What Are The Types Of Coated Abrasive . Coated abrasives are developed using abrasive grains. Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials such as paper or. A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. They are used to remove surface materials such as metal, ceramics, glass,. Coated abrasives consist of the following components: Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. Coated abrasives are manufactured using abrasive grains; The foremost common abrasive grains are alumina, zirconium,. The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other binders. An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,.

from www.biko.it

The foremost common abrasive grains are alumina, zirconium,. An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. They are used to remove surface materials such as metal, ceramics, glass,. A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials such as paper or. Coated abrasives are manufactured using abrasive grains; Coated abrasives are developed using abrasive grains. Coated abrasives consist of the following components: The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet.

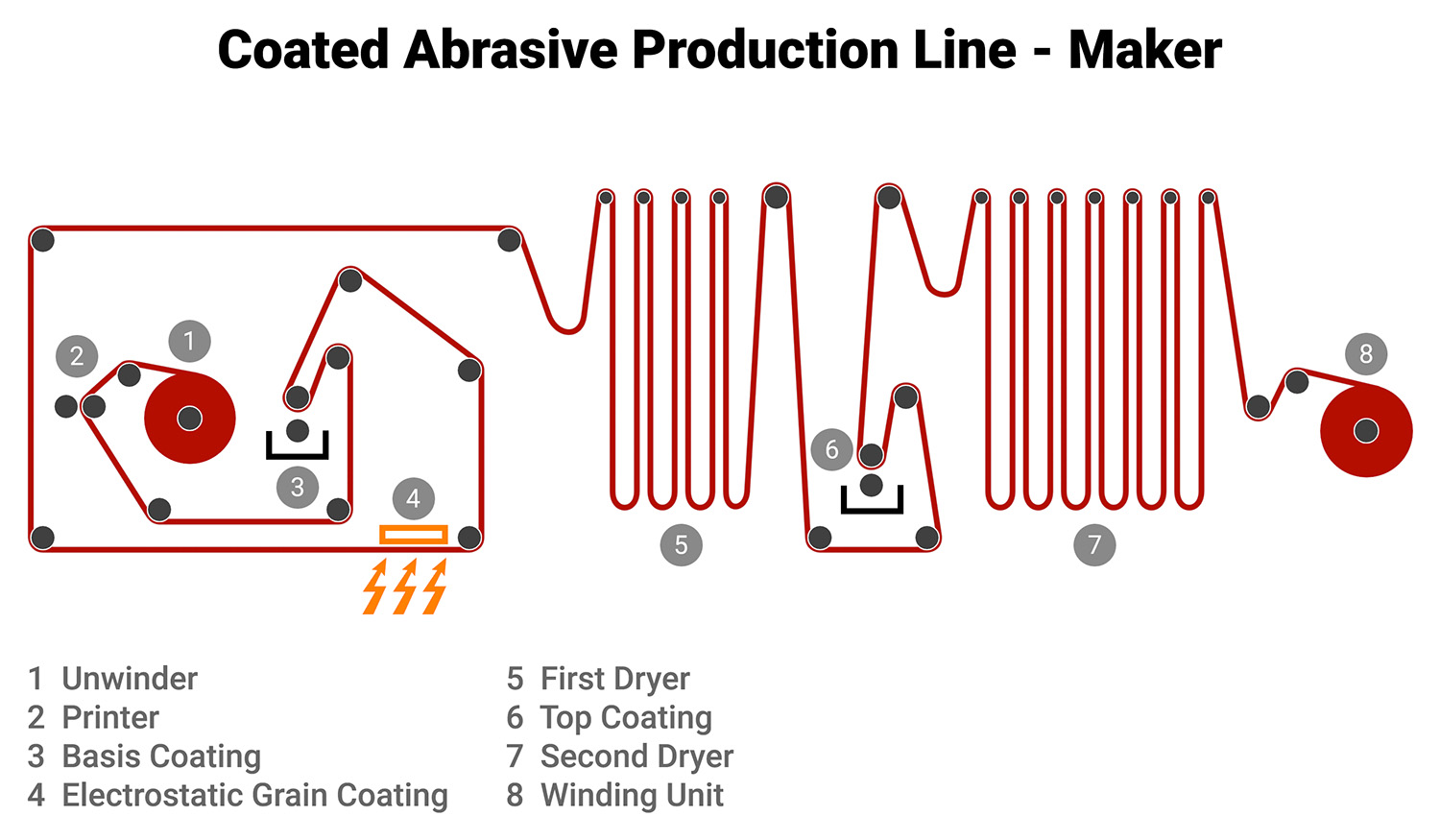

Coated Abrasive Production Systems Products Biko

What Are The Types Of Coated Abrasive An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. The foremost common abrasive grains are alumina, zirconium,. Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. Coated abrasives are developed using abrasive grains. Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other binders. Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials such as paper or. Coated abrasives are manufactured using abrasive grains; The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. They are used to remove surface materials such as metal, ceramics, glass,. An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. Coated abrasives consist of the following components:

From www.unitedabrasives.com

Coated Abrasives United Abrasives What Are The Types Of Coated Abrasive Coated abrasives consist of the following components: Coated abrasives are manufactured using abrasive grains; The foremost common abrasive grains are alumina, zirconium,. Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. A coated abrasive is an. What Are The Types Of Coated Abrasive.

From greatlakesminerals.com

Coated Abrasive Materials Great Lakes Minerals What Are The Types Of Coated Abrasive Coated abrasives consist of the following components: Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials such as paper or. An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. The foremost common abrasive grains are alumina, zirconium,. A coated abrasive is an abrasive tool made up of a thin film. What Are The Types Of Coated Abrasive.

From www.sakabrasives.com

Coated Abrasive Products Abrasive Product Manufacturing SAK Abrasives What Are The Types Of Coated Abrasive Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. The foremost common abrasive grains are alumina, zirconium,. Coated abrasives are manufactured using abrasive grains; An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. Coated abrasives are developed using abrasive grains. Coated abrasives consist of the. What Are The Types Of Coated Abrasive.

From www.slideserve.com

PPT Abrasive Manufacturers USA PowerPoint Presentation, free download What Are The Types Of Coated Abrasive Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials such as paper or. Coated abrasives consist of the following components: The foremost common abrasive grains are alumina, zirconium,. Coated abrasives are manufactured using abrasive grains; Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other binders. The. What Are The Types Of Coated Abrasive.

From www.slideserve.com

PPT What Are Coated Abrasives PowerPoint Presentation, free download What Are The Types Of Coated Abrasive Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other binders. Coated abrasives consist of the following components: Coated abrasives are developed using abrasive grains. A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. Bonded abrasives consist of. What Are The Types Of Coated Abrasive.

From www.consulting-trading.com

Coated Abrasives ICT What Are The Types Of Coated Abrasive Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other binders. A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials such as. What Are The Types Of Coated Abrasive.

From www.empireabrasives.com

Types of Abrasives Bonded vs Coated vs NonWoven Abrasives Empire What Are The Types Of Coated Abrasive They are used to remove surface materials such as metal, ceramics, glass,. Coated abrasives are manufactured using abrasive grains; A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other. What Are The Types Of Coated Abrasive.

From in.pinterest.com

Coated Abrasives in 2022 Abrasive, Substrate, Coat What Are The Types Of Coated Abrasive An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. Coated abrasives are manufactured using abrasive grains; The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. Coated abrasives are developed using abrasive grains. Coated abrasives consist of the following components: Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible. What Are The Types Of Coated Abrasive.

From www.slideserve.com

PPT Abrasives PowerPoint Presentation, free download ID11560468 What Are The Types Of Coated Abrasive The foremost common abrasive grains are alumina, zirconium,. Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. They are used to remove surface materials such as metal, ceramics, glass,. Coated abrasives are instruments used for polishing. What Are The Types Of Coated Abrasive.

From altusalumina.com

Coated Abrasives ALTUS What Are The Types Of Coated Abrasive Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. Coated abrasives consist of the following components: Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials such as paper or. Coated abrasives contain abrasive grains held together in a matrix of glass,. What Are The Types Of Coated Abrasive.

From www.empireabrasives.com

Types of Coated Abrasives Backing Empire Abrasives What Are The Types Of Coated Abrasive Coated abrasives are manufactured using abrasive grains; The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. They are used to remove surface materials such as metal, ceramics, glass,. A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. The foremost common abrasive. What Are The Types Of Coated Abrasive.

From www.slideserve.com

PPT Coated Abrasives Types Components and Uses PowerPoint What Are The Types Of Coated Abrasive The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. Coated abrasives consist of the following components: A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. Bonded abrasives consist of. What Are The Types Of Coated Abrasive.

From uama.org

Coated Abrasive Overview UAMA What Are The Types Of Coated Abrasive Coated abrasives are developed using abrasive grains. Coated abrasives consist of the following components: Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials such as paper or. They are used to remove surface materials such as metal, ceramics, glass,. A coated abrasive is an abrasive tool made up of a thin film of. What Are The Types Of Coated Abrasive.

From www.jct-abrasives.com

The Selection Of Abrasive Materials For Abrasive Tools What Are The Types Of Coated Abrasive Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other binders. Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. Coated abrasives are instruments used for polishing and grinding created. What Are The Types Of Coated Abrasive.

From www.agt-india.com

Coated Bonded Abrasives Agt India What Are The Types Of Coated Abrasive Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. They are used to remove surface materials such as metal, ceramics, glass,. Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other binders. Coated abrasives are instruments used for polishing and grinding created. What Are The Types Of Coated Abrasive.

From jjscanada.ca

sia Abrasives JJS Canada What Are The Types Of Coated Abrasive Coated abrasives consist of the following components: An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. Coated abrasives are developed using abrasive grains. Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. The foremost common abrasive grains are alumina, zirconium,. Coated abrasives contain abrasive grains. What Are The Types Of Coated Abrasive.

From binictools.com

Selecting Coated Abrasives Flap Disc Binic Abrasive What Are The Types Of Coated Abrasive Coated abrasives consist of the following components: Coated abrasives are manufactured using abrasive grains; The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. The foremost common abrasive grains are alumina, zirconium,. An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is. What Are The Types Of Coated Abrasive.

From www.youtube.com

Types of Abrasives YouTube What Are The Types Of Coated Abrasive Coated abrasives consist of the following components: They are used to remove surface materials such as metal, ceramics, glass,. Coated abrasives are developed using abrasive grains. Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials such as paper or. The foremost common abrasive grains are alumina, zirconium,. A coated abrasive is an abrasive. What Are The Types Of Coated Abrasive.

From catalogo.mab.tools

Coated abrasives MABTOOLS Abrasives Catalog What Are The Types Of Coated Abrasive Coated abrasives are developed using abrasive grains. The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials such as paper or. Coated abrasives consist of the following components: A coated. What Are The Types Of Coated Abrasive.

From www.dxpe.com

Bonded vs. Coated Types of Abrasives Used in Grinding Wheels What Are The Types Of Coated Abrasive An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. Coated abrasives are manufactured using abrasive grains; A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate. What Are The Types Of Coated Abrasive.

From www.cheefatt.com

7 Types of Abrasive Discs Abrasives Chee Fatt Singapore What Are The Types Of Coated Abrasive The foremost common abrasive grains are alumina, zirconium,. Coated abrasives are developed using abrasive grains. Coated abrasives consist of the following components: The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. Coated abrasives are manufactured using abrasive grains; Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials such as paper. What Are The Types Of Coated Abrasive.

From www.sakabrasives.com

Coated Abrasive Products Bonded and Coated Abrasives Manufacturer What Are The Types Of Coated Abrasive Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials such as paper or. A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. The foremost common abrasive grains are alumina, zirconium,. Coated abrasives are manufactured using abrasive grains;. What Are The Types Of Coated Abrasive.

From www.kemet.co.uk

Coated Abrasive Sample Chart Kemet What Are The Types Of Coated Abrasive An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. Coated abrasives consist of the following components: Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other binders. They are used to remove surface materials such as metal, ceramics, glass,.. What Are The Types Of Coated Abrasive.

From www.slideserve.com

PPT Coated Abrasives Types Components and Uses PowerPoint What Are The Types Of Coated Abrasive Coated abrasives are manufactured using abrasive grains; The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate. What Are The Types Of Coated Abrasive.

From www.unitedabrasives.com

Coated Abrasives United Abrasives What Are The Types Of Coated Abrasive Coated abrasives are manufactured using abrasive grains; A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. The foremost common abrasive grains are alumina, zirconium,. They are used to remove surface materials such as metal, ceramics, glass,. The most common are aluminum oxide, zirconium, ceramic,. What Are The Types Of Coated Abrasive.

From altusalumina.com

Coated Abrasives ALTUS What Are The Types Of Coated Abrasive A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. They are used to remove surface materials such as metal, ceramics, glass,. Bonded abrasives consist of abrasive grains that are fixed within a. What Are The Types Of Coated Abrasive.

From www.sandpaper.com

Decoding Coated Abrasives A Guide to Selecting the Ideal Sandpaper for What Are The Types Of Coated Abrasive They are used to remove surface materials such as metal, ceramics, glass,. A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. Coated abrasives are manufactured using abrasive grains; Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made. What Are The Types Of Coated Abrasive.

From www.unitedabrasives.com

Coated Abrasives United Abrasives What Are The Types Of Coated Abrasive Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other binders. Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. They are used to remove surface materials such as metal, ceramics, glass,. Coated abrasives are instruments used for polishing and grinding created. What Are The Types Of Coated Abrasive.

From www.slideserve.com

PPT Coated Abrasives Types Components and Uses PowerPoint What Are The Types Of Coated Abrasive Coated abrasives are manufactured using abrasive grains; The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other binders. Coated abrasives are developed using abrasive grains. Bonded abrasives consist of abrasive. What Are The Types Of Coated Abrasive.

From www.linkedin.com

Types of Substrates and Fabrication Processes for Coated Abrasives What Are The Types Of Coated Abrasive Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other binders. Coated abrasives consist of the following components: Coated abrasives are manufactured using abrasive grains; They are used to remove surface materials such as metal, ceramics, glass,. Coated abrasives are developed using abrasive grains. The most common are aluminum oxide, zirconium, ceramic, silicon carbide. What Are The Types Of Coated Abrasive.

From www.consulting-trading.com

Coated Abrasives ICT What Are The Types Of Coated Abrasive Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. An abrasive. What Are The Types Of Coated Abrasive.

From www.pinterest.com

Pin on abrasive tools What Are The Types Of Coated Abrasive Coated abrasives are manufactured using abrasive grains; Coated abrasives consist of the following components: An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. The foremost common abrasive grains are alumina, zirconium,. Coated abrasives are developed using abrasive grains. Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber,. What Are The Types Of Coated Abrasive.

From www.vehicleservicepros.com

Coated abrasives Vehicle Service Pros What Are The Types Of Coated Abrasive Bonded abrasives consist of abrasive grains that are fixed within a matrix, which is often made of resin, rubber, or vitrified. The foremost common abrasive grains are alumina, zirconium,. They are used to remove surface materials such as metal, ceramics, glass,. Coated abrasives are developed using abrasive grains. Coated abrasives are instruments used for polishing and grinding created by gluing. What Are The Types Of Coated Abrasive.

From www.biko.it

Coated Abrasive Production Systems Products Biko What Are The Types Of Coated Abrasive Coated abrasives consist of the following components: The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. Coated abrasives contain abrasive grains held together in a matrix of glass, resin, rubber, or other binders. An abrasive grain attached to the backing material (i.e., cloth, paper, cotton,. Coated abrasives are instruments used for polishing and grinding created by gluing. What Are The Types Of Coated Abrasive.

From www.exportersindia.com

Coated Abrasives at Best Price in Raipur ID 4295406 rahul enterprises What Are The Types Of Coated Abrasive Coated abrasives consist of the following components: A coated abrasive is an abrasive tool made up of a thin film of abrasive grain attached to a substrate such as paper, fabric, etc. The most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. Coated abrasives are instruments used for polishing and grinding created by gluing abrasives to flexible materials. What Are The Types Of Coated Abrasive.