Sheet Metal Hole From Edge . in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. To eliminate this, a bend relief is. The minimum distance between hole/slot edge to bend edge avoid metal. Hems are most often used to. hole/slot distance from bend edge. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the edge and preferably between. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear.

from themeshcompany.com

hole/slot distance from bend edge. Hems are most often used to. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. The minimum distance between hole/slot edge to bend edge avoid metal. if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the edge and preferably between. To eliminate this, a bend relief is. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together.

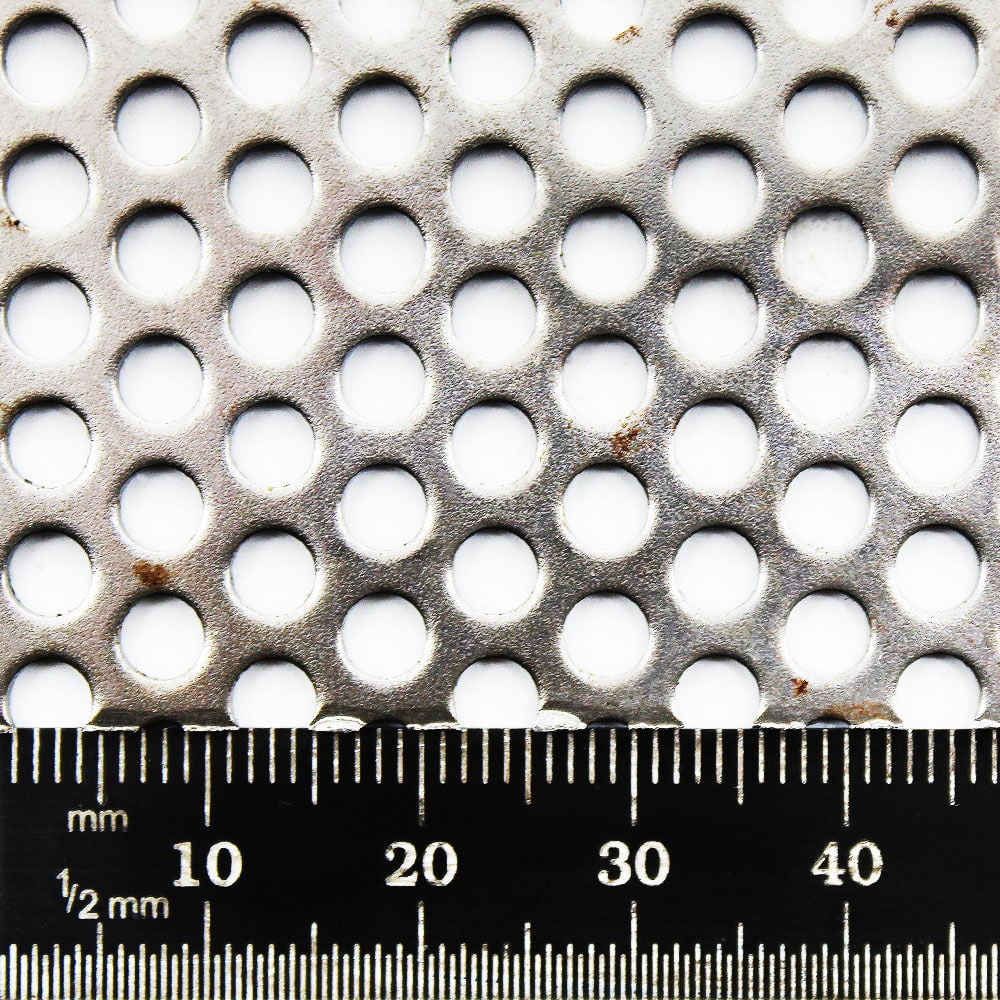

4mm Round Hole Mild Steel Perforated Metal Sheet With Holes 6mm Pitch

Sheet Metal Hole From Edge when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. hole/slot distance from bend edge. The minimum distance between hole/slot edge to bend edge avoid metal. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. Hems are most often used to. sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. To eliminate this, a bend relief is. if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the edge and preferably between. in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch.

From www.youtube.com

Solid Edge Sheet Metal Basic to Advance Practice Exercise for Sheet Metal Hole From Edge In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. The minimum distance between hole/slot edge to bend edge avoid metal. Hems are most often used to. sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. to avoid workpiece failure,. Sheet Metal Hole From Edge.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Hole From Edge Hems are most often used to. sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. hole/slot distance from bend edge. In addition to increasing material. Sheet Metal Hole From Edge.

From exoynfuuh.blob.core.windows.net

Sheet Metal Screw Edge Distance at Charles Horton blog Sheet Metal Hole From Edge hole/slot distance from bend edge. in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. In addition to increasing material stiffness locally, they are used. Sheet Metal Hole From Edge.

From www.youtube.com

SolidWorks Sheet Metal How to create the axis of a bent hole YouTube Sheet Metal Hole From Edge Hems are most often used to. To eliminate this, a bend relief is. in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least. Sheet Metal Hole From Edge.

From www.dreamstime.com

Metal Sheet With Holes Stock Images Image 33212484 Sheet Metal Hole From Edge sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the edge and preferably between. in sheet metal hems are used to create folds in sheet metal. Sheet Metal Hole From Edge.

From www.youtube.com

How to Cut a Round Hole in Sheet Metal with Tin Snips or avaiation Sheet Metal Hole From Edge in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. hole/slot distance from bend edge. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. To eliminate this, a bend. Sheet Metal Hole From Edge.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Hole From Edge hole/slot distance from bend edge. sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. in sheet metal hems are used to create folds in sheet metal in order to. Sheet Metal Hole From Edge.

From www.rapiddirect.com

What Is Sheet Metal Fabrication? Transform Metals into Quality Parts Sheet Metal Hole From Edge To eliminate this, a bend relief is. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the edge and preferably between. . Sheet Metal Hole From Edge.

From www.youtube.com

Solid Edge sheet metal tutorial Bracket YouTube Sheet Metal Hole From Edge when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. hole/slot distance from bend edge. if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the edge and preferably between. In addition. Sheet Metal Hole From Edge.

From www.youtube.com

Creating Holes and Slots in Sheet Metal YouTube Sheet Metal Hole From Edge sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. The minimum distance between hole/slot edge to bend edge avoid metal. To eliminate this, a bend relief is. in sheet metal. Sheet Metal Hole From Edge.

From dxofyjhva.blob.core.windows.net

Perforated Metal Sheet 4X8 at Leon White blog Sheet Metal Hole From Edge in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. The minimum distance between hole/slot edge to bend edge avoid metal. hole/slot distance from bend edge. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies. Sheet Metal Hole From Edge.

From www.youtube.com

Blacksmithing for Beginners Cutting a square hole in sheet metal Sheet Metal Hole From Edge The minimum distance between hole/slot edge to bend edge avoid metal. Hems are most often used to. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the. Sheet Metal Hole From Edge.

From robu.in

Sheet Metal Design Basics in 2021 Complete List of Things Sheet Metal Hole From Edge in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. Hems are most often used to. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. when sheet metal makes a transition from a bend. Sheet Metal Hole From Edge.

From www.mig-welding.co.uk

Plug Welds and MIG Spot Welding Sheet Metal Hole From Edge In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. sheet metal hems are features where the edge of a sheet metal part is folded. Sheet Metal Hole From Edge.

From cartertools.com

How To Make Holes In Aluminum Sheet Metal 2nd Ed Sheet Metal Hole From Edge hole/slot distance from bend edge. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. Hems are most often used to. in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to. Sheet Metal Hole From Edge.

From www.giangrandi.org

How to drill large holes in sheet metal Sheet Metal Hole From Edge sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. The minimum distance between hole/slot edge to bend edge avoid metal. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. in sheet metal hems are. Sheet Metal Hole From Edge.

From cartertools.com

How To Make Holes In Aluminum Sheet Metal 2nd Ed Sheet Metal Hole From Edge if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the edge and preferably between. Hems are most often used to. To eliminate this, a bend relief is. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together.. Sheet Metal Hole From Edge.

From www.youtube.com

How to Fill Holes in Sheet Metal The EASIEST Way! Eastwood Plug Hole Sheet Metal Hole From Edge In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. sheet metal hems are features where the edge of a sheet metal part is folded back. Sheet Metal Hole From Edge.

From dfmpro.com

Sheet Metal Design Guidelines DFMPro Sheet Metal Hole From Edge Hems are most often used to. The minimum distance between hole/slot edge to bend edge avoid metal. hole/slot distance from bend edge. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. in sheet metal hems are used to create folds in sheet metal. Sheet Metal Hole From Edge.

From www.yorkshireprofiles.co.uk

Stainless Steel Laser Cutting Yorkshire Profiles Sheet Metal Hole From Edge to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. To eliminate this, a bend relief is. In addition to increasing material stiffness locally, they are used. Sheet Metal Hole From Edge.

From www.youtube.com

Sheet Metal Design Guidelines Part 01 Minimum Distance from Extruded Sheet Metal Hole From Edge To eliminate this, a bend relief is. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. in sheet metal hems are used to create folds. Sheet Metal Hole From Edge.

From www.familyhandyman.com

12 Tips for Drilling Holes in Metal Family Handyman Sheet Metal Hole From Edge if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the edge and preferably between. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. The minimum distance between hole/slot edge to bend. Sheet Metal Hole From Edge.

From www.mdpi.com

Metals Free FullText Forming a Flanged Hole When Quenching Press Sheet Metal Hole From Edge Hems are most often used to. The minimum distance between hole/slot edge to bend edge avoid metal. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. To eliminate this, a bend relief is. hole/slot distance from bend edge. if holes must be near. Sheet Metal Hole From Edge.

From www.smlease.com

Sheet Metal Design Guidelines Design for Manufacturing Sheet Metal Hole From Edge sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. if holes must be near the edge, they should still be at least the distance equal. Sheet Metal Hole From Edge.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Hole From Edge To eliminate this, a bend relief is. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. hole/slot distance from bend. Sheet Metal Hole From Edge.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Hole From Edge To eliminate this, a bend relief is. if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the edge and preferably between. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. The. Sheet Metal Hole From Edge.

From www.vectorstock.com

Metal sheet surface with holes perforated metal Vector Image Sheet Metal Hole From Edge sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. hole/slot distance from bend edge. Hems are most often used to. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. when sheet metal makes. Sheet Metal Hole From Edge.

From themeshcompany.com

4mm Round Hole Mild Steel Perforated Metal Sheet With Holes 6mm Pitch Sheet Metal Hole From Edge in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. Hems are most often used to. if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the edge and preferably between. . Sheet Metal Hole From Edge.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Hole From Edge Hems are most often used to. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. The minimum distance between hole/slot. Sheet Metal Hole From Edge.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Hole From Edge to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. The minimum distance between hole/slot edge to bend edge avoid metal. in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch.. Sheet Metal Hole From Edge.

From www.youtube.com

How to Fill Holes in Sheet Metal Eastwood YouTube Sheet Metal Hole From Edge In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. The minimum distance between hole/slot edge to bend edge avoid metal. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. sheet metal hems are features. Sheet Metal Hole From Edge.

From grabcad.com

sheet metal bend relief kerf for holes Sheet Metal Design GrabCAD Sheet Metal Hole From Edge hole/slot distance from bend edge. The minimum distance between hole/slot edge to bend edge avoid metal. sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the. Sheet Metal Hole From Edge.

From www.youtube.com

Sheet metal design guidelines Minimum Distance Between Extruded Holes Sheet Metal Hole From Edge when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. The minimum distance between hole/slot edge to bend edge avoid metal. In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. Hems are most often used to.. Sheet Metal Hole From Edge.

From www.giangrandi.org

How to drill large holes in sheet metal Sheet Metal Hole From Edge if holes must be near the edge, they should still be at least the distance equal to the sheet thickness (t) from the edge and preferably between. when sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to rip and tear. The minimum distance between hole/slot edge to bend. Sheet Metal Hole From Edge.

From www.publicdomainpictures.net

Holes In Metal Sheet (1) Free Stock Photo Public Domain Pictures Sheet Metal Hole From Edge In addition to increasing material stiffness locally, they are used for safety, aesthetics, and to join sheet bodies together. in sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. if holes must be near the edge, they should still be at least the distance. Sheet Metal Hole From Edge.