Temperature Cycling Ramp Rate . In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. Learn more about which ramp rates are best for defining a test and discover the array of. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. We recommend 8 to 10 min. The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time.

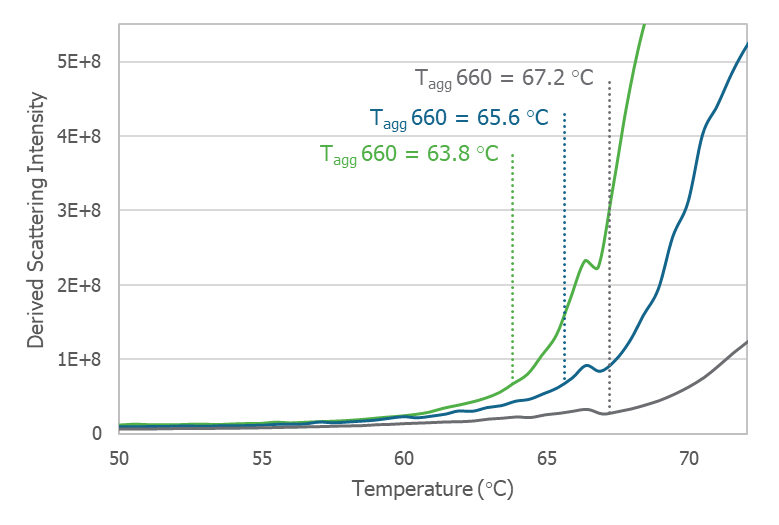

from www.unchainedlabs.com

In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. We recommend 8 to 10 min. Learn more about which ramp rates are best for defining a test and discover the array of.

Sizing with thermal ramp Unchained Labs

Temperature Cycling Ramp Rate We recommend 8 to 10 min. The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. Learn more about which ramp rates are best for defining a test and discover the array of. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. We recommend 8 to 10 min.

From www.thermofisher.com

Six Key Considerations for Selecting a PCR Thermal Cycler Thermo Temperature Cycling Ramp Rate We recommend 8 to 10 min. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. This study uses the mean values of the ramp rates, dwell times,. Temperature Cycling Ramp Rate.

From www.researchgate.net

Temperature behaviour in a ramp 1 and b ramp 2 Download Scientific Temperature Cycling Ramp Rate The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which. Temperature Cycling Ramp Rate.

From www.researchgate.net

Timetemperature profile with ramp rates for slowly heating both Temperature Cycling Ramp Rate The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. Learn more about which ramp rates are best for defining a test and discover the array. Temperature Cycling Ramp Rate.

From www.scribd.com

Thermal Cyclers Key Thermal Cycling Concepts and Ramp Rates PDF Temperature Cycling Ramp Rate In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. We recommend 8 to 10 min. The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. The parameters of the atc test, such as temperature. Temperature Cycling Ramp Rate.

From www.researchgate.net

Timetemperature profile with ramp rates for slowly heating both Temperature Cycling Ramp Rate The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. Learn more about which ramp rates are best for defining a test and discover the array of. In addition. Temperature Cycling Ramp Rate.

From dokumen.tips

(PDF) Board level solder reliability versus ramp rate and dwell time Temperature Cycling Ramp Rate Learn more about which ramp rates are best for defining a test and discover the array of. This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time.. Temperature Cycling Ramp Rate.

From www.researchgate.net

Variation of ramp rate between the zones (C/s) and residence time (s Temperature Cycling Ramp Rate In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures. Temperature Cycling Ramp Rate.

From www.researchgate.net

Dynamic temperature ramp curve of CCE during the heating cycle from 20 Temperature Cycling Ramp Rate This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. Learn more about which ramp rates are best for defining a test and discover the array of. The. Temperature Cycling Ramp Rate.

From www.researchgate.net

(A) Optimal observed temperature ramp rates for efficient amplification Temperature Cycling Ramp Rate This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. Learn more about which ramp rates are best for defining a test and discover the array of. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which. Temperature Cycling Ramp Rate.

From www.thermofisher.com

Six Key Considerations for Selecting a PCR Thermal Cycler Thermo Temperature Cycling Ramp Rate In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. We recommend 8 to 10 min. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. This study uses the mean values of the ramp rates, dwell times,. Temperature Cycling Ramp Rate.

From www.researchgate.net

4 DSC Curve without the sample for temperature ramp rate 15 Kpm Temperature Cycling Ramp Rate The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. We recommend 8 to 10 min. In addition to maximum and minimum temperature, δt, the ramp rate, and. Temperature Cycling Ramp Rate.

From www.researchgate.net

Calculated maximum temperature evolution during cyclic operation with Temperature Cycling Ramp Rate This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. Learn more about which ramp rates are best for defining a test and discover the array of. We recommend 8 to 10 min. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time. Temperature Cycling Ramp Rate.

From www.semanticscholar.org

Accelerated temperature cycle test and CoffinManson model for Temperature Cycling Ramp Rate Learn more about which ramp rates are best for defining a test and discover the array of. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. We recommend 8 to 10 min. This study uses the mean values of the ramp rates, dwell times, maximum. Temperature Cycling Ramp Rate.

From www.researchgate.net

Temperature ramps for 400, 500, 600 • C set temperature and 15, 25, 50 Temperature Cycling Ramp Rate This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. Learn more about which ramp rates are best for defining a test and discover the array of. In addition to. Temperature Cycling Ramp Rate.

From www.researchgate.net

Dynamic temperature ramp test (TimeCure) at high temperature (25 to 130 Temperature Cycling Ramp Rate This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and.. Temperature Cycling Ramp Rate.

From www.researchgate.net

Effect of Temperature Ramp Rates on the Evolution of Inelastic Strain Temperature Cycling Ramp Rate The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. We recommend 8 to 10 min. Learn more about which ramp rates are best for defining a test and discover the array of. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also. Temperature Cycling Ramp Rate.

From www.researchgate.net

(a) Cyclic temperature ramp curves ranging from 55 to 100 °C with a Temperature Cycling Ramp Rate This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. Learn more about which ramp rates are best for defining a test and discover the array of. We recommend 8 to 10 min. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time. Temperature Cycling Ramp Rate.

From studylib.net

Thermal cyclers key thermal cycling concepts and ramp rates Temperature Cycling Ramp Rate In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by. Temperature Cycling Ramp Rate.

From www.researchgate.net

Ramp rates of the ASTM HIP. Above transus HIP (a) and low temperature Temperature Cycling Ramp Rate We recommend 8 to 10 min. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. Learn more about which ramp rates are best for defining a test and discover the array of. This study uses the mean values of the ramp rates, dwell times, maximum. Temperature Cycling Ramp Rate.

From www.lenpure.com

Test Standard JESD22A105C Power and Temperature Cycling_LENPURE Temperature Cycling Ramp Rate The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. Learn more about which ramp rates are best for defining a test and discover the array of. The parameters of the. Temperature Cycling Ramp Rate.

From www.researchgate.net

Ramps of temperature for every heat treatment (350 and 600 °C Temperature Cycling Ramp Rate The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. Learn more about which ramp rates are best for defining a test and discover the array of. In addition. Temperature Cycling Ramp Rate.

From www.researchgate.net

3 DSC Curve for V 2 O 3 sample with temperature ramp rate 15 Kpm Temperature Cycling Ramp Rate The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. Learn more about which ramp rates are best for defining a test and discover the array of. This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. We. Temperature Cycling Ramp Rate.

From www.researchgate.net

(a) Temperature ramp results at frequency of 1.0 rad/s and heating rate Temperature Cycling Ramp Rate Learn more about which ramp rates are best for defining a test and discover the array of. The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from. Temperature Cycling Ramp Rate.

From arduino103.blogspot.com

PlanchaCMS Refroidissement et rampes de température MCHobby Le Blog Temperature Cycling Ramp Rate In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. Learn more about which ramp rates are best for defining a test and discover the. Temperature Cycling Ramp Rate.

From www.researchgate.net

Example of rheometric temperature ramp data. Variation in storage and Temperature Cycling Ramp Rate The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. This study uses the mean values of the ramp rates, dwell times, maximum and minimum. Temperature Cycling Ramp Rate.

From www.semanticscholar.org

Figure 3 from Effect of Peak Temperature and Ramp Rate on Thermal Temperature Cycling Ramp Rate The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. Learn more about which ramp rates are best for defining a test and discover the array of.. Temperature Cycling Ramp Rate.

From advancedta.com

KEY Thermal Testing Test Profiles — ATA Modular Flow Management Temperature Cycling Ramp Rate This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. We recommend 8 to 10 min. Learn more about which ramp rates are best for defining a. Temperature Cycling Ramp Rate.

From www.researchgate.net

The effect of ramp rate on (a) maximum temperature difference across Temperature Cycling Ramp Rate This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. Learn more about which ramp rates are best for defining a test and discover the array of. The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. We. Temperature Cycling Ramp Rate.

From www.researchgate.net

Temperature ramps for 400, 500, 600 • C set temperature and 15, 25, 50 Temperature Cycling Ramp Rate Learn more about which ramp rates are best for defining a test and discover the array of. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is also a crucial parameter, which ranges from 1. We recommend 8 to 10 min. This study uses the mean values of the ramp rates, dwell times, maximum. Temperature Cycling Ramp Rate.

From www.trelic.fi

Critical parameters of thermal cycling testing Trelic Solutions for Temperature Cycling Ramp Rate Learn more about which ramp rates are best for defining a test and discover the array of. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. This study uses the mean. Temperature Cycling Ramp Rate.

From www.unchainedlabs.com

Sizing with thermal ramp Unchained Labs Temperature Cycling Ramp Rate We recommend 8 to 10 min. This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. Learn more about which ramp rates are best for defining a test and discover the array of. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time. Temperature Cycling Ramp Rate.

From www.researchgate.net

(a) An example of temperature ramps for F127 20 PEO blends at Temperature Cycling Ramp Rate This study uses the mean values of the ramp rates, dwell times, maximum and minimum temperatures experienced by the module in each. The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. Learn more about which ramp rates are best for defining a test and discover the array of.. Temperature Cycling Ramp Rate.

From www.researchgate.net

Characteristic temperature profiles for rampup to 37 • C set Temperature Cycling Ramp Rate The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. The focus of temperature cycling tests should not be on number of chambers, nor upon ramp rate, but upon dwell time. In. Temperature Cycling Ramp Rate.

From www.researchgate.net

Temperaturetime cure cycle ramps. Download Scientific Diagram Temperature Cycling Ramp Rate The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. Learn more about which ramp rates are best for defining a test and discover the array of. Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. The focus of temperature cycling. Temperature Cycling Ramp Rate.

From www.semanticscholar.org

Figure 2 from Effect of Peak Temperature and Ramp Rate on Thermal Temperature Cycling Ramp Rate Temperature ramping rates, dwell time and dwell temperature, evolution of solder microstructures, presence of intermetallics, soldering defects, and. We recommend 8 to 10 min. The parameters of the atc test, such as temperature ramp rate and dwell time, significantly influence fatigue failure in solder. In addition to maximum and minimum temperature, δt, the ramp rate, and the holding time is. Temperature Cycling Ramp Rate.