Lead Flashing Overlap . Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water penetration in areas where the roof meets other surfaces,. The most common method of fixing lead flashing is to make a lead bung or chock'. Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for stepped flashings. In this project you will find out the answer to this question along with a great many others including how to install lead flashing and why lead is. Work the lead so that it’s as tight to the wall as possible. Each sheet should overlap the previous one by around 100mm to prevent leaking. Then, grind out a straight chase into the brickwork mortar joint and carefully push the lead all the way in. How to fix lead roof flashing. How to install lead flashing. Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. This is made by rolling up a 25mm or less strip of lead into an oval shape just.

from www.sigroofing.co.uk

The most common method of fixing lead flashing is to make a lead bung or chock'. Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. How to install lead flashing. This is made by rolling up a 25mm or less strip of lead into an oval shape just. Each sheet should overlap the previous one by around 100mm to prevent leaking. Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for stepped flashings. Work the lead so that it’s as tight to the wall as possible. Then, grind out a straight chase into the brickwork mortar joint and carefully push the lead all the way in. Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water penetration in areas where the roof meets other surfaces,. How to fix lead roof flashing.

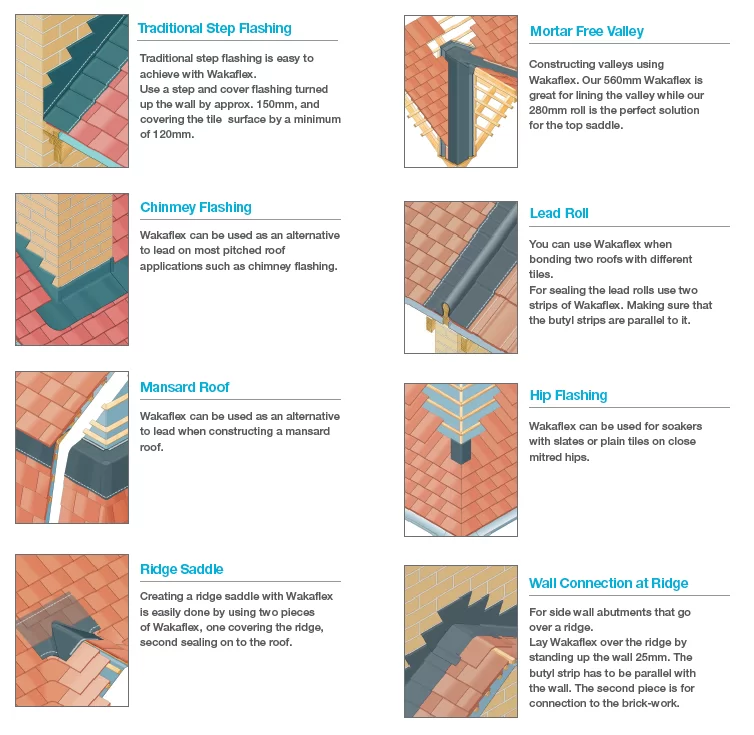

Wakaflex® Leadfree flashings and accessories SIG Roofing

Lead Flashing Overlap Then, grind out a straight chase into the brickwork mortar joint and carefully push the lead all the way in. How to fix lead roof flashing. Then, grind out a straight chase into the brickwork mortar joint and carefully push the lead all the way in. Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. This is made by rolling up a 25mm or less strip of lead into an oval shape just. Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for stepped flashings. In this project you will find out the answer to this question along with a great many others including how to install lead flashing and why lead is. Each sheet should overlap the previous one by around 100mm to prevent leaking. The most common method of fixing lead flashing is to make a lead bung or chock'. Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water penetration in areas where the roof meets other surfaces,. Work the lead so that it’s as tight to the wall as possible. How to install lead flashing.

From adv-group.co.uk

Lead Flashing Replacement Advanced Construction & Roofing Lead Flashing Overlap Work the lead so that it’s as tight to the wall as possible. Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for stepped flashings. How to install lead flashing. Lead flashing is a thin, flexible sheet made from lead and is used. Lead Flashing Overlap.

From www.mikehorizonroofing.co.uk

Lead Work Specialist in Essex Mike Horizon Roofing Lead Flashing Overlap Work the lead so that it’s as tight to the wall as possible. Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. Each sheet should overlap the previous one by around 100mm to prevent leaking. In this project you will find out the answer to this question along with a great many others including how. Lead Flashing Overlap.

From www.alamy.com

Lead Flashing Stock Photos & Lead Flashing Stock Images Alamy Lead Flashing Overlap Each sheet should overlap the previous one by around 100mm to prevent leaking. In this project you will find out the answer to this question along with a great many others including how to install lead flashing and why lead is. Work the lead so that it’s as tight to the wall as possible. Lead flashing is a thin, flexible. Lead Flashing Overlap.

From evobuild.com.au

What are the Dangers of Lead Flashing, and What Are the Best Alternatives? Lead Flashing Overlap Work the lead so that it’s as tight to the wall as possible. Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. How to install lead flashing. Then, grind out a straight chase into the brickwork mortar joint and carefully push the lead all the way in. The most common method of fixing lead flashing. Lead Flashing Overlap.

From www.roofingandguttersdirect.com

Lead & Flashing Roofing & Gutters Direct Lead Flashing Overlap Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water penetration in areas where the roof meets other surfaces,. Work the lead so that it’s as tight to the wall as possible. This is made by rolling up a 25mm or less strip of lead into an oval shape just. The. Lead Flashing Overlap.

From mcclellandsroofing.com

The Importance of Drip Edge Overlap Extending the Lifespan of Your Roof Lead Flashing Overlap Each sheet should overlap the previous one by around 100mm to prevent leaking. Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water penetration in areas where the roof meets other surfaces,. The most common method of fixing lead flashing is to make a lead bung or chock'. How to install. Lead Flashing Overlap.

From charlesroofing.co.uk

Lead Work Canterbury Charles Roofing Lead Flashing Overlap Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for stepped flashings. Work the lead so that it’s as tight to the wall as possible. Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. How to install lead. Lead Flashing Overlap.

From www.youtube.com

7 Regulations & Lead Flashing Details YouTube Lead Flashing Overlap The most common method of fixing lead flashing is to make a lead bung or chock'. In this project you will find out the answer to this question along with a great many others including how to install lead flashing and why lead is. How to install lead flashing. Flashings should be tucked 25mm into a bed joint and wedged. Lead Flashing Overlap.

From www.diynot.com

Lead flashing DIYnot Forums Lead Flashing Overlap The most common method of fixing lead flashing is to make a lead bung or chock'. Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water penetration in areas where the roof meets other surfaces,. This is made by rolling up a 25mm or less strip of lead into an oval. Lead Flashing Overlap.

From www.animalia-life.club

Roof Edge Flashing Details Lead Flashing Overlap The most common method of fixing lead flashing is to make a lead bung or chock'. Work the lead so that it’s as tight to the wall as possible. This is made by rolling up a 25mm or less strip of lead into an oval shape just. In this project you will find out the answer to this question along. Lead Flashing Overlap.

From theleadlads.co.uk

Lead Flashing Lead Flashing Lead Roofing The Lead Lads Lead Flashing Overlap This is made by rolling up a 25mm or less strip of lead into an oval shape just. In this project you will find out the answer to this question along with a great many others including how to install lead flashing and why lead is. Each sheet should overlap the previous one by around 100mm to prevent leaking. Lead. Lead Flashing Overlap.

From www.alamy.com

Close up detail of lead flashings dressed around dormer window and roof Lead Flashing Overlap Then, grind out a straight chase into the brickwork mortar joint and carefully push the lead all the way in. Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. How to fix lead roof flashing. How to install lead flashing. Each sheet should overlap the previous one by around 100mm to prevent leaking. This is. Lead Flashing Overlap.

From www.youtube.com

HS12 Lead flashing repair (Do it yourself) YouTube Lead Flashing Overlap Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water penetration in areas where the roof meets other surfaces,. Each sheet should overlap the previous one by around 100mm to prevent leaking. In this project you will. Lead Flashing Overlap.

From www.roofworx.ie

Lead Flashing Repairs Roof Worx Dublin Lead Flashing Overlap Then, grind out a straight chase into the brickwork mortar joint and carefully push the lead all the way in. This is made by rolling up a 25mm or less strip of lead into an oval shape just. How to fix lead roof flashing. How to install lead flashing. Each sheet should overlap the previous one by around 100mm to. Lead Flashing Overlap.

From www.nachi.org

InterNACHI Inspection Graphics Library Roofing » Flashing » sidewall Lead Flashing Overlap How to install lead flashing. This is made by rolling up a 25mm or less strip of lead into an oval shape just. Then, grind out a straight chase into the brickwork mortar joint and carefully push the lead all the way in. In this project you will find out the answer to this question along with a great many. Lead Flashing Overlap.

From www.holcroftroofing.co.nz

Lead Flashings Holcroft Roofing Christchurch Lead Flashing Overlap Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water penetration in areas where the roof meets other surfaces,. This is made by rolling up a 25mm or less strip of lead into an oval shape just. How to fix lead roof flashing. Flashings should be tucked 25mm into a bed. Lead Flashing Overlap.

From www.buckleyroofing.co.uk

Leadwork Gravesend Lead Flashing Repair & Installation Kent Lead Flashing Overlap Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for stepped flashings. Each sheet should overlap the previous one by around 100mm to prevent leaking. The most common method of fixing lead flashing is to make a lead bung or chock'. Then, grind. Lead Flashing Overlap.

From www.wonkeedonkeetools.co.uk

What Is Lead Flashing? Wonkee Donkee Tools Lead Flashing Overlap Each sheet should overlap the previous one by around 100mm to prevent leaking. This is made by rolling up a 25mm or less strip of lead into an oval shape just. Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for stepped flashings.. Lead Flashing Overlap.

From forum.buildhub.org.uk

Poor Lead Flashing Advice Needed Roofing, Tiling & Slating Lead Flashing Overlap The most common method of fixing lead flashing is to make a lead bung or chock'. This is made by rolling up a 25mm or less strip of lead into an oval shape just. Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step. Lead Flashing Overlap.

From www.sigroofing.co.uk

Wakaflex® Leadfree flashings and accessories SIG Roofing Lead Flashing Overlap Each sheet should overlap the previous one by around 100mm to prevent leaking. Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for stepped flashings. How to install lead flashing. Work the lead so that it’s as tight to the wall as possible.. Lead Flashing Overlap.

From homefixcontractors.co.uk

Lead Roof Flashing Fleet Lead Roof Flash Services Lead Flashing Overlap Work the lead so that it’s as tight to the wall as possible. Then, grind out a straight chase into the brickwork mortar joint and carefully push the lead all the way in. Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for. Lead Flashing Overlap.

From evobuild.com.au

What is Lead Flashing Made Of, and Should You Consider Alternatives? Lead Flashing Overlap Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for stepped flashings. Work the lead so that it’s as tight to the wall as possible. In this project you will find out the answer to this question along with a great many others. Lead Flashing Overlap.

From iconsurveyors.co.uk

What are lead flashings and how are they commonly used Lead Flashing Overlap Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water penetration in areas where the roof meets other surfaces,. Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for stepped flashings. How to fix. Lead Flashing Overlap.

From www.diynot.com

Lead flashing not overlapped DIYnot Forums Lead Flashing Overlap This is made by rolling up a 25mm or less strip of lead into an oval shape just. Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for stepped flashings. Work the lead so that it’s as tight to the wall as possible.. Lead Flashing Overlap.

From myhomecomplex.com

Everything You Need to Know About Roof Flashing Lead Flashing Overlap Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water penetration in areas where the roof meets other surfaces,. Then, grind out a straight chase into the brickwork mortar joint and carefully push the lead all the way in. How to fix lead roof flashing. How to install lead flashing. Lead. Lead Flashing Overlap.

From apexroofingspecialists.co.uk

Lead Work & Flashing Apex Roofing Lead Flashing Overlap How to fix lead roof flashing. Work the lead so that it’s as tight to the wall as possible. In this project you will find out the answer to this question along with a great many others including how to install lead flashing and why lead is. Lead flashings should have a minimum upstand of 75mm and minimum lap of. Lead Flashing Overlap.

From bestlifehax.com

What Is Roof Flashing? DIY Home Improvement Lead Flashing Overlap Work the lead so that it’s as tight to the wall as possible. In this project you will find out the answer to this question along with a great many others including how to install lead flashing and why lead is. Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water. Lead Flashing Overlap.

From forum.buildhub.org.uk

Lead soakers and flashing at abutment can flashing lay on tiles as Lead Flashing Overlap Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. How to fix lead roof flashing. Each sheet should overlap the previous one by around 100mm to prevent leaking. Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for. Lead Flashing Overlap.

From evobuild.com.au

What is Lead Flashing Made Of, and Should You Consider Alternatives? Lead Flashing Overlap The most common method of fixing lead flashing is to make a lead bung or chock'. In this project you will find out the answer to this question along with a great many others including how to install lead flashing and why lead is. How to install lead flashing. Each sheet should overlap the previous one by around 100mm to. Lead Flashing Overlap.

From ravenroofingandrepairs.co.uk

Flashing Grimsby Roof Leadwork Repairs & Replacement in Louth Lead Flashing Overlap Each sheet should overlap the previous one by around 100mm to prevent leaking. Work the lead so that it’s as tight to the wall as possible. How to install lead flashing. How to fix lead roof flashing. Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. Flashings should be tucked 25mm into a bed joint. Lead Flashing Overlap.

From www.inspectmt.com

Chimney Flashing Inspection Guide Inspect Montana Lead Flashing Overlap How to fix lead roof flashing. This is made by rolling up a 25mm or less strip of lead into an oval shape just. Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. Each sheet should overlap the previous one by around 100mm to prevent leaking. The most common method of fixing lead flashing is. Lead Flashing Overlap.

From www.wonkeedonkeetools.co.uk

What Is Lead Flashing? Wonkee Donkee Tools Lead Flashing Overlap Flashings should be tucked 25mm into a bed joint and wedged in place at not more than 450mm centres, or a minimum of one per step for stepped flashings. How to fix lead roof flashing. Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. Lead flashing is a thin, flexible sheet made from lead and. Lead Flashing Overlap.

From forum.buildhub.org.uk

Poor Lead Flashing Advice Needed Roofing, Tiling & Slating Lead Flashing Overlap How to install lead flashing. Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water penetration in areas where the roof meets other surfaces,. This is made by rolling up a 25mm or less strip of lead into an oval shape just. Lead flashings should have a minimum upstand of 75mm. Lead Flashing Overlap.

From www.youtube.com

Lead Flashing A Chimney YouTube Lead Flashing Overlap How to fix lead roof flashing. Work the lead so that it’s as tight to the wall as possible. Then, grind out a straight chase into the brickwork mortar joint and carefully push the lead all the way in. Each sheet should overlap the previous one by around 100mm to prevent leaking. In this project you will find out the. Lead Flashing Overlap.

From forum.buildhub.org.uk

Dormer cladding and lead flashing Lofts, Dormers & Loft Conversions Lead Flashing Overlap Lead flashing is a thin, flexible sheet made from lead and is used to waterproof joints and prevent water penetration in areas where the roof meets other surfaces,. How to fix lead roof flashing. Lead flashings should have a minimum upstand of 75mm and minimum lap of 100mm. Each sheet should overlap the previous one by around 100mm to prevent. Lead Flashing Overlap.