Steel Lap Formula . To get the desired design length, lapping of two bars side. Where l is the lap length, ld is the development length, db is the diameter of the reinforcing. Enter concrete grade, bar diameter. Learn how to calculate lap length for reinforcement in concrete sections, such as beams, columns and slabs. Spalling of the concrete in the neighbourhood of the joints. During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. Find out the types, methods and factors of lap splices in tension and. Learn the lap length formula for tension and compression, the lap splices. The lap length is typically calculated using the following formula: Here’s a breakdown of two common. The transmission of the forces from one bar to the next is assured; (1)p the detailing of laps between bars shall be such that: Lap length is the length of overlapping between two bars to achieve the required design length. L = ld x db / 4 x σst. Different design codes and standards provide methods for calculating lap length.

from structx.com

Where l is the lap length, ld is the development length, db is the diameter of the reinforcing. The transmission of the forces from one bar to the next is assured; Learn the lap length formula for tension and compression, the lap splices. To get the desired design length, lapping of two bars side. L = ld x db / 4 x σst. Here’s a breakdown of two common. Spalling of the concrete in the neighbourhood of the joints. Learn how to calculate lap length for reinforcement in concrete sections, such as beams, columns and slabs. Lap length is the length of overlapping between two bars to achieve the required design length. The lap length is typically calculated using the following formula:

StructX Reinforcement Details

Steel Lap Formula The lap length is typically calculated using the following formula: Learn the lap length formula for tension and compression, the lap splices. Different design codes and standards provide methods for calculating lap length. L = ld x db / 4 x σst. Find out the types, methods and factors of lap splices in tension and. Here’s a breakdown of two common. Calculate development and lap lengths for reinforced concrete according to as 3600:2018. Where l is the lap length, ld is the development length, db is the diameter of the reinforcing. Learn how to calculate lap length for reinforcement in concrete sections, such as beams, columns and slabs. Lap length is the length of overlapping between two bars to achieve the required design length. To get the desired design length, lapping of two bars side. The transmission of the forces from one bar to the next is assured; During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. (1)p the detailing of laps between bars shall be such that: The lap length is typically calculated using the following formula: Spalling of the concrete in the neighbourhood of the joints.

From www.pinterest.com

Steel Bars OverLap Formulas Used In Column, slab And beams Steel Lap Formula The transmission of the forces from one bar to the next is assured; Spalling of the concrete in the neighbourhood of the joints. Calculate development and lap lengths for reinforced concrete according to as 3600:2018. Where l is the lap length, ld is the development length, db is the diameter of the reinforcing. Different design codes and standards provide methods. Steel Lap Formula.

From www.scribd.com

Steel Bars OverLap Formulas Used in Column, Slab and Beams Steel Lap Formula Enter concrete grade, bar diameter. Find out the types, methods and factors of lap splices in tension and. To get the desired design length, lapping of two bars side. Where l is the lap length, ld is the development length, db is the diameter of the reinforcing. Learn the lap length formula for tension and compression, the lap splices. Calculate. Steel Lap Formula.

From www.youtube.com

Quantity of Steel Rebar Calculation in Beam YouTube Steel Lap Formula During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. Here’s a breakdown of two common. Enter concrete grade, bar diameter. Different design codes and standards provide methods for calculating lap length. Learn how to calculate lap length for reinforcement in concrete sections, such as beams, columns and slabs. The transmission. Steel Lap Formula.

From civildigital.com

Everything about Bar Bending Schedule BBS Terms & Rules CivilDigital Steel Lap Formula During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. To get the desired design length, lapping of two bars side. Different design codes and standards provide methods for calculating lap length. Calculate development and lap lengths for reinforced concrete according to as 3600:2018. (1)p the detailing of laps between bars. Steel Lap Formula.

From dailyengineering.com

Steel Bars OverLap Formulas Used In Column, Slab And Beams Daily Steel Lap Formula Spalling of the concrete in the neighbourhood of the joints. Lap length is the length of overlapping between two bars to achieve the required design length. The transmission of the forces from one bar to the next is assured; Calculate development and lap lengths for reinforced concrete according to as 3600:2018. Enter concrete grade, bar diameter. To get the desired. Steel Lap Formula.

From aroobantharsy.blogspot.com

A.Roobantharsy Anchorage detailing ( IStructE guide) Steel Lap Formula (1)p the detailing of laps between bars shall be such that: Spalling of the concrete in the neighbourhood of the joints. Learn the lap length formula for tension and compression, the lap splices. Calculate development and lap lengths for reinforced concrete according to as 3600:2018. To get the desired design length, lapping of two bars side. Here’s a breakdown of. Steel Lap Formula.

From www.vrogue.co

Calculate The Lap Length In Beam Columns Raft Lap Zon vrogue.co Steel Lap Formula Where l is the lap length, ld is the development length, db is the diameter of the reinforcing. The lap length is typically calculated using the following formula: L = ld x db / 4 x σst. Spalling of the concrete in the neighbourhood of the joints. Calculate development and lap lengths for reinforced concrete according to as 3600:2018. Here’s. Steel Lap Formula.

From www.lceted.com

What is Lap Length Lap length of Beams Lap Length of Slabs Lap Steel Lap Formula The transmission of the forces from one bar to the next is assured; Learn the lap length formula for tension and compression, the lap splices. During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. To get the desired design length, lapping of two bars side. Spalling of the concrete in. Steel Lap Formula.

From www.pinterest.fr

What is Lap Length? Steel Lap Formula L = ld x db / 4 x σst. Calculate development and lap lengths for reinforced concrete according to as 3600:2018. Learn the lap length formula for tension and compression, the lap splices. Learn how to calculate lap length for reinforcement in concrete sections, such as beams, columns and slabs. To get the desired design length, lapping of two bars. Steel Lap Formula.

From engindaily.com

Steel Bars OverLap Formulas Used In Column, slab and beams Engindaily Steel Lap Formula Spalling of the concrete in the neighbourhood of the joints. The transmission of the forces from one bar to the next is assured; Learn the lap length formula for tension and compression, the lap splices. Lap length is the length of overlapping between two bars to achieve the required design length. During the placement of steel in reinforced concrete structure,. Steel Lap Formula.

From engindaily.com

Steel Bars OverLap Formulas Used In Column, slab and beams Engindaily Steel Lap Formula (1)p the detailing of laps between bars shall be such that: The lap length is typically calculated using the following formula: L = ld x db / 4 x σst. Lap length is the length of overlapping between two bars to achieve the required design length. Learn how to calculate lap length for reinforcement in concrete sections, such as beams,. Steel Lap Formula.

From www.civilenggnotes.com

anchorage length of reinforcement bars Archives » Civil Engineering Notes Steel Lap Formula Learn the lap length formula for tension and compression, the lap splices. During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. To get the desired design length, lapping of two bars side. Calculate development and lap lengths for reinforced concrete according to as 3600:2018. Find out the types, methods and. Steel Lap Formula.

From www.researchgate.net

Doublesided lap joint between the steel plate and the rebar Steel Lap Formula Learn the lap length formula for tension and compression, the lap splices. (1)p the detailing of laps between bars shall be such that: Where l is the lap length, ld is the development length, db is the diameter of the reinforcing. Enter concrete grade, bar diameter. The transmission of the forces from one bar to the next is assured; L. Steel Lap Formula.

From www.youtube.com

How To Calculate Cutting Length Of Bent Up Bar in steel Reinforcement Steel Lap Formula During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. The lap length is typically calculated using the following formula: Learn how to calculate lap length for reinforcement in concrete sections, such as beams, columns and slabs. Learn the lap length formula for tension and compression, the lap splices. Where l. Steel Lap Formula.

From www.youtube.com

How to calculate the overlapping length of steel bars in slab,column Steel Lap Formula During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. (1)p the detailing of laps between bars shall be such that: Different design codes and standards provide methods for calculating lap length. Lap length is the length of overlapping between two bars to achieve the required design length. Spalling of the. Steel Lap Formula.

From www.youtube.com

Basic Knowledge of Lapping Length for Steel Rebars YouTube Steel Lap Formula Here’s a breakdown of two common. L = ld x db / 4 x σst. (1)p the detailing of laps between bars shall be such that: Lap length is the length of overlapping between two bars to achieve the required design length. Different design codes and standards provide methods for calculating lap length. The transmission of the forces from one. Steel Lap Formula.

From www.youtube.com

Bolted Connections Failure Modes Steel and Concrete Design YouTube Steel Lap Formula Learn how to calculate lap length for reinforcement in concrete sections, such as beams, columns and slabs. Different design codes and standards provide methods for calculating lap length. During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. (1)p the detailing of laps between bars shall be such that: Lap length. Steel Lap Formula.

From www.cannondigi.com

Lap Length For Beam Column And Slab The Best Picture Of Beam Steel Lap Formula Find out the types, methods and factors of lap splices in tension and. Here’s a breakdown of two common. The transmission of the forces from one bar to the next is assured; Learn how to calculate lap length for reinforcement in concrete sections, such as beams, columns and slabs. Enter concrete grade, bar diameter. Calculate development and lap lengths for. Steel Lap Formula.

From www.youtube.com

Steel bar hooks size / hooks construction YouTube Steel Lap Formula To get the desired design length, lapping of two bars side. Where l is the lap length, ld is the development length, db is the diameter of the reinforcing. Here’s a breakdown of two common. Learn how to calculate lap length for reinforcement in concrete sections, such as beams, columns and slabs. Find out the types, methods and factors of. Steel Lap Formula.

From www.youtube.com

Over Lapping of Steel How to calculate lapping length of steel Bar Steel Lap Formula Calculate development and lap lengths for reinforced concrete according to as 3600:2018. Find out the types, methods and factors of lap splices in tension and. To get the desired design length, lapping of two bars side. (1)p the detailing of laps between bars shall be such that: Here’s a breakdown of two common. Lap length is the length of overlapping. Steel Lap Formula.

From structville.com

How to Calculate the Anchorage and Lap Length of Steel Reinforcements Steel Lap Formula Calculate development and lap lengths for reinforced concrete according to as 3600:2018. Find out the types, methods and factors of lap splices in tension and. During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. Here’s a breakdown of two common. Learn the lap length formula for tension and compression, the. Steel Lap Formula.

From dailycivil.com

What Is Lap Length Of Reinforcement Bars Lapping Length of Steel Bars Steel Lap Formula During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. Enter concrete grade, bar diameter. Here’s a breakdown of two common. Spalling of the concrete in the neighbourhood of the joints. To get the desired design length, lapping of two bars side. L = ld x db / 4 x σst.. Steel Lap Formula.

From www.youtube.com

what is lap length How to calculate lap length Structural Design to Steel Lap Formula Where l is the lap length, ld is the development length, db is the diameter of the reinforcing. To get the desired design length, lapping of two bars side. Learn how to calculate lap length for reinforcement in concrete sections, such as beams, columns and slabs. The transmission of the forces from one bar to the next is assured; (1)p. Steel Lap Formula.

From www.dailycivil.com

Bar Bending Schedule (BBS) Estimates Of Steel In Building Steel Lap Formula L = ld x db / 4 x σst. (1)p the detailing of laps between bars shall be such that: Learn the lap length formula for tension and compression, the lap splices. Spalling of the concrete in the neighbourhood of the joints. The transmission of the forces from one bar to the next is assured; Here’s a breakdown of two. Steel Lap Formula.

From engindaily.com

Steel Bars OverLap Formulas Used In Column, slab and beams Engindaily Steel Lap Formula Enter concrete grade, bar diameter. During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. The transmission of the forces from one bar to the next is assured; Spalling of the concrete in the neighbourhood of the joints. Learn the lap length formula for tension and compression, the lap splices. Different. Steel Lap Formula.

From engineeringdiscoveries.com

Steel Bars OverLap Formulas Used In Column, Slab And Beams Steel Lap Formula Learn the lap length formula for tension and compression, the lap splices. Here’s a breakdown of two common. Enter concrete grade, bar diameter. Different design codes and standards provide methods for calculating lap length. The transmission of the forces from one bar to the next is assured; During the placement of steel in reinforced concrete structure, if the required length. Steel Lap Formula.

From www.vrogue.co

What Is Development Length And Lap Length Civil Plane vrogue.co Steel Lap Formula Where l is the lap length, ld is the development length, db is the diameter of the reinforcing. Calculate development and lap lengths for reinforced concrete according to as 3600:2018. Here’s a breakdown of two common. Enter concrete grade, bar diameter. Different design codes and standards provide methods for calculating lap length. (1)p the detailing of laps between bars shall. Steel Lap Formula.

From engindaily.com

Steel Bars OverLap Formulas Used In Column, slab and beams Engindaily Steel Lap Formula Lap length is the length of overlapping between two bars to achieve the required design length. Enter concrete grade, bar diameter. Calculate development and lap lengths for reinforced concrete according to as 3600:2018. Learn the lap length formula for tension and compression, the lap splices. Learn how to calculate lap length for reinforcement in concrete sections, such as beams, columns. Steel Lap Formula.

From structville.com

How to Calculate the Anchorage and Lap Length of Steel Reinforcements Steel Lap Formula To get the desired design length, lapping of two bars side. Calculate development and lap lengths for reinforced concrete according to as 3600:2018. Enter concrete grade, bar diameter. Here’s a breakdown of two common. The transmission of the forces from one bar to the next is assured; Find out the types, methods and factors of lap splices in tension and.. Steel Lap Formula.

From www.researchgate.net

Lap length reinforcement details for EC2 Control beam (12mm, 16mm, 20mm Steel Lap Formula During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. Where l is the lap length, ld is the development length, db is the diameter of the reinforcing. Different design codes and standards provide methods for calculating lap length. To get the desired design length, lapping of two bars side. Learn. Steel Lap Formula.

From www.youtube.com

Difference between Development Length and Lap Length YouTube Steel Lap Formula Enter concrete grade, bar diameter. To get the desired design length, lapping of two bars side. Lap length is the length of overlapping between two bars to achieve the required design length. The lap length is typically calculated using the following formula: Spalling of the concrete in the neighbourhood of the joints. Find out the types, methods and factors of. Steel Lap Formula.

From structx.com

StructX Reinforcement Details Steel Lap Formula During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. Learn how to calculate lap length for reinforcement in concrete sections, such as beams, columns and slabs. The lap length is typically calculated using the following formula: Find out the types, methods and factors of lap splices in tension and. Lap. Steel Lap Formula.

From www.vrogue.co

What Is Lap Length How To Calculate It For Column Bea vrogue.co Steel Lap Formula To get the desired design length, lapping of two bars side. During the placement of steel in reinforced concrete structure, if the required length of single bar may fall short. Spalling of the concrete in the neighbourhood of the joints. Where l is the lap length, ld is the development length, db is the diameter of the reinforcing. Find out. Steel Lap Formula.

From www.vrogue.co

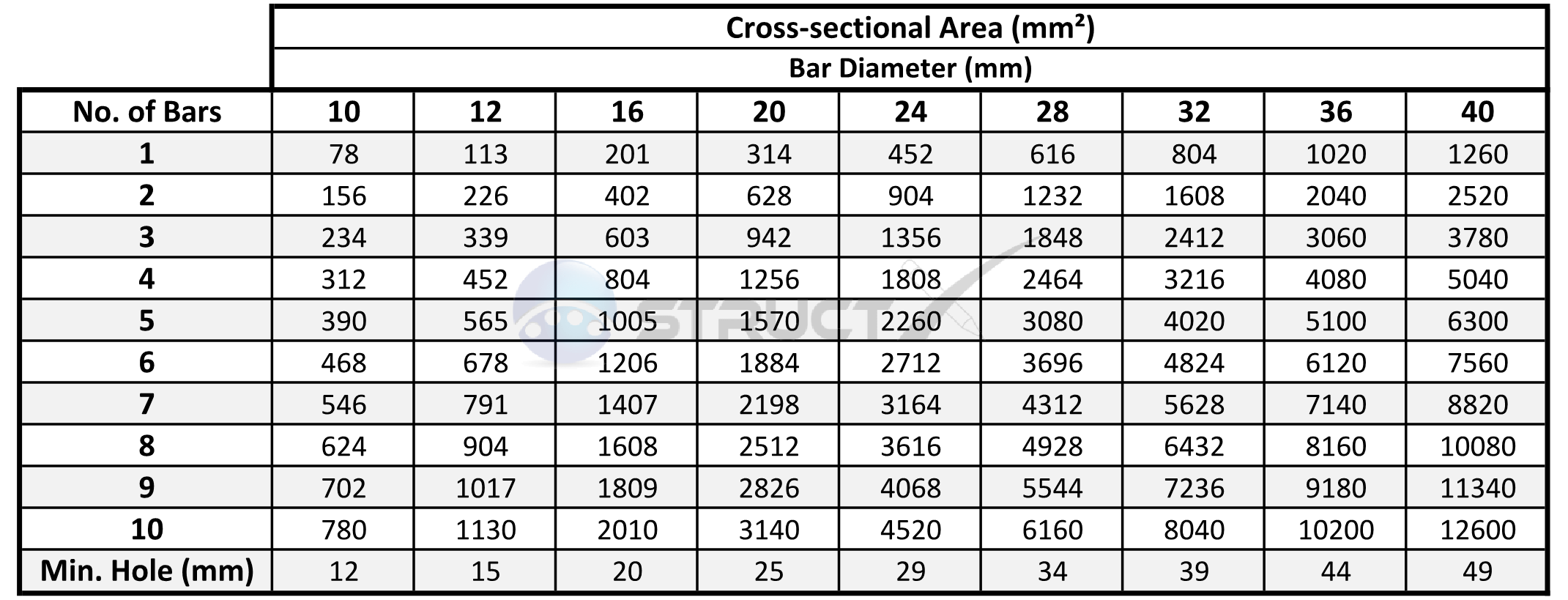

Reinforcement Bar Area Chart Chart Examples vrogue.co Steel Lap Formula Learn the lap length formula for tension and compression, the lap splices. Lap length is the length of overlapping between two bars to achieve the required design length. Here’s a breakdown of two common. Calculate development and lap lengths for reinforced concrete according to as 3600:2018. Learn how to calculate lap length for reinforcement in concrete sections, such as beams,. Steel Lap Formula.

From engindaily.com

Steel Bars OverLap Formulas Used In Column, slab and beams Engindaily Steel Lap Formula To get the desired design length, lapping of two bars side. Different design codes and standards provide methods for calculating lap length. Lap length is the length of overlapping between two bars to achieve the required design length. Here’s a breakdown of two common. The transmission of the forces from one bar to the next is assured; Enter concrete grade,. Steel Lap Formula.