How To Cut Chamfers On A Lathe . Chamfer milling operations made easy: Start by making an initial cut to define the edge of the chamfer. Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. The chamfering tool is held securely in the lathe. The cut is generally made at an angle, and the performing face is known as a chamfer. In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. One common method is using a chamfering tool, which is a cutting tool specifically designed for creating chamfers. How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. For wood, use a shallow angled.

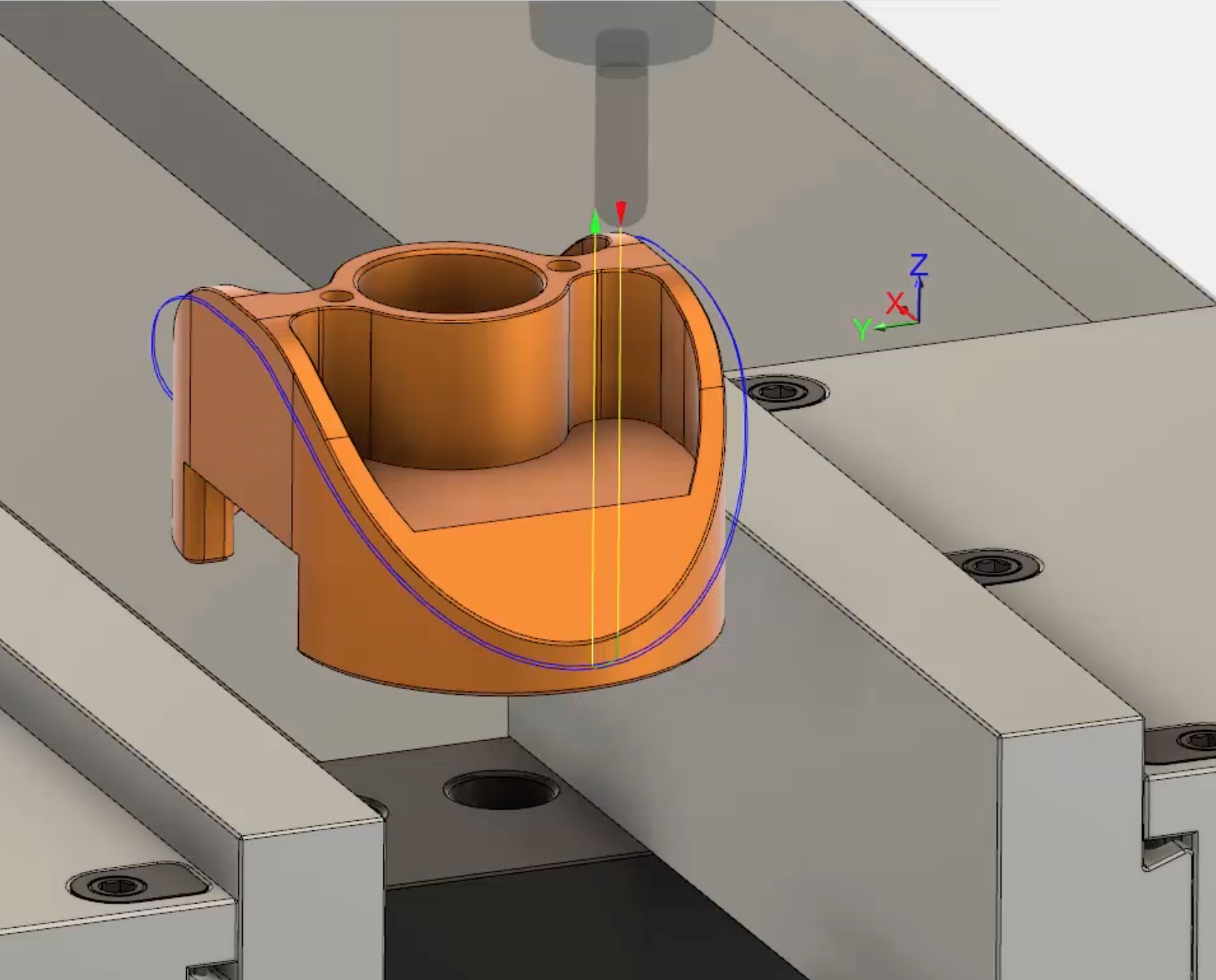

from www.autodesk.com

For wood, use a shallow angled. Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. Chamfer milling operations made easy: How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. One common method is using a chamfering tool, which is a cutting tool specifically designed for creating chamfers. The cut is generally made at an angle, and the performing face is known as a chamfer. The chamfering tool is held securely in the lathe. In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. Start by making an initial cut to define the edge of the chamfer.

QUICK TIP How to machine 3D chamfers Fusion Blog

How To Cut Chamfers On A Lathe Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. Chamfer milling operations made easy: One common method is using a chamfering tool, which is a cutting tool specifically designed for creating chamfers. Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. For wood, use a shallow angled. In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. The chamfering tool is held securely in the lathe. Start by making an initial cut to define the edge of the chamfer. The cut is generally made at an angle, and the performing face is known as a chamfer. How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection.

From www.dreamstime.com

The Multitasking CNC Lathe Machine Chamfer Cutting the Metal Shaft How To Cut Chamfers On A Lathe How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. The chamfering tool is held securely in the lathe. The cut is generally made at an angle, and the performing face is. How To Cut Chamfers On A Lathe.

From www.youtube.com

roughcut2022 Making A Universal Chamferring Tool For The Lathe YouTube How To Cut Chamfers On A Lathe The chamfering tool is held securely in the lathe. Start by making an initial cut to define the edge of the chamfer. In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of. How To Cut Chamfers On A Lathe.

From kmtools.com

How to Cut Even Chamfers with a Hand Plane (Quick Tip) KatzMoses Tools How To Cut Chamfers On A Lathe In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. For wood, use a shallow angled. The chamfering tool is held securely in the lathe. How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. With proper grinding, a thread relief can. How To Cut Chamfers On A Lathe.

From www.youtube.com

How To Cut Chamfers In Wood With a Hand Plane YouTube How To Cut Chamfers On A Lathe The chamfering tool is held securely in the lathe. Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. The cut is generally made at an angle, and the performing. How To Cut Chamfers On A Lathe.

From kmtools.com

How to Chamfer and Round Over Edges with 9 Different Tools KatzMoses How To Cut Chamfers On A Lathe In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. The chamfering tool is held securely in the lathe. One common method is using a chamfering tool, which is a cutting tool specifically designed for creating chamfers. How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including. How To Cut Chamfers On A Lathe.

From www.youtube.com

Lathe processes Chamfering YouTube How To Cut Chamfers On A Lathe The chamfering tool is held securely in the lathe. The cut is generally made at an angle, and the performing face is known as a chamfer. For wood, use a shallow angled. One common method is using a chamfering tool, which is a cutting tool specifically designed for creating chamfers. Start by making an initial cut to define the edge. How To Cut Chamfers On A Lathe.

From www.kitplanes.com

Chamfers and Tapers KITPLANES How To Cut Chamfers On A Lathe In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. How to chamfer on a lathe tool ensure you are wearing applicable safety gear,. How To Cut Chamfers On A Lathe.

From www.youtube.com

How to Make a 45 Degree Chamfer Tool for a Lathe, The Old School Way How To Cut Chamfers On A Lathe Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. The cut is generally made at an angle, and the performing face is known as a chamfer. With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the. How To Cut Chamfers On A Lathe.

From www.youtube.com

Chamfering operation on lathe machine with tool settings chamfering on How To Cut Chamfers On A Lathe One common method is using a chamfering tool, which is a cutting tool specifically designed for creating chamfers. Start by making an initial cut to define the edge of the chamfer. In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. With proper grinding, a thread relief can be cut in a. How To Cut Chamfers On A Lathe.

From www.youtube.com

Chamfering YouTube How To Cut Chamfers On A Lathe Chamfer milling operations made easy: The cut is generally made at an angle, and the performing face is known as a chamfer. With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. Start by making an initial cut to define the edge. How To Cut Chamfers On A Lathe.

From shuntool.com

Mastering Precision Cuts How To Create Chamfers With Your Table Saw How To Cut Chamfers On A Lathe Start by making an initial cut to define the edge of the chamfer. Chamfer milling operations made easy: How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer.. How To Cut Chamfers On A Lathe.

From www.youtube.com

How To Cut Chamfers By Hand YouTube How To Cut Chamfers On A Lathe The cut is generally made at an angle, and the performing face is known as a chamfer. In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. Start by making an initial cut to define the edge of the chamfer. One common method is using a chamfering tool, which is a cutting. How To Cut Chamfers On A Lathe.

From www.emag.com

ChamferCut process for Precise Chamfers on Gearwheels. How To Cut Chamfers On A Lathe Start by making an initial cut to define the edge of the chamfer. How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. The cut is generally made at an angle, and the performing face is known as a chamfer. Chamfer milling operations made easy: With proper grinding, a thread. How To Cut Chamfers On A Lathe.

From www.autodesk.com

QUICK TIP How to machine 3D chamfers Fusion Blog How To Cut Chamfers On A Lathe Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. How to chamfer on a lathe tool ensure you are. How To Cut Chamfers On A Lathe.

From www.albanycountyfasteners.com

How To Properly Cut, Deburr and Chamfer Threaded Rod How To Cut Chamfers On A Lathe How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. For wood, use a shallow angled. The chamfering tool is held securely in the lathe. Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. The cut is. How To Cut Chamfers On A Lathe.

From kmtools.com

How to Chamfer and Round Over Edges with 9 Different Tools KatzMoses How To Cut Chamfers On A Lathe The cut is generally made at an angle, and the performing face is known as a chamfer. Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. How to chamfer. How To Cut Chamfers On A Lathe.

From www.dreamstime.com

The Lathe Machine Finish Cut the Brass Parts by Lathe Tools Stock Image How To Cut Chamfers On A Lathe Chamfer milling operations made easy: With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. How to chamfer on a lathe tool ensure you. How To Cut Chamfers On A Lathe.

From www.kitplanes.com

Chamfers and Tapers KITPLANES How To Cut Chamfers On A Lathe The chamfering tool is held securely in the lathe. Start by making an initial cut to define the edge of the chamfer. The cut is generally made at an angle, and the performing face is known as a chamfer. How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. For. How To Cut Chamfers On A Lathe.

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics How To Cut Chamfers On A Lathe Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. For wood, use a shallow angled. Chamfer milling operations made easy: How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. The cut is generally made at an. How To Cut Chamfers On A Lathe.

From www.youtube.com

Introduction to Chamfering & Deburring Operations Using a Lathe Machine How To Cut Chamfers On A Lathe How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. For wood, use a shallow angled. The cut is generally made at an angle, and the performing face is known as a chamfer. One common method is using a chamfering tool, which is a cutting tool specifically designed for creating. How To Cut Chamfers On A Lathe.

From www.youtube.com

How To Make Chamfer Cut On Workpiece In Lathe Machine Lathe Machine How To Cut Chamfers On A Lathe The chamfering tool is held securely in the lathe. Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. Start by making an initial cut to define the. How To Cut Chamfers On A Lathe.

From craftwithlathes.com

How to chamfer on a lathe Using Different Steps and Tools How To Cut Chamfers On A Lathe The chamfering tool is held securely in the lathe. Chamfer milling operations made easy: Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. One common method is using a chamfering tool, which is a cutting tool specifically designed for creating chamfers. In this video, we will demonstrate. How To Cut Chamfers On A Lathe.

From www.dreamstime.com

The Multitasking CNC Lathe Machine Chamfer Cut the Metal Shaft Parts How To Cut Chamfers On A Lathe Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. The cut is generally made at an angle, and the. How To Cut Chamfers On A Lathe.

From kmtools.com

How to Cut Even Chamfers with a Hand Plane (Quick Tip) KatzMoses Tools How To Cut Chamfers On A Lathe Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. The cut is generally made at an angle, and the performing face is known as a chamfer. Start by making an initial cut to define the edge of the chamfer. The chamfering tool is held securely in the. How To Cut Chamfers On A Lathe.

From www.cnccookbook.com

Easy Guide to Chamfer Mills, Cutters & Router Bits [ Feeds/Speeds, and How To Cut Chamfers On A Lathe Chamfer milling operations made easy: In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. One common method is using a chamfering tool, which is a cutting tool specifically designed for creating chamfers. For wood, use a shallow angled. With proper grinding, a thread relief can be cut in a single operation. How To Cut Chamfers On A Lathe.

From www.youtube.com

Mastercam Tip Chamfer any angle with a 45° Chamfering Tool YouTube How To Cut Chamfers On A Lathe Start by making an initial cut to define the edge of the chamfer. One common method is using a chamfering tool, which is a cutting tool specifically designed for creating chamfers. Chamfer milling operations made easy: In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. With proper grinding, a thread relief. How To Cut Chamfers On A Lathe.

From www.youtube.com

The Facing, boring chamfering and turning by Nine9 cutting tool on CNC How To Cut Chamfers On A Lathe For wood, use a shallow angled. Chamfer milling operations made easy: The cut is generally made at an angle, and the performing face is known as a chamfer. With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. Dimensioning chamfers is done. How To Cut Chamfers On A Lathe.

From fractory.com

CNC Milling a Complete Guide to Understand the Process How To Cut Chamfers On A Lathe The chamfering tool is held securely in the lathe. How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. Chamfer milling operations made easy: Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. In this video, we. How To Cut Chamfers On A Lathe.

From www.youtube.com

Cutting chamfers Howto. YouTube How To Cut Chamfers On A Lathe In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. One common method is using a chamfering tool, which is a cutting tool specifically designed for creating chamfers. How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. For wood, use a. How To Cut Chamfers On A Lathe.

From shuntool.com

Mastering The Art Of Creating Chamfers On A Lathe A StepByStep Guide How To Cut Chamfers On A Lathe For wood, use a shallow angled. Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. In this video, we. How To Cut Chamfers On A Lathe.

From www.syil.com

StepbyStep Guide How to Program a Chamfer on a CNC L... How To Cut Chamfers On A Lathe Chamfer milling operations made easy: With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. The chamfering tool is held securely in the lathe. In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine.. How To Cut Chamfers On A Lathe.

From www.youtube.com

Lathe set up to cut 30 Degree chamfer or 60 degree included angle YouTube How To Cut Chamfers On A Lathe Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. One common method is using a chamfering tool, which is. How To Cut Chamfers On A Lathe.

From www.autodesk.com

QUICK TIP How to machine 3D chamfers Fusion Blog How To Cut Chamfers On A Lathe For wood, use a shallow angled. Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. The cut is generally made at an angle, and the performing face is known as a chamfer. One common method is using a chamfering tool, which is a cutting tool specifically designed. How To Cut Chamfers On A Lathe.

From www.kitplanes.com

Chamfers and Tapers KITPLANES How To Cut Chamfers On A Lathe For wood, use a shallow angled. How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. In this video, we will demonstrate how to make chamfer cuts on a workpiece using a lathe machine. Chamfer milling operations made easy: With proper grinding, a thread relief can be cut in a. How To Cut Chamfers On A Lathe.

From rsvautomotive.co.uk

chamfering Tool makes It a Workhorse Facing New Lathe 45 Degree Turning How To Cut Chamfers On A Lathe With proper grinding, a thread relief can be cut in a single operation if the left edge is square to the axis of the work, and the right. How to chamfer on a lathe tool ensure you are wearing applicable safety gear, including safety specs and hearing protection. Chamfer milling operations made easy: In this video, we will demonstrate how. How To Cut Chamfers On A Lathe.