Turning Insert Lead Angle . learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. function of tool features for turning. The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. How does the material being machined affect insert selection? learn how to choose the correct cnc turning insert shape for different operations, such as turning, facing, boring and profiling. learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity.

from www.mscdirect.com

How does the material being machined affect insert selection? The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. function of tool features for turning. learn how to choose the correct cnc turning insert shape for different operations, such as turning, facing, boring and profiling. a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life.

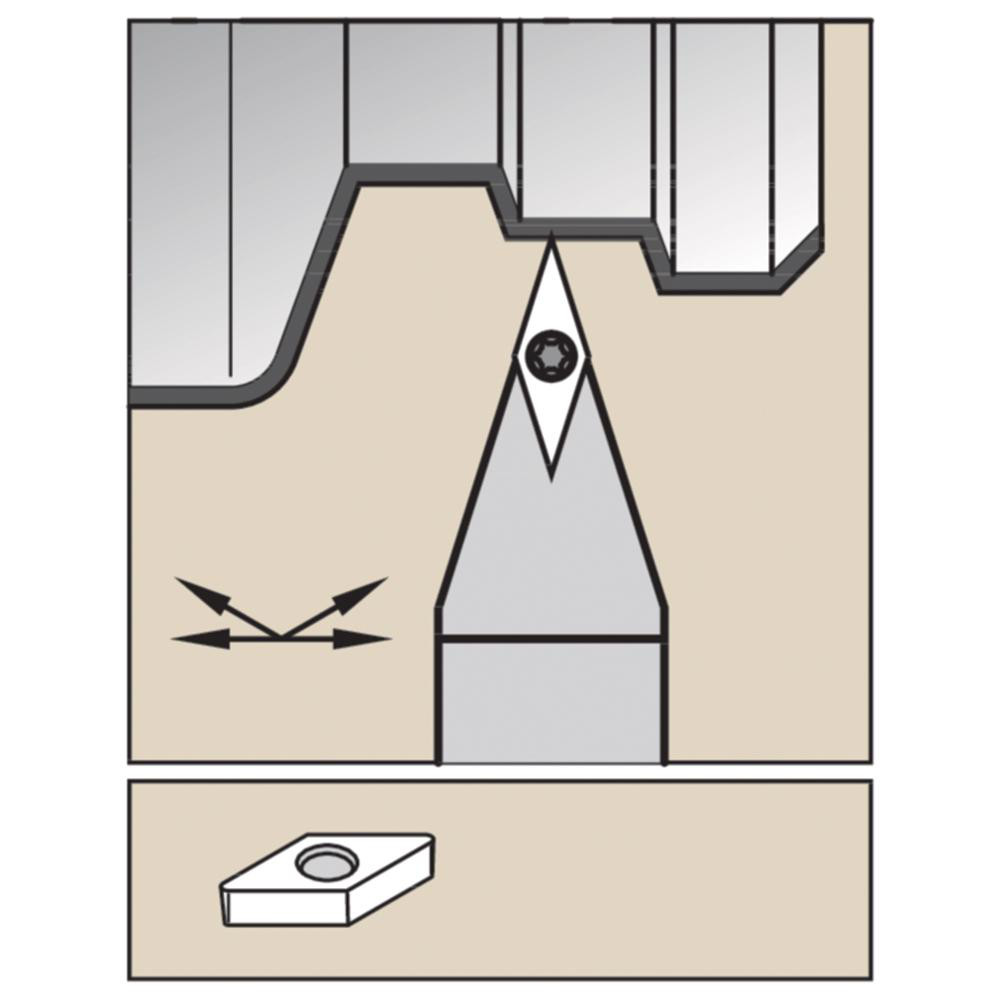

Widia Indexable Turning Toolholder SVVBN2020K16, 72.500 deg Lead

Turning Insert Lead Angle learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. function of tool features for turning. learn how to choose the correct cnc turning insert shape for different operations, such as turning, facing, boring and profiling. learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. How does the material being machined affect insert selection?

From www.mscdirect.com

Arno Indexable Turning Toolholder SDACL 1616 E11IKAFC, 0.500 deg Turning Insert Lead Angle How does the material being machined affect insert selection? learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. learn how to choose the correct cnc turning insert shape for different operations, such as turning, facing, boring and profiling. when selecting a turning insert, it's important to consider. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder TZXNN203.3DTB Turning Insert Lead Angle a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. How does the material being machined affect insert selection? when selecting a turning insert, it's important to consider insert geometry, grade, shape, size,. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder TMS20HSVUBL11 Turning Insert Lead Angle learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. function of tool features for turning. a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. learn how to choose the best lead angle for your turning operations to prevent tool failure and. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder TXJNR163.5D Turning Insert Lead Angle when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. The side cutting edge angle reduces impact load and effects the amount of feed force,. Turning Insert Lead Angle.

From www.mscdirect.com

Tungaloy Indexable Turning Toolholder ASDNN124A, 45 ° Lead Angle Turning Insert Lead Angle learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. function of tool features for turning. The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. learn how to choose the correct cnc turning insert shape for different operations, such as. Turning Insert Lead Angle.

From www.fowkes.co.za

INSERT KNUX 160405 R11 IC 9025 TURNING INSERT Fowkes Bros Turning Insert Lead Angle How does the material being machined affect insert selection? when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. learn how the. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder TCLNL1633D, 95 Turning Insert Lead Angle How does the material being machined affect insert selection? function of tool features for turning. learn how to choose the correct cnc turning insert shape for different operations, such as turning, facing, boring and profiling. learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. when selecting a turning. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder HSDNN1655D, 45 Turning Insert Lead Angle learn how to choose the correct cnc turning insert shape for different operations, such as turning, facing, boring and profiling. a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. How does the material. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder HVVNN162.53D Turning Insert Lead Angle How does the material being machined affect insert selection? learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. The side cutting edge angle reduces impact load and effects the amount of. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder HWLNL1033A, 95 Turning Insert Lead Angle The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. function of tool features for turning. a comprehensive guide to turning operations, with tips and recommendations for different conditions,. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder TCRNR1633DTB Turning Insert Lead Angle The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. function of tool. Turning Insert Lead Angle.

From www.slideserve.com

PPT CHAPTER 23 PowerPoint Presentation, free download ID1275516 Turning Insert Lead Angle learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. How does the material being machined affect insert selection? The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. learn how the lead angle of a facemill affects the cutting. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder HCLNL1655D, 95 Turning Insert Lead Angle when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. learn how to choose the correct cnc turning insert shape for different operations, such. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder BCLCR1212K06SH Turning Insert Lead Angle function of tool features for turning. learn how to choose the correct cnc turning insert shape for different operations, such as turning, facing, boring and profiling. when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. a comprehensive guide to. Turning Insert Lead Angle.

From www.mscdirect.com

Widia Indexable Turning Toolholder PWLNR1616H06, 95.000 deg Lead Turning Insert Lead Angle How does the material being machined affect insert selection? learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. The side cutting edge. Turning Insert Lead Angle.

From www.mscdirect.com

Widia Indexable Turning Toolholder SVJBR123, 93 ° Lead Angle, Screw Turning Insert Lead Angle when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. learn how the lead angle of a facemill affects the cutting forces, chip. Turning Insert Lead Angle.

From www.mscdirect.com

Accupro 1/2 x 1/2" Shank, Lead Angle Turning Single Point Tool Bit Turning Insert Lead Angle learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. function of tool features for turning. a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. The side cutting edge angle reduces impact load and effects the amount of feed force, back. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder HSDNN1633D, 45 Turning Insert Lead Angle learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. How does the material being machined affect insert selection? The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. function of tool features for turning. when selecting a turning. Turning Insert Lead Angle.

From huanatools.com

Positive Angle Inserts VS Negative Angle Inserts Huana Tools Turning Insert Lead Angle learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. function of tool features for turning. How does the material being machined affect insert selection? The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. learn how the lead. Turning Insert Lead Angle.

From www.ukocarbide.com

How to choose a suitable corner radius for CNC turning inserts? Turning Insert Lead Angle function of tool features for turning. learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. The side cutting edge angle reduces. Turning Insert Lead Angle.

From www.manufacturingguide.com

Turning tool angles Find suppliers, processes & material Turning Insert Lead Angle learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. How does the material being. Turning Insert Lead Angle.

From www.mcctcarbide.com

How to choose the turning insert angle Meetyou Carbide Cutting Tool Turning Insert Lead Angle learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. function of tool features for. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder HSKNR1633D, 75 Turning Insert Lead Angle a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. learn how to choose the correct cnc turning insert shape for different operations, such as turning, facing, boring and profiling. learn. Turning Insert Lead Angle.

From shopmetaltech.com

Positive lead angle tooling increases metal removal rates and extends Turning Insert Lead Angle How does the material being machined affect insert selection? learn how to choose the correct cnc turning insert shape for different operations, such as turning, facing, boring and profiling. The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. a comprehensive guide to turning operations, with tips and recommendations. Turning Insert Lead Angle.

From www.hoffmann-group.com

Simply buy PTGNL 2020K16X 91° Lead Angle Lever Lock External Turning Turning Insert Lead Angle The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. a comprehensive. Turning Insert Lead Angle.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Turning Toolholder HTFNL122.53B Turning Insert Lead Angle when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. How does the material being machined affect insert selection? The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. learn how to choose. Turning Insert Lead Angle.

From www.machinemfg.com

Lathe Cutting Tool Angles Selection Principle MachineMFG Turning Insert Lead Angle The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. learn how the lead angle of a facemill affects the cutting forces, chip. Turning Insert Lead Angle.

From www.mscdirect.com

Sandvik Coromant DDJNL, Left Hand Cut, 3° Lead Angle, 11/4" Shank Turning Insert Lead Angle a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. function of tool features for. Turning Insert Lead Angle.

From www.fowkes.co.za

INSERT KNUX 160405 L11 IC 9025 TURNING INSERT Fowkes Bros Turning Insert Lead Angle The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. learn how to choose the correct cnc turning insert shape for different operations, such as turning, facing, boring and profiling. learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. when. Turning Insert Lead Angle.

From www.machiningdoctor.com

Lead Angle (Threads) Machining Doctor Turning Insert Lead Angle learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. learn how to choose the best lead angle for your turning operations to prevent tool failure and improve productivity. learn how to choose the correct cnc turning insert shape for different operations, such as turning, facing, boring and profiling. . Turning Insert Lead Angle.

From www.mscdirect.com

Widia Indexable Turning Toolholder SVVBN2020K16, 72.500 deg Lead Turning Insert Lead Angle when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. learn how the lead angle of a facemill affects the cutting forces, chip. Turning Insert Lead Angle.

From www.mmc-carbide.com

Rake Angle Technical Info / Cutting Formula MITSUBISHI MATERIALS Turning Insert Lead Angle a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. function of tool features for turning. learn how to choose the best lead angle for your turning operations to prevent tool failure. Turning Insert Lead Angle.

From www.machiningdoctor.com

Lead Angle (Threads) Machining Doctor Turning Insert Lead Angle a comprehensive guide to turning operations, with tips and recommendations for different conditions, materials and inserts. function of tool features for turning. The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius,. Turning Insert Lead Angle.

From www.mscdirect.com

Kennametal Indexable Turning Toolholder FIX8PCJNL166DC, 93 ° Lead Turning Insert Lead Angle learn how to choose the correct cnc turning insert shape for different operations, such as turning, facing, boring and profiling. The side cutting edge angle reduces impact load and effects the amount of feed force, back force and chip. How does the material being machined affect insert selection? learn how the lead angle of a facemill affects the. Turning Insert Lead Angle.

From www.hoffmann-group.com

Simply buy PTGNL 2020K16X 91° Lead Angle Lever Lock External Turning Turning Insert Lead Angle learn how the lead angle of a facemill affects the cutting forces, chip thinning and part quality. How does the material being machined affect insert selection? when selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life. learn how to choose the. Turning Insert Lead Angle.