Pressure Sensor Span Error . Learn about other terms related to. Three specific types of errors have a negative impact on pressure sensor accuracy. Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. In order to eliminate the span error, the pressure must be regulated exactly at full scale value. Mount the sensor so that no condensate from the compressed air lines can gather in the device. Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. One adjustment is called the zero. Install the sensor so that it cannot be heated. On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero.

from www.chegg.com

Learn about other terms related to. One adjustment is called the zero. Three specific types of errors have a negative impact on pressure sensor accuracy. The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero. Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. Mount the sensor so that no condensate from the compressed air lines can gather in the device. Install the sensor so that it cannot be heated. On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. In order to eliminate the span error, the pressure must be regulated exactly at full scale value.

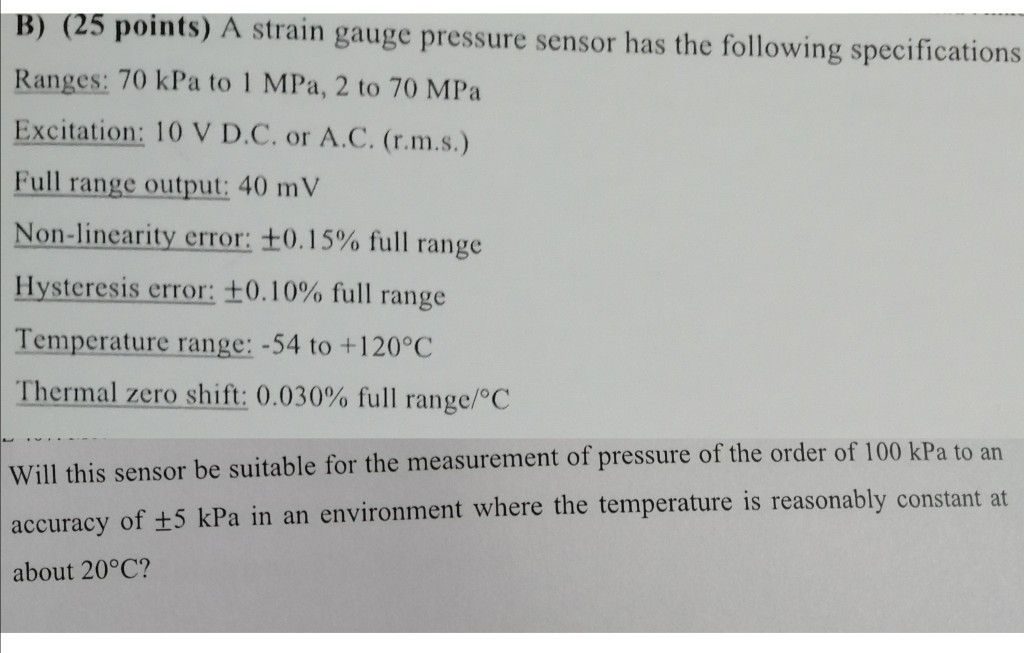

Solved B) (25 points) A strain gauge pressure sensor has the

Pressure Sensor Span Error Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. One adjustment is called the zero. Mount the sensor so that no condensate from the compressed air lines can gather in the device. Learn about other terms related to. Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. Install the sensor so that it cannot be heated. In order to eliminate the span error, the pressure must be regulated exactly at full scale value. Three specific types of errors have a negative impact on pressure sensor accuracy. The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero.

From instrumentationtools.com

Instrument Percent of Span Error Instrumentation Tools Pressure Sensor Span Error On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. Learn about other terms related to. Install the sensor so that it cannot be heated. Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. Mount the. Pressure Sensor Span Error.

From control.com

Calibration Errors and Testing Basic Principles of Instrument Pressure Sensor Span Error In order to eliminate the span error, the pressure must be regulated exactly at full scale value. Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. One adjustment is called the zero. On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to. Pressure Sensor Span Error.

From www.eastsensor.com

Span Error of Pressure Sensor Eastsensor Technology Pressure Sensor Span Error Learn about other terms related to. The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero. Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span,. Pressure Sensor Span Error.

From www.eastsensor.com

Zero Point Error of Pressure Sensor Eastsensor Technology Pressure Sensor Span Error On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. Mount the sensor so that no condensate from the compressed air lines can gather in the device. Install the sensor so that it cannot be heated. Hysteresis is the maximum deviation between the output signals of a pressure. Pressure Sensor Span Error.

From www.sensorsone.com

Pressure Sensor Calibration Error Calculator Pressure Sensor Span Error Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. Learn about other terms related to. Install the sensor so that it cannot be heated. Mount the sensor so that no condensate from the compressed air lines can gather in the device. One adjustment is called the zero. In order to eliminate. Pressure Sensor Span Error.

From control.com

Zero and Span Adjustments (Analog Instruments) Basic Principles of Pressure Sensor Span Error In order to eliminate the span error, the pressure must be regulated exactly at full scale value. One adjustment is called the zero. On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. Span error refers to the deviation of a pressure sensor’s actual output span from its. Pressure Sensor Span Error.

From mechanicbase.com

Tire Pressure Sensor Fault Meaning & 4 Common Causes Pressure Sensor Span Error On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. Three specific types of errors have a negative impact on pressure sensor accuracy. One adjustment is called. Pressure Sensor Span Error.

From www.youtube.com

Pressure gauge Errors and its remedy YouTube Pressure Sensor Span Error Install the sensor so that it cannot be heated. The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero. Three specific types of errors have a negative impact on pressure sensor accuracy. In order to eliminate the span error, the pressure must be regulated exactly at full scale value. One adjustment is. Pressure Sensor Span Error.

From www.gghyd.com

Pressure Gauge, liquid, air Pressure Sensor Span Error One adjustment is called the zero. Mount the sensor so that no condensate from the compressed air lines can gather in the device. On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. Span error refers to the deviation of a pressure sensor’s actual output span from its. Pressure Sensor Span Error.

From www.stssensors.com

Long term stability Archives STS Switzerland (EN) Pressure Sensor Span Error In order to eliminate the span error, the pressure must be regulated exactly at full scale value. Mount the sensor so that no condensate from the compressed air lines can gather in the device. One adjustment is called the zero. Learn about other terms related to. Install the sensor so that it cannot be heated. Hysteresis is the maximum deviation. Pressure Sensor Span Error.

From rohdvest.ro

How to fix P0238 Manifold Pressure/Boost Sensor (G31) Signal too High Pressure Sensor Span Error One adjustment is called the zero. Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. Install the sensor so that it cannot be heated. Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. On the actual instrument (the pressure. Pressure Sensor Span Error.

From www.linkedin.com

[Video] WIKA Group on LinkedIn Accuracy of pressure sensors Keep an Pressure Sensor Span Error One adjustment is called the zero. Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. Install the sensor so that it cannot be heated. Learn about other terms related to. Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure.. Pressure Sensor Span Error.

From www.chegg.com

Solved B) (25 points) A strain gauge pressure sensor has the Pressure Sensor Span Error Install the sensor so that it cannot be heated. Learn about other terms related to. Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. Three specific types of errors have a negative impact on pressure sensor accuracy. Span error refers to the deviation of a pressure sensor’s actual output span from. Pressure Sensor Span Error.

From muralipneumatics.co.in

Category SPAN Pressure Sensors Murali Pneumatics Pressure Sensor Span Error Mount the sensor so that no condensate from the compressed air lines can gather in the device. Three specific types of errors have a negative impact on pressure sensor accuracy. Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. One adjustment is called the zero. The measuring error. Pressure Sensor Span Error.

From www.festo.com

Pressure sensor SPANV1RG18MPNPNL1 Festo USA Pressure Sensor Span Error On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. Install the sensor so that it cannot be heated. Three specific types of errors have a negative impact on pressure sensor accuracy. Mount the sensor so that no condensate from the compressed air lines can gather in the. Pressure Sensor Span Error.

From www.scribd.com

AN743 Approaches For Compensating Span and Offset in Pressure Sensors Pressure Sensor Span Error On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero. One adjustment is called the zero. Three specific types of errors have a negative impact on pressure sensor accuracy. Span. Pressure Sensor Span Error.

From www.eastsensor.com

Offset Error ZeroPoint Error Span Error Eastsensor Technology Pressure Sensor Span Error The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero. One adjustment is called the zero. Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. Three specific types of errors have a negative impact on pressure sensor accuracy. Span error refers to the. Pressure Sensor Span Error.

From www.stator.co.za

Pressure sensor SPAN Stator Pressure Sensor Span Error Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero. Learn about other terms related to. In order to eliminate the span error, the pressure must be regulated exactly at full scale value. Three. Pressure Sensor Span Error.

From www.youtube.com

What is the total error band of pressure sensors? Accuracy under Pressure Sensor Span Error Install the sensor so that it cannot be heated. The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero. On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. Three specific types of errors have a negative impact on pressure. Pressure Sensor Span Error.

From www.youtube.com

What is Span in Sensor YouTube Pressure Sensor Span Error Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. In order to eliminate the span error, the pressure must be regulated exactly at full scale value. Three specific types of errors have a negative impact on pressure sensor accuracy. Hysteresis is the maximum deviation between the output signals. Pressure Sensor Span Error.

From gahess.com

Pressure Transducer Sensor How it works (2022) Pressure Sensor Span Error The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero. Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. Three specific types of errors have a negative impact on pressure sensor accuracy. In order to eliminate the span error, the. Pressure Sensor Span Error.

From www.eastsensor.com

Span Error of Pressure Sensor Eastsensor Technology Pressure Sensor Span Error In order to eliminate the span error, the pressure must be regulated exactly at full scale value. Three specific types of errors have a negative impact on pressure sensor accuracy. Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. The measuring error includes all relevant errors at a. Pressure Sensor Span Error.

From www.eastsensor.com

Pressure Measurement Errors Eastsensor Technology Pressure Sensor Span Error Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. In order to eliminate the span error, the pressure must be regulated exactly at full scale value. Mount the sensor so that no condensate from the compressed air lines can gather in the device. Span error refers to the deviation of a. Pressure Sensor Span Error.

From appmeas.co.uk

What are Hysteresis Errors? Pressure Sensor Span Error On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. Mount the sensor so that no condensate from the compressed air lines can gather in the device. Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. The measuring error. Pressure Sensor Span Error.

From www.youtube.com

FESTO / Pressure Sensor (SPANP10RG18MPNLKPNVBAL1) / INV03106 Pressure Sensor Span Error One adjustment is called the zero. Learn about other terms related to. On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. Three specific types of errors have a negative impact on pressure sensor accuracy. In order to eliminate the span error, the pressure must be regulated exactly. Pressure Sensor Span Error.

From www.festo.com

Pressure sensor SPANP10RR18MPNPNL1 Festo USA Pressure Sensor Span Error Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. In order to eliminate the span error, the pressure must be regulated exactly at full scale value. Install the sensor so. Pressure Sensor Span Error.

From www.youtube.com

How to Calibrate and Span a Pressure Transmitter YouTube Pressure Sensor Span Error Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. Learn about other terms related to. On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. In order to eliminate the span error, the pressure must be. Pressure Sensor Span Error.

From www.researchgate.net

Reference error diagram of pressure sensor Download Scientific Diagram Pressure Sensor Span Error Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. Install the sensor so that it cannot be heated. One adjustment is called the zero. Mount the sensor so that no condensate from the compressed air lines can gather in the device. In order to eliminate the span error, the pressure must. Pressure Sensor Span Error.

From www.youtube.com

Unboxing the new pressure sensor SPANB YouTube Pressure Sensor Span Error Learn about other terms related to. Mount the sensor so that no condensate from the compressed air lines can gather in the device. Install the sensor so that it cannot be heated. In order to eliminate the span error, the pressure must be regulated exactly at full scale value. The measuring error includes all relevant errors at a constant (reference). Pressure Sensor Span Error.

From www.basicairdata.eu

Introduction to Sensor Testing Pressure Sensor Span Error One adjustment is called the zero. In order to eliminate the span error, the pressure must be regulated exactly at full scale value. The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero. Learn about other terms related to. Mount the sensor so that no condensate from the compressed air lines can. Pressure Sensor Span Error.

From www.pinterest.co.uk

Checklist Pressure Transmitter 420mA Common Faults and Error Pressure Sensor Span Error One adjustment is called the zero. Learn about other terms related to. Mount the sensor so that no condensate from the compressed air lines can gather in the device. On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. Install the sensor so that it cannot be heated.. Pressure Sensor Span Error.

From www.tequipment.net

Pressure Calibration TEquipment Pressure Sensor Span Error Install the sensor so that it cannot be heated. Span error refers to the deviation of a pressure sensor’s actual output span from its specified ideal span, span error affects. Three specific types of errors have a negative impact on pressure sensor accuracy. Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing. Pressure Sensor Span Error.

From instrumentationtools.com

How to Decrease Span of Pressure Gauge? Pressure Sensor Span Error On the actual instrument (the pressure transmitter), there are two adjustments which let us match the instrument’s behavior to the ideal equation. In order to eliminate the span error, the pressure must be regulated exactly at full scale value. Mount the sensor so that no condensate from the compressed air lines can gather in the device. Three specific types of. Pressure Sensor Span Error.

From www.researchgate.net

Pressure estimation errors with respect to the real system using Pressure Sensor Span Error Mount the sensor so that no condensate from the compressed air lines can gather in the device. Learn about other terms related to. Three specific types of errors have a negative impact on pressure sensor accuracy. The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero. Hysteresis is the maximum deviation between. Pressure Sensor Span Error.

From www.eastsensor.com

Span Error of Pressure Sensor Eastsensor Technology Pressure Sensor Span Error Hysteresis is the maximum deviation between the output signals of a pressure sensor at increasing and decreasing pressure. The measuring error includes all relevant errors at a constant (reference) temperature, such as nonlinearity, hysteresis, nonrepeatability, zero. Mount the sensor so that no condensate from the compressed air lines can gather in the device. Three specific types of errors have a. Pressure Sensor Span Error.