Gasket Compression Calculation . The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. Load / area = 720lb / 72 in² = 10 lb/in². The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The flat gasket is the oldest and most popular way to seal a flange or joint.

from www.jepistons.com

The force required to achieve the proper seal compression (squeeze) is a result of three main factors. Load / area = 720lb / 72 in² = 10 lb/in². Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The flat gasket is the oldest and most popular way to seal a flange or joint.

How To Calculate Engine Compression Ratio And Displacement JE Pistons

Gasket Compression Calculation The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The flat gasket is the oldest and most popular way to seal a flange or joint. The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). Load / area = 720lb / 72 in² = 10 lb/in². Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for.

From www.wikihow.com

How to Calculate Compression Ratio 11 Steps (with Pictures) Gasket Compression Calculation Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The flat gasket is the oldest and most popular way to seal a flange or joint. Load. Gasket Compression Calculation.

From www.thetechedvocate.org

How calculate compression ratio The Tech Edvocate Gasket Compression Calculation Load / area = 720lb / 72 in² = 10 lb/in². Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The flat gasket is the oldest and most popular way to seal a flange or joint. The force required to achieve the proper seal compression. Gasket Compression Calculation.

From www.researchgate.net

A characteristic curve of metal gasket. After a cycle of compression Gasket Compression Calculation The flat gasket is the oldest and most popular way to seal a flange or joint. Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). Load. Gasket Compression Calculation.

From www.globaloring.com

ORing Groove Design Global ORing and Seal Gasket Compression Calculation The flat gasket is the oldest and most popular way to seal a flange or joint. Load / area = 720lb / 72 in² = 10 lb/in². The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face. Gasket Compression Calculation.

From blog.projectmaterials.com

Spiral Wound Gasket Gasket Compression Calculation The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The flat gasket is the oldest and most popular way to seal a flange or joint. Load / area = 720lb / 72 in². Gasket Compression Calculation.

From ls1tech.com

Calculating compression ratio a common figure overlooked LS1TECH Gasket Compression Calculation The force required to achieve the proper seal compression (squeeze) is a result of three main factors. Load / area = 720lb / 72 in² = 10 lb/in². Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The flat gasket is the oldest and most. Gasket Compression Calculation.

From www.wikihow.com

How to Calculate Compression Ratio 11 Steps (with Pictures) Gasket Compression Calculation The force required to achieve the proper seal compression (squeeze) is a result of three main factors. Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The flat gasket is the oldest and most popular way to seal a flange or joint. The images below. Gasket Compression Calculation.

From www.littlepeng.com

Functions of Gaskets Little P.Eng. for Engineers Training ASME Gasket Compression Calculation Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The flat gasket is the oldest and most popular way to seal a flange or joint. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The. Gasket Compression Calculation.

From www.researchgate.net

Comparison of the gasketingroove compression process [Colour figure Gasket Compression Calculation The flat gasket is the oldest and most popular way to seal a flange or joint. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The. Gasket Compression Calculation.

From www.hotrod.com

How to Calculate Compression Ratio Like A Pro Gasket Compression Calculation Load / area = 720lb / 72 in² = 10 lb/in². The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised. Gasket Compression Calculation.

From www.youtube.com

how to calculator compression ratio and head gasket thickness bodgit Gasket Compression Calculation The flat gasket is the oldest and most popular way to seal a flange or joint. The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). Gasket calculator (excel spreadsheet) this excel (xlxs) file. Gasket Compression Calculation.

From www.applerubber.com

How much force is needed to compress static axial seals and gaskets Gasket Compression Calculation Load / area = 720lb / 72 in² = 10 lb/in². The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The flat gasket is the oldest and most popular way to seal a. Gasket Compression Calculation.

From calculatorshub.net

Gasket Compression Calculator Online Gasket Compression Calculation Load / area = 720lb / 72 in² = 10 lb/in². The flat gasket is the oldest and most popular way to seal a flange or joint. Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The force required to achieve the proper seal compression. Gasket Compression Calculation.

From automotorpad.com

Compression ratio calculators for honda motors Gasket Compression Calculation Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The flat gasket is the oldest and most popular way to seal a flange or joint. Load / area = 720lb / 72 in² = 10 lb/in². The force required to achieve the proper seal compression. Gasket Compression Calculation.

From mechasource.blogspot.com

An Introduction To Introduction To gaskets and Its Types Gasket Compression Calculation The flat gasket is the oldest and most popular way to seal a flange or joint. The force required to achieve the proper seal compression (squeeze) is a result of three main factors. Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. Load / area. Gasket Compression Calculation.

From www.doghouserepair.com

Calculate Compression Ratio Doghouse Repair Gasket Compression Calculation Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. Load / area = 720lb / 72 in² = 10 lb/in². The flat gasket is the oldest and most popular way to seal a flange or joint. The images below illustrate how the gasket sealing element. Gasket Compression Calculation.

From audiaelastomers.com

Compression Set Test Audia Elastomers Gasket Compression Calculation Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. Load / area = 720lb / 72 in² = 10 lb/in². The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The images below illustrate how the gasket sealing. Gasket Compression Calculation.

From info.jepistons.com

Compression Ratio Theory and How to Calculate in Powersports Gasket Compression Calculation The flat gasket is the oldest and most popular way to seal a flange or joint. The force required to achieve the proper seal compression (squeeze) is a result of three main factors. Load / area = 720lb / 72 in² = 10 lb/in². Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque,. Gasket Compression Calculation.

From www.bluey.com.au

Ensuring TBM Compression Gaskets Resist Natural Groundwater Pressure Gasket Compression Calculation Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. Load / area = 720lb / 72 in² = 10 lb/in². The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The force required to achieve the. Gasket Compression Calculation.

From www.scribd.com

Initial Gasket Compression Materials Science Engineering Gasket Compression Calculation Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness).. Gasket Compression Calculation.

From www.wikihow.com

How to Calculate Compression Ratio 9 Steps (with Pictures) Gasket Compression Calculation The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The flat gasket is the oldest and most popular way to seal a flange or joint. Load. Gasket Compression Calculation.

From www.applerubber.com

How much force is needed to compress static axial seals and gaskets Gasket Compression Calculation The flat gasket is the oldest and most popular way to seal a flange or joint. Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The. Gasket Compression Calculation.

From www.iqsdirectory.com

Gasket What Is It? How Is It Made? Types Of & Safety Gasket Compression Calculation The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The flat gasket is the oldest and most popular way to seal a flange or joint. Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. Load. Gasket Compression Calculation.

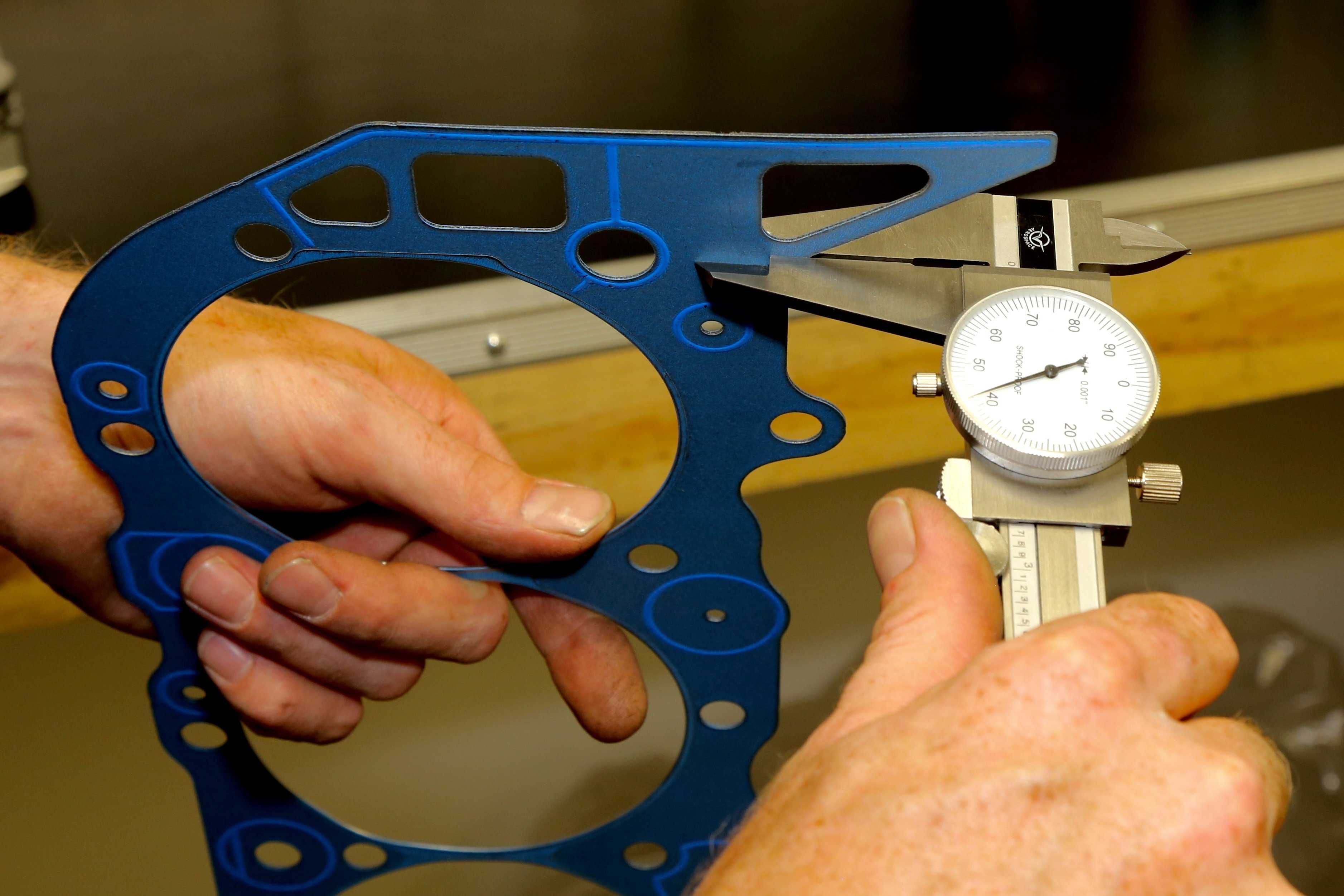

From hswhite.com

How to Measure Gaskets H.S. White Corporation Gasket Compression Calculation Load / area = 720lb / 72 in² = 10 lb/in². The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The flat gasket is the oldest and most popular way to seal a flange or joint. Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque,. Gasket Compression Calculation.

From www.motortrend.com

How to Calculate Compression Ratio Like A Pro Gasket Compression Calculation The force required to achieve the proper seal compression (squeeze) is a result of three main factors. Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness).. Gasket Compression Calculation.

From www.youtube.com

GT40 BUILD Part 7 Compression Ratio Calculation for Head Gasket YouTube Gasket Compression Calculation Load / area = 720lb / 72 in² = 10 lb/in². The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The flat gasket is the oldest and most popular way to seal a. Gasket Compression Calculation.

From www.troopindustrial.com

Dimensions for Spiral Wound SemiMetallic Gaskets Troop Industrial Gasket Compression Calculation Load / area = 720lb / 72 in² = 10 lb/in². The force required to achieve the proper seal compression (squeeze) is a result of three main factors. Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The images below illustrate how the gasket sealing. Gasket Compression Calculation.

From www.youtube.com

FE Exam Review How to Calculate the Maximum Compression of a Spring Gasket Compression Calculation Load / area = 720lb / 72 in² = 10 lb/in². The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The force required to achieve the proper seal compression (squeeze) is a result of three main factors. Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised. Gasket Compression Calculation.

From forums.autodesk.com

How to model thin element (gasket) compression? Autodesk Community Gasket Compression Calculation The flat gasket is the oldest and most popular way to seal a flange or joint. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The force required to achieve the proper seal compression (squeeze) is a result of three main factors. Gasket calculator (excel spreadsheet) this excel (xlxs) file. Gasket Compression Calculation.

From innovationdiscoveries.space

How To Calculate Engine Compression Ratio And Displacement Gasket Compression Calculation Load / area = 720lb / 72 in² = 10 lb/in². The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised. Gasket Compression Calculation.

From www.jepistons.com

How To Calculate Engine Compression Ratio And Displacement JE Pistons Gasket Compression Calculation The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The force required to achieve the proper seal compression (squeeze) is a result of three main factors. Load / area = 720lb / 72 in² = 10 lb/in². Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised. Gasket Compression Calculation.

From whatispiping.com

Types of Gaskets Used with Pipe Flanges What Is Piping Gasket Compression Calculation Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and tech conversions for. The flat gasket is the oldest and most popular way to seal a flange or joint. The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The images below. Gasket Compression Calculation.

From www.motortrend.com

How to Calculate Compression Ratio Gasket Compression Calculation The force required to achieve the proper seal compression (squeeze) is a result of three main factors. The flat gasket is the oldest and most popular way to seal a flange or joint. The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). Load / area = 720lb / 72 in². Gasket Compression Calculation.

From www.scribd.com

Gasket Compression and Recovery Temperature Mechanical Engineering Gasket Compression Calculation The images below illustrate how the gasket sealing element (windings and filler) may be manufactured to different densities (stiffness). The flat gasket is the oldest and most popular way to seal a flange or joint. The force required to achieve the proper seal compression (squeeze) is a result of three main factors. Load / area = 720lb / 72 in². Gasket Compression Calculation.