When To Hone Vs Bore . Achieve optimal performance with precision. As lake speed points out, what’s. Most general application blocks use. I'd recommend that you bore, but i'm not sure that block can be bored. Let’s start out by clarifying that there is not a hard and fast rule here. Sometimes, even, those that say. But by paying attention to how the. If diamond stones are used, bore or rough hone to within.005˝ of final size. Learn the importance of proper bore geometry and surface finish for engine cylinders. Most honing is done with a hand drill, so it is impossible to hold a hone perfectly true, especially while stroking aggressively. The honed cylinder bore crosshatch angle determines ring rotation speed and its ability to promote proper oil migration up and down the cylinder wall. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. Then hone the cylinder to final dimensions with #325 to. “this ensures you get to base metal after boring operation.”. When to hone a cylinder.

from motormission.com

“we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. “this ensures you get to base metal after boring operation.”. Achieve optimal performance with precision. Let’s start out by clarifying that there is not a hard and fast rule here. When to hone a cylinder. Most honing is done with a hand drill, so it is impossible to hold a hone perfectly true, especially while stroking aggressively. As lake speed points out, what’s. Most general application blocks use. Sometimes, even, those that say. In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations.

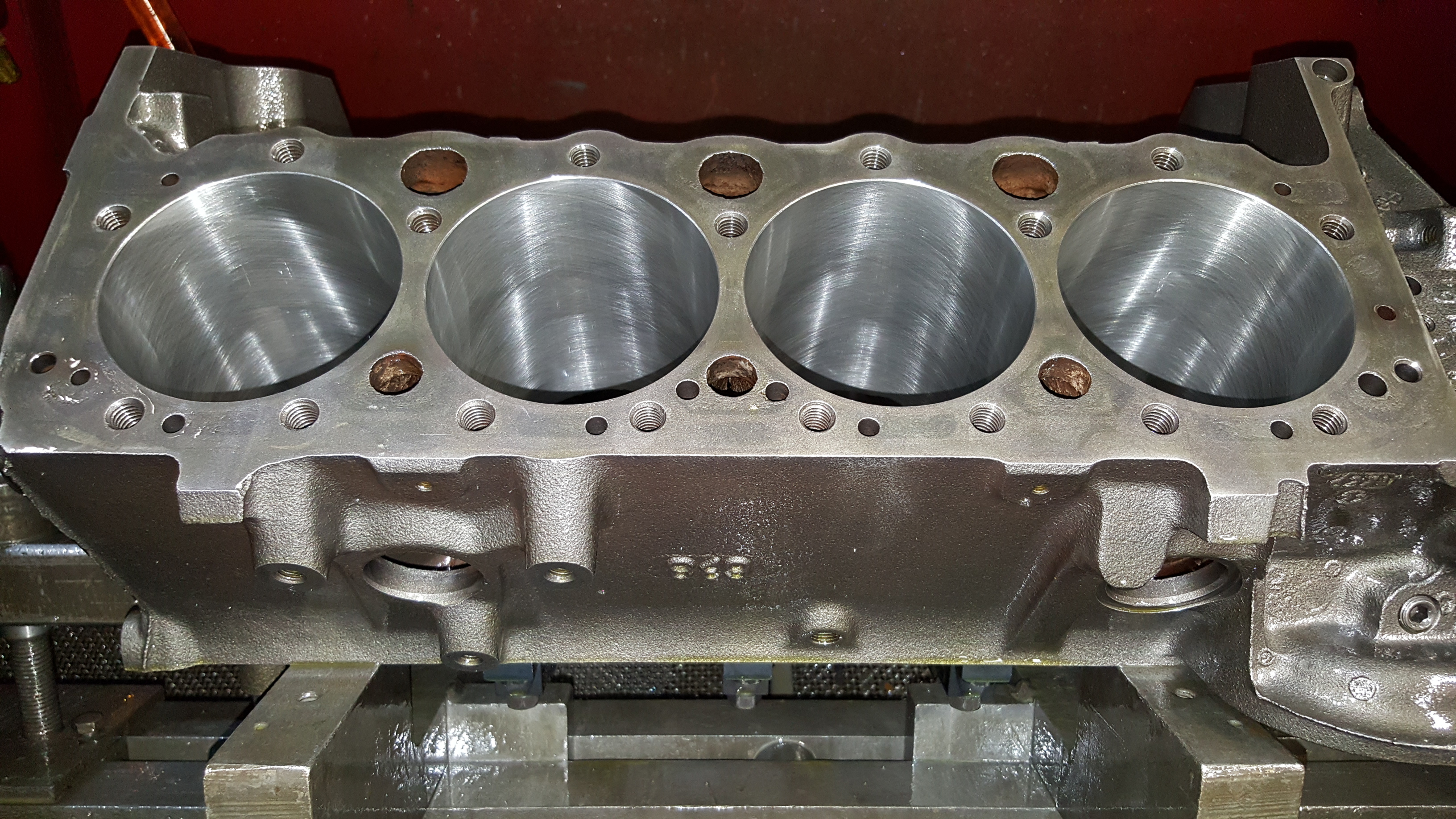

Blower Motor Engine Block Cylinder Bore & Hone & Housing Bore Machining

When To Hone Vs Bore Learn the importance of proper bore geometry and surface finish for engine cylinders. If diamond stones are used, bore or rough hone to within.005˝ of final size. I'd recommend that you bore, but i'm not sure that block can be bored. “this ensures you get to base metal after boring operation.”. Sometimes, even, those that say. The honed cylinder bore crosshatch angle determines ring rotation speed and its ability to promote proper oil migration up and down the cylinder wall. When to hone a cylinder. Learn the importance of proper bore geometry and surface finish for engine cylinders. Achieve optimal performance with precision. As lake speed points out, what’s. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. But by paying attention to how the. Most general application blocks use. Then hone the cylinder to final dimensions with #325 to. Most honing is done with a hand drill, so it is impossible to hold a hone perfectly true, especially while stroking aggressively. Let’s start out by clarifying that there is not a hard and fast rule here.

From www.grainger.com

FLEXHONE, For 11/4 in Bore, 3 in Hone Lg, Flexible Cylinder Hone When To Hone Vs Bore Then hone the cylinder to final dimensions with #325 to. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. If diamond stones are used, bore or rough hone to. When To Hone Vs Bore.

From www.enginebuildermag.com

Boring & Honing in the Digital Age Engine Builder Magazine When To Hone Vs Bore “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. But by paying attention to how the. Most general application blocks use. Learn the importance of proper bore geometry and surface finish for engine cylinders. Sometimes, even, those that say. When to hone a cylinder. In boring operations, it is dependent on what oversize. When To Hone Vs Bore.

From www.sansmachining.com

Drilling VS Reaming VS Boring VS Honing, What Is The Difference? SANS When To Hone Vs Bore Then hone the cylinder to final dimensions with #325 to. Let’s start out by clarifying that there is not a hard and fast rule here. As lake speed points out, what’s. Most general application blocks use. In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations.. When To Hone Vs Bore.

From www.grainger.com

FLEXHONE, For 7 in Bore, 7 in Hone Lg, Flexible Cylinder Hone 59XZ65 When To Hone Vs Bore In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. If diamond stones are used, bore or rough hone to within.005˝ of final size. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. “this ensures you get to base. When To Hone Vs Bore.

From www.hondatwins.net

Honing vs Boring Honda Twins When To Hone Vs Bore “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. When to hone a cylinder. Most honing is done with a hand drill, so it is impossible to hold a hone perfectly true, especially while stroking aggressively. Sometimes, even, those that say. Achieve optimal performance with precision. Then hone the cylinder to final dimensions. When To Hone Vs Bore.

From www.grainger.com

FLEXHONE, For 3 in Bore, 3 in Hone Lg, Flexible Cylinder Hone 2ZZC1 When To Hone Vs Bore The honed cylinder bore crosshatch angle determines ring rotation speed and its ability to promote proper oil migration up and down the cylinder wall. If diamond stones are used, bore or rough hone to within.005˝ of final size. Let’s start out by clarifying that there is not a hard and fast rule here. As lake speed points out, what’s. “this. When To Hone Vs Bore.

From www.grainger.com

FLEXHONE TOOL Flexible Cylinder Hone 3 1/2 in Bore Dia., Silicon When To Hone Vs Bore If diamond stones are used, bore or rough hone to within.005˝ of final size. But by paying attention to how the. I'd recommend that you bore, but i'm not sure that block can be bored. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. Achieve optimal performance with precision. Most honing is done. When To Hone Vs Bore.

From www.youtube.com

DRILLING,BORING & REAMING(DIFFERENCE) YouTube When To Hone Vs Bore Learn the importance of proper bore geometry and surface finish for engine cylinders. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. Let’s start out by clarifying that there is not a hard and fast rule here. Achieve optimal performance with precision. The honed cylinder bore crosshatch angle determines ring rotation speed and. When To Hone Vs Bore.

From www.researchgate.net

Perfecting the bore geometry via honing. Download Scientific Diagram When To Hone Vs Bore In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. When to hone a cylinder. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. The honed cylinder bore crosshatch angle determines ring rotation speed and its ability to promote. When To Hone Vs Bore.

From www.engis.com

ENGIS MULTISTROKE HONING AND SINGLE PASS BORE FINISHING When To Hone Vs Bore But by paying attention to how the. In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. When to hone a cylinder. Then hone the cylinder to final dimensions with #325 to. The honed cylinder bore crosshatch angle determines ring rotation speed and its ability to. When To Hone Vs Bore.

From www.hondatwins.net

Honing vs Boring Honda Twins When To Hone Vs Bore “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. But by paying attention to how the. In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. As lake speed points out, what’s. Most honing is done with a hand. When To Hone Vs Bore.

From www.grainger.com

FLEXHONE, For 27/8 in Bore, 3 in Hone Lg, Flexible Cylinder Hone When To Hone Vs Bore Let’s start out by clarifying that there is not a hard and fast rule here. I'd recommend that you bore, but i'm not sure that block can be bored. Sometimes, even, those that say. Then hone the cylinder to final dimensions with #325 to. Most general application blocks use. As lake speed points out, what’s. When to hone a cylinder.. When To Hone Vs Bore.

From www.precision-surface.de

Stroke Honing Impact on Bore Shapes When To Hone Vs Bore Let’s start out by clarifying that there is not a hard and fast rule here. But by paying attention to how the. Most honing is done with a hand drill, so it is impossible to hold a hone perfectly true, especially while stroking aggressively. Achieve optimal performance with precision. “we always suggest leaving a minimum of.003˝ on the diameter to. When To Hone Vs Bore.

From www.youtube.com

The Difference Between Boring & Honing m54rebuild 17 YouTube When To Hone Vs Bore Most honing is done with a hand drill, so it is impossible to hold a hone perfectly true, especially while stroking aggressively. Achieve optimal performance with precision. Let’s start out by clarifying that there is not a hard and fast rule here. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. I'd recommend. When To Hone Vs Bore.

From www.grainger.com

FLEXHONE, For 1 in Bore, 3 in Hone Lg, Flexible Cylinder Hone 2ZYU1 When To Hone Vs Bore Most honing is done with a hand drill, so it is impossible to hold a hone perfectly true, especially while stroking aggressively. Achieve optimal performance with precision. Most general application blocks use. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. The honed cylinder bore crosshatch angle determines ring rotation speed and its. When To Hone Vs Bore.

From www.grainger.com

FLEXHONE TOOL Flexible Cylinder Hone 1 7/8 in Bore Dia., Silicon When To Hone Vs Bore Achieve optimal performance with precision. “this ensures you get to base metal after boring operation.”. If diamond stones are used, bore or rough hone to within.005˝ of final size. In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. Let’s start out by clarifying that there. When To Hone Vs Bore.

From www.grainger.com

FLEXHONE TOOL Flexible Cylinder Hone 3 in Bore Dia., Silicon Carbide When To Hone Vs Bore As lake speed points out, what’s. Then hone the cylinder to final dimensions with #325 to. Let’s start out by clarifying that there is not a hard and fast rule here. Learn the importance of proper bore geometry and surface finish for engine cylinders. The honed cylinder bore crosshatch angle determines ring rotation speed and its ability to promote proper. When To Hone Vs Bore.

From www.youtube.com

How to Hone the bore to oversize pistons YouTube When To Hone Vs Bore Let’s start out by clarifying that there is not a hard and fast rule here. Then hone the cylinder to final dimensions with #325 to. When to hone a cylinder. As lake speed points out, what’s. Learn the importance of proper bore geometry and surface finish for engine cylinders. Achieve optimal performance with precision. The honed cylinder bore crosshatch angle. When To Hone Vs Bore.

From www.grainger.com

FLEXHONE, For 41/2 in Bore, 6 in Hone Lg, Flexible Cylinder Hone When To Hone Vs Bore Learn the importance of proper bore geometry and surface finish for engine cylinders. The honed cylinder bore crosshatch angle determines ring rotation speed and its ability to promote proper oil migration up and down the cylinder wall. Then hone the cylinder to final dimensions with #325 to. Most honing is done with a hand drill, so it is impossible to. When To Hone Vs Bore.

From exosfmcaa.blob.core.windows.net

Cylinder Hone Vs Bore at Matthew Hiles blog When To Hone Vs Bore The honed cylinder bore crosshatch angle determines ring rotation speed and its ability to promote proper oil migration up and down the cylinder wall. As lake speed points out, what’s. Then hone the cylinder to final dimensions with #325 to. Most honing is done with a hand drill, so it is impossible to hold a hone perfectly true, especially while. When To Hone Vs Bore.

From motormission.com

Blower Motor Engine Block Cylinder Bore & Hone & Housing Bore Machining When To Hone Vs Bore Sometimes, even, those that say. But by paying attention to how the. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. Most honing is done with a hand drill, so it is impossible to hold a hone perfectly true, especially while stroking aggressively. If diamond stones are used, bore or rough hone to. When To Hone Vs Bore.

From exosfmcaa.blob.core.windows.net

Cylinder Hone Vs Bore at Matthew Hiles blog When To Hone Vs Bore I'd recommend that you bore, but i'm not sure that block can be bored. In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. But by paying attention to how the. Sometimes, even, those that say. Learn the importance of proper bore geometry and surface finish. When To Hone Vs Bore.

From www.youtube.com

MAN 4stroke smallbore medium speed honing procedure of cylinder liner When To Hone Vs Bore But by paying attention to how the. The honed cylinder bore crosshatch angle determines ring rotation speed and its ability to promote proper oil migration up and down the cylinder wall. Achieve optimal performance with precision. In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations.. When To Hone Vs Bore.

From www.buellxb.com

Cylinder Bore Surface Finish When To Hone Vs Bore If diamond stones are used, bore or rough hone to within.005˝ of final size. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. As lake speed points out, what’s. Sometimes, even, those that say. Achieve optimal performance with precision. But by paying attention to how the. In boring operations, it is dependent on. When To Hone Vs Bore.

From www.youtube.com

honing explained with diagram What is honing ? honing finishing When To Hone Vs Bore Learn the importance of proper bore geometry and surface finish for engine cylinders. Sometimes, even, those that say. Let’s start out by clarifying that there is not a hard and fast rule here. The honed cylinder bore crosshatch angle determines ring rotation speed and its ability to promote proper oil migration up and down the cylinder wall. If diamond stones. When To Hone Vs Bore.

From motormission.com

390 Cadillac Bore & Hone and 365 Cadillac Valve Job & Surface Motor When To Hone Vs Bore Most honing is done with a hand drill, so it is impossible to hold a hone perfectly true, especially while stroking aggressively. In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. Learn the importance of proper bore geometry and surface finish for engine cylinders. Most. When To Hone Vs Bore.

From exosfmcaa.blob.core.windows.net

Cylinder Hone Vs Bore at Matthew Hiles blog When To Hone Vs Bore In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. “this ensures you get to base metal after boring operation.”. Sometimes, even, those that say. But by paying attention to how the. Most honing is done with a hand drill, so it is impossible to hold. When To Hone Vs Bore.

From www.grainger.com

FLEXHONE, For 4 in Bore, 6 in Hone Lg, Flexible Cylinder Hone 59XW64 When To Hone Vs Bore When to hone a cylinder. I'd recommend that you bore, but i'm not sure that block can be bored. Achieve optimal performance with precision. Most general application blocks use. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. But by paying attention to how the. Then hone the cylinder to final dimensions with. When To Hone Vs Bore.

From www.grainger.com

FLEXHONE, For 21/2 in Bore, 3 in Hone Lg, Flexible Cylinder Hone When To Hone Vs Bore In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. As lake speed points out, what’s. Sometimes, even, those that say. Most honing is done with a hand drill, so it is impossible to hold a hone perfectly true, especially while stroking aggressively. I'd recommend that. When To Hone Vs Bore.

From www.grainger.com

FLEXHONE, For 15/8 in Bore, 3 in Hone Lg, Flexible Cylinder Hone When To Hone Vs Bore Let’s start out by clarifying that there is not a hard and fast rule here. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. “this ensures you get to. When To Hone Vs Bore.

From www.precision-surface.com

What is the honing process and define what each operation and machine When To Hone Vs Bore The honed cylinder bore crosshatch angle determines ring rotation speed and its ability to promote proper oil migration up and down the cylinder wall. Then hone the cylinder to final dimensions with #325 to. “we always suggest leaving a minimum of.003˝ on the diameter to hone,” notes rottler’s ed kiebler. I'd recommend that you bore, but i'm not sure that. When To Hone Vs Bore.

From www.grainger.com

FLEXHONE, For 1 in Bore, 3 in Hone Lg, Flexible Cylinder Hone 59WK72 When To Hone Vs Bore In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. But by paying attention to how the. “this ensures you get to base metal after boring operation.”. Most honing is done with a hand drill, so it is impossible to hold a hone perfectly true, especially. When To Hone Vs Bore.

From www.slideserve.com

PPT Chapter 13 Reconditioning engine blocks PowerPoint Presentation When To Hone Vs Bore As lake speed points out, what’s. Sometimes, even, those that say. Achieve optimal performance with precision. Learn the importance of proper bore geometry and surface finish for engine cylinders. I'd recommend that you bore, but i'm not sure that block can be bored. “this ensures you get to base metal after boring operation.”. The honed cylinder bore crosshatch angle determines. When To Hone Vs Bore.

From blog.hone-all.co.uk

How Much Should Deep Hole Drilling, Boring And Honing Cost? When To Hone Vs Bore Then hone the cylinder to final dimensions with #325 to. Let’s start out by clarifying that there is not a hard and fast rule here. If diamond stones are used, bore or rough hone to within.005˝ of final size. When to hone a cylinder. Sometimes, even, those that say. Achieve optimal performance with precision. As lake speed points out, what’s.. When To Hone Vs Bore.

From exosfmcaa.blob.core.windows.net

Cylinder Hone Vs Bore at Matthew Hiles blog When To Hone Vs Bore But by paying attention to how the. Learn the importance of proper bore geometry and surface finish for engine cylinders. In boring operations, it is dependent on what oversize you want to go, but typically, engine builders take anywhere from.020˝ to.100˝ in boring operations. I'd recommend that you bore, but i'm not sure that block can be bored. If diamond. When To Hone Vs Bore.