainy surface appearance. Testing for a good solder connections. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with.

from fabacademy.org

In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. Additionally, check for cold solder joints with a dull or grainy surface appearance. A multimeter can measure continuity, resistance,. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. Testing for a good solder connections. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter.

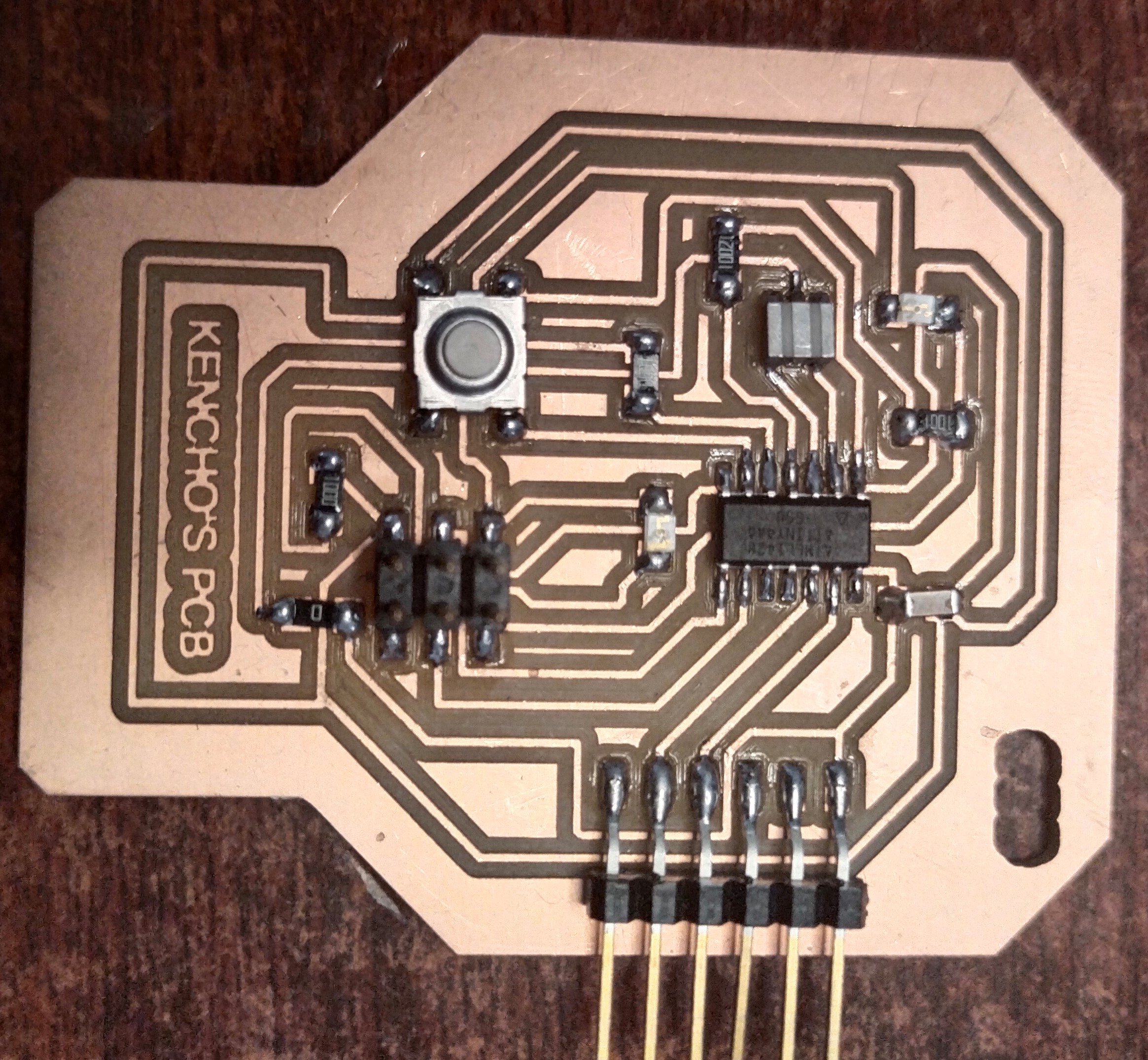

7. Electronics design KENCHO WANGDI Fab Academy 2022

Checking Solder Joints With Multimeter If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. A multimeter can measure continuity, resistance,. Testing for a good solder connections. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. Additionally, check for cold solder joints with a dull or grainy surface appearance. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Checking Solder Joints With Multimeter The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. A multimeter can measure continuity, resistance,. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. Additionally, check for cold solder joints with a dull or grainy surface appearance. The process involves taking a. Checking Solder Joints With Multimeter.

From www.reddit.com

How do I check the value of this solder joint with multimeter and Checking Solder Joints With Multimeter The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. A multimeter can measure continuity, resistance,. By meticulously. Checking Solder Joints With Multimeter.

From www.youtube.com

How to Check Your Soldering Iron Over Heating Problem YouTube Checking Solder Joints With Multimeter The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. Testing for a good solder connections. A multimeter can measure continuity, resistance,. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. By meticulously observing these surface characteristics, you can identify and rectify soldering. Checking Solder Joints With Multimeter.

From www.instructables.com

Soldering Multiple Wires for a Distribution Joint 4 Steps (with Checking Solder Joints With Multimeter The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. By meticulously observing these surface characteristics, you can. Checking Solder Joints With Multimeter.

From www.dreamstime.com

Digital Multimeter with Probe and Soldering Iron in the Engineer`s Checking Solder Joints With Multimeter The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. A multimeter can measure continuity, resistance,. In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. Additionally, check for cold solder joints. Checking Solder Joints With Multimeter.

From pcbassemblymanufacturing.com

Solder joint one basic lesson about PCB soldering Checking Solder Joints With Multimeter Testing for a good solder connections. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. Additionally, check for cold solder joints with a dull or grainy surface appearance. In this comprehensive guide, we will explain common. Checking Solder Joints With Multimeter.

From www.dreamstime.com

10. the Hands of the Electrician Check the Broken Iron with the Meter Checking Solder Joints With Multimeter The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. Testing for a good solder connections. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos. Checking Solder Joints With Multimeter.

From www.mingledorffs.com

Soldering, Brazing, and Welding Mingledorff's Checking Solder Joints With Multimeter If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree. Checking Solder Joints With Multimeter.

From www.electronicsandyou.com

Hand Soldering Tutorial How to Solder Electronic Components Checking Solder Joints With Multimeter A multimeter can measure continuity, resistance,. In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. Testing for a good solder connections. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. The most important debugging tool in any e.e.'s toolbox. Checking Solder Joints With Multimeter.

From www.youtube.com

How to Solder Properly 5 Soldering Joint Splices YouTube Checking Solder Joints With Multimeter The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. Additionally, check for cold solder joints with a dull or grainy surface appearance. In this comprehensive guide, we. Checking Solder Joints With Multimeter.

From www.seekpng.com

Cold Solder Joint3 Multimeter Continuity Test PNG Image Transparent Checking Solder Joints With Multimeter A multimeter can measure continuity, resistance,. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. Additionally, check for cold solder joints with a dull or grainy surface. Checking Solder Joints With Multimeter.

From pcbassemblymanufacturing.com

Solder joint one basic lesson about PCB soldering Checking Solder Joints With Multimeter The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. Additionally, check for cold solder joints with a dull or grainy surface appearance. A multimeter can measure continuity, resistance,. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder. Checking Solder Joints With Multimeter.

From pcbassemblymanufacturing.com

Solder joint one basic lesson about PCB soldering Checking Solder Joints With Multimeter Testing for a good solder connections. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. Additionally, check for cold solder joints with a dull or grainy. Checking Solder Joints With Multimeter.

From exosypdwj.blob.core.windows.net

Soldering Joint at Samantha Jimmerson blog Checking Solder Joints With Multimeter The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. Testing for a good solder connections. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread,. Checking Solder Joints With Multimeter.

From www.reddit.com

How do I check the value of this solder joint with multimeter and Checking Solder Joints With Multimeter If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. Testing for a good solder. Checking Solder Joints With Multimeter.

From electro-dan.co.uk

Building your own PCBs Checking Solder Joints With Multimeter By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread,. Checking Solder Joints With Multimeter.

From www.alamy.com

soldering an electrical device Stock Photo Alamy Checking Solder Joints With Multimeter The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust. Checking Solder Joints With Multimeter.

From dxonrjfhg.blob.core.windows.net

How To Check Resistance Value In Multimeter at Kaye Rickert blog Checking Solder Joints With Multimeter In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. Testing for a good solder connections. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. If not caught immediately, a solder connection on a circuit board can turn into a. Checking Solder Joints With Multimeter.

From www.dreamstime.com

Soldering stock image. Image of multi, people, multimeter 23414427 Checking Solder Joints With Multimeter A multimeter can measure continuity, resistance,. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. Testing for a good solder connections. In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. If not caught immediately, a solder connection on a circuit board can turn into a real. Checking Solder Joints With Multimeter.

From www.dreamstime.com

The Multimeters, Clamp Meter, Soldering Iron, Screwdrivers Fire Check Checking Solder Joints With Multimeter The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between. Checking Solder Joints With Multimeter.

From www.youtube.com

How to Test Continuity with Multimeter? YouTube Checking Solder Joints With Multimeter By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. A multimeter can measure continuity, resistance,. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. Testing for a good solder connections. If not caught immediately, a solder connection on a circuit board can turn into a. Checking Solder Joints With Multimeter.

From solderingmind.com

How to Check Capacitance Using Multimeter Checking Solder Joints With Multimeter The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. Testing for a good solder connections. The most important debugging tool in. Checking Solder Joints With Multimeter.

From fabacademy.org

7. Electronics design KENCHO WANGDI Fab Academy 2022 Checking Solder Joints With Multimeter In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. Testing for a good solder connections. A multimeter can measure continuity, resistance,. The process involves taking a two. Checking Solder Joints With Multimeter.

From www.pcbaaa.com

Understanding solder joint basics and techniques IBE Electronics Checking Solder Joints With Multimeter The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. The most important debugging tool in any e.e.'s toolbox is a. Checking Solder Joints With Multimeter.

From plus.fluke.com

How to Test for Continuity with a Multimeter Fluke Checking Solder Joints With Multimeter The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. A multimeter can measure continuity, resistance,. By meticulously. Checking Solder Joints With Multimeter.

From www.reddit.com

How do I check the value of this solder joint with multimeter and Checking Solder Joints With Multimeter The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. Testing for a good solder connections. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use. Checking Solder Joints With Multimeter.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Checking Solder Joints With Multimeter If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. A multimeter can measure continuity, resistance,. In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use. Checking Solder Joints With Multimeter.

From www.engineerlive.com

How To Perfect Your Solder Joint Formation Engineer Live Checking Solder Joints With Multimeter By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. Testing for a good solder connections. Additionally, check for cold solder joints with a dull or grainy surface appearance. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. If not caught immediately, a solder connection on. Checking Solder Joints With Multimeter.

From www.youtube.com

How to use a multimeter or voltmeter Basics you need to know. YouTube Checking Solder Joints With Multimeter By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. The process involves taking. Checking Solder Joints With Multimeter.

From www.dreamstime.com

Digital Multimeter with Probe and Soldering Iron in the Engineer`s Checking Solder Joints With Multimeter If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. Testing for a good solder connections. The most. Checking Solder Joints With Multimeter.

From wiredataboettiy2.z21.web.core.windows.net

How To Connect Wires With Solder Checking Solder Joints With Multimeter By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. A multimeter can measure continuity, resistance,. In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. Additionally, check for cold solder joints with a dull or grainy surface appearance. Testing for. Checking Solder Joints With Multimeter.

From www.instructables.com

Soldering Multiple Wires for a Distribution Joint 4 Steps (with Checking Solder Joints With Multimeter A multimeter can measure continuity, resistance,. If not caught immediately, a solder connection on a circuit board can turn into a real nightmare, especially if using cmos components with. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. Testing for a good solder connections. By meticulously observing these surface characteristics, you can identify and rectify soldering. Checking Solder Joints With Multimeter.

From absolutepcbassembly.com

Cold Solder Joint Definitive Guide to Soldering Absolute Checking Solder Joints With Multimeter The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic formation of the interface between solder joint. Testing for a good solder connections. Additionally, check for cold solder joints with a dull or grainy surface appearance. If not caught immediately, a solder connection on a circuit board can. Checking Solder Joints With Multimeter.

From www.nextpcb.com

Dry Solder Joints How to Identify and Fix Them? Checking Solder Joints With Multimeter In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. Testing for a good solder connections. Additionally, check for cold solder joints with a dull or grainy surface appearance. The process involves taking a two dimensional slice from a solder joint sample and assessing the degree of wetting, solder spread, intermetallic. Checking Solder Joints With Multimeter.

From www.youtube.com

Tool Tip Check solder joints (or broken electronics) with a multimeter Checking Solder Joints With Multimeter In this comprehensive guide, we will explain common electronic components failure reasons, symptoms, and how to effectively use a. By meticulously observing these surface characteristics, you can identify and rectify soldering defects, ensuring a reliable and robust solder joint. Testing for a good solder connections. The most important debugging tool in any e.e.'s toolbox is a trusty multimeter. The process. Checking Solder Joints With Multimeter.