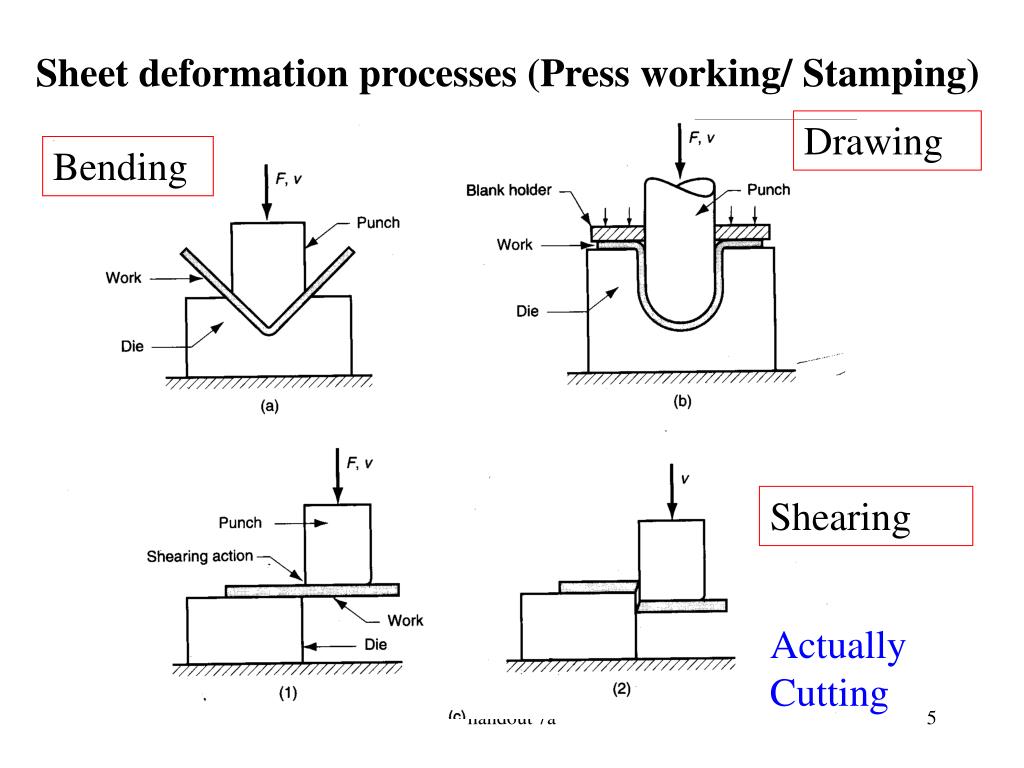

Sheet Metal Deformation Calculation . To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. .describe different forming processes, when they might be used, and. Analyse forming of intricate sheet metal parts. By the end of today you should be able to. Metallic sheet typically < 6 mm thick. An accurate prediction of springback in sheet metal forming processes requires complex hardening material models.

from www.slideserve.com

An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. Metallic sheet typically < 6 mm thick. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. .describe different forming processes, when they might be used, and. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. By the end of today you should be able to. Analyse forming of intricate sheet metal parts. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet.

PPT Metal Forming PowerPoint Presentation, free download ID6122858

Sheet Metal Deformation Calculation To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. Analyse forming of intricate sheet metal parts. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. By the end of today you should be able to. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. Metallic sheet typically < 6 mm thick. .describe different forming processes, when they might be used, and.

From exowmprwm.blob.core.windows.net

Steel Force Weight Limit at Misty Ramirez blog Sheet Metal Deformation Calculation To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. Analyse forming of intricate sheet metal parts. .describe different forming processes, when they might be used, and. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the. Sheet Metal Deformation Calculation.

From engineeringlibrary.org

Analysis of Plates in Bending Engineering Library Sheet Metal Deformation Calculation There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. Analyse forming of intricate sheet metal parts. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. An accurate prediction of springback in sheet metal forming processes requires complex. Sheet Metal Deformation Calculation.

From learnmech.com

Metal Forming Basic, Types , Diagram , Classification Sheet Metal Deformation Calculation By the end of today you should be able to. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. An accurate prediction of springback in sheet metal forming. Sheet Metal Deformation Calculation.

From www.youtube.com

03_03_P5 Calculating Force Required for Sheet Metal Bending YouTube Sheet Metal Deformation Calculation An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. Metallic sheet typically < 6 mm thick. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. There is, however, a wide gulf between the statement of the basic laws governing. Sheet Metal Deformation Calculation.

From www.youtube.com

18 types of bending operations in sheet metal Sheet metal bending Sheet Metal Deformation Calculation An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. By the end of today you should be able to. There is, however, a wide gulf between the. Sheet Metal Deformation Calculation.

From www.mdpi.com

Metals Free FullText TensileShear Fracture Behavior Prediction of Sheet Metal Deformation Calculation An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. Metallic sheet typically < 6 mm thick. Analyse forming of intricate sheet metal parts. .describe different forming processes, when they might be used, and. By the end of today you should be able to. It is the force applied parallel to the surface of the. Sheet Metal Deformation Calculation.

From skill-lync.com

Week 3 Sheet metal Bending challenge SkillLync Sheet Metal Deformation Calculation An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. .describe different forming processes, when they might be used, and. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. Analyse forming of intricate sheet metal parts. There is, however, a. Sheet Metal Deformation Calculation.

From www.youtube.com

Beam Deflection Formula's YouTube Sheet Metal Deformation Calculation By the end of today you should be able to. Analyse forming of intricate sheet metal parts. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. .describe different forming processes, when they might be used, and. An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. It. Sheet Metal Deformation Calculation.

From www.mdpi.com

Applied Sciences Free FullText Evolution of Residual Stress Based Sheet Metal Deformation Calculation By the end of today you should be able to. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the. Sheet Metal Deformation Calculation.

From www.mdpi.com

Metals Free FullText Numerical Modeling Rolling Contact Problem Sheet Metal Deformation Calculation .describe different forming processes, when they might be used, and. Analyse forming of intricate sheet metal parts. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. There is, however, a wide gulf between the statement of the basic laws governing deformation in. Sheet Metal Deformation Calculation.

From www.researchgate.net

Deformation and fracture modes of the steel beams at the beginning and Sheet Metal Deformation Calculation By the end of today you should be able to. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. To give users an understanding of. Sheet Metal Deformation Calculation.

From www.researchgate.net

Deformation of a section of a thick plate Download Scientific Diagram Sheet Metal Deformation Calculation It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. To give users an understanding of sheet metal calculations in general and how they are used. Sheet Metal Deformation Calculation.

From mavink.com

Deflection Calculation Examples Beam Sheet Metal Deformation Calculation To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. Analyse forming of intricate sheet metal parts. By the end of today you should be able to. It is the force. Sheet Metal Deformation Calculation.

From www.youtube.com

Sheet Metal Working Cutting Force Analysis YouTube Sheet Metal Deformation Calculation By the end of today you should be able to. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. Analyse forming of intricate sheet metal parts. Metallic sheet typically <. Sheet Metal Deformation Calculation.

From ahssinsights.org

Total Elongation AHSS Guidelines Sheet Metal Deformation Calculation There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. Metallic sheet typically < 6 mm thick. An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will. Sheet Metal Deformation Calculation.

From www.scribd.com

Sheet Metal Forming Processes PDF Sheet Metal Deformation Sheet Metal Deformation Calculation .describe different forming processes, when they might be used, and. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. By the end of today you should be able to. There is, however, a wide gulf between the statement of the basic laws. Sheet Metal Deformation Calculation.

From www.theengineeringcommunity.org

Stress In a Plate Due To a Point Load Spreadsheet Sheet Metal Deformation Calculation .describe different forming processes, when they might be used, and. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. Analyse forming of intricate sheet metal parts. Metallic sheet typically < 6 mm thick. An accurate prediction of springback in sheet metal forming processes requires complex. Sheet Metal Deformation Calculation.

From cadinfield.com

Sheet Metal Fabrication Fundamental Cad Infield Fabrication Design Sheet Metal Deformation Calculation It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. Analyse forming of intricate sheet metal parts. .describe different forming processes, when they might be used, and. There is, however, a wide gulf between the statement of the basic laws governing deformation in. Sheet Metal Deformation Calculation.

From www.researchgate.net

Definition of terms and phases of steel deformation Download Sheet Metal Deformation Calculation To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. Analyse forming of intricate sheet metal parts. .describe different forming processes, when they might be used, and. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. It is. Sheet Metal Deformation Calculation.

From www.slideshare.net

Structures and Materials Section 6 Axially Loaded Structural Members Sheet Metal Deformation Calculation By the end of today you should be able to. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. Metallic sheet typically < 6 mm thick. .describe different forming processes, when they might be used, and. An accurate prediction of springback in sheet metal forming. Sheet Metal Deformation Calculation.

From www.youtube.com

Simulation of sheet metal deformation YouTube Sheet Metal Deformation Calculation .describe different forming processes, when they might be used, and. Metallic sheet typically < 6 mm thick. An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. To. Sheet Metal Deformation Calculation.

From engineering.stackexchange.com

statics What are the units used in beam bending equations? Do they Sheet Metal Deformation Calculation It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. Analyse forming of intricate sheet metal parts. An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. There is, however, a wide gulf between the statement of the. Sheet Metal Deformation Calculation.

From www.youtube.com

Axial Deformation Calculation YouTube Sheet Metal Deformation Calculation Analyse forming of intricate sheet metal parts. Metallic sheet typically < 6 mm thick. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. An accurate. Sheet Metal Deformation Calculation.

From www.studocu.com

2 4 ME232 Sheet metal deformation processes Chapter 4 Sheet Metal Sheet Metal Deformation Calculation .describe different forming processes, when they might be used, and. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. An accurate prediction of springback in. Sheet Metal Deformation Calculation.

From www.slideserve.com

PPT Metal Forming PowerPoint Presentation, free download ID6122858 Sheet Metal Deformation Calculation To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. By the end of today you should be able to. Analyse forming of intricate sheet metal parts. Metallic sheet typically <. Sheet Metal Deformation Calculation.

From www.chegg.com

Bulk deformation processes and sheet metal formin You Sheet Metal Deformation Calculation An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. Analyse forming of intricate sheet metal parts. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will. Sheet Metal Deformation Calculation.

From www.thefabricator.com

Precision sheet metal bending and the V groove Sheet Metal Deformation Calculation It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. An accurate prediction of springback in sheet metal forming. Sheet Metal Deformation Calculation.

From www.researchgate.net

Schematic diagrams of the sheet forming. a Before deformation. b After Sheet Metal Deformation Calculation Metallic sheet typically < 6 mm thick. Analyse forming of intricate sheet metal parts. .describe different forming processes, when they might be used, and. By the end of today you should be able to. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. To give users an understanding of sheet metal calculations. Sheet Metal Deformation Calculation.

From engineering.stackexchange.com

mechanical engineering Force required to deform sheet metal Sheet Metal Deformation Calculation By the end of today you should be able to. Metallic sheet typically < 6 mm thick. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. There is, however, a. Sheet Metal Deformation Calculation.

From www.admet.com

Sheet Metal Tension Testing ADMET Sheet Metal Deformation Calculation To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the following:. .describe different forming processes, when they might be used, and. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. Analyse forming of intricate sheet metal parts. An accurate. Sheet Metal Deformation Calculation.

From www.machinemfg.com

Deformation Process in Sheet Metal Bending Explained MachineMFG Sheet Metal Deformation Calculation .describe different forming processes, when they might be used, and. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. By the end of today you should be able to. Metallic sheet typically < 6 mm thick. There is, however, a wide gulf. Sheet Metal Deformation Calculation.

From www.thefabricator.com

The differences between stiffness and strength in metal Sheet Metal Deformation Calculation An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. Analyse forming of intricate sheet metal parts. .describe different forming processes, when they might be used, and. It is the force applied parallel to the surface of the. Sheet Metal Deformation Calculation.

From www.mdpi.com

Materials Free FullText Theory, Method and Practice of Metal Sheet Metal Deformation Calculation By the end of today you should be able to. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. To give users an understanding of sheet metal calculations in general and how they are used in solidworks, this article will review the. Sheet Metal Deformation Calculation.

From www.hardwareinterviews.fyi

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI Sheet Metal Deformation Calculation Metallic sheet typically < 6 mm thick. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing. Sheet Metal Deformation Calculation.

From www.simscale.com

Elasto Plastic Yield Point / Youngs Modulus Using SimScale SimScale Sheet Metal Deformation Calculation There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet. It is the force applied parallel to the surface of the sheet metal that induces shear stress within the material, causing it to deform and eventually separate. An accurate prediction of springback in sheet metal forming processes requires complex hardening material models. By. Sheet Metal Deformation Calculation.