Turning Tool Rake Angle . A tool’s rake angle will affect how much material. In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. Its relief or clearance angle. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. Function of tool features for turning. The insert's inscribed circle or ic. The geometry of an insert includes: Function of tool features for turning. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. Rake angle is the cutting edge angle that has a large effect on cutting resistance,. When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°, in exceptional cases up to + 18°. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life.

from www.minaprem.com

Function of tool features for turning. The insert's inscribed circle or ic. Function of tool features for turning. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. Its relief or clearance angle. A tool’s rake angle will affect how much material. In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. The geometry of an insert includes: 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits.

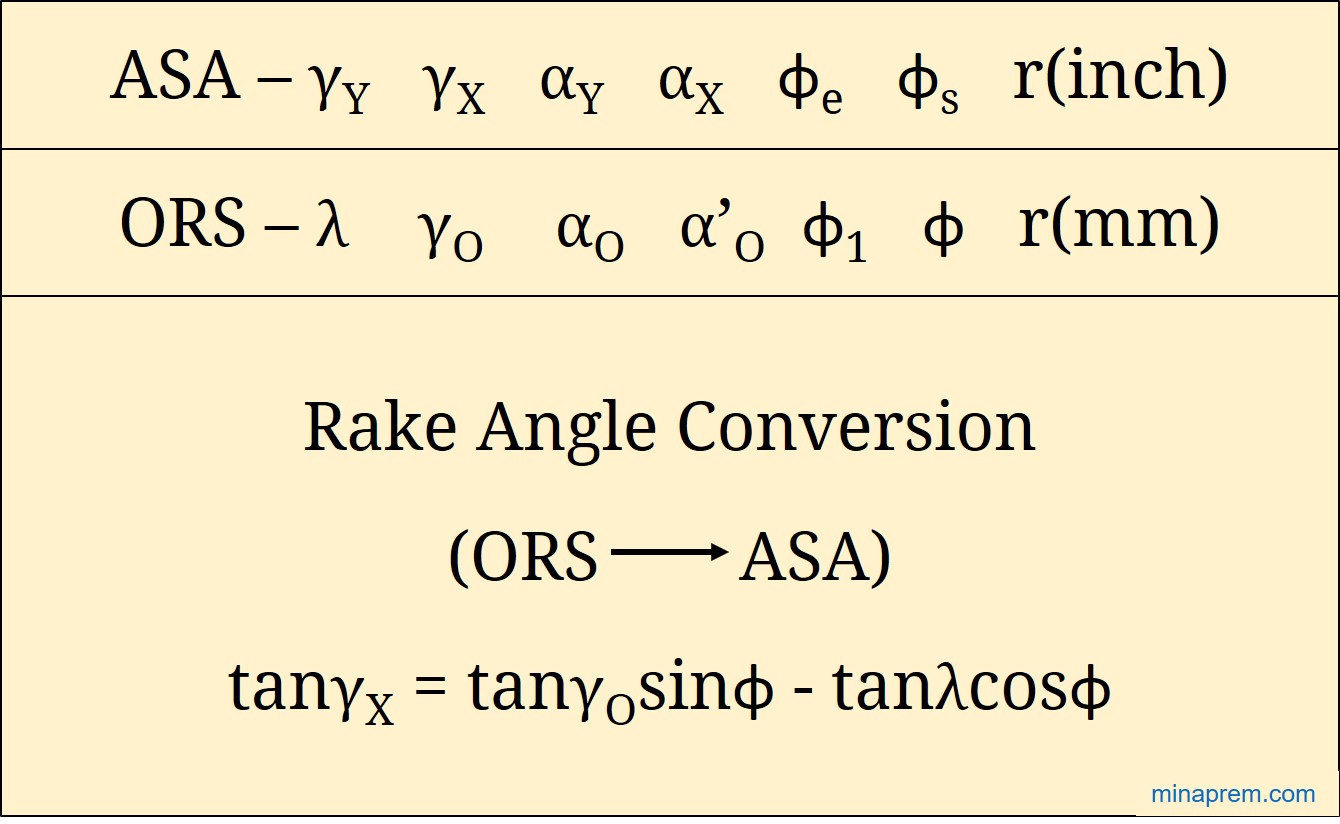

Determine principal cutting edge angle for equal side and orthogonal

Turning Tool Rake Angle Rake angle is the cutting edge angle that has a large effect on cutting resistance,. The insert's inscribed circle or ic. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. The geometry of an insert includes: Rake angle is the cutting edge angle that has a large effect on cutting resistance,. Function of tool features for turning. When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°, in exceptional cases up to + 18°. In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. Its relief or clearance angle. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. A tool’s rake angle will affect how much material. Function of tool features for turning. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle.

From www.manufacturingguide.com

Turning tool angles Find suppliers, processes & material Turning Tool Rake Angle In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°, in exceptional cases up to + 18°. Function of tool features for turning. Rake angle is the cutting. Turning Tool Rake Angle.

From www.cobanengineering.com

Cutting Tools Terms and Definitions, Cutting Tool, Rake Face, Flank Turning Tool Rake Angle Function of tool features for turning. In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. The geometry of an insert includes: Function of tool features for turning. When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°,. Turning Tool Rake Angle.

From www.minaprem.com

Calculate shear velocity in terms of rake angle, shear angle, cutting Turning Tool Rake Angle Function of tool features for turning. The geometry of an insert includes: One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. Function of tool features for. Turning Tool Rake Angle.

From www.machinemfg.com

Lathe Cutting Tool Angles Selection Principle MachineMFG Turning Tool Rake Angle Function of tool features for turning. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. Rake angle is the cutting edge angle that has a large effect on cutting resistance,. The geometry of an insert includes: When turning medium strength steel with cemented carbide tools, the rake angles range from. Turning Tool Rake Angle.

From www.mmc-carbide.com

Rake Angle Technical Info/Cutting Formula MITSUBISHI MATERIALS Turning Tool Rake Angle One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. The geometry of an insert includes: In machining, the rake angle is a parameter used. Turning Tool Rake Angle.

From www.themachinedesign.com

Single Point Cutting Tool Tool Angles , Nomenclature, Geometry Turning Tool Rake Angle The insert's inscribed circle or ic. Function of tool features for turning. Rake angle is the cutting edge angle that has a large effect on cutting resistance,. In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. The geometry of an insert includes: Rake angle is. Turning Tool Rake Angle.

From www.pinterest.com

Negative Rake Scraper Basics Wood turning, Scraper, Woodturning tools Turning Tool Rake Angle Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. The insert's inscribed circle or ic. The geometry of an insert includes: 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. Rake angle is the cutting edge angle that. Turning Tool Rake Angle.

From tubingchina.com

Speeds and Feeds for Turning Stainless Steel Turning Tool Rake Angle Function of tool features for turning. When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°, in exceptional cases up to + 18°. The insert's inscribed circle or ic. The geometry of an insert includes: In machining, the rake angle is a parameter used in various cutting processes, describing the angle of. Turning Tool Rake Angle.

From www.sharpeninghandbook.info

Sharpening Handbook Turning Tool Rake Angle The geometry of an insert includes: Function of tool features for turning. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. A tool’s rake angle will affect how much material. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool. Turning Tool Rake Angle.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Turning Tool Rake Angle The geometry of an insert includes: In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°, in exceptional cases up to + 18°. Its relief or clearance angle.. Turning Tool Rake Angle.

From www.hobby-machinist.com

Rake angles The HobbyMachinist Turning Tool Rake Angle Function of tool features for turning. When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°, in exceptional cases up to + 18°. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. Rake angle is the cutting edge angle that. Turning Tool Rake Angle.

From www.minaprem.com

ORS System of Tool Designation Orthogonal Rake System Turning Tool Rake Angle Its relief or clearance angle. In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. Rake angle is the cutting edge angle that has a large effect on cutting resistance,. Function of tool features for turning. Function of tool features for turning. A tool’s rake angle. Turning Tool Rake Angle.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Turning Tool Rake Angle In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°, in exceptional cases up to + 18°. One of the most important factors in machining is the geometry. Turning Tool Rake Angle.

From www.youtube.com

Differences between Positive Rake Angle and Negative Rake Angle Turning Tool Rake Angle In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. The insert's inscribed circle or ic. Function of tool features for turning. Function of tool features for turning. The geometry of an insert includes: Rake angle is the cutting edge angle that has a large effect. Turning Tool Rake Angle.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Turning Tool Rake Angle When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°, in exceptional cases up to + 18°. Its relief or clearance angle. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. Rake angle is a cutting edge angle that has large effects. Turning Tool Rake Angle.

From www.minaprem.com

Name of the angle between face and flank of single point cutting tool Turning Tool Rake Angle The insert's inscribed circle or ic. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. Function of tool features for turning. Rake angle is the cutting edge angle that has a large effect on cutting resistance,. The geometry of an insert includes: A tool’s rake angle will affect how much. Turning Tool Rake Angle.

From www.researchgate.net

(PDF) Effects of Tool Rake Angle on Tool Life in Turning Tools Turning Tool Rake Angle In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°, in exceptional cases up to + 18°. One of the most important factors in machining is the geometry. Turning Tool Rake Angle.

From www.performers.hk

Tool_Geometry Turning Tool Rake Angle Its relief or clearance angle. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. Function of tool features for turning. The geometry of an insert includes: 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits.. Turning Tool Rake Angle.

From www.pinterest.com

Lathe Turning tool, Grind angles lathe tools Pinterest Turning Turning Tool Rake Angle 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. Function of tool features for turning. Its relief or clearance angle. The insert's inscribed circle or ic.. Turning Tool Rake Angle.

From www.themachinedesign.com

Single Point Cutting Tool Nomenclature, Geometry The Machine Design Turning Tool Rake Angle 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. Function of tool features for turning. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. Function of tool features for turning. When turning medium strength steel with cemented carbide. Turning Tool Rake Angle.

From www.ukocarbide.com

How Important to Know Each Part of the CNC Lath Tool? Turning Tool Rake Angle When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°, in exceptional cases up to + 18°. In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. 9 rows this page give rake and relief angles for turning. Turning Tool Rake Angle.

From sharpeninghandbook.info

Sharpening Handbook Turning Tool Rake Angle Function of tool features for turning. The geometry of an insert includes: One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. A tool’s rake angle will affect how much material. In machining, the rake angle is a parameter used in various cutting processes, describing the. Turning Tool Rake Angle.

From www.minaprem.com

Concept of Positive Rake, Negative Rake and Zero Rake Angle Turning Tool Rake Angle 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face. Turning Tool Rake Angle.

From www.difference.minaprem.com

Difference Between Rake Angle and Clearance Angle Turning Tool Rake Angle Its relief or clearance angle. Rake angle is the cutting edge angle that has a large effect on cutting resistance,. The geometry of an insert includes: One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. Function of tool features for turning. The insert's inscribed circle. Turning Tool Rake Angle.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Turning Tool Rake Angle Function of tool features for turning. Its relief or clearance angle. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. A tool’s rake angle will affect how much material. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal,. Turning Tool Rake Angle.

From www.smartlathe.com

Components Of A Lathe Cutting Tool Turning Tool Rake Angle One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. A tool’s rake angle will affect how much material. Rake angle is the cutting edge angle that has a large effect on cutting resistance,. In machining, the rake angle is a parameter used in various cutting. Turning Tool Rake Angle.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Turning Tool Rake Angle Function of tool features for turning. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. Function of tool features for turning. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. The geometry of an insert includes: When turning. Turning Tool Rake Angle.

From www.mmc-carbide.com

Rake Angle Technical Info / Cutting Formula MITSUBISHI MATERIALS Turning Tool Rake Angle The geometry of an insert includes: In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. Function of tool features for turning. Rake angle is. Turning Tool Rake Angle.

From www.minaprem.com

Concept of Positive Rake, Negative Rake and Zero Rake Angle Turning Tool Rake Angle A tool’s rake angle will affect how much material. Rake angle is a cutting edge angle that has large effects on cutting resistance, chip disposal, cutting temperature and tool life. In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. The insert's inscribed circle or ic.. Turning Tool Rake Angle.

From www.riansclub.com

Rake Angle Types Of Rake Angle, Advantages, And Disadvantages Turning Tool Rake Angle Function of tool features for turning. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. A tool’s rake angle will affect how much material. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. The geometry. Turning Tool Rake Angle.

From www.cobanengineering.com

Back Rake, Side Rake, Rake angle, wedge angle and flank angles,the Turning Tool Rake Angle Rake angle is the cutting edge angle that has a large effect on cutting resistance,. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. A tool’s rake angle will affect how much material. The insert's inscribed circle or ic. Function of tool features for turning. One of the most important. Turning Tool Rake Angle.

From learnmechanical.com

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature Turning Tool Rake Angle The insert's inscribed circle or ic. When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°, in exceptional cases up to + 18°. Its relief or clearance angle. Rake angle is the cutting edge angle that has a large effect on cutting resistance,. Function of tool features for turning. 9 rows this. Turning Tool Rake Angle.

From www.minaprem.com

What is Clearance Angle in Cutting Tool? Machining Principles Turning Tool Rake Angle The insert's inscribed circle or ic. In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. Rake angle is the cutting edge angle that has a large effect on cutting resistance,. When turning medium strength steel with cemented carbide tools, the rake angles range from 0. Turning Tool Rake Angle.

From www.minaprem.com

Determine principal cutting edge angle for equal side and orthogonal Turning Tool Rake Angle One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. When turning medium strength steel with cemented carbide tools, the rake angles range from 0 to + 6°, in exceptional cases up to + 18°. The insert's inscribed circle or ic. The geometry of an insert. Turning Tool Rake Angle.

From www.youtube.com

Single Point Cutting Tool Nomenclature, Tool Signature, Side Rake Turning Tool Rake Angle Rake angle is the cutting edge angle that has a large effect on cutting resistance,. Its relief or clearance angle. One of the most important factors in machining is the geometry of the cutting tool, and one component of that is the rake angle. In machining, the rake angle is a parameter used in various cutting processes, describing the angle. Turning Tool Rake Angle.