Solder Joint Graping . Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. It’s called “graping” because it looks like a bunch of. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. Solder graping is the incomplete coalescence of solder powder into a solder joint. The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. There are cost implications to this approach as well as an increase in tombstoning of passive components.

from joiaapsxb.blob.core.windows.net

The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. Solder graping is the incomplete coalescence of solder powder into a solder joint. There are cost implications to this approach as well as an increase in tombstoning of passive components. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. It’s called “graping” because it looks like a bunch of. The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,.

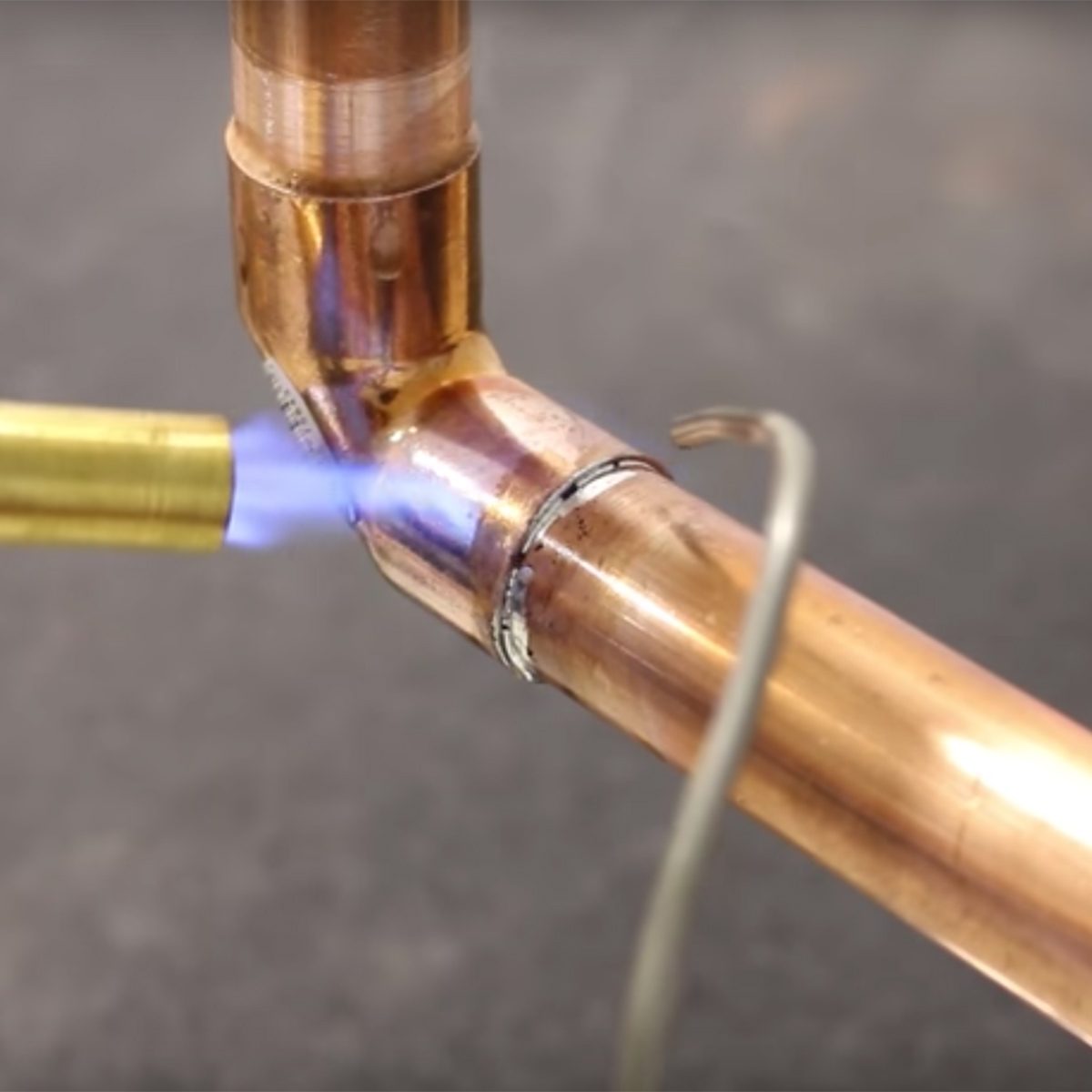

How To Solder A Copper Pipe Fitting at Ira Ericson blog

Solder Joint Graping In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. Solder graping is the incomplete coalescence of solder powder into a solder joint. Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. It’s called “graping” because it looks like a bunch of. There are cost implications to this approach as well as an increase in tombstoning of passive components.

From www.youtube.com

How To Get The Perfect Soldering Joint YouTube Solder Joint Graping The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. There. Solder Joint Graping.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The Solder Joint Graping It’s called “graping” because it looks like a bunch of. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. Solder graping is the incomplete coalescence of solder powder into a. Solder Joint Graping.

From fctsolder.com

F2A printed graping 2 Solder Paste, Solder Flux FCT Solder Solder Joint Graping Solder graping is the incomplete coalescence of solder powder into a solder joint. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. The. Solder Joint Graping.

From www.ept.ca

Soldering defects and atmosphere explained Electronic Products Solder Joint Graping The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. It’s called “graping” because it looks like a bunch of. Typically, a reflow profile is. Solder Joint Graping.

From www.dreamstime.com

Technician Bonding Two Wires with a Solder Joint. Stock Photo Image Solder Joint Graping Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. Solder graping is the incomplete coalescence of solder powder into a solder joint. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. To reduce the graping effect, it is vital. Solder Joint Graping.

From www.engineerlive.com

How To Perfect Your Solder Joint Formation Engineer Live Solder Joint Graping In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. There are cost implications to this approach as well as an increase in tombstoning of passive components.. Solder Joint Graping.

From www.circuitbasics.com

Tips for Good Soldering Technique Circuit Basics Solder Joint Graping In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. Solder graping is the incomplete coalescence of solder powder into a solder joint. To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to. Solder Joint Graping.

From www.youtube.com

How to Solder Properly 5 Soldering Joint Splices YouTube Solder Joint Graping There are cost implications to this approach as well as an increase in tombstoning of passive components. To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. Solder graping is the incomplete coalescence of solder powder into a solder joint. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces. Solder Joint Graping.

From exoffjmgy.blob.core.windows.net

Solder Paste Graping at Janice Marcus blog Solder Joint Graping Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. It’s called “graping” because it looks like a bunch of. There are cost implications to this approach as well as an increase in. Solder Joint Graping.

From pcbassemblymanufacturing.com

Solder joint one basic lesson about PCB soldering Solder Joint Graping It’s called “graping” because it looks like a bunch of. There are cost implications to this approach as well as an increase in tombstoning of passive components. Solder graping is the incomplete coalescence of solder powder into a solder joint. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste. Solder Joint Graping.

From exoffjmgy.blob.core.windows.net

Solder Paste Graping at Janice Marcus blog Solder Joint Graping Solder graping is the incomplete coalescence of solder powder into a solder joint. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. To. Solder Joint Graping.

From www.electronicsandyou.com

Hand Soldering Tutorial How to Solder Electronic Components Solder Joint Graping To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. There are cost implications to this approach as well as an increase in tombstoning of passive components. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. Solder graping is the incomplete coalescence of solder powder. Solder Joint Graping.

From fctsolder.com

F2A reflow graping Solder Paste, Solder Flux FCT Solder Solder Joint Graping The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. To reduce the graping effect, it is vital to ensure an optimal printing and. Solder Joint Graping.

From www.researchgate.net

Schematic drawing showing two types of solder joints, flipchip joints Solder Joint Graping Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. There are cost implications to this approach as well as an increase in tombstoning of passive components. It’s called “graping” because it looks like a bunch of. Solder graping is the incomplete coalescence of solder powder into a solder. Solder Joint Graping.

From www.instructables.com

Soldering Multiple Wires for a Distribution Joint 4 Steps (with Solder Joint Graping The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. There are cost implications to this approach as well as an increase in tombstoning of passive components. The activator(s) within the flux. Solder Joint Graping.

From www.instructables.com

Soldering Multiple Wires for a Distribution Joint 4 Steps (with Solder Joint Graping The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence. Solder Joint Graping.

From www.semlab.com

Solder Joint Analysis SEM Lab Inc. Solder Joint Graping The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. It’s called “graping” because it looks like a bunch of. Solder graping is the incomplete coalescence of solder powder into a solder joint. To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. There. Solder Joint Graping.

From www.youtube.com

3 Steps to Achieving a Perfect Soldering Joint YouTube Solder Joint Graping The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. It’s called “graping” because it looks like a bunch of. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. There are cost implications to this approach as well as an increase. Solder Joint Graping.

From www.pcbaservices.com

What Is A Cold Solder Joint? Understanding The Basics Solder Joint Graping Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. It’s called “graping”. Solder Joint Graping.

From www.researchgate.net

Schematic diagram illustrating the experimental steps for solder joint Solder Joint Graping To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the. Solder Joint Graping.

From exoffjmgy.blob.core.windows.net

Solder Paste Graping at Janice Marcus blog Solder Joint Graping In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. There are cost implications to this approach as well as an increase in tombstoning of passive components. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste.. Solder Joint Graping.

From exoffjmgy.blob.core.windows.net

Solder Paste Graping at Janice Marcus blog Solder Joint Graping The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. There are cost implications to this approach as well as an increase in tombstoning of passive components. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder.. Solder Joint Graping.

From www.instructables.com

How to Make a Proper Western Union Solder Joint 4 Steps (with Solder Joint Graping Solder graping is the incomplete coalescence of solder powder into a solder joint. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. There are cost implications to this approach as well as an increase in tombstoning of passive components. It’s called “graping” because it. Solder Joint Graping.

From www.pcbaaa.com

Understanding solder joint basics and techniques IBE Electronics Solder Joint Graping To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. Solder graping is the incomplete coalescence of solder powder into a solder joint. The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. The activator(s) within the flux chemistry removes the current oxides on. Solder Joint Graping.

From rushpcb.com

What is a Solder Joint? RushPcb Solder Joint Graping The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. Solder graping is the incomplete coalescence of solder powder into a solder joint. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. Typically, a reflow profile is configured to work with. Solder Joint Graping.

From www.youtube.com

Beginner how to Solder YouTube Solder Joint Graping In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. There are cost implications to this approach as well as an increase in tombstoning of passive components.. Solder Joint Graping.

From methodsautomation.com

AMP One Ultra Low Voiding Solder Paste Methods Automation Solder Joint Graping It’s called “graping” because it looks like a bunch of. The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. Solder graping is the incomplete. Solder Joint Graping.

From www.circuitbasics.com

How to Solder Circuit Basics Solder Joint Graping Solder graping is the incomplete coalescence of solder powder into a solder joint. In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. It’s called “graping” because it looks like a bunch. Solder Joint Graping.

From www.semanticscholar.org

Figure 1 from The Graping Phenomenon Improving PbFree Solder Solder Joint Graping To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. Solder graping is the incomplete coalescence of solder powder into a solder joint. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. Typically, a reflow profile is configured. Solder Joint Graping.

From www.youtube.com

How to Create a Good Joint Soldering YouTube Solder Joint Graping In the reflow soldering process of surface mount technology (smt) in electronic assembly, the occurrence of “graping” solder. To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. Typically,. Solder Joint Graping.

From exoffjmgy.blob.core.windows.net

Solder Paste Graping at Janice Marcus blog Solder Joint Graping To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. It’s called “graping” because it looks like a bunch of. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder paste. Typically, a reflow profile is configured to work with. Solder Joint Graping.

From studylib.net

15 Soldering Brazing and riveting Solder Joint Graping To reduce the graping effect, it is vital to ensure an optimal printing and reflow process. The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the solder. Solder Joint Graping.

From joiaapsxb.blob.core.windows.net

How To Solder A Copper Pipe Fitting at Ira Ericson blog Solder Joint Graping There are cost implications to this approach as well as an increase in tombstoning of passive components. Typically, a reflow profile is configured to work with the available solder and components to give the highest tensile strength possible. It’s called “graping” because it looks like a bunch of. Solder graping is the incomplete coalescence of solder powder into a solder. Solder Joint Graping.

From www.electronicsandyou.com

Basic Soldering Guide How to Solder Electronic Components to PCB Solder Joint Graping Solder graping is the incomplete coalescence of solder powder into a solder joint. The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. It’s called “graping” because it looks like a bunch of. Typically, a reflow profile is configured to work with the available solder and components to give the. Solder Joint Graping.

From oscarliang.com

How to Solder Guide for FPV Beginners Oscar Liang Solder Joint Graping There are cost implications to this approach as well as an increase in tombstoning of passive components. The phenomenon where small/fine pitch pad deposits (0402, 0201, 01005 etc) appear to not reflow has been recently termed “graping”,. The activator(s) within the flux chemistry removes the current oxides on the joining surfaces as well as the solder paste particles within the. Solder Joint Graping.