Non Contact Liquid Level Sensor Working Principle . Prevent overflows and leaks, reducing accident risks. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Unparalleled precision and reliability, independent of surface. If the frequency is dampened, the. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Improve process efficiency, leading to reduced waste and lower operational costs. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Benefits of liquid level sensors. Non contact design eliminates the requirement of material compatibility between.

from www.tek-trol.com

Non contact design eliminates the requirement of material compatibility between. Benefits of liquid level sensors. Prevent overflows and leaks, reducing accident risks. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Improve process efficiency, leading to reduced waste and lower operational costs. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. If the frequency is dampened, the. Unparalleled precision and reliability, independent of surface.

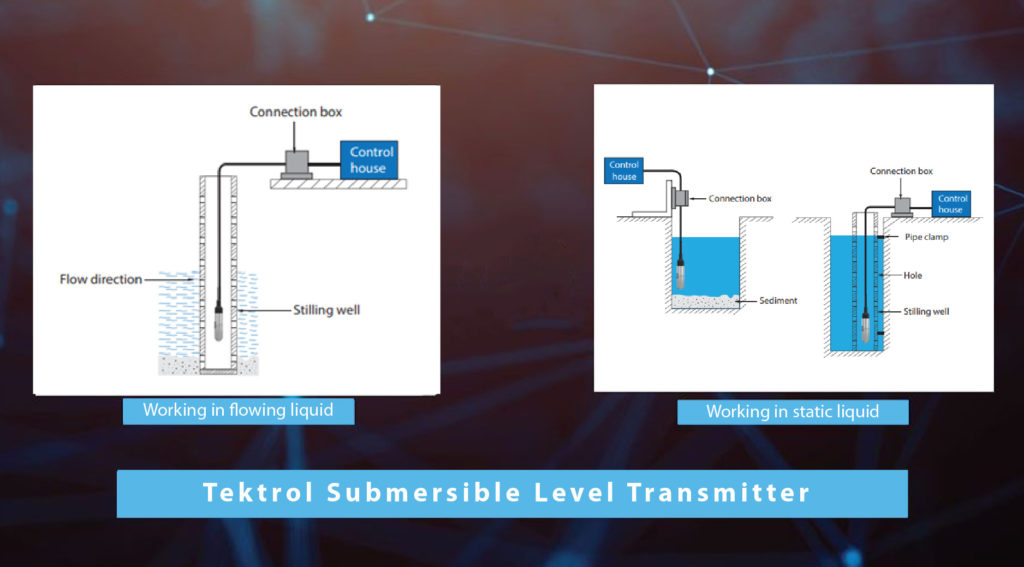

How Do Submersible Liquid Level Sensors Work? TekTrol Technology

Non Contact Liquid Level Sensor Working Principle Non contact design eliminates the requirement of material compatibility between. Non contact design eliminates the requirement of material compatibility between. Improve process efficiency, leading to reduced waste and lower operational costs. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Prevent overflows and leaks, reducing accident risks. Benefits of liquid level sensors. Unparalleled precision and reliability, independent of surface. If the frequency is dampened, the.

From www.keyestudio.com

Keyestudio Noncontact Liquid Level Sensor(Black and Friendly) Non Contact Liquid Level Sensor Working Principle Non contact design eliminates the requirement of material compatibility between. If the frequency is dampened, the. Unparalleled precision and reliability, independent of surface. Benefits of liquid level sensors. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at. Non Contact Liquid Level Sensor Working Principle.

From www.nandantechnicals.com

Level sensor working principle and applications Non Contact Liquid Level Sensor Working Principle Improve process efficiency, leading to reduced waste and lower operational costs. Unparalleled precision and reliability, independent of surface. If the frequency is dampened, the. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Benefits of liquid level sensors. Non. Non Contact Liquid Level Sensor Working Principle.

From www.dfrobot.com

Gravity Noncontact Capacitive Flexible Liquid Level Sensor(5V) DFRobot Non Contact Liquid Level Sensor Working Principle Benefits of liquid level sensors. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Improve. Non Contact Liquid Level Sensor Working Principle.

From www.renkeer.com

Water Level Sensor What, How, Where, Benefits, Types Renke Non Contact Liquid Level Sensor Working Principle Unparalleled precision and reliability, independent of surface. Improve process efficiency, leading to reduced waste and lower operational costs. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Prevent. Non Contact Liquid Level Sensor Working Principle.

From www.abestmeter.com

Top 5 Types of Non Contact Level Sensor Measurement Non Contact Liquid Level Sensor Working Principle Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. If the frequency is dampened, the. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Unparalleled precision and reliability, independent of surface. Non contact design eliminates the requirement. Non Contact Liquid Level Sensor Working Principle.

From www.tek-trol.com

How Do Submersible Liquid Level Sensors Work? TekTrol Technology Non Contact Liquid Level Sensor Working Principle Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. If the frequency is dampened, the. Benefits of liquid level sensors. Unparalleled precision and reliability, independent of surface. Non contact level sensors for liquids are an efficient method to measure. Non Contact Liquid Level Sensor Working Principle.

From www.mdpi.com

Sensors Free FullText Design and Implementation of an Non Contact Liquid Level Sensor Working Principle Non contact design eliminates the requirement of material compatibility between. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Benefits of liquid level sensors. Unparalleled precision and reliability, independent of surface. Improve process efficiency, leading to reduced waste and lower operational costs. Level sensors use one of several principles to detect the. Non Contact Liquid Level Sensor Working Principle.

From www.vrogue.co

Liquid Level Sensor Module Water Level Supporting Sou vrogue.co Non Contact Liquid Level Sensor Working Principle Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Non contact design eliminates the requirement of material compatibility between. Improve process efficiency,. Non Contact Liquid Level Sensor Working Principle.

From www.mgsuperlabs.in

Noncontact Capacitive Liquid Level Sensor MG Super Labs Non Contact Liquid Level Sensor Working Principle Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Unparalleled precision and reliability, independent of. Non Contact Liquid Level Sensor Working Principle.

From circuitdigest.com

Arduino Water Level Sensor Tutorial How Water Level Sensor Works and Non Contact Liquid Level Sensor Working Principle Prevent overflows and leaks, reducing accident risks. Benefits of liquid level sensors. Unparalleled precision and reliability, independent of surface. Improve process efficiency, leading to reduced waste and lower operational costs. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication.. Non Contact Liquid Level Sensor Working Principle.

From www.icstation.com

XKCY25NPN NonContact Liquid Level Sensor IP67 Waterproof DC 512V Non Contact Liquid Level Sensor Working Principle Improve process efficiency, leading to reduced waste and lower operational costs. Non contact design eliminates the requirement of material compatibility between. If the frequency is dampened, the. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Non contact level. Non Contact Liquid Level Sensor Working Principle.

From www.trumsense.com

Water level sensor switch noncontact liquid level sensor small tube Non Contact Liquid Level Sensor Working Principle Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Level sensors use one of several principles to detect the level of liquid in a container and convert the. Non Contact Liquid Level Sensor Working Principle.

From www.mondaykids.com

Monday Kids Noncontact Liquid Level Detection Sensor Water Level Non Contact Liquid Level Sensor Working Principle If the frequency is dampened, the. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Benefits of liquid level sensors. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Improve process efficiency, leading to reduced waste and. Non Contact Liquid Level Sensor Working Principle.

From www.robo-tank.ca

NonContact Liquid Level Water Sensor XKCY25V Arduino Compatible Non Contact Liquid Level Sensor Working Principle Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Improve process efficiency, leading to reduced waste and lower operational costs. Vibrating or. Non Contact Liquid Level Sensor Working Principle.

From topelectronics.gr

Gravity Noncontact Digital Water / Liquid Level Sensor For Arduino Non Contact Liquid Level Sensor Working Principle Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Benefits of liquid level sensors. Prevent overflows and leaks, reducing accident risks. If the frequency is dampened, the. Level sensors use one of several principles to detect the level of liquid in a container and convert. Non Contact Liquid Level Sensor Working Principle.

From www.flo-corp.com

GWR vs NonContact radar level transmitter FLOCORP Non Contact Liquid Level Sensor Working Principle Benefits of liquid level sensors. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. If the frequency is dampened, the. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a. Non Contact Liquid Level Sensor Working Principle.

From www.fluidswitch.com

How Do Optical Level Sensors Work? SMD Fluid Controls Non Contact Liquid Level Sensor Working Principle Prevent overflows and leaks, reducing accident risks. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Non contact design eliminates the requirement of material compatibility between. Benefits of liquid level sensors. Vibrating or ultrasonic level switches work under the. Non Contact Liquid Level Sensor Working Principle.

From www.bestdealplus.com

Non Contact Liquid Level Sensor Contactless Water Tank Water Level Non Contact Liquid Level Sensor Working Principle Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Unparalleled precision and reliability, independent of surface. Improve process efficiency, leading to reduced waste and lower operational costs. If the frequency is dampened, the. Non contact design eliminates the requirement of material compatibility between. Level sensors. Non Contact Liquid Level Sensor Working Principle.

From www.drurylandetheatre.com

How does a capacitive liquid level sensor work? SinoInst Non Contact Liquid Level Sensor Working Principle If the frequency is dampened, the. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Unparalleled precision and reliability, independent of surface. Prevent overflows and leaks, reducing accident risks. Non contact design eliminates the requirement of material compatibility between.. Non Contact Liquid Level Sensor Working Principle.

From www.youtube.com

Radar Level Sensor Working Principle Guided Wave & Non Contact Level Non Contact Liquid Level Sensor Working Principle Unparalleled precision and reliability, independent of surface. Benefits of liquid level sensors. Prevent overflows and leaks, reducing accident risks. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Improve process efficiency, leading to reduced waste and lower operational costs.. Non Contact Liquid Level Sensor Working Principle.

From www.youtube.com

how non contact liquid level sensor work YouTube Non Contact Liquid Level Sensor Working Principle Unparalleled precision and reliability, independent of surface. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local. Non Contact Liquid Level Sensor Working Principle.

From www.drurylandetheatre.com

Industrial Non Contact Liquid Level SensorsTanksopen channels Non Contact Liquid Level Sensor Working Principle Unparalleled precision and reliability, independent of surface. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Benefits of liquid level sensors. Prevent overflows and leaks, reducing accident risks. If the frequency is dampened, the. Level sensors use one of several principles to detect the level. Non Contact Liquid Level Sensor Working Principle.

From www.circuits-diy.com

XKCY26V NonContact Liquid Level Sensor with Arduino Non Contact Liquid Level Sensor Working Principle Unparalleled precision and reliability, independent of surface. Benefits of liquid level sensors. Non contact design eliminates the requirement of material compatibility between. Improve process efficiency, leading to reduced waste and lower operational costs. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Prevent overflows and leaks, reducing accident risks. Level sensors use. Non Contact Liquid Level Sensor Working Principle.

From instrumentationtools.com

Capacitance Level Sensor Principle, Limitations, Installation & Calibration Non Contact Liquid Level Sensor Working Principle Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Non contact design eliminates the requirement of material compatibility between. Improve process efficiency, leading to reduced waste and lower operational costs. If the frequency is dampened, the. Level sensors use one of several principles to detect. Non Contact Liquid Level Sensor Working Principle.

From www.robo-tank.ca

NonContact Liquid Level Water Sensor XKCY25V Arduino Compatible Non Contact Liquid Level Sensor Working Principle Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Improve process efficiency, leading to reduced waste and lower operational costs. Benefits of liquid level sensors. If the frequency is dampened, the. Non contact design eliminates the requirement of material. Non Contact Liquid Level Sensor Working Principle.

From wiki.dfrobot.com

Noncontact Capacitive Liquid Level Sensor Arduino Wiki DFRobot Non Contact Liquid Level Sensor Working Principle Prevent overflows and leaks, reducing accident risks. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local. Non Contact Liquid Level Sensor Working Principle.

From www.analog.com

Liquid Level Sensing Using CapacitivetoDigital Converters Analog Non Contact Liquid Level Sensor Working Principle Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Unparalleled precision and reliability, independent of surface. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Prevent overflows and leaks, reducing accident. Non Contact Liquid Level Sensor Working Principle.

From www.aliexpress.com

XKCY25 Liquid Sensing Switch Water Level Detection Noncontact Liquid Non Contact Liquid Level Sensor Working Principle Benefits of liquid level sensors. Non contact design eliminates the requirement of material compatibility between. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. If the frequency is dampened, the. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical. Non Contact Liquid Level Sensor Working Principle.

From electropeak.com

Interfacing XKCY26V Noncontact Liquid Level Sensor with Arduino Non Contact Liquid Level Sensor Working Principle Benefits of liquid level sensors. Prevent overflows and leaks, reducing accident risks. Non contact design eliminates the requirement of material compatibility between. Improve process efficiency, leading to reduced waste and lower operational costs. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement. Non Contact Liquid Level Sensor Working Principle.

From www.dfrobot.com

Noncontact Capacitive Liquid Level Sensor for container OD>11mm (512V Non Contact Liquid Level Sensor Working Principle Unparalleled precision and reliability, independent of surface. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Prevent overflows and leaks, reducing accident risks. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its. Non Contact Liquid Level Sensor Working Principle.

From www.walmart.ca

0.5 1A NonContact Liquid Level Sensor 10 + 85 Degrees Celsius Non Contact Liquid Level Sensor Working Principle Improve process efficiency, leading to reduced waste and lower operational costs. If the frequency is dampened, the. Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Benefits of liquid level sensors. Prevent overflows and leaks, reducing accident risks. Non. Non Contact Liquid Level Sensor Working Principle.

From www.amazon.com

Taidacent Non Contact Liquid Level Sensor Contactless Water Non Contact Liquid Level Sensor Working Principle Level sensors use one of several principles to detect the level of liquid in a container and convert the measurement to electrical signals or a mechanical movement for local indication. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Non contact design eliminates the requirement of material compatibility between. Vibrating or ultrasonic. Non Contact Liquid Level Sensor Working Principle.

From lpgtanklevelsensor.blogspot.com

liquid level sensor for LPG tank level measuring non contact liquid Non Contact Liquid Level Sensor Working Principle Prevent overflows and leaks, reducing accident risks. Improve process efficiency, leading to reduced waste and lower operational costs. Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. If the frequency is dampened, the. Benefits of liquid level sensors. Non contact design eliminates the requirement of. Non Contact Liquid Level Sensor Working Principle.

From www.icstation.com

XKCY25NPN NonContact Liquid Level Sensor IP67 Waterproof DC 512V Non Contact Liquid Level Sensor Working Principle Improve process efficiency, leading to reduced waste and lower operational costs. Non contact design eliminates the requirement of material compatibility between. If the frequency is dampened, the. Non contact level sensors for liquids are an efficient method to measure tank level for several reasons. Prevent overflows and leaks, reducing accident risks. Unparalleled precision and reliability, independent of surface. Benefits of. Non Contact Liquid Level Sensor Working Principle.