Drill With End Mill . The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials, including metal,. I keep breaking my tool (3 flute solid carbide.) using 15000rpm and 30imp. I drill with an end mill all the time. Drilling with an end mill. 1m+ visitors in the past month I'm using a 3/32 end mill to drill a hole in 6061. 1m+ visitors in the past month Unlike a drill bit, an end mill has a flat end, which is why it is used for boring holes with flat bottoms. End mills are convenient as. Drill bits and end mills both remove material in the same way in the form of solid chips due to the rotation of the tool. The reason being the endmill is also an edge rounding tool. For instance, which are the best end mills? And which is the best end mill for aluminium, and which are the best end mill for stainless steel. End mills under 1.5mm become increasingly fragile, and subsequently cannot be run as aggressively, as a drill can be. If you’re making a very small hole, say, less than 1.5mm in diameter, go with a drill.

from www.dreamstime.com

If you’re making a very small hole, say, less than 1.5mm in diameter, go with a drill. Drilling with an end mill. I also use it to put pin holes in the cutting boards i make. End mills are convenient as. 1m+ visitors in the past month The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials, including metal,. And which bit do i need for what job? Drill bits and end mills both remove material in the same way in the form of solid chips due to the rotation of the tool. The reason being the endmill is also an edge rounding tool. And which is the best end mill for aluminium, and which are the best end mill for stainless steel.

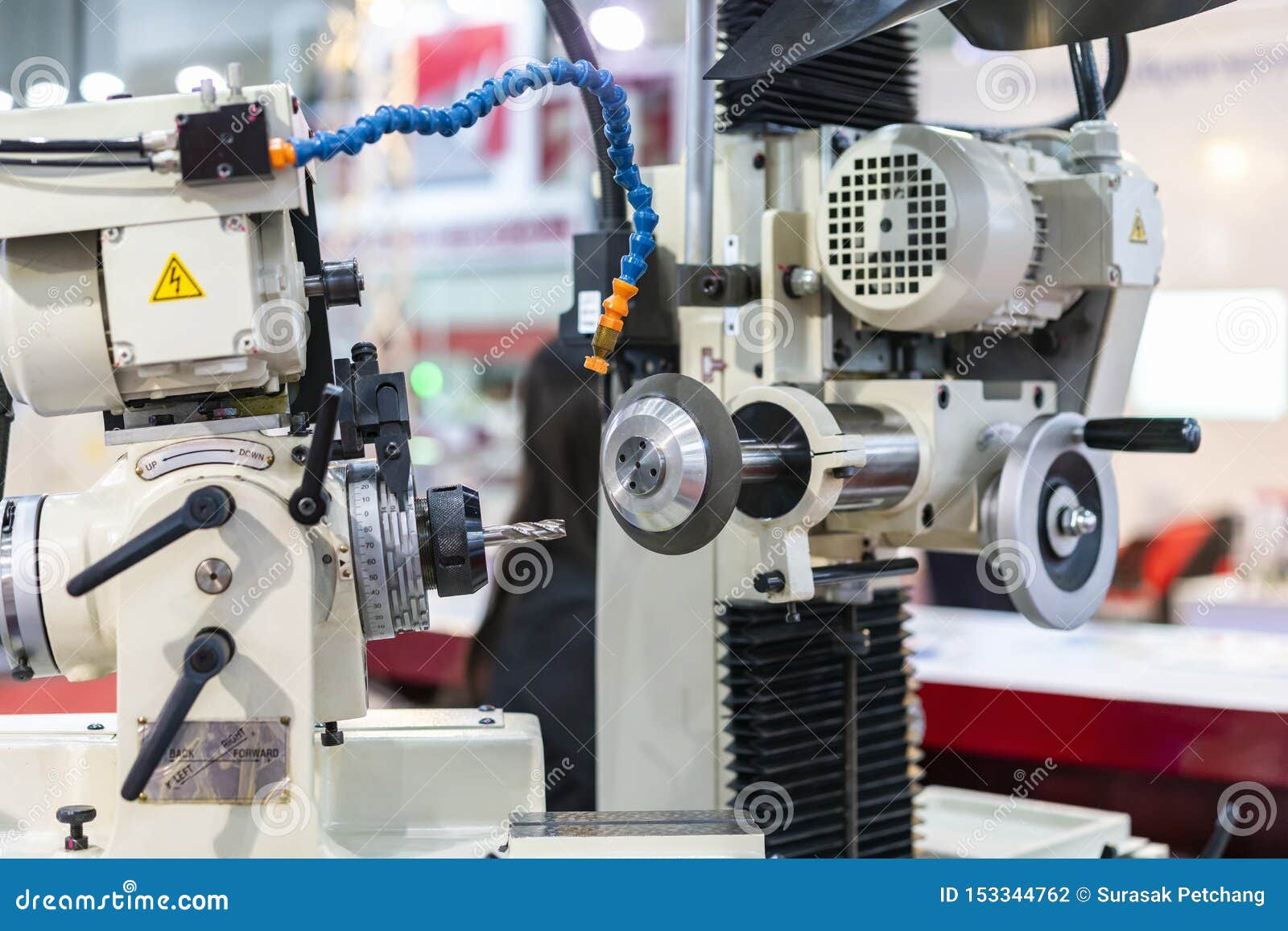

End Mill or Drills during Sharpening of Grinding by Automatic & High

Drill With End Mill 1m+ visitors in the past month The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials, including metal,. If you’re making a very small hole, say, less than 1.5mm in diameter, go with a drill. End mills are convenient as. Drilling with an end mill. 1m+ visitors in the past month Drill bits and end mills both remove material in the same way in the form of solid chips due to the rotation of the tool. And which is the best end mill for aluminium, and which are the best end mill for stainless steel. Unlike a drill bit, an end mill has a flat end, which is why it is used for boring holes with flat bottoms. 1m+ visitors in the past month I also use it to put pin holes in the cutting boards i make. The reason being the endmill is also an edge rounding tool. And which bit do i need for what job? I keep breaking my tool (3 flute solid carbide.) using 15000rpm and 30imp. I drill with an end mill all the time. I'm using a 3/32 end mill to drill a hole in 6061.

From www.dreamstime.com

Close Up End Mill or Drills during Sharpening of Grinding by Automatic Drill With End Mill If you’re making a very small hole, say, less than 1.5mm in diameter, go with a drill. And which is the best end mill for aluminium, and which are the best end mill for stainless steel. I also use it to put pin holes in the cutting boards i make. 1m+ visitors in the past month And which bit do. Drill With End Mill.

From www.tools-zone.com

End Mill vs Drill Bit What Is The Difference? Tools Zone Drill With End Mill The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials, including metal,. And which bit do i need for what job? If you’re making a very small hole, say, less than 1.5mm in diameter, go with a drill. I'm using a 3/32 end mill to drill a. Drill With End Mill.

From www.amazon.com

VEVOR U3 Multifunctional Cutter Grinder Sharpener, Universal Grinder Drill With End Mill End mills are convenient as. Drill bits and end mills both remove material in the same way in the form of solid chips due to the rotation of the tool. I drill with an end mill all the time. I keep breaking my tool (3 flute solid carbide.) using 15000rpm and 30imp. If you’re making a very small hole, say,. Drill With End Mill.

From www.youtube.com

84 make an end mill or slot drill from a standard HSS drill . YouTube Drill With End Mill I'm using a 3/32 end mill to drill a hole in 6061. Drill bits and end mills both remove material in the same way in the form of solid chips due to the rotation of the tool. Drilling with an end mill. For instance, which are the best end mills? The reason being the endmill is also an edge rounding. Drill With End Mill.

From www.youtube.com

Basics 2 Can you use an endmill in a drill chuck? YouTube Drill With End Mill Drill bits and end mills both remove material in the same way in the form of solid chips due to the rotation of the tool. I drill with an end mill all the time. End mills are convenient as. 1m+ visitors in the past month If you’re making a very small hole, say, less than 1.5mm in diameter, go with. Drill With End Mill.

From redfoxmachinery.com.au

End Mill Slot Drill Set Milling Cutters OPTIMUM 20pc Metric Titanium Drill With End Mill End mills are convenient as. I drill with an end mill all the time. The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials, including metal,. The reason being the endmill is also an edge rounding tool. If you’re making a very small hole, say, less than. Drill With End Mill.

From www.youtube.com

Differences between Drilling and End Milling (Drill Vs End Mill) YouTube Drill With End Mill 1m+ visitors in the past month The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials, including metal,. I drill with an end mill all the time. For instance, which are the best end mills? I'm using a 3/32 end mill to drill a hole in 6061.. Drill With End Mill.

From www.exportersindia.com

Hard Line End Mills & Drills at Best Price in Chennai ID 1021709 Drill With End Mill Drilling with an end mill. I drill with an end mill all the time. I keep breaking my tool (3 flute solid carbide.) using 15000rpm and 30imp. The reason being the endmill is also an edge rounding tool. And which is the best end mill for aluminium, and which are the best end mill for stainless steel. For instance, which. Drill With End Mill.

From cuttermasters.com

End Mill Sharpeners Cuttermasters Drill and End Mill Sharpening Drill With End Mill End mills under 1.5mm become increasingly fragile, and subsequently cannot be run as aggressively, as a drill can be. The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials, including metal,. Drill bits and end mills both remove material in the same way in the form of. Drill With End Mill.

From www.dreamstime.com

End Mill or Drills during Sharpening of Grinding by Automatic & High Drill With End Mill The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials, including metal,. Unlike a drill bit, an end mill has a flat end, which is why it is used for boring holes with flat bottoms. For instance, which are the best end mills? The reason being the. Drill With End Mill.

From www.walmart.ca

10 Pcs HSS Carbide 4 Flute End Mill Drill Bit Set Attachment Kit CNC Drill With End Mill Drill bits and end mills both remove material in the same way in the form of solid chips due to the rotation of the tool. I also use it to put pin holes in the cutting boards i make. And which is the best end mill for aluminium, and which are the best end mill for stainless steel. 1m+ visitors. Drill With End Mill.

From www.tools-zone.com

End Mill vs Drill Bit What Is The Difference? Tools Zone Drill With End Mill I drill with an end mill all the time. And which is the best end mill for aluminium, and which are the best end mill for stainless steel. End mills are convenient as. I'm using a 3/32 end mill to drill a hole in 6061. Unlike a drill bit, an end mill has a flat end, which is why it. Drill With End Mill.

From goldstarkitchen.com

Best end mill on drill press Kitchen Smarter Drill With End Mill 1m+ visitors in the past month For instance, which are the best end mills? If you’re making a very small hole, say, less than 1.5mm in diameter, go with a drill. And which is the best end mill for aluminium, and which are the best end mill for stainless steel. The main purpose of using an end mill to drill. Drill With End Mill.

From gmmtools.com

Addison HSS Drill, End Mill, Slot Drill, Reamer, Core Drill, Long Drill With End Mill I'm using a 3/32 end mill to drill a hole in 6061. End mills are convenient as. End mills under 1.5mm become increasingly fragile, and subsequently cannot be run as aggressively, as a drill can be. For instance, which are the best end mills? I also use it to put pin holes in the cutting boards i make. If you’re. Drill With End Mill.

From www.tradekorea.com

carbide drill carbide end mills tradekorea Drill With End Mill End mills under 1.5mm become increasingly fragile, and subsequently cannot be run as aggressively, as a drill can be. For instance, which are the best end mills? End mills are convenient as. Unlike a drill bit, an end mill has a flat end, which is why it is used for boring holes with flat bottoms. Drilling with an end mill.. Drill With End Mill.

From scmtstools.en.made-in-china.com

HRC45/55/65 Carbide Twist Drill with End Mill Cutting Tool CNC Milling Drill With End Mill End mills are convenient as. The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials, including metal,. I'm using a 3/32 end mill to drill a hole in 6061. I keep breaking my tool (3 flute solid carbide.) using 15000rpm and 30imp. And which is the best. Drill With End Mill.

From www.desertbusinesswind.com

End Mills & Drills DBW Drill With End Mill 1m+ visitors in the past month And which bit do i need for what job? If you’re making a very small hole, say, less than 1.5mm in diameter, go with a drill. End mills under 1.5mm become increasingly fragile, and subsequently cannot be run as aggressively, as a drill can be. I keep breaking my tool (3 flute solid carbide.). Drill With End Mill.

From www.hss-drillbits.com

HSS CNC Straight Shank 4 Flute End Mill Milling / Fully Ground Cutting Drill With End Mill Unlike a drill bit, an end mill has a flat end, which is why it is used for boring holes with flat bottoms. I'm using a 3/32 end mill to drill a hole in 6061. The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials, including metal,.. Drill With End Mill.

From www.cgstool.com

What is End Milling? CGS Tool End Mills Solid Carbide Cutting Tools Drill With End Mill I drill with an end mill all the time. End mills under 1.5mm become increasingly fragile, and subsequently cannot be run as aggressively, as a drill can be. Drilling with an end mill. For instance, which are the best end mills? The reason being the endmill is also an edge rounding tool. And which bit do i need for what. Drill With End Mill.

From cuttermasters.com

2017 CS320 Combination Drill and End Mill Sharpener Drill With End Mill End mills under 1.5mm become increasingly fragile, and subsequently cannot be run as aggressively, as a drill can be. I also use it to put pin holes in the cutting boards i make. Drilling with an end mill. 1m+ visitors in the past month End mills are convenient as. For instance, which are the best end mills? I keep breaking. Drill With End Mill.

From redfoxmachinery.com.au

End Mill Slot Drill Set Milling Cutters OPTIMUM 20pc Metric Titanium Drill With End Mill Drilling with an end mill. I'm using a 3/32 end mill to drill a hole in 6061. End mills are convenient as. End mills under 1.5mm become increasingly fragile, and subsequently cannot be run as aggressively, as a drill can be. And which is the best end mill for aluminium, and which are the best end mill for stainless steel.. Drill With End Mill.

From applianceselloff.com

Best Drill Point End Mills Home Appliances Drill With End Mill 1m+ visitors in the past month Drilling with an end mill. For instance, which are the best end mills? I drill with an end mill all the time. I'm using a 3/32 end mill to drill a hole in 6061. End mills under 1.5mm become increasingly fragile, and subsequently cannot be run as aggressively, as a drill can be. I. Drill With End Mill.

From allofkitchen.com

Can I Use End Mill In Drill Press? Drill With End Mill The reason being the endmill is also an edge rounding tool. Drilling with an end mill. I also use it to put pin holes in the cutting boards i make. The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials, including metal,. I keep breaking my tool. Drill With End Mill.

From www.ebay.co.uk

Ball Nose Round End Mill Drill HSS Milling Cutter 1MM to 12.5MM in Drill With End Mill Unlike a drill bit, an end mill has a flat end, which is why it is used for boring holes with flat bottoms. 1m+ visitors in the past month End mills under 1.5mm become increasingly fragile, and subsequently cannot be run as aggressively, as a drill can be. Drill bits and end mills both remove material in the same way. Drill With End Mill.

From www.dreamstime.com

End mills and drills stock photo. Image of mechanic 256935992 Drill With End Mill Drill bits and end mills both remove material in the same way in the form of solid chips due to the rotation of the tool. For instance, which are the best end mills? 1m+ visitors in the past month I'm using a 3/32 end mill to drill a hole in 6061. And which is the best end mill for aluminium,. Drill With End Mill.

From www.grainger.com

DAYTON, R8, 16 in Swing, Mill Drill Machine 2LKP92LKP9 Grainger Drill With End Mill 1m+ visitors in the past month I also use it to put pin holes in the cutting boards i make. I'm using a 3/32 end mill to drill a hole in 6061. End mills are convenient as. The reason being the endmill is also an edge rounding tool. Drill bits and end mills both remove material in the same way. Drill With End Mill.

From decaturdiamond.com

Diamond Coated End Mills, Drills & Inserts Decatur Diamond Drill With End Mill And which is the best end mill for aluminium, and which are the best end mill for stainless steel. I drill with an end mill all the time. I keep breaking my tool (3 flute solid carbide.) using 15000rpm and 30imp. 1m+ visitors in the past month I also use it to put pin holes in the cutting boards i. Drill With End Mill.

From www.shop-apt.co.uk

6mm Diameter 1 Flute Carbide End Mill Slot Drill for Aluminium 22mm Drill With End Mill 1m+ visitors in the past month I also use it to put pin holes in the cutting boards i make. The reason being the endmill is also an edge rounding tool. End mills under 1.5mm become increasingly fragile, and subsequently cannot be run as aggressively, as a drill can be. End mills are convenient as. The main purpose of using. Drill With End Mill.

From www.grainger.com

Drill Bit & End Mill Sharpeners Grainger Industrial Supply Drill With End Mill The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials, including metal,. If you’re making a very small hole, say, less than 1.5mm in diameter, go with a drill. The reason being the endmill is also an edge rounding tool. Drilling with an end mill. 1m+ visitors. Drill With End Mill.

From www.aliexpress.com

1pc Solid Carbide 4 Flute End Mill Straight Shank CNC Milling Cutter Drill With End Mill 1m+ visitors in the past month Drilling with an end mill. 1m+ visitors in the past month End mills are convenient as. I drill with an end mill all the time. If you’re making a very small hole, say, less than 1.5mm in diameter, go with a drill. The main purpose of using an end mill to drill holes is. Drill With End Mill.

From www.aliexpress.com

high quality COMPLEX GRINDER MACHINE MILL & DRILL MR F4 Drill End Mill Drill With End Mill Drill bits and end mills both remove material in the same way in the form of solid chips due to the rotation of the tool. Unlike a drill bit, an end mill has a flat end, which is why it is used for boring holes with flat bottoms. If you’re making a very small hole, say, less than 1.5mm in. Drill With End Mill.

From thegodalmingpost.blogspot.com

end mill types and uses Best Bit EZine Fonction Drill With End Mill For instance, which are the best end mills? Drill bits and end mills both remove material in the same way in the form of solid chips due to the rotation of the tool. I drill with an end mill all the time. I keep breaking my tool (3 flute solid carbide.) using 15000rpm and 30imp. If you’re making a very. Drill With End Mill.

From gmmtools.com

Addison HSS Drill, End Mill, Slot Drill, Reamer, Core Drill, Long Drill With End Mill I drill with an end mill all the time. Drill bits and end mills both remove material in the same way in the form of solid chips due to the rotation of the tool. Unlike a drill bit, an end mill has a flat end, which is why it is used for boring holes with flat bottoms. I keep breaking. Drill With End Mill.

From www.ebay.co.uk

Ball Nose Round End Mill Drill HSS Milling Cutter 1MM to 12.5MM in Drill With End Mill I drill with an end mill all the time. 1m+ visitors in the past month End mills are convenient as. The reason being the endmill is also an edge rounding tool. Unlike a drill bit, an end mill has a flat end, which is why it is used for boring holes with flat bottoms. Drilling with an end mill. End. Drill With End Mill.

From www.ebay.co.uk

Ball Nose Round End Mill Drill HSS Milling Cutter 1MM to 12.5MM in Drill With End Mill And which bit do i need for what job? I also use it to put pin holes in the cutting boards i make. 1m+ visitors in the past month For instance, which are the best end mills? The main purpose of using an end mill to drill holes is to create accurate and precise holes in a variety of materials,. Drill With End Mill.