Small End Mill Feeds And Speeds . The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. For long and extra carbide. All posted parameters are suggested. During a machining operation, chips are created by the compression and shearing of. Axial depth of cut = 1.5 x tool dia. For radial depth of cut use 0.25 x tool dia. Milling speed and feed calculator. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. In milling, burring increases as feed increases, and decreases as speed increases.

from mavink.com

For radial depth of cut use 0.25 x tool dia. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. In milling, burring increases as feed increases, and decreases as speed increases. During a machining operation, chips are created by the compression and shearing of. For long and extra carbide. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. All posted parameters are suggested. Axial depth of cut = 1.5 x tool dia. Milling speed and feed calculator.

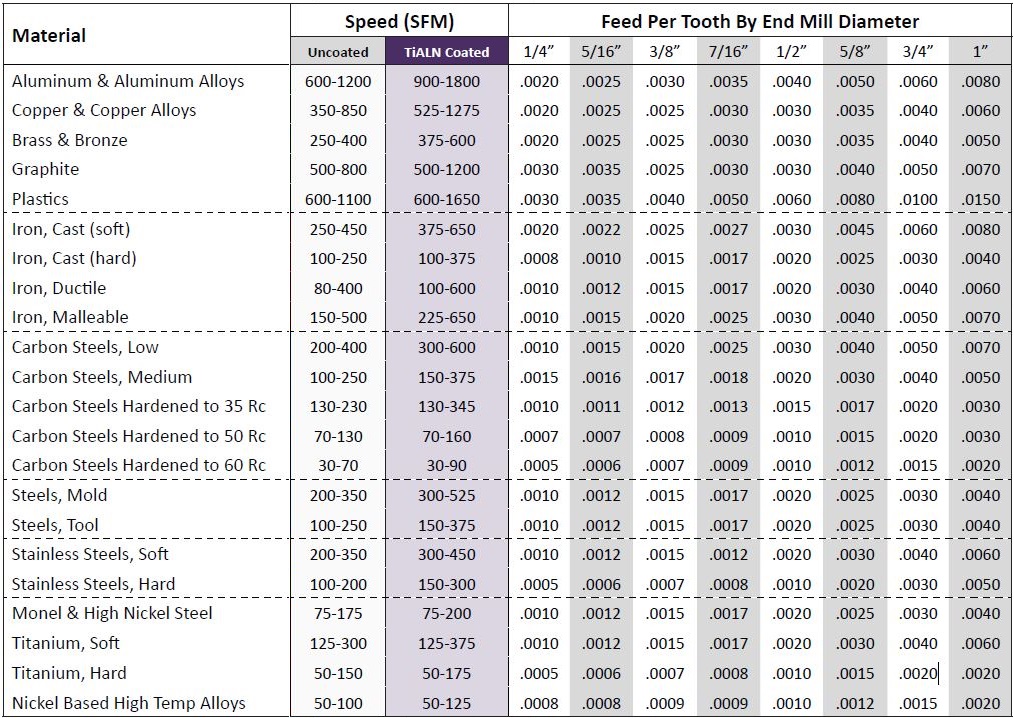

Carbide End Mill Speed And Feed Chart

Small End Mill Feeds And Speeds The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. All posted parameters are suggested. For radial depth of cut use 0.25 x tool dia. For long and extra carbide. During a machining operation, chips are created by the compression and shearing of. Axial depth of cut = 1.5 x tool dia. In milling, burring increases as feed increases, and decreases as speed increases. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. Milling speed and feed calculator.

From www.scribd.com

Milling Speeds and Feeds PDF PDF Cast Iron Alloy Small End Mill Feeds And Speeds The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. For long and extra carbide. Axial depth of cut = 1.5 x tool dia. All posted parameters are suggested. Milling speed and feed calculator. During a machining operation, chips are created by the compression and shearing of.. Small End Mill Feeds And Speeds.

From ar.inspiredpencil.com

End Mill Speed Chart Small End Mill Feeds And Speeds For long and extra carbide. For radial depth of cut use 0.25 x tool dia. In milling, burring increases as feed increases, and decreases as speed increases. All posted parameters are suggested. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. The speeds and feeds. Small End Mill Feeds And Speeds.

From blog.tormach.com

Getting Started With Speeds & Feeds Small End Mill Feeds And Speeds During a machining operation, chips are created by the compression and shearing of. For long and extra carbide. In milling, burring increases as feed increases, and decreases as speed increases. Milling speed and feed calculator. Axial depth of cut = 1.5 x tool dia. For radial depth of cut use 0.25 x tool dia. All posted parameters are suggested. Determine. Small End Mill Feeds And Speeds.

From samhotool.com

Mastering Carbide End Mill Feeds and Speeds A Comprehensive Guide SAMHO Small End Mill Feeds And Speeds For radial depth of cut use 0.25 x tool dia. Axial depth of cut = 1.5 x tool dia. Milling speed and feed calculator. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. During a machining operation, chips are created by the compression and shearing of.. Small End Mill Feeds And Speeds.

From mungfali.com

End Mill Speed And Feed Chart Small End Mill Feeds And Speeds Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. During a machining operation, chips are created by the compression and shearing of. For long and extra carbide. All posted parameters are suggested. In milling, burring increases as feed increases, and decreases as speed increases. Milling. Small End Mill Feeds And Speeds.

From www.qualitytechtool.com

Premium Class End Mills Metric Quality Tech Tool Small End Mill Feeds And Speeds Axial depth of cut = 1.5 x tool dia. Milling speed and feed calculator. For long and extra carbide. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. In milling, burring increases as feed increases, and decreases as speed increases. All posted parameters are suggested. Determine. Small End Mill Feeds And Speeds.

From ar.inspiredpencil.com

End Mill Speed Chart Small End Mill Feeds And Speeds Axial depth of cut = 1.5 x tool dia. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. During a machining operation, chips are created by the compression and shearing of. In milling, burring increases as feed increases, and decreases as speed increases. Milling speed. Small End Mill Feeds And Speeds.

From mavink.com

Carbide End Mill Speed And Feed Chart Small End Mill Feeds And Speeds All posted parameters are suggested. For radial depth of cut use 0.25 x tool dia. In milling, burring increases as feed increases, and decreases as speed increases. Axial depth of cut = 1.5 x tool dia. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Milling. Small End Mill Feeds And Speeds.

From ar.inspiredpencil.com

End Mill Speed Chart Small End Mill Feeds And Speeds For long and extra carbide. During a machining operation, chips are created by the compression and shearing of. All posted parameters are suggested. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. In milling, burring increases as feed increases, and decreases as speed increases. For. Small End Mill Feeds And Speeds.

From studylib.net

millspeedsandfeedsformulasmetric Small End Mill Feeds And Speeds All posted parameters are suggested. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. Axial depth of cut = 1.5 x tool dia. For long and extra carbide. During a machining operation, chips are created by the compression and shearing of. The speeds and feeds. Small End Mill Feeds And Speeds.

From simmonslosonfere.blogspot.com

Ball Nose End Mill Speeds and Feeds Simmons Losonfere Small End Mill Feeds And Speeds Milling speed and feed calculator. For radial depth of cut use 0.25 x tool dia. During a machining operation, chips are created by the compression and shearing of. Axial depth of cut = 1.5 x tool dia. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut. Small End Mill Feeds And Speeds.

From mungfali.com

Milling Speed Chart Small End Mill Feeds And Speeds Axial depth of cut = 1.5 x tool dia. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. Milling speed and feed calculator. For radial depth of cut use 0.25 x tool dia. The speeds and feeds calculator may be employed for calculations of estimated. Small End Mill Feeds And Speeds.

From www.scribd.com

Speed and Feed Carbide End Mills and Drills Small End Mill Feeds And Speeds For radial depth of cut use 0.25 x tool dia. During a machining operation, chips are created by the compression and shearing of. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. All posted parameters are suggested. In milling, burring increases as feed increases, and decreases. Small End Mill Feeds And Speeds.

From pct-imc.com

Speeds and Feeds Small End Mill Feeds And Speeds In milling, burring increases as feed increases, and decreases as speed increases. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Axial. Small End Mill Feeds And Speeds.

From mungfali.com

Mill Cutting Speed Chart Small End Mill Feeds And Speeds During a machining operation, chips are created by the compression and shearing of. Milling speed and feed calculator. In milling, burring increases as feed increases, and decreases as speed increases. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. All posted parameters are suggested. For. Small End Mill Feeds And Speeds.

From samhotool.com

Mastering Carbide End Mill Feeds and Speeds A Comprehensive Guide SAMHO Small End Mill Feeds And Speeds Axial depth of cut = 1.5 x tool dia. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. For radial depth of cut use 0.25 x tool dia. All posted parameters are suggested. During a machining operation, chips are created by the compression and shearing of.. Small End Mill Feeds And Speeds.

From ar.inspiredpencil.com

End Mill Speed Chart Small End Mill Feeds And Speeds Milling speed and feed calculator. In milling, burring increases as feed increases, and decreases as speed increases. All posted parameters are suggested. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well. Small End Mill Feeds And Speeds.

From lexingtoncutter.com

Feeds & Speeds Charts Lexington Cutter Small End Mill Feeds And Speeds During a machining operation, chips are created by the compression and shearing of. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. All posted parameters are suggested. For long and extra carbide. Axial depth of cut = 1.5 x tool dia. For radial depth of. Small End Mill Feeds And Speeds.

From www.2linc.com

Speeds And Feeds End Mills, Engraving, Spring Loaded Tools 2L Inc. Small End Mill Feeds And Speeds Milling speed and feed calculator. All posted parameters are suggested. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. For radial depth. Small End Mill Feeds And Speeds.

From www.zyjcarbide.com

2 Flutes Square Tungsten Carbide End Mill Speeds Feeds Small End Mill Feeds And Speeds For long and extra carbide. Milling speed and feed calculator. For radial depth of cut use 0.25 x tool dia. In milling, burring increases as feed increases, and decreases as speed increases. Axial depth of cut = 1.5 x tool dia. During a machining operation, chips are created by the compression and shearing of. Determine the spindle speed (rpm) and. Small End Mill Feeds And Speeds.

From fmcarbide.com

Carbide End Mill Feeds and Speeds Explained FM Carbide Small End Mill Feeds And Speeds Axial depth of cut = 1.5 x tool dia. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Milling speed and feed calculator. For long and extra carbide. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut. Small End Mill Feeds And Speeds.

From ar.inspiredpencil.com

End Mill Speed Chart Small End Mill Feeds And Speeds Axial depth of cut = 1.5 x tool dia. For long and extra carbide. For radial depth of cut use 0.25 x tool dia. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. During a machining operation, chips are created by the compression and shearing of.. Small End Mill Feeds And Speeds.

From mecsoft.com

The Milling Feeds & Speeds Calculator MecSoft Corporation Small End Mill Feeds And Speeds In milling, burring increases as feed increases, and decreases as speed increases. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. For. Small End Mill Feeds And Speeds.

From dat.perueduca.edu.pe

End Mill Cutting Speed Chart Printable Templates Free Small End Mill Feeds And Speeds Axial depth of cut = 1.5 x tool dia. During a machining operation, chips are created by the compression and shearing of. For long and extra carbide. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. In milling, burring increases as feed increases, and decreases as. Small End Mill Feeds And Speeds.

From www.qualitytechtool.com

General Purpose End Mills Metric Quality Tech Tool Small End Mill Feeds And Speeds All posted parameters are suggested. In milling, burring increases as feed increases, and decreases as speed increases. For long and extra carbide. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. Milling speed and feed calculator. For radial depth of cut use 0.25 x tool. Small End Mill Feeds And Speeds.

From www.2linc.com

Speeds And Feeds End Mills, Engraving, Spring Loaded Tools 2L Inc. Small End Mill Feeds And Speeds Milling speed and feed calculator. For radial depth of cut use 0.25 x tool dia. Axial depth of cut = 1.5 x tool dia. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. During a machining operation, chips are created by the compression and shearing. Small End Mill Feeds And Speeds.

From www.edwoodcrafting.com

CNC Speed/Feed Calculator EdwoodCrafting Small End Mill Feeds And Speeds For radial depth of cut use 0.25 x tool dia. In milling, burring increases as feed increases, and decreases as speed increases. During a machining operation, chips are created by the compression and shearing of. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. The. Small End Mill Feeds And Speeds.

From huanatools.com

Four Different type End Mill Feeds and Speeds Huana Tools Small End Mill Feeds And Speeds All posted parameters are suggested. In milling, burring increases as feed increases, and decreases as speed increases. For radial depth of cut use 0.25 x tool dia. For long and extra carbide. Axial depth of cut = 1.5 x tool dia. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time. Small End Mill Feeds And Speeds.

From www.scribd.com

Carbide End Mill Feeds and Speeds TuffCut XR 177 Metric Cast Iron Steel Small End Mill Feeds And Speeds Milling speed and feed calculator. For radial depth of cut use 0.25 x tool dia. During a machining operation, chips are created by the compression and shearing of. All posted parameters are suggested. In milling, burring increases as feed increases, and decreases as speed increases. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well. Small End Mill Feeds And Speeds.

From allindustrial.com

Speed and feed charts for Colton Cutting Tools Small End Mill Feeds And Speeds During a machining operation, chips are created by the compression and shearing of. Milling speed and feed calculator. For radial depth of cut use 0.25 x tool dia. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. In milling, burring increases as feed increases, and decreases. Small End Mill Feeds And Speeds.

From ar.inspiredpencil.com

End Mill Speed Chart Small End Mill Feeds And Speeds Axial depth of cut = 1.5 x tool dia. For radial depth of cut use 0.25 x tool dia. All posted parameters are suggested. Milling speed and feed calculator. In milling, burring increases as feed increases, and decreases as speed increases. For long and extra carbide. The speeds and feeds calculator may be employed for calculations of estimated speeds and. Small End Mill Feeds And Speeds.

From huanatools.com

Four Different type End Mill Feeds and Speeds Huana Tools Small End Mill Feeds And Speeds The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. For radial depth of cut use 0.25 x tool dia. During a machining operation, chips are created by the compression and shearing of. Milling speed and feed calculator. All posted parameters are suggested. Determine the spindle speed. Small End Mill Feeds And Speeds.

From mellowpine.com

Speeds and Feeds Beginner Guide with Table MellowPine Small End Mill Feeds And Speeds In milling, burring increases as feed increases, and decreases as speed increases. All posted parameters are suggested. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Axial depth of cut = 1.5 x tool dia. Determine the spindle speed (rpm) and feed rate (ipm) for a. Small End Mill Feeds And Speeds.

From charolettebutterfield.blogspot.com

indexable end mill speeds and feeds Charolette Butterfield Small End Mill Feeds And Speeds In milling, burring increases as feed increases, and decreases as speed increases. All posted parameters are suggested. During a machining operation, chips are created by the compression and shearing of. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. Axial depth of cut = 1.5. Small End Mill Feeds And Speeds.

From es.scribd.com

Feeds And Speeds For General Purpose Altin Coated Carbide Endmills Small End Mill Feeds And Speeds For radial depth of cut use 0.25 x tool dia. During a machining operation, chips are created by the compression and shearing of. In milling, burring increases as feed increases, and decreases as speed increases. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut length. Axial. Small End Mill Feeds And Speeds.