How To Adjust Oxy Acetylene Torch For Brazing . · adjust regulator p/a screws to tip pressure settings. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. · stand away from front of regulator. move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. hardluckcharlie shows how to set up and adjust oxygen and. to set up an oxy acetylene torch, start by cleaning any dust or dirt. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube. · separately and slowly open the oxygen and acetylene cylinder valves. It can also be used to cut.

from www.hampdon.com.au

use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube. to set up an oxy acetylene torch, start by cleaning any dust or dirt. hardluckcharlie shows how to set up and adjust oxygen and. · separately and slowly open the oxygen and acetylene cylinder valves. · stand away from front of regulator. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. It can also be used to cut. · adjust regulator p/a screws to tip pressure settings.

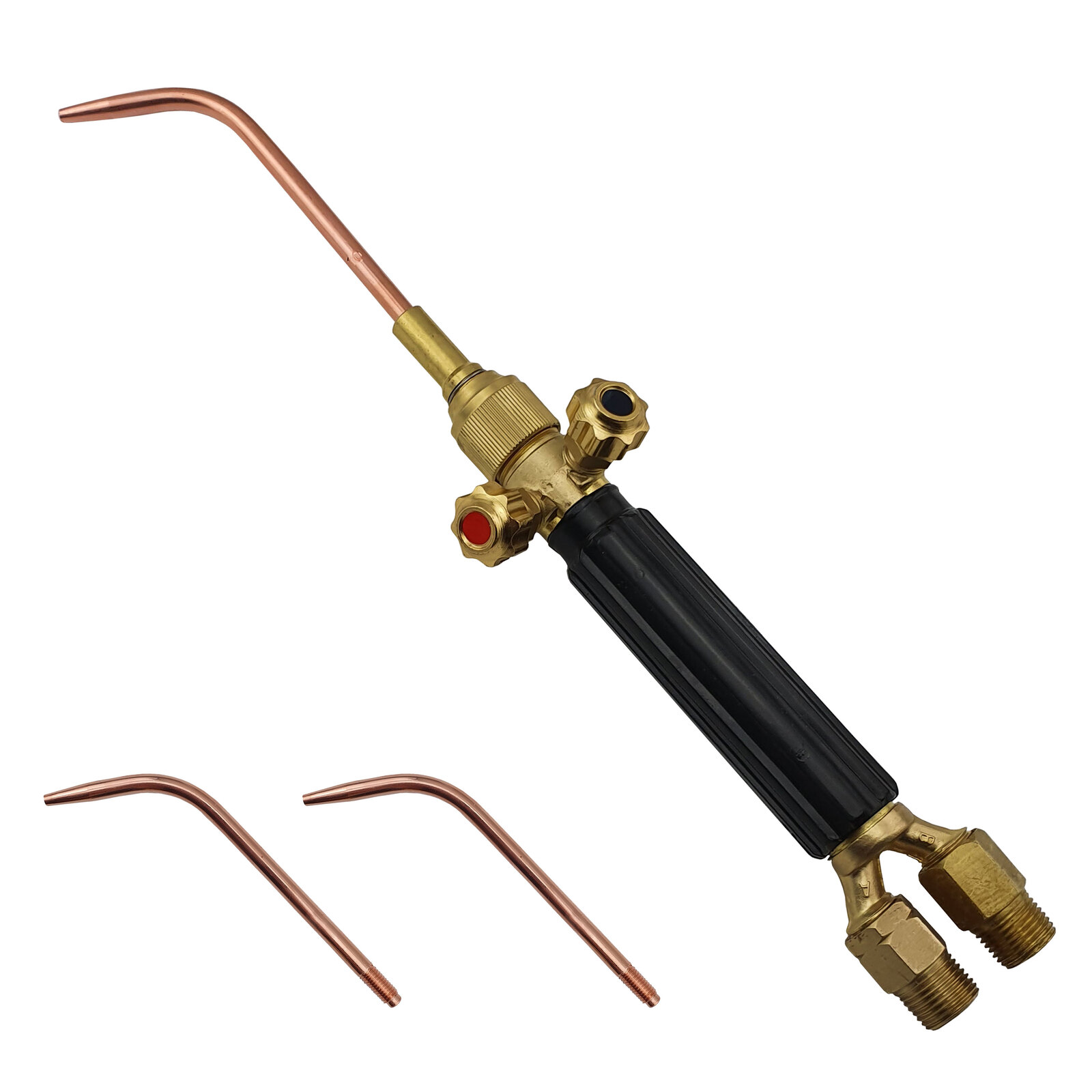

UWELD Oxygen / Acetylene Micro Torch Kit for Brazing

How To Adjust Oxy Acetylene Torch For Brazing this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. · stand away from front of regulator. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. · separately and slowly open the oxygen and acetylene cylinder valves. · adjust regulator p/a screws to tip pressure settings. It can also be used to cut. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. hardluckcharlie shows how to set up and adjust oxygen and. move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. to set up an oxy acetylene torch, start by cleaning any dust or dirt. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube.

From www.desertcart.nz

Buy AWLOLWA Professional Portable Tote Oxy Acetylene Welding Brazing How To Adjust Oxy Acetylene Torch For Brazing hardluckcharlie shows how to set up and adjust oxygen and. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. · separately and slowly open the oxygen and acetylene cylinder valves. It can also be used to cut. to set up an oxy acetylene torch, start by cleaning any dust or. How To Adjust Oxy Acetylene Torch For Brazing.

From theweldingpro.com

5 Best Cutting Torch Kits Plus a buying guide. How To Adjust Oxy Acetylene Torch For Brazing · separately and slowly open the oxygen and acetylene cylinder valves. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube. · adjust regulator p/a screws to tip pressure settings.. How To Adjust Oxy Acetylene Torch For Brazing.

From dailystars.blob.core.windows.net

Ultimate Guide To Oxy Acetylene Torches Applications, Safety, And Tips How To Adjust Oxy Acetylene Torch For Brazing · separately and slowly open the oxygen and acetylene cylinder valves. · adjust regulator p/a screws to tip pressure settings. It can also be used to cut. to set up an oxy acetylene torch, start by cleaning any dust or dirt. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt. How To Adjust Oxy Acetylene Torch For Brazing.

From www.express.fr

The pressure setting for oxyacetylene welding Express How To Adjust Oxy Acetylene Torch For Brazing to set up an oxy acetylene torch, start by cleaning any dust or dirt. · adjust regulator p/a screws to tip pressure settings. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. It can also be used to cut. hardluckcharlie shows how to set up and adjust oxygen. How To Adjust Oxy Acetylene Torch For Brazing.

From www.youtube.com

New torch setup for oxy propane and oxy acetylene torch options YouTube How To Adjust Oxy Acetylene Torch For Brazing this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube. move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame. How To Adjust Oxy Acetylene Torch For Brazing.

From dxomfgmrn.blob.core.windows.net

Oxy Acetylene Brazing Torch Tips at Martha Lamar blog How To Adjust Oxy Acetylene Torch For Brazing It can also be used to cut. to set up an oxy acetylene torch, start by cleaning any dust or dirt. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. hardluckcharlie shows how to set up and adjust oxygen and. · separately and slowly open the oxygen and. How To Adjust Oxy Acetylene Torch For Brazing.

From dxoyewajc.blob.core.windows.net

Oxy Acetylene Torch Napa at Lindy Baker blog How To Adjust Oxy Acetylene Torch For Brazing use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube. hardluckcharlie shows how to set up and adjust oxygen and. move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. the torch is thus suitable. How To Adjust Oxy Acetylene Torch For Brazing.

From www.weldingsuppliesfromioc.com

How To Get Started With Oxy Acetylene Cutting How To Adjust Oxy Acetylene Torch For Brazing the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube. hardluckcharlie shows how to set up and adjust oxygen and. It can also be used to cut. · separately and slowly. How To Adjust Oxy Acetylene Torch For Brazing.

From dxoiomgni.blob.core.windows.net

How To Use OxyAcetylene Torch For Brazing at James Cross blog How To Adjust Oxy Acetylene Torch For Brazing hardluckcharlie shows how to set up and adjust oxygen and. move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. this video is just a quick overview of how. How To Adjust Oxy Acetylene Torch For Brazing.

From www.youtube.com

This New Compact Torch For HVAC Brazing Is A GAME CHANGER. YouTube How To Adjust Oxy Acetylene Torch For Brazing hardluckcharlie shows how to set up and adjust oxygen and. · stand away from front of regulator. · adjust regulator p/a screws to tip pressure settings. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. the torch is thus suitable for welding using a filler metal, supplied. How To Adjust Oxy Acetylene Torch For Brazing.

From rapidhireservices.co.uk

Rapid Hire Services OxyAcetylene Kit Rapid Hire Services How To Adjust Oxy Acetylene Torch For Brazing · stand away from front of regulator. hardluckcharlie shows how to set up and adjust oxygen and. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. use oxygen/acetylene with care—. How To Adjust Oxy Acetylene Torch For Brazing.

From 13.237.128.103

How to properly light, adjust and shut down an oxyacetylene torch How To Adjust Oxy Acetylene Torch For Brazing this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. · adjust regulator p/a screws to tip pressure settings. It can also be used to cut. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. · separately and slowly open the oxygen and. How To Adjust Oxy Acetylene Torch For Brazing.

From dxoaafqnw.blob.core.windows.net

Brazing Steel With Propane Torch at Maria Fraley blog How To Adjust Oxy Acetylene Torch For Brazing to set up an oxy acetylene torch, start by cleaning any dust or dirt. · adjust regulator p/a screws to tip pressure settings. · stand away from front of regulator. · separately and slowly open the oxygen and acetylene cylinder valves. this video is just a quick overview of how to set your oxygen and acetylene pressures. How To Adjust Oxy Acetylene Torch For Brazing.

From fractory.com

OxyAcetylene Welding Explained Gas Welding Fractory How To Adjust Oxy Acetylene Torch For Brazing this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube. · stand away from front of regulator. move the torch over the plate in a circular motion and. How To Adjust Oxy Acetylene Torch For Brazing.

From dxomfgmrn.blob.core.windows.net

Oxy Acetylene Brazing Torch Tips at Martha Lamar blog How To Adjust Oxy Acetylene Torch For Brazing the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. It can. How To Adjust Oxy Acetylene Torch For Brazing.

From www.wikihow.com

How to Set Up an Oxy Acetylene Torch (with Pictures) wikiHow How To Adjust Oxy Acetylene Torch For Brazing the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. hardluckcharlie shows how to set up and adjust oxygen and. · stand away from front of regulator. · separately and slowly open the oxygen and acetylene cylinder valves. It can also be used to cut. this video is just a. How To Adjust Oxy Acetylene Torch For Brazing.

From blog.thepipingmart.com

What is Oxy Acetylene Cutting? Working and Uses How To Adjust Oxy Acetylene Torch For Brazing to set up an oxy acetylene torch, start by cleaning any dust or dirt. move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. · stand away from front of regulator. hardluckcharlie shows how to set up and adjust oxygen and. use oxygen/acetylene with. How To Adjust Oxy Acetylene Torch For Brazing.

From exoizfati.blob.core.windows.net

Oxy Acetylene Tip For Brazing at Maurice Davis blog How To Adjust Oxy Acetylene Torch For Brazing to set up an oxy acetylene torch, start by cleaning any dust or dirt. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. · stand away from front of regulator. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum. How To Adjust Oxy Acetylene Torch For Brazing.

From www.youtube.com

How to use brazing torch how to use oxy acetylene torch for brazing set How To Adjust Oxy Acetylene Torch For Brazing to set up an oxy acetylene torch, start by cleaning any dust or dirt. · separately and slowly open the oxygen and acetylene cylinder valves. · stand away from front of regulator. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. move the torch over the plate in a. How To Adjust Oxy Acetylene Torch For Brazing.

From diagramlibraryhelen.z6.web.core.windows.net

How To Adjust Cutting Torch How To Adjust Oxy Acetylene Torch For Brazing · adjust regulator p/a screws to tip pressure settings. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. the torch is thus suitable for welding using a filler. How To Adjust Oxy Acetylene Torch For Brazing.

From mavink.com

Oxy Acetylene Welding Torch How To Adjust Oxy Acetylene Torch For Brazing this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. It can also be used to cut. use oxygen/acetylene with care— the higher flame temperature, especially close to. How To Adjust Oxy Acetylene Torch For Brazing.

From www.hampdon.com.au

UWELD Oxygen / Acetylene Micro Torch Kit for Brazing How To Adjust Oxy Acetylene Torch For Brazing this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. hardluckcharlie shows how to set up and adjust oxygen and. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube. It can also be used to cut. move. How To Adjust Oxy Acetylene Torch For Brazing.

From www.hampdon.com.au

Harris Acetylene Flexible Brazing Welding Tip Size 00908 How To Adjust Oxy Acetylene Torch For Brazing move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. · stand away from front of regulator. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube. · separately and slowly open the oxygen and acetylene. How To Adjust Oxy Acetylene Torch For Brazing.

From www.desertcart.co.uk

Buy Walbest Oxy Acetylene Torch Kit Oxygen Acetylene Welding Brazing How To Adjust Oxy Acetylene Torch For Brazing hardluckcharlie shows how to set up and adjust oxygen and. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. · separately and slowly open the oxygen and acetylene cylinder valves. to set up an oxy acetylene torch, start by cleaning any dust or dirt. It can also be. How To Adjust Oxy Acetylene Torch For Brazing.

From antigua.desertcart.com

Buy RX WELD Oxygen & Acetylene Cutting Torch and Welding Kit Portable How To Adjust Oxy Acetylene Torch For Brazing move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube.. How To Adjust Oxy Acetylene Torch For Brazing.

From aptidco.in

When Brazing With Oxy Acetylene, What Pressures Should The, 46 OFF How To Adjust Oxy Acetylene Torch For Brazing · adjust regulator p/a screws to tip pressure settings. hardluckcharlie shows how to set up and adjust oxygen and. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. · stand away from front of regulator. It can also be used to cut. · separately and slowly open the oxygen and. How To Adjust Oxy Acetylene Torch For Brazing.

From exoizfati.blob.core.windows.net

Oxy Acetylene Tip For Brazing at Maurice Davis blog How To Adjust Oxy Acetylene Torch For Brazing the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. · stand away from front of regulator. move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. · separately and slowly open the oxygen and acetylene cylinder valves. to. How To Adjust Oxy Acetylene Torch For Brazing.

From dxomfgmrn.blob.core.windows.net

Oxy Acetylene Brazing Torch Tips at Martha Lamar blog How To Adjust Oxy Acetylene Torch For Brazing · separately and slowly open the oxygen and acetylene cylinder valves. hardluckcharlie shows how to set up and adjust oxygen and. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube. · adjust regulator p/a screws to tip pressure settings. this video is just a quick overview. How To Adjust Oxy Acetylene Torch For Brazing.

From ubicaciondepersonas.cdmx.gob.mx

UWELD Oxygen Acetylene Micro Torch Kit For Brazing How To Adjust Oxy Acetylene Torch For Brazing move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. to set up an oxy acetylene torch, start by cleaning any dust or dirt. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. use oxygen/acetylene with. How To Adjust Oxy Acetylene Torch For Brazing.

From exoizfati.blob.core.windows.net

Oxy Acetylene Tip For Brazing at Maurice Davis blog How To Adjust Oxy Acetylene Torch For Brazing · adjust regulator p/a screws to tip pressure settings. to set up an oxy acetylene torch, start by cleaning any dust or dirt. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. · separately and slowly open the oxygen and acetylene cylinder valves. move the torch over the. How To Adjust Oxy Acetylene Torch For Brazing.

From www.vrogue.co

Complete Oxygen Acetylene Oxy Welding Cutting Weld To vrogue.co How To Adjust Oxy Acetylene Torch For Brazing · separately and slowly open the oxygen and acetylene cylinder valves. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. this video is just a quick overview of how. How To Adjust Oxy Acetylene Torch For Brazing.

From www.ebay.com.au

OxyAcetylene Welding Tips Model WJ Compatible with "J" Series Victor How To Adjust Oxy Acetylene Torch For Brazing · adjust regulator p/a screws to tip pressure settings. move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. the torch is thus suitable for welding using a. How To Adjust Oxy Acetylene Torch For Brazing.

From dxolqyfyt.blob.core.windows.net

OxyAcetylene Gas Welding Procedure at Janice Deangelo blog How To Adjust Oxy Acetylene Torch For Brazing · separately and slowly open the oxygen and acetylene cylinder valves. hardluckcharlie shows how to set up and adjust oxygen and. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. · stand away from front of regulator. · adjust regulator p/a screws to tip pressure settings. move the torch. How To Adjust Oxy Acetylene Torch For Brazing.

From www.desertcart.in

Buy RX WELD Upgraded version Portable Tote Brazing Hvac Torch Kit Oxy How To Adjust Oxy Acetylene Torch For Brazing · separately and slowly open the oxygen and acetylene cylinder valves. the torch is thus suitable for welding using a filler metal, supplied by the brazing rod. use oxygen/acetylene with care— the higher flame temperature, especially close to the inner cone, can quickly melt the aluminum tube. · stand away from front of regulator. · adjust regulator. How To Adjust Oxy Acetylene Torch For Brazing.

From dxoiomgni.blob.core.windows.net

How To Use OxyAcetylene Torch For Brazing at James Cross blog How To Adjust Oxy Acetylene Torch For Brazing It can also be used to cut. · adjust regulator p/a screws to tip pressure settings. this video is just a quick overview of how to set your oxygen and acetylene pressures for brazing. hardluckcharlie shows how to set up and adjust oxygen and. move the torch over the plate in a circular motion and at a. How To Adjust Oxy Acetylene Torch For Brazing.