Brazing Strength Calculation . Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). Joint strength depends on several factors: There are six fundamentals of brazing that every. Whether you want to evaluate your brazing results or find the root cause of poor components or. Clearance chart created from work done in the handy & harman laboratories in fairfield, connecticut back in the 1930's. These brazing procedures boil down the brazing process to six basic steps. Making your process as efficient as possible. One of the most widely used charts in the field of brazing is the strength vs. Calculating the amount of brazing alloy to use. Tensile strength of brazed joints. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,.

from www.mechero.my

Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Whether you want to evaluate your brazing results or find the root cause of poor components or. Making your process as efficient as possible. These brazing procedures boil down the brazing process to six basic steps. Tensile strength of brazed joints. Calculating the amount of brazing alloy to use. One of the most widely used charts in the field of brazing is the strength vs. There are six fundamentals of brazing that every. Clearance chart created from work done in the handy & harman laboratories in fairfield, connecticut back in the 1930's.

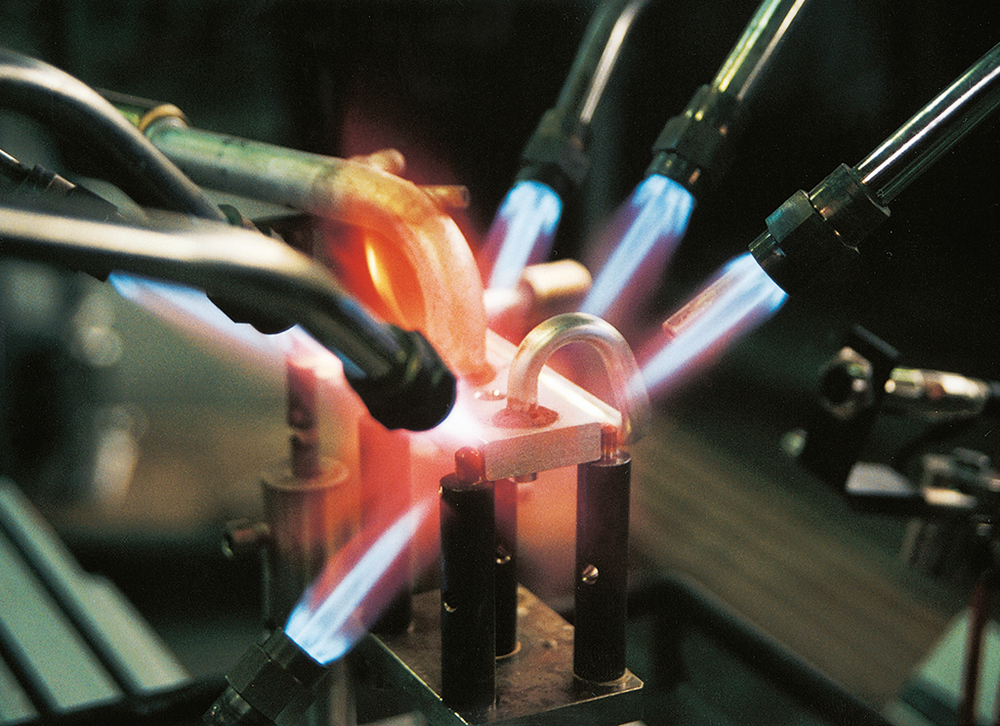

What is Brazing Process? Brazing Types & Applications

Brazing Strength Calculation Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). Making your process as efficient as possible. Tensile strength of brazed joints. One of the most widely used charts in the field of brazing is the strength vs. These brazing procedures boil down the brazing process to six basic steps. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Calculating the amount of brazing alloy to use. There are six fundamentals of brazing that every. Clearance chart created from work done in the handy & harman laboratories in fairfield, connecticut back in the 1930's. Whether you want to evaluate your brazing results or find the root cause of poor components or. Joint strength depends on several factors: Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration).

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum Brazing Strength Calculation Calculating the amount of brazing alloy to use. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Joint strength depends on several factors: Tensile strength of brazed joints. Whether you want to evaluate your brazing results or find the root cause of poor components or. These brazing procedures boil down the. Brazing Strength Calculation.

From www.mdpi.com

Metals Free FullText Effect of Brazing Temperature on Brazing Strength Calculation Whether you want to evaluate your brazing results or find the root cause of poor components or. Calculating the amount of brazing alloy to use. These brazing procedures boil down the brazing process to six basic steps. One of the most widely used charts in the field of brazing is the strength vs. Tensile strength of brazed joints. There are. Brazing Strength Calculation.

From engineeringlearner.com

Types of Brazing Definition, Principle, Applications, Advantages Brazing Strength Calculation There are six fundamentals of brazing that every. Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). These brazing procedures boil down the brazing process to six basic steps. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Clearance chart created from work done in. Brazing Strength Calculation.

From www.altexinc.com

Evaluating TubetoTubesheet Joints in Heat Exchangers Brazing Strength Calculation Making your process as efficient as possible. Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). There are six fundamentals of brazing that every. One of the most widely used charts in the field of brazing is the strength vs. These brazing procedures boil down the brazing process to six basic steps. Joint strength. Brazing Strength Calculation.

From www.youtube.com

Strength of Transverse Fillet Weld Design of Welded Joints Design Brazing Strength Calculation Tensile strength of brazed joints. One of the most widely used charts in the field of brazing is the strength vs. Making your process as efficient as possible. These brazing procedures boil down the brazing process to six basic steps. There are six fundamentals of brazing that every. Clearance between parts, base metal composition, service temperature and joint quality (low. Brazing Strength Calculation.

From blog.thepipingmart.com

What Is Metal Brazing And How Does It Work? Brazing Strength Calculation Tensile strength of brazed joints. Joint strength depends on several factors: These brazing procedures boil down the brazing process to six basic steps. Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). There are six fundamentals of brazing that every. There are six fundamentals of brazing that every brazer should follow to ensure consistent. Brazing Strength Calculation.

From www.researchgate.net

Effects of brazing time and temperature on shear strength of joints Brazing Strength Calculation Clearance chart created from work done in the handy & harman laboratories in fairfield, connecticut back in the 1930's. Making your process as efficient as possible. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Calculating the amount of brazing alloy to use. Whether you want to evaluate your brazing results. Brazing Strength Calculation.

From www.mdpi.com

Metals Free FullText Microstructure and Shear Strength of SiC Brazing Strength Calculation There are six fundamentals of brazing that every. Calculating the amount of brazing alloy to use. Joint strength depends on several factors: Making your process as efficient as possible. Tensile strength of brazed joints. These brazing procedures boil down the brazing process to six basic steps. There are six fundamentals of brazing that every brazer should follow to ensure consistent. Brazing Strength Calculation.

From www.youtube.com

Aluminum Brazing Demo & Strength Test Spoiler Alert FAIL! YouTube Brazing Strength Calculation Making your process as efficient as possible. Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). Calculating the amount of brazing alloy to use. One of the most widely used charts in the field of brazing is the strength vs. Joint strength depends on several factors: These brazing procedures boil down the brazing process. Brazing Strength Calculation.

From www.youtube.com

Fillet & Butt Weld Axial Stress & Strength A Simple & Conservative Brazing Strength Calculation Clearance chart created from work done in the handy & harman laboratories in fairfield, connecticut back in the 1930's. These brazing procedures boil down the brazing process to six basic steps. Making your process as efficient as possible. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Tensile strength of brazed. Brazing Strength Calculation.

From civilquery.com

What is Compressive Strength of Concrete Cube Test and Procedure Brazing Strength Calculation Tensile strength of brazed joints. There are six fundamentals of brazing that every. Making your process as efficient as possible. One of the most widely used charts in the field of brazing is the strength vs. These brazing procedures boil down the brazing process to six basic steps. Joint strength depends on several factors: Clearance chart created from work done. Brazing Strength Calculation.

From blog.thepipingmart.com

How to Aluminum Brazing Strength and Benefits Brazing Strength Calculation Joint strength depends on several factors: These brazing procedures boil down the brazing process to six basic steps. Making your process as efficient as possible. Whether you want to evaluate your brazing results or find the root cause of poor components or. Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). Clearance chart created. Brazing Strength Calculation.

From www.researchgate.net

Scheme of joints for a) induction brazing, b) arc brazing and c Brazing Strength Calculation Tensile strength of brazed joints. There are six fundamentals of brazing that every. Clearance chart created from work done in the handy & harman laboratories in fairfield, connecticut back in the 1930's. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Calculating the amount of brazing alloy to use. These brazing. Brazing Strength Calculation.

From www.mdpi.com

Metals Free FullText Microstructure and Shear Strength of Brazing Brazing Strength Calculation Clearance chart created from work done in the handy & harman laboratories in fairfield, connecticut back in the 1930's. Joint strength depends on several factors: Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). Making your process as efficient as possible. There are six fundamentals of brazing that every brazer should follow to ensure. Brazing Strength Calculation.

From arvengtraining.com

Understanding Piping Wall thickness calculation Arveng Training Brazing Strength Calculation Clearance chart created from work done in the handy & harman laboratories in fairfield, connecticut back in the 1930's. Joint strength depends on several factors: There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). Calculating the. Brazing Strength Calculation.

From www.researchgate.net

Summary of procedures for shear strength calculation Download Table Brazing Strength Calculation Joint strength depends on several factors: These brazing procedures boil down the brazing process to six basic steps. There are six fundamentals of brazing that every. Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). Tensile strength of brazed joints. There are six fundamentals of brazing that every brazer should follow to ensure consistent. Brazing Strength Calculation.

From www.desertcart.nz

Buy HOW TO BRAZE COPPER COMPLETE DIY GUIDE Basic step by step guide to Brazing Strength Calculation There are six fundamentals of brazing that every. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Calculating the amount of brazing alloy to use. One of the most widely used charts in the field of brazing is the strength vs. Joint strength depends on several factors: Whether you want to. Brazing Strength Calculation.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Brazing Strength Calculation There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. These brazing procedures boil down the brazing process to six basic steps. Joint strength depends on several factors: Whether you want to evaluate your brazing results or find the root cause of poor components or. Calculating the amount of brazing alloy to. Brazing Strength Calculation.

From www.scribd.com

Brazing Strength Of Materials Industrial Processes Brazing Strength Calculation These brazing procedures boil down the brazing process to six basic steps. One of the most widely used charts in the field of brazing is the strength vs. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Calculating the amount of brazing alloy to use. Clearance chart created from work done. Brazing Strength Calculation.

From weldingtorchapes.com

Brazing welding of common metal materials APES Brazing Strength Calculation Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). One of the most widely used charts in the field of brazing is the strength vs. Joint strength depends on several factors: Calculating the amount of brazing alloy to use. These brazing procedures boil down the brazing process to six basic steps. There are six. Brazing Strength Calculation.

From weldingintro.com

How Strong Is Aluminum Brazing (Reasons & Strength Comparison With Welding) Brazing Strength Calculation There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. There are six fundamentals of brazing that every. These brazing procedures boil down the brazing process to six basic steps. Making your process as efficient as possible. Clearance chart created from work done in the handy & harman laboratories in fairfield, connecticut. Brazing Strength Calculation.

From www.researchgate.net

(a) Forcedisplacement curve of brazing joint and (b) columnar diagram Brazing Strength Calculation One of the most widely used charts in the field of brazing is the strength vs. These brazing procedures boil down the brazing process to six basic steps. Whether you want to evaluate your brazing results or find the root cause of poor components or. There are six fundamentals of brazing that every brazer should follow to ensure consistent and. Brazing Strength Calculation.

From www.pinterest.com

Pin on dimecsa works Brazing Strength Calculation Whether you want to evaluate your brazing results or find the root cause of poor components or. Joint strength depends on several factors: Calculating the amount of brazing alloy to use. These brazing procedures boil down the brazing process to six basic steps. Tensile strength of brazed joints. Making your process as efficient as possible. One of the most widely. Brazing Strength Calculation.

From weldingintro.com

How Strong Is Aluminum Brazing (Reasons & Strength Comparison With Welding) Brazing Strength Calculation There are six fundamentals of brazing that every. Tensile strength of brazed joints. Calculating the amount of brazing alloy to use. Whether you want to evaluate your brazing results or find the root cause of poor components or. These brazing procedures boil down the brazing process to six basic steps. One of the most widely used charts in the field. Brazing Strength Calculation.

From www.pinterest.co.uk

Pin by Ray on JIC JIS BSP DIN ISO SAE hydraulic fittings Drawing size Brazing Strength Calculation Tensile strength of brazed joints. These brazing procedures boil down the brazing process to six basic steps. Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). Whether you want to evaluate your brazing results or find the root cause of poor components or. There are six fundamentals of brazing that every. Calculating the amount. Brazing Strength Calculation.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Brazing Strength Calculation Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). Clearance chart created from work done in the handy & harman laboratories in fairfield, connecticut back in the 1930's. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Tensile strength of brazed joints. Whether you want. Brazing Strength Calculation.

From www.pinterest.com.au

WELDGRP by Alex Tomanovich WELDGRP is a spreadsheet program written Brazing Strength Calculation Making your process as efficient as possible. Whether you want to evaluate your brazing results or find the root cause of poor components or. Calculating the amount of brazing alloy to use. These brazing procedures boil down the brazing process to six basic steps. Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). There. Brazing Strength Calculation.

From exodrddcz.blob.core.windows.net

How To Check Brazing Strength at Brian Chambless blog Brazing Strength Calculation Calculating the amount of brazing alloy to use. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Joint strength depends on several factors: These brazing procedures boil down the brazing process to six basic steps. Tensile strength of brazed joints. Making your process as efficient as possible. Whether you want to. Brazing Strength Calculation.

From www.twi-global.com

What are the different methods of brazing? TWI Brazing Strength Calculation Calculating the amount of brazing alloy to use. There are six fundamentals of brazing that every. Making your process as efficient as possible. Tensile strength of brazed joints. Joint strength depends on several factors: There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. These brazing procedures boil down the brazing process. Brazing Strength Calculation.

From www.textileadvisor.com

Textile Adviser FABRIC TEARING STRENGTH TESTING BY FALLING PENDULUM Brazing Strength Calculation These brazing procedures boil down the brazing process to six basic steps. Clearance chart created from work done in the handy & harman laboratories in fairfield, connecticut back in the 1930's. Joint strength depends on several factors: Making your process as efficient as possible. Tensile strength of brazed joints. One of the most widely used charts in the field of. Brazing Strength Calculation.

From exodrddcz.blob.core.windows.net

How To Check Brazing Strength at Brian Chambless blog Brazing Strength Calculation Whether you want to evaluate your brazing results or find the root cause of poor components or. Making your process as efficient as possible. These brazing procedures boil down the brazing process to six basic steps. Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). Tensile strength of brazed joints. There are six fundamentals. Brazing Strength Calculation.

From exodrddcz.blob.core.windows.net

How To Check Brazing Strength at Brian Chambless blog Brazing Strength Calculation Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). Clearance chart created from work done in the handy & harman laboratories in fairfield, connecticut back in the 1930's. Making your process as efficient as possible. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Joint. Brazing Strength Calculation.

From www.researchgate.net

Tensile strength of AA3005 before and after brazing process. Download Brazing Strength Calculation There are six fundamentals of brazing that every. Joint strength depends on several factors: Whether you want to evaluate your brazing results or find the root cause of poor components or. Making your process as efficient as possible. Tensile strength of brazed joints. One of the most widely used charts in the field of brazing is the strength vs. There. Brazing Strength Calculation.

From vacaero.com

The Famous JointStrength vs. JointClearance Chart Brazing Strength Calculation There are six fundamentals of brazing that every. Joint strength depends on several factors: Making your process as efficient as possible. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Clearance between parts, base metal composition, service temperature and joint quality (low voids, good penetration). Clearance chart created from work done. Brazing Strength Calculation.

From heater.heat-tech.biz

About Brazing HEATTECH Brazing Strength Calculation One of the most widely used charts in the field of brazing is the strength vs. Joint strength depends on several factors: These brazing procedures boil down the brazing process to six basic steps. Making your process as efficient as possible. There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality,. Clearance. Brazing Strength Calculation.