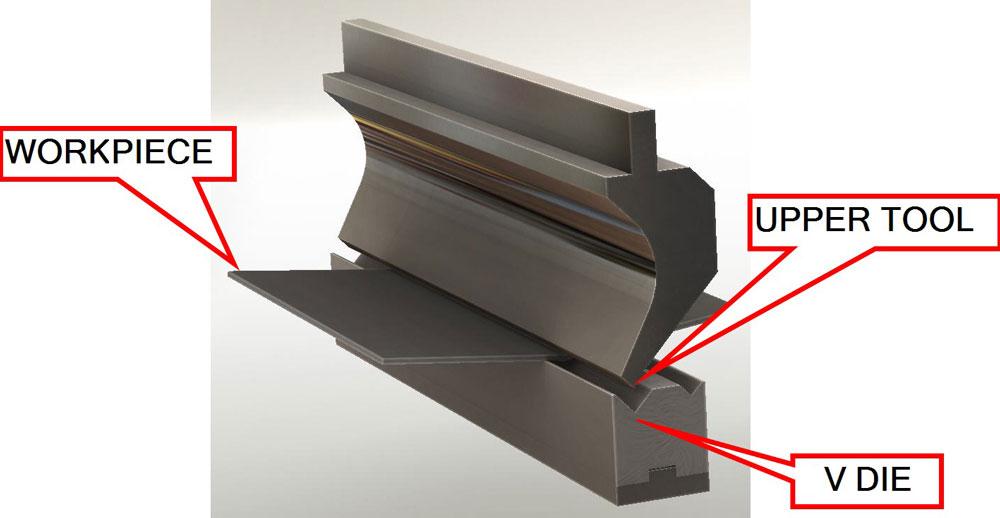

Air Bending Sheet Metal Radius . The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. The smallest inside radius that can be achieved by. Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. Air forming, bottom bending, and coining are metal forming methods. Air bending is the most common type of 3 types of bending used in sheet metal shops today. The punch tip radius should be no less than 63% of the material thickness. In this process the workpiece comes in contact with the outside edges of the die, as well as the.

from www.thefabricator.com

Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. Air bending is the most common type of 3 types of bending used in sheet metal shops today. The smallest inside radius that can be achieved by. The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. Air forming, bottom bending, and coining are metal forming methods. Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. In this process the workpiece comes in contact with the outside edges of the die, as well as the. The punch tip radius should be no less than 63% of the material thickness. Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending.

What sheet metal shops wish you knew Minimum flange, bend radius, and

Air Bending Sheet Metal Radius Air bending is the most common type of 3 types of bending used in sheet metal shops today. The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. The smallest inside radius that can be achieved by. Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. Air bending is the most common type of 3 types of bending used in sheet metal shops today. Air forming, bottom bending, and coining are metal forming methods. In this process the workpiece comes in contact with the outside edges of the die, as well as the. Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. The punch tip radius should be no less than 63% of the material thickness.

From www.smlease.com

Sheet Metal Bending Operation Types Methods and applications Air Bending Sheet Metal Radius Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. The smallest inside radius that can be achieved by. Air forming, bottom bending, and coining are metal forming methods. Air bending is the most common type of 3 types of bending used in sheet metal shops today.. Air Bending Sheet Metal Radius.

From www.thefabricator.com

What sheet metal shops wish you knew Minimum flange, bend radius, and Air Bending Sheet Metal Radius The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. Air bending is the most common type of 3 types of bending used in sheet metal shops today. In this process the workpiece comes in contact with the outside edges of the die, as well as the.. Air Bending Sheet Metal Radius.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Air Bending Sheet Metal Radius Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. The smallest inside radius that can be achieved by. Air bending is the most common type of 3 types of bending used in sheet metal shops today. Air forming, bottom bending, and coining are metal forming methods. The punch tip. Air Bending Sheet Metal Radius.

From www.thefabricator.com

What to know about sheet metal bend radius and minimum flange Air Bending Sheet Metal Radius The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. Air bending is the most common type of 3 types of bending used in sheet metal shops today. The punch tip radius should be no less than 63% of the material thickness. In this process the workpiece. Air Bending Sheet Metal Radius.

From mavink.com

Sheet Metal Minimum Bend Radius Chart Air Bending Sheet Metal Radius Air bending is the most common type of 3 types of bending used in sheet metal shops today. The punch tip radius should be no less than 63% of the material thickness. Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart. Air Bending Sheet Metal Radius.

From nomnorth.weebly.com

1.5 inch ss tube bend radius nomnorth Air Bending Sheet Metal Radius In this process the workpiece comes in contact with the outside edges of the die, as well as the. The punch tip radius should be no less than 63% of the material thickness. Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. Sheet metal bend radius. Air Bending Sheet Metal Radius.

From www.indiamart.com

MS Sheet Metal Radius Bending, Bend Radius 3D at Rs 15/kg in Ahmedabad Air Bending Sheet Metal Radius Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. The smallest inside radius that can be achieved by. Air forming, bottom bending, and coining are metal forming methods. Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal. Air Bending Sheet Metal Radius.

From aaronconnolly.z19.web.core.windows.net

Aluminum Sheet Metal Bend Radius Air Bending Sheet Metal Radius The punch tip radius should be no less than 63% of the material thickness. The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. In this process the workpiece comes in contact with the outside edges of the die, as well as the. The smallest inside radius. Air Bending Sheet Metal Radius.

From amada.de

Hydraulic PressBrake Air Bending Sheet Metal Radius The punch tip radius should be no less than 63% of the material thickness. Air forming, bottom bending, and coining are metal forming methods. The smallest inside radius that can be achieved by. Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. Among them are the workpiece material and. Air Bending Sheet Metal Radius.

From mungfali.com

Stainless Steel Bend Radius Chart Air Bending Sheet Metal Radius Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. Air bending is the most common type of. Air Bending Sheet Metal Radius.

From sheetmetalshiijin.blogspot.com

Sheet Metal Formula For Bending Sheet Metal Air Bending Sheet Metal Radius Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. Air forming, bottom bending, and coining are metal forming methods. The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. Among them are the workpiece material and. Air Bending Sheet Metal Radius.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Air Bending Sheet Metal Radius Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. In this process the workpiece comes in contact with the outside edges of the die, as well as the. Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and. Air Bending Sheet Metal Radius.

From inchbyinch.de

INCH Technical English pictorial bending & drawing (sheet metal) Air Bending Sheet Metal Radius Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. The punch tip radius should be no less than 63% of. Air Bending Sheet Metal Radius.

From www.vrogue.co

Sheet Metal Bend Radius Unfold Table Autodesk Communi vrogue.co Air Bending Sheet Metal Radius The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. The punch tip radius should be no less than 63% of the material thickness. Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs.. Air Bending Sheet Metal Radius.

From www.indiamart.com

MS Sheet Metal Radius Bending, Bend Radius 3D at Rs 15/kg in Ahmedabad Air Bending Sheet Metal Radius The punch tip radius should be no less than 63% of the material thickness. Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. The smallest inside radius that can be achieved by. Air bending is the most common type of. Air Bending Sheet Metal Radius.

From www.researchgate.net

The sheet metal stretchbending with bending radius R die (a) the Air Bending Sheet Metal Radius The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. The smallest inside radius that can be achieved. Air Bending Sheet Metal Radius.

From www.indiamart.com

MS Sheet Metal Radius Bending, Bend Radius 3D at Rs 15/kg in Ahmedabad Air Bending Sheet Metal Radius Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. Air forming, bottom bending, and coining are metal forming methods. In this process the workpiece comes in contact with the outside edges of the die, as well as the. The punch tip radius should be no less. Air Bending Sheet Metal Radius.

From www.thefabricator.com

Predicting an airformed sheet metal inside bend radius Air Bending Sheet Metal Radius Air forming, bottom bending, and coining are metal forming methods. Air bending is the most common type of 3 types of bending used in sheet metal shops today. Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. The smallest inside radius that can be achieved by.. Air Bending Sheet Metal Radius.

From casitademausi.org.pa

calca caro Scully sheet metal bending force calculation enorme Air Bending Sheet Metal Radius Air bending is the most common type of 3 types of bending used in sheet metal shops today. Air forming, bottom bending, and coining are metal forming methods. In this process the workpiece comes in contact with the outside edges of the die, as well as the. Among them are the workpiece material and thickness, the bend angle and inside. Air Bending Sheet Metal Radius.

From www.wilatooling.com

Large radius bending WILA Air Bending Sheet Metal Radius Air forming, bottom bending, and coining are metal forming methods. The punch tip radius should be no less than 63% of the material thickness. Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. The relationship between the bending radius of. Air Bending Sheet Metal Radius.

From www.machinemfg.com

How to determine the bending radius of sheet metal? MachineMfg Air Bending Sheet Metal Radius Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. The punch tip radius should be no less than 63% of the material thickness. Air forming, bottom bending, and coining are metal forming methods. Learn the 20 percent rule to better predict the sheet metal inside bend. Air Bending Sheet Metal Radius.

From reecehayes.z13.web.core.windows.net

Aluminum Sheet Metal Bend Radius Air Bending Sheet Metal Radius Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. The smallest inside radius that can be achieved by. The relationship between the bending radius of sheet. Air Bending Sheet Metal Radius.

From www.youtube.com

Making a Radius Bending Fixture for Sheetmetal YouTube Air Bending Sheet Metal Radius Air forming, bottom bending, and coining are metal forming methods. Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. Learn the 20 percent rule to better. Air Bending Sheet Metal Radius.

From www.huimfg.com

Free Air Bending Force Chart HUI Manufacturing Air Bending Sheet Metal Radius Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. The smallest inside radius that can be achieved by. In this process the workpiece comes in contact with the outside edges of the die, as well as the. Air bending is the most common type of 3 types of bending. Air Bending Sheet Metal Radius.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Air Bending Sheet Metal Radius The punch tip radius should be no less than 63% of the material thickness. Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. Air forming, bottom bending, and coining are metal forming methods. Among them are the workpiece material and thickness, the bend angle and inside radius, the method. Air Bending Sheet Metal Radius.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Air Bending Sheet Metal Radius In this process the workpiece comes in contact with the outside edges of the die, as well as the. Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. The punch tip radius should be no less than 63% of the. Air Bending Sheet Metal Radius.

From www.harsle.com

sheet metal bending machine for sale news HARSLE Air Bending Sheet Metal Radius In this process the workpiece comes in contact with the outside edges of the die, as well as the. Air bending is the most common type of 3 types of bending used in sheet metal shops today. The punch tip radius should be no less than 63% of the material thickness. The relationship between the bending radius of sheet metal. Air Bending Sheet Metal Radius.

From unitymanufacture.com

How To Bend A Radius In Sheet Metal? Unity Manufacture Air Bending Sheet Metal Radius The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. The smallest inside radius that can be achieved by. Learn the 20 percent rule to better predict. Air Bending Sheet Metal Radius.

From mungfali.com

Sheet Metal Bend Radius Air Bending Sheet Metal Radius Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. The smallest inside radius that can be achieved by. In this process the workpiece comes in contact with the outside edges of the die, as well as the. The relationship between the bending radius of sheet metal and the width. Air Bending Sheet Metal Radius.

From www.thefabricator.com

Precision sheet metal bending and the V groove Air Bending Sheet Metal Radius The smallest inside radius that can be achieved by. Air forming, bottom bending, and coining are metal forming methods. The punch tip radius should be no less than 63% of the material thickness. The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. Among them are the. Air Bending Sheet Metal Radius.

From sheetmetal.me

Air Bend Force Chart Numbers SheetMetal.Me Air Bending Sheet Metal Radius Air forming, bottom bending, and coining are metal forming methods. Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. The punch tip radius should be no less than 63% of the material thickness. Sheet metal bend radius is an essential. Air Bending Sheet Metal Radius.

From www.modumic.com

钣金弯曲设计技巧,弯曲余量,K系数工厂 manbetx2.0.ios Air Bending Sheet Metal Radius Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. The punch tip radius should be no less than 63% of the material thickness. Air bending is the most common type of 3 types of bending used in sheet metal shops today. In this process the workpiece. Air Bending Sheet Metal Radius.

From www.vrogue.co

Bend Radius Chart For Steel vrogue.co Air Bending Sheet Metal Radius Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. The punch tip radius should be no less. Air Bending Sheet Metal Radius.

From www.indiamart.com

Sheet Metal Radius Bending Service in Kamrej, Surat ID 23083914188 Air Bending Sheet Metal Radius Air forming, bottom bending, and coining are metal forming methods. Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. In this process the workpiece comes in contact with the outside edges of the die, as well as the. Air bending is the most common type of 3 types of. Air Bending Sheet Metal Radius.

From classlibraryfruehauf.z19.web.core.windows.net

Press Brake Bend Radius Chart Air Bending Sheet Metal Radius The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been. Air forming, bottom bending, and coining are metal forming methods. Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending. In this process the workpiece comes in. Air Bending Sheet Metal Radius.