Vibration Sensors Monitoring . Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. It also includes a software application for data analysis, trend visualization, and fault detection. learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis.

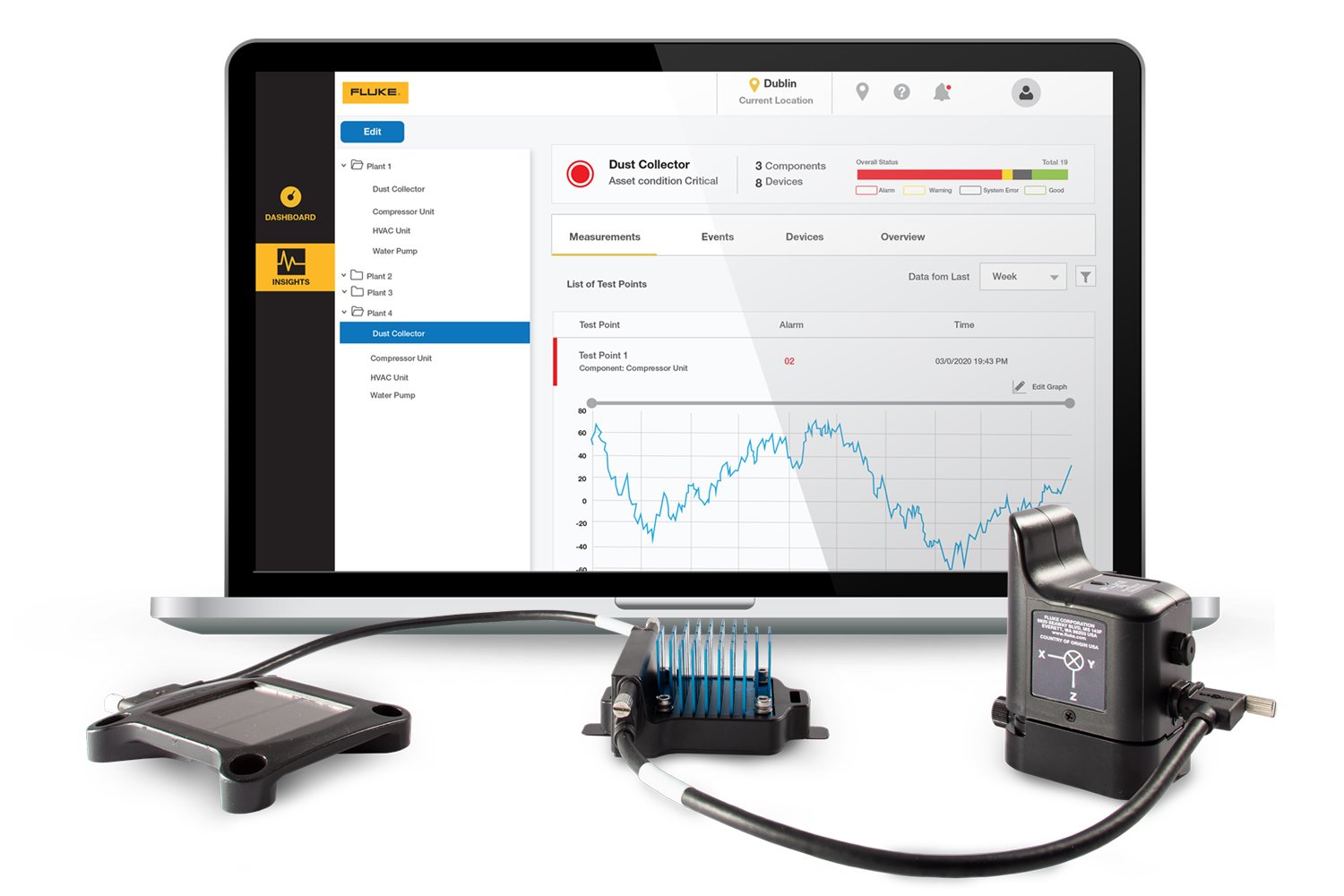

from www.fluke.com

advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. It also includes a software application for data analysis, trend visualization, and fault detection. learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction.

Vibration Monitoring System Fluke 3562 Screening Vibration Sensor

Vibration Sensors Monitoring skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. It also includes a software application for data analysis, trend visualization, and fault detection. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis.

From www.emerson.com

Emerson’s New EasytoDeploy Vibration Sensor Simplifies Asset Vibration Sensors Monitoring skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. a vibration sensor, or vibration detector,. Vibration Sensors Monitoring.

From www.youtube.com

ARGUS Triaxial Wireless Vibration Sensor for Condition Monitoring Vibration Sensors Monitoring advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. a vibration sensor, or vibration detector, measures vibration. Vibration Sensors Monitoring.

From www.fluke.com

Top 5 Industrial Vibration Sensor Applications Fluke Vibration Sensors Monitoring learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. skf offers a range of vibration sensors for various. Vibration Sensors Monitoring.

From www.madincos.com

MVT100 2 Wire Type Integrated Vibration Sensor Transmitter Vibration Sensors Monitoring a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. It also includes a software application for data analysis, trend visualization, and fault detection. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the. Vibration Sensors Monitoring.

From www.environmentalsiteservices.com.au

Vibration Monitoring Equipment Environmental Site Services Vibration Sensors Monitoring It also includes a software application for data analysis, trend visualization, and fault detection. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. a vibration sensor, or vibration detector, measures vibration levels in machinery for. Vibration Sensors Monitoring.

From www.indiamart.com

Vs425 Vibration Monitoring System Vibration Sensor Accelerometer Vms Vibration Sensors Monitoring a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. It also includes a software application for data analysis, trend visualization, and fault detection. learn how to use vibration monitors, sensors, and software to assess and. Vibration Sensors Monitoring.

From blog.pruftechnik.com

Types of Vibration Sensors for Condition Monitoring Vibration sensors Vibration Sensors Monitoring advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. Maintenance teams use industrial vibration sensors for condition monitoring, giving. Vibration Sensors Monitoring.

From www.omega.ca

Vibration Sensors and Their Importance in Vibration Monitoring of Vibration Sensors Monitoring Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. It also includes a software application for data analysis, trend visualization, and fault detection. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. a vibration sensor, or vibration detector, measures vibration levels. Vibration Sensors Monitoring.

From www.automation24.biz

Vibration monitor ifm electronic VKV022 Automation24 Vibration Sensors Monitoring a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. It also includes a software application for data analysis, trend visualization, and fault detection. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. learn how to use vibration monitors, sensors, and software to assess and mitigate. Vibration Sensors Monitoring.

From mylargebox.com

All You Need To Know About Vibration Monitoring MyLargeBox Vibration Sensors Monitoring advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. learn how to use vibration monitors, sensors,. Vibration Sensors Monitoring.

From www.fluke.com

Vibration Monitoring System Fluke 3562 Screening Vibration Sensor Vibration Sensors Monitoring learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. Maintenance teams use industrial vibration sensors for condition monitoring,. Vibration Sensors Monitoring.

From rms-reliability.com

AMS Wireless Vibration Monitor Emerson Wireless Vibration Monitor Vibration Sensors Monitoring advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. Maintenance teams use industrial vibration sensors for condition monitoring, giving them. Vibration Sensors Monitoring.

From www.aggrowth.com

CMC mVM001 Vibration Monitoring System AGI Vibration Sensors Monitoring It also includes a software application for data analysis, trend visualization, and fault detection. learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. a vibration sensor, or vibration detector, measures. Vibration Sensors Monitoring.

From ncd.io

Monitoring Pumps Health Using Vibration Sensors NCD.io Vibration Sensors Monitoring learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. It also includes a software application for data analysis, trend visualization, and fault detection. Maintenance teams use industrial vibration sensors for condition monitoring, giving them. Vibration Sensors Monitoring.

From www.madincos.com

MVT100 2 Wire Type Integrated Vibration Sensor Transmitter Vibration Sensors Monitoring It also includes a software application for data analysis, trend visualization, and fault detection. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. a vibration sensor, or vibration detector, measures vibration levels in machinery for. Vibration Sensors Monitoring.

From www.advancedtech.com

Vibration Monitoring Sensors ATS Vibration Sensors Monitoring a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. It also includes a software application for data. Vibration Sensors Monitoring.

From www.yokogawa.com

Wireless Vibration Sensor Wireless Vibration Monitoring Yokogawa Vibration Sensors Monitoring Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. It also includes a software application for data analysis, trend visualization, and fault detection. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. skf offers a range of vibration sensors for various. Vibration Sensors Monitoring.

From rms-reliability.com

Vibration Monitoring Sensors, Accelerometers, Modules, Cables and Vibration Sensors Monitoring advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. a vibration sensor, or vibration. Vibration Sensors Monitoring.

From www.spectrumacoustic.com

Spectrum provides vital realtime vibration monitoring services to Vibration Sensors Monitoring advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. a vibration sensor, or vibration detector,. Vibration Sensors Monitoring.

From www.madincos.com

MVT100 2 Wire Type Integrated Vibration Sensor Transmitter Vibration Sensors Monitoring skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. It also includes a software application for data analysis, trend visualization, and fault detection. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. learn how to use vibration monitors, sensors, and software to assess and. Vibration Sensors Monitoring.

From www.fluke.com

Vibration Monitoring System Fluke 3562 Screening Vibration Sensor Vibration Sensors Monitoring It also includes a software application for data analysis, trend visualization, and fault detection. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. skf offers a range of vibration sensors for various industrial applications,. Vibration Sensors Monitoring.

From hardware.iox-connect.com

Accelerometers & Vibration Sensors ioXConnect Vibration Sensors Monitoring learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. It also includes a software application for data analysis, trend visualization, and fault detection. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. Maintenance teams use industrial vibration sensors for condition monitoring, giving them. Vibration Sensors Monitoring.

From www.colletplc.com

Bently Nevada 3500 Vibration Monitoring Vibration Sensors Monitoring advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. It also includes a software application for data. Vibration Sensors Monitoring.

From www.spectotechnology.com

Wireless Vibration Monitoring System, Noise & Vibration Measurement Vibration Sensors Monitoring skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. advanced vibration sensors and. Vibration Sensors Monitoring.

From okgo.net

Metrix Vibration Industrial Vibration Monitoring Systems, metrix Vibration Sensors Monitoring Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. learn how to use vibration monitors, sensors,. Vibration Sensors Monitoring.

From www.fluke.com

Vibration Monitoring System Fluke 3562 Screening Vibration Sensor Vibration Sensors Monitoring learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. Maintenance teams use industrial vibration sensors for condition monitoring, giving. Vibration Sensors Monitoring.

From www.spectotechnology.com

Wireless Vibration Monitoring System Noise & Vibration Monitoring Vibration Sensors Monitoring a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. It also includes a software application for data analysis, trend visualization, and fault detection. advanced vibration sensors and monitoring help by providing precise,. Vibration Sensors Monitoring.

From ritec-eg.com

RITEC Vibration Sensors Monitoring learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. It also includes a software application for data analysis, trend. Vibration Sensors Monitoring.

From ncd.io

HVAC Remote Monitoring Systems with Vibration Sensors Vibration Sensors Monitoring learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. It also includes a software application for data analysis, trend visualization, and fault detection. skf offers a range of vibration sensors for various industrial applications,. Vibration Sensors Monitoring.

From www.vrogue.co

What Are The Types And Uses Of Vibration Sensors vrogue.co Vibration Sensors Monitoring advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. It also includes a software application for. Vibration Sensors Monitoring.

From www.miniotec.com

Revolutionise Equipment Monitoring and Maintenance with IIoT Wireless Vibration Sensors Monitoring skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. Maintenance teams use industrial vibration sensors for condition monitoring,. Vibration Sensors Monitoring.

From www.directindustry.com

MEMS vibration sensor / / for machine monitoring / for process Vibration Sensors Monitoring skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. a vibration sensor, or vibration detector, measures vibration. Vibration Sensors Monitoring.

From www.spectotechnology.com

Wireless Vibration Monitoring System, Noise & Vibration Measurement Vibration Sensors Monitoring learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. a vibration sensor, or vibration detector, measures vibration levels in machinery for screening and analysis. It also includes a software application for data analysis, trend visualization, and fault detection. skf offers a range of vibration sensors for various industrial applications,. Vibration Sensors Monitoring.

From www.ifm.com

RtM IOLink vibration monitoring ifm electronic Vibration Sensors Monitoring learn how to use vibration monitors, sensors, and software to assess and mitigate the impact of construction. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. Maintenance teams use industrial vibration sensors for condition monitoring,. Vibration Sensors Monitoring.

From www.omega.com

Vibration Sensors and Their Importance in Vibration Monitoring of Vibration Sensors Monitoring skf offers a range of vibration sensors for various industrial applications, with different features and characteristics. advanced vibration sensors and monitoring help by providing precise, timely alerts necessary to maintain operational. Maintenance teams use industrial vibration sensors for condition monitoring, giving them insight into the magnitude and frequency of vibration signals. a vibration sensor, or vibration detector,. Vibration Sensors Monitoring.