Tig Vs Mig Welding Youtube . Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. Mig, tig & stick welding: Those are the correct terms for stick, mig and tig welding. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. The 1,000 foot view of the most common welding processes. For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision. Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. Either will blow holes in the base. All of the different welding processes and acronyms can be really. If you’re working with delicate or thin materials, tig welding is.

from americantorchtip.com

All of the different welding processes and acronyms can be really. Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. Those are the correct terms for stick, mig and tig welding. For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision. The 1,000 foot view of the most common welding processes. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. Either will blow holes in the base. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. If you’re working with delicate or thin materials, tig welding is. Mig, tig & stick welding:

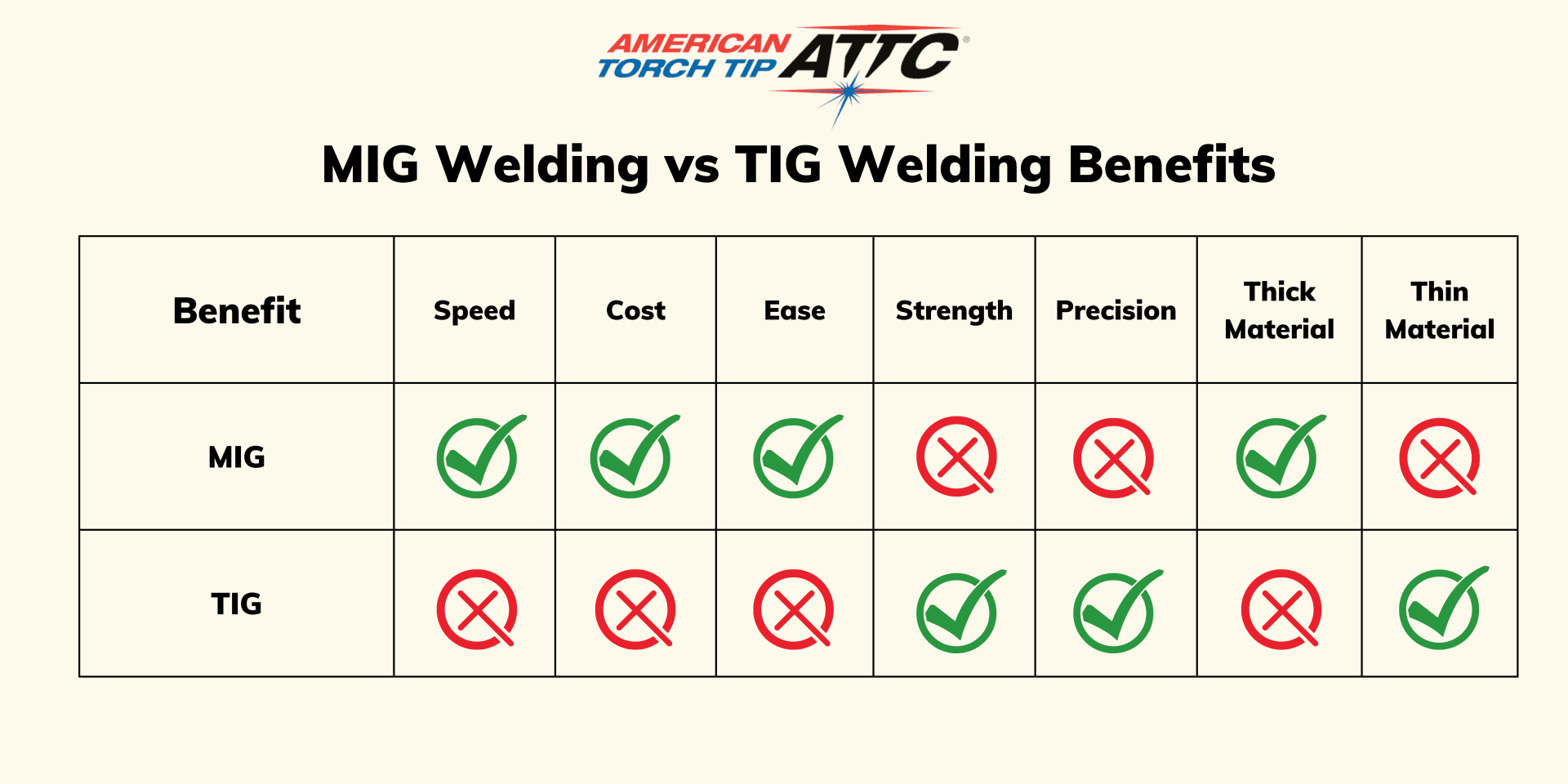

MIG vs TIG Welding Why a MIG Welder is More Efficient

Tig Vs Mig Welding Youtube Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. Those are the correct terms for stick, mig and tig welding. For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision. Either will blow holes in the base. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. If you’re working with delicate or thin materials, tig welding is. Mig, tig & stick welding: The 1,000 foot view of the most common welding processes. All of the different welding processes and acronyms can be really. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc.

From www.youtube.com

MIG Welding vs. TIG Welding YouTube Tig Vs Mig Welding Youtube Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. All of the different welding processes and acronyms can be really. Those are the correct. Tig Vs Mig Welding Youtube.

From www.pinterest.de

TIG vs MIG Welding Sheet Metal How & When to Use Them!! Roadster Hood Tig Vs Mig Welding Youtube The 1,000 foot view of the most common welding processes. If you’re working with delicate or thin materials, tig welding is. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. Those are the correct terms for stick,. Tig Vs Mig Welding Youtube.

From weldinguru.com

MIG VS TIG Welding Ultimate Guide Weldinguru Tig Vs Mig Welding Youtube The 1,000 foot view of the most common welding processes. Either will blow holes in the base. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. If you’re working with delicate or thin materials, tig welding is. Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. Those are the correct. Tig Vs Mig Welding Youtube.

From weldguru.com

MIG vs TIG Welding The Main Differences Weld Guru Tig Vs Mig Welding Youtube Either will blow holes in the base. The 1,000 foot view of the most common welding processes. Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. Those are the correct terms for stick, mig and tig welding. For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision.. Tig Vs Mig Welding Youtube.

From www.youtube.com

Fabrication Basics // Mig vs Tig Which is Faster? YouTube Tig Vs Mig Welding Youtube At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. Mig, tig & stick welding: All of the different welding processes and acronyms can be really. For beginners, mig welding is easier to learn and more forgiving, while. Tig Vs Mig Welding Youtube.

From www.youtube.com

MIG Versus TIG Welding on car bodywork, thin sheet steel. Vs Panel Tig Vs Mig Welding Youtube Either will blow holes in the base. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. Mig, tig & stick welding: All of the different welding processes and acronyms can be really. If you’re working with delicate. Tig Vs Mig Welding Youtube.

From www.youtube.com

MIG vs. TIG vs. Stick Welding? Learn more at Tig Vs Mig Welding Youtube At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. If you’re working with delicate or thin materials, tig welding is. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. For beginners,. Tig Vs Mig Welding Youtube.

From www.youtube.com

TIG, MIG, and Stick Welding with a Lincoln Power Mig 210mp YouTube Tig Vs Mig Welding Youtube If you’re working with delicate or thin materials, tig welding is. The 1,000 foot view of the most common welding processes. All of the different welding processes and acronyms can be really. Either will blow holes in the base. Those are the correct terms for stick, mig and tig welding. Mig, tig & stick welding: Stick = shielded metal arc. Tig Vs Mig Welding Youtube.

From finemetalworking.com

TIG vs MIG Welding (Differences). Which Is Better & Why? Tig Vs Mig Welding Youtube Either will blow holes in the base. If you’re working with delicate or thin materials, tig welding is. For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision. Those are the correct terms for stick, mig and tig welding. All of the different welding processes and acronyms can be really. Tig. Tig Vs Mig Welding Youtube.

From www.youtube.com

DIFFERENCE BETWEEN MIG WELDING AND TIG WELDING TIG Vs MIG Tig Vs Mig Welding Youtube Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. Mig, tig & stick welding: Those are the correct terms for stick, mig and tig welding. All of the different welding processes and acronyms can be really. For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and. Tig Vs Mig Welding Youtube.

From makemoneywelding.com

MIG vs. TIG Welding Differences Which Is Better? Tig Vs Mig Welding Youtube The 1,000 foot view of the most common welding processes. For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision. Those are the correct terms for stick, mig and tig welding. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. At a most basic level,. Tig Vs Mig Welding Youtube.

From www.youtube.com

MIG vs. TIG vs. STICK Welding YouTube Tig Vs Mig Welding Youtube The 1,000 foot view of the most common welding processes. All of the different welding processes and acronyms can be really. If you’re working with delicate or thin materials, tig welding is. Mig, tig & stick welding: Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. Stick = shielded metal arc welding (consumable electrode). Tig Vs Mig Welding Youtube.

From www.youtube.com

MIG VS TIG Welding With Aluminum YouTube Tig Vs Mig Welding Youtube Mig, tig & stick welding: Either will blow holes in the base. Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. Those are the. Tig Vs Mig Welding Youtube.

From toolsngoods.com

MIG vs TIG Welding Simple Guide to the Differences Tig Vs Mig Welding Youtube For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision. Either will blow holes in the base. Mig, tig & stick welding: Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. If you’re working with delicate or thin materials, tig welding is. The 1,000 foot. Tig Vs Mig Welding Youtube.

From www.youtube.com

TIG AND MIG WELDING YouTube Tig Vs Mig Welding Youtube If you’re working with delicate or thin materials, tig welding is. Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. All of the different welding processes and acronyms can be really. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal. Tig Vs Mig Welding Youtube.

From www.youtube.com

TIG vs MIG Welding for Hobbyists Which Type of Welding is Best? YouTube Tig Vs Mig Welding Youtube Either will blow holes in the base. Those are the correct terms for stick, mig and tig welding. Mig, tig & stick welding: Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. The 1,000 foot view of the most common welding processes. All of the different welding processes and acronyms can be really. If you’re working. Tig Vs Mig Welding Youtube.

From www.vrogue.co

Mig Vs Tig Welding Ultimate Guide vrogue.co Tig Vs Mig Welding Youtube Mig, tig & stick welding: Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. Either will blow holes in the base. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. Tig is generally. Tig Vs Mig Welding Youtube.

From www.youtube.com

welding MIG VS TIG VS stick YouTube Tig Vs Mig Welding Youtube All of the different welding processes and acronyms can be really. If you’re working with delicate or thin materials, tig welding is. Those are the correct terms for stick, mig and tig welding. For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision. Mig, tig & stick welding: Tig is generally. Tig Vs Mig Welding Youtube.

From www.youtube.com

Mig vs Tig Welding YouTube Tig Vs Mig Welding Youtube All of the different welding processes and acronyms can be really. If you’re working with delicate or thin materials, tig welding is. The 1,000 foot view of the most common welding processes. For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision. Tig is generally better for thin metals (auto body,. Tig Vs Mig Welding Youtube.

From www.youtube.com

Differences between MIG Welding and TIG Welding. YouTube Tig Vs Mig Welding Youtube For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. Mig, tig & stick welding: Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. All of the different welding processes and acronyms. Tig Vs Mig Welding Youtube.

From www.youtube.com

MIG, TIG or Stick? WeekendWelder Double Mitre YouTube Tig Vs Mig Welding Youtube If you’re working with delicate or thin materials, tig welding is. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. For beginners,. Tig Vs Mig Welding Youtube.

From www.theengineerspost.com

Tig and Mig Welding The Real Differences Explained [PDF] Tig Vs Mig Welding Youtube Those are the correct terms for stick, mig and tig welding. For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. The 1,000 foot view of the most common welding processes. Either will blow holes in. Tig Vs Mig Welding Youtube.

From www.youtube.com

पहली बार हिंदी में Gouging Welding Machine। Mig welding Tig Welding Tig Vs Mig Welding Youtube For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. The 1,000 foot view of the most common welding processes. If you’re working with delicate or thin materials, tig welding is. Stick = shielded metal arc. Tig Vs Mig Welding Youtube.

From www.vrogue.co

Mig Vs Tig Welding Ultimate Guide vrogue.co Tig Vs Mig Welding Youtube Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. All of the different welding processes and acronyms can be really. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. For beginners, mig welding. Tig Vs Mig Welding Youtube.

From www.youtube.com

Learn to weld! TIG vs MIG part 1 YouTube Tig Vs Mig Welding Youtube If you’re working with delicate or thin materials, tig welding is. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. Either will blow holes in the base. Those are the correct terms for stick, mig and tig welding. Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. The 1,000 foot. Tig Vs Mig Welding Youtube.

From www.youtube.com

4 Types of Welding Explained MIG vs TIG vs Stick vs Flux Core YouTube Tig Vs Mig Welding Youtube All of the different welding processes and acronyms can be really. Either will blow holes in the base. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so. Tig Vs Mig Welding Youtube.

From www.youtube.com

MIG WELDING ALUMINIUM VS TIG WELDING ALUMINIUM YouTube Tig Vs Mig Welding Youtube Mig, tig & stick welding: At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. Either will blow holes in the base. For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more. Tig Vs Mig Welding Youtube.

From www.youtube.com

MIG VS TIG WELDING Mig is definitely better YouTube Tig Vs Mig Welding Youtube Those are the correct terms for stick, mig and tig welding. Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove. Tig Vs Mig Welding Youtube.

From www.youtube.com

Difference between TIG and MIG welding in hindi YouTube Tig Vs Mig Welding Youtube Those are the correct terms for stick, mig and tig welding. Mig, tig & stick welding: All of the different welding processes and acronyms can be really. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. For. Tig Vs Mig Welding Youtube.

From www.youtube.com

MIG vs TIG for your first welder? YouTube Tig Vs Mig Welding Youtube Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. All of the different welding processes and acronyms can be really. Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. Either will blow holes in the base. Mig, tig & stick welding: For beginners, mig welding is easier to learn and. Tig Vs Mig Welding Youtube.

From americantorchtip.com

MIG vs TIG Welding Why a MIG Welder is More Efficient Tig Vs Mig Welding Youtube Those are the correct terms for stick, mig and tig welding. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. If you’re working with delicate or thin materials, tig welding is. Mig, tig & stick welding: Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. All of the different welding. Tig Vs Mig Welding Youtube.

From www.youtube.com

How to Choose Which Welding Process to Use MIG vs TIG TIG Time YouTube Tig Vs Mig Welding Youtube Either will blow holes in the base. At a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal. Tig is generally better for thin metals (auto body, sheet metal), where fusion is required. Mig, tig & stick welding: For. Tig Vs Mig Welding Youtube.

From makemoneywelding.com

MIG vs. TIG Welding Differences Which Is Better? Tig Vs Mig Welding Youtube Either will blow holes in the base. Mig, tig & stick welding: The 1,000 foot view of the most common welding processes. Those are the correct terms for stick, mig and tig welding. If you’re working with delicate or thin materials, tig welding is. Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. Tig is generally. Tig Vs Mig Welding Youtube.

From www.youtube.com

The 4 types of welding Guide MIG vs TIG vs Stick vs Flux Core YouTube Tig Vs Mig Welding Youtube Those are the correct terms for stick, mig and tig welding. Mig, tig & stick welding: If you’re working with delicate or thin materials, tig welding is. For beginners, mig welding is easier to learn and more forgiving, while tig welding requires more skill and precision. Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. Either. Tig Vs Mig Welding Youtube.

From www.youtube.com

MIG VS TIG What's Quicker? YouTube Tig Vs Mig Welding Youtube The 1,000 foot view of the most common welding processes. If you’re working with delicate or thin materials, tig welding is. Mig, tig & stick welding: Stick = shielded metal arc welding (consumable electrode) tig = gas tungsten arc. All of the different welding processes and acronyms can be really. For beginners, mig welding is easier to learn and more. Tig Vs Mig Welding Youtube.