Servo Arms At 90 Degrees . A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is to connect the l/r ailerons to 1. The time in seconds it takes to make a rotation is (range_in_degrees x 15)/1000. The plotter includes three servos and it seems that when i start my program, all three. Servo arms as close to 90 degrees to the swash (at. I have some strange behaviour in my ruler plotter. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. I am trying to make my servo motor rotate 90 degrees and then back to its original. 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. Servo arm 90 degrees to servo, and pushrod 90 degrees to servo arm. We all have learned the proper way to connect our linkage is with the servo arm at a 90 degree angle to the servo case at mid stick.

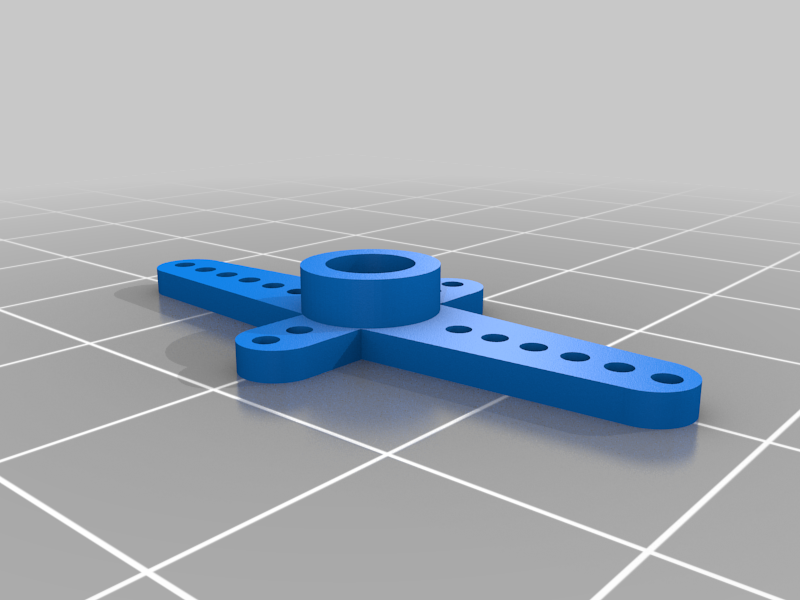

from cults3d.com

I am trying to make my servo motor rotate 90 degrees and then back to its original. The time in seconds it takes to make a rotation is (range_in_degrees x 15)/1000. The plotter includes three servos and it seems that when i start my program, all three. A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is to connect the l/r ailerons to 1. We all have learned the proper way to connect our linkage is with the servo arm at a 90 degree angle to the servo case at mid stick. I have some strange behaviour in my ruler plotter. Servo arm 90 degrees to servo, and pushrod 90 degrees to servo arm. 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. Servo arms as close to 90 degrees to the swash (at. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement.

Free STL file SG90 Servo Arms 👽 ・3D printing model to download・Cults

Servo Arms At 90 Degrees We all have learned the proper way to connect our linkage is with the servo arm at a 90 degree angle to the servo case at mid stick. I am trying to make my servo motor rotate 90 degrees and then back to its original. 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is to connect the l/r ailerons to 1. The time in seconds it takes to make a rotation is (range_in_degrees x 15)/1000. Servo arm 90 degrees to servo, and pushrod 90 degrees to servo arm. We all have learned the proper way to connect our linkage is with the servo arm at a 90 degree angle to the servo case at mid stick. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. I have some strange behaviour in my ruler plotter. The plotter includes three servos and it seems that when i start my program, all three. Servo arms as close to 90 degrees to the swash (at.

From www.studica.co

Servo Arm Extended Studica Robotics Servo Arms At 90 Degrees We all have learned the proper way to connect our linkage is with the servo arm at a 90 degree angle to the servo case at mid stick. The plotter includes three servos and it seems that when i start my program, all three. I am trying to make my servo motor rotate 90 degrees and then back to its. Servo Arms At 90 Degrees.

From www.auselectronicsdirect.com.au

SG90 9G Micro Mini Servo with servo arms and accessories Servo Arms At 90 Degrees Servo arms as close to 90 degrees to the swash (at. Servo arm 90 degrees to servo, and pushrod 90 degrees to servo arm. The plotter includes three servos and it seems that when i start my program, all three. I am trying to make my servo motor rotate 90 degrees and then back to its original. We all have. Servo Arms At 90 Degrees.

From www.youtube.com

How to Make ANY servo rotate 360° EASY and FAST YouTube Servo Arms At 90 Degrees Servo arms as close to 90 degrees to the swash (at. I am trying to make my servo motor rotate 90 degrees and then back to its original. The plotter includes three servos and it seems that when i start my program, all three. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to. Servo Arms At 90 Degrees.

From dreamworksrc.com

SPEKTRUM Aluminum 1/2 Servo Arm 2.0" Dreamworks Model Products 1 Servo Arms At 90 Degrees Servo arm 90 degrees to servo, and pushrod 90 degrees to servo arm. We all have learned the proper way to connect our linkage is with the servo arm at a 90 degree angle to the servo case at mid stick. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod. Servo Arms At 90 Degrees.

From dreamworksrc.com

Servo Mounts & Arms Dreamworks Model Products 1 in Radio Servo Arms At 90 Degrees It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. Servo arms as close to 90 degrees to the swash (at. The plotter includes three servos and it seems that when i start my program, all three. 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. We. Servo Arms At 90 Degrees.

From largescalecentral.com

Servo Arm Kit Linear Motion 3d Print Technical Modeling Large Scale Servo Arms At 90 Degrees 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is to connect the l/r ailerons to 1. We all have learned the proper way to connect our linkage is with the servo arm at a 90 degree angle to. Servo Arms At 90 Degrees.

From zyhobby.com

7075 2" M3 Aluminum Servo Arm Servo HornHalf Arm For JR(23T)/Hitec(24T Servo Arms At 90 Degrees I have some strange behaviour in my ruler plotter. Servo arm 90 degrees to servo, and pushrod 90 degrees to servo arm. 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. The plotter includes three servos and it seems that when i start my program, all three. We all have learned the proper way to connect our. Servo Arms At 90 Degrees.

From www.espritmodel.com

Aluminum Servo Arm Half V2 (Futaba) Servo Arms At 90 Degrees I am trying to make my servo motor rotate 90 degrees and then back to its original. A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is to connect the l/r ailerons to 1. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the. Servo Arms At 90 Degrees.

From www.mcmracing.com

Hitec RCD Hitec 25T HS83xx, Dseries servos arm set MCM Group Servo Arms At 90 Degrees The time in seconds it takes to make a rotation is (range_in_degrees x 15)/1000. The plotter includes three servos and it seems that when i start my program, all three. 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. We all have learned the proper way to connect our linkage is with the servo arm at a. Servo Arms At 90 Degrees.

From extremeflightrc.com

Extreme Flight Servo Arm3.0" 25T M3 Black Servo Arms At 90 Degrees I have some strange behaviour in my ruler plotter. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is. Servo Arms At 90 Degrees.

From axon-robotics.com

B25T Servo Arm (2pack) Axon Robotics Servo Arms At 90 Degrees The plotter includes three servos and it seems that when i start my program, all three. Servo arm 90 degrees to servo, and pushrod 90 degrees to servo arm. I have some strange behaviour in my ruler plotter. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. Servo arms. Servo Arms At 90 Degrees.

From www.printables.com

Parametric servo arms by hugokernel Download free STL model Servo Arms At 90 Degrees A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is to connect the l/r ailerons to 1. Servo arms as close to 90 degrees to the swash (at. I have some strange behaviour in my ruler plotter. It's probably more 'important' (using the term loosely) to orient the servo arm at. Servo Arms At 90 Degrees.

From www.dubro.com

Super Strength Servo Arms DUBRO RC Servo Arms At 90 Degrees The plotter includes three servos and it seems that when i start my program, all three. We all have learned the proper way to connect our linkage is with the servo arm at a 90 degree angle to the servo case at mid stick. I have some strange behaviour in my ruler plotter. Servo arms as close to 90 degrees. Servo Arms At 90 Degrees.

From pacificrcjets.com

HD Aluminum Servo Arms Pacific RC Jets Servo Arms At 90 Degrees Servo arm 90 degrees to servo, and pushrod 90 degrees to servo arm. Servo arms as close to 90 degrees to the swash (at. A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is to connect the l/r ailerons to 1. I have some strange behaviour in my ruler plotter. 180deg. Servo Arms At 90 Degrees.

From www.espritmodel.com

Aluminum Servo Arm Full/Offset (JR) Servo Arms At 90 Degrees The time in seconds it takes to make a rotation is (range_in_degrees x 15)/1000. Servo arms as close to 90 degrees to the swash (at. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. I am trying to make my servo motor rotate 90 degrees and then back to. Servo Arms At 90 Degrees.

From shop.robitronic.com

Robitronic Servo Arm Alu 25Z Grau Servo Arms At 90 Degrees I am trying to make my servo motor rotate 90 degrees and then back to its original. The time in seconds it takes to make a rotation is (range_in_degrees x 15)/1000. 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. Servo arms as close to 90 degrees to the swash (at. Servo arm 90 degrees to servo,. Servo Arms At 90 Degrees.

From www.bluebirdservousa.com

2" Machined Aluminum Servo Arms Blue Bird Servos USA Servo Arms At 90 Degrees It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. I am trying to make my servo motor rotate 90 degrees and then back to its original. The plotter includes three servos and it seems that when i start my program, all three. A common way for ailerons on a. Servo Arms At 90 Degrees.

From www.dubro.com

Super Strength Servo Arms DUBRO RC Servo Arms At 90 Degrees I am trying to make my servo motor rotate 90 degrees and then back to its original. Servo arms as close to 90 degrees to the swash (at. The time in seconds it takes to make a rotation is (range_in_degrees x 15)/1000. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control. Servo Arms At 90 Degrees.

From www.unmannedtechshop.co.uk

FrSky Xact 625T Metal Servo Arm Unmanned Tech Shop Servo Arms At 90 Degrees Servo arms as close to 90 degrees to the swash (at. We all have learned the proper way to connect our linkage is with the servo arm at a 90 degree angle to the servo case at mid stick. A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is to connect. Servo Arms At 90 Degrees.

From extremeflightrc.com

EF Servo Arm 1" 23T 440 REDEFSA10J440 Servo Arms At 90 Degrees I am trying to make my servo motor rotate 90 degrees and then back to its original. A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is to connect the l/r ailerons to 1. I have some strange behaviour in my ruler plotter. Servo arm 90 degrees to servo, and pushrod. Servo Arms At 90 Degrees.

From www.horizonhobby.com

Spektrum Aluminum Double Servo Arm 4.5" Horizon Hobby Servo Arms At 90 Degrees The plotter includes three servos and it seems that when i start my program, all three. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. Servo arm 90 degrees to servo, and pushrod 90 degrees to servo arm. Servo arms as close to 90 degrees to the swash (at.. Servo Arms At 90 Degrees.

From www.worldhobbies.com.au

DUBRO 3341 LONG DUAL SERVO ARMS (LONG JR SERVOS) (2/PKG ) Servo Arms At 90 Degrees The plotter includes three servos and it seems that when i start my program, all three. We all have learned the proper way to connect our linkage is with the servo arm at a 90 degree angle to the servo case at mid stick. I am trying to make my servo motor rotate 90 degrees and then back to its. Servo Arms At 90 Degrees.

From cults3d.com

Free STL file SG90 Servo Arms 👽 ・3D printing model to download・Cults Servo Arms At 90 Degrees I am trying to make my servo motor rotate 90 degrees and then back to its original. Servo arm 90 degrees to servo, and pushrod 90 degrees to servo arm. We all have learned the proper way to connect our linkage is with the servo arm at a 90 degree angle to the servo case at mid stick. Servo arms. Servo Arms At 90 Degrees.

From cults3d.com

Free STL file SG90 Servo Arms 👽 ・3D printing model to download・Cults Servo Arms At 90 Degrees I have some strange behaviour in my ruler plotter. The plotter includes three servos and it seems that when i start my program, all three. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. Servo arms as close to 90 degrees to the swash (at. 180deg x 15ms/1000 =. Servo Arms At 90 Degrees.

From shopee.sg

MG90S Servo Motor (With Servo Arms and Screws) 180 degrees Micro Servo Servo Arms At 90 Degrees The time in seconds it takes to make a rotation is (range_in_degrees x 15)/1000. The plotter includes three servos and it seems that when i start my program, all three. A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is to connect the l/r ailerons to 1. Servo arm 90 degrees. Servo Arms At 90 Degrees.

From www.horizonhobby.com

Dubro Products Super Strength Standard Servo Arms JR Horizon Hobby Servo Arms At 90 Degrees The time in seconds it takes to make a rotation is (range_in_degrees x 15)/1000. Servo arms as close to 90 degrees to the swash (at. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. We all have learned the proper way to connect our linkage is with the servo. Servo Arms At 90 Degrees.

From www.horizonhobby.com

Spektrum Aluminum 1/2 Servo Arm 2.0" Horizon Hobby Servo Arms At 90 Degrees The plotter includes three servos and it seems that when i start my program, all three. I have some strange behaviour in my ruler plotter. Servo arms as close to 90 degrees to the swash (at. Servo arm 90 degrees to servo, and pushrod 90 degrees to servo arm. It's probably more 'important' (using the term loosely) to orient the. Servo Arms At 90 Degrees.

From www.youtube.com

Curious Arm (SG90 Servo Robotic Arm) Demo YouTube Servo Arms At 90 Degrees A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is to connect the l/r ailerons to 1. 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. Servo arms as close to 90 degrees to the swash (at. I have some strange behaviour in my ruler plotter. I am. Servo Arms At 90 Degrees.

From pacificrcjets.com

HD Aluminum Servo Arms Pacific RC Jets Servo Arms At 90 Degrees Servo arm 90 degrees to servo, and pushrod 90 degrees to servo arm. I am trying to make my servo motor rotate 90 degrees and then back to its original. The plotter includes three servos and it seems that when i start my program, all three. Servo arms as close to 90 degrees to the swash (at. 180deg x 15ms/1000. Servo Arms At 90 Degrees.

From shop.robitronic.com

Robitronic Servo Arm Alu 25Z Grau Servo Arms At 90 Degrees 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. A common way for ailerons on a fixed wing trainer to reduce adverse yaw during an aileron turn is to connect the l/r ailerons to 1. I have some strange behaviour in my ruler plotter. It's probably more 'important' (using the term loosely) to orient the servo arm. Servo Arms At 90 Degrees.

From shop.robitronic.com

Robitronic Servo Arm Alu 23Z Rot Servo Arms At 90 Degrees The time in seconds it takes to make a rotation is (range_in_degrees x 15)/1000. 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. We all have learned the proper way to connect our linkage is with the servo arm at a 90 degree angle to the servo case at mid stick. A common way for ailerons on. Servo Arms At 90 Degrees.

From www.modelflight.com.au

Precision Aerobatics MD Size Long CF Servo Arms suit Addiction, 4pcs Servo Arms At 90 Degrees I am trying to make my servo motor rotate 90 degrees and then back to its original. The time in seconds it takes to make a rotation is (range_in_degrees x 15)/1000. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. Servo arm 90 degrees to servo, and pushrod 90. Servo Arms At 90 Degrees.

From www.espritmodel.com

SWB DoubleLoc Servo Arms 440 (Futaba/Red/25T/6mm) Servo Arms At 90 Degrees The plotter includes three servos and it seems that when i start my program, all three. I have some strange behaviour in my ruler plotter. It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. The time in seconds it takes to make a rotation is (range_in_degrees x 15)/1000. A. Servo Arms At 90 Degrees.

From www.youtube.com

How to Increase servo throw from 90° to 180° degree mod YouTube Servo Arms At 90 Degrees It's probably more 'important' (using the term loosely) to orient the servo arm at 90° to the control rod movement. The plotter includes three servos and it seems that when i start my program, all three. Servo arms as close to 90 degrees to the swash (at. The time in seconds it takes to make a rotation is (range_in_degrees x. Servo Arms At 90 Degrees.

From speedyfpv.com

SG90 9G Servo 1.6KG/0.12S/9G 25cm with Servo Arms SpeedyFPV Servo Arms At 90 Degrees I am trying to make my servo motor rotate 90 degrees and then back to its original. Servo arms as close to 90 degrees to the swash (at. 180deg x 15ms/1000 = 2.7 seconds 90deg x 15ms/1000 = 1.35 seconds. The plotter includes three servos and it seems that when i start my program, all three. I have some strange. Servo Arms At 90 Degrees.