What Is A Bessemer Converter . The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. Air is blown in through openings (tuyeres). The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. The conversion process was rapid, typically taking around 20 minutes. Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. They place iron in the furnace.

from www.sheffieldmuseums.org.uk

The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. They place iron in the furnace. Air is blown in through openings (tuyeres). Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. The conversion process was rapid, typically taking around 20 minutes.

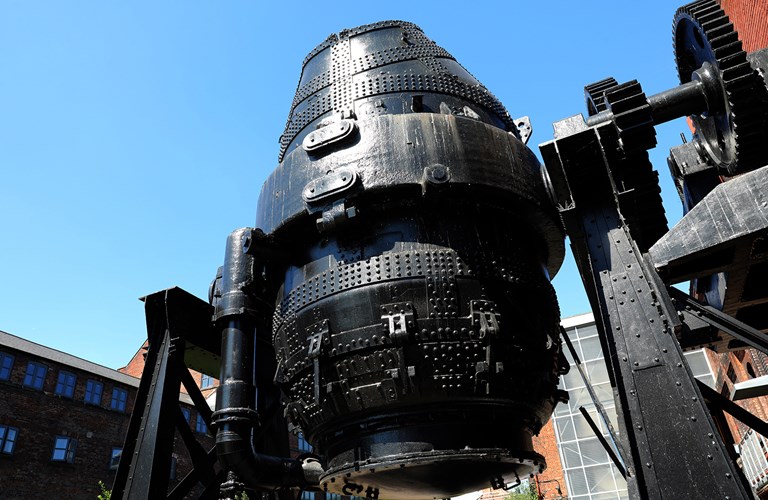

Bessemer Converter Sheffield Museums Trust

What Is A Bessemer Converter Air is blown in through openings (tuyeres). The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. Air is blown in through openings (tuyeres). They place iron in the furnace. Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. The conversion process was rapid, typically taking around 20 minutes. The method involved steelmakers heating pig iron in a furnace to reach a specific temperature.

From www.alamy.com

Bessemer converter hires stock photography and images Alamy What Is A Bessemer Converter They place iron in the furnace. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Air is blown in through openings (tuyeres). Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. Steel manufacturers use a special. What Is A Bessemer Converter.

From www.worldhistory.org

Bessemer Converter, Sheffield (Illustration) World History Encyclopedia What Is A Bessemer Converter Air is blown in through openings (tuyeres). The conversion process was rapid, typically taking around 20 minutes. Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. The bessemer converter. What Is A Bessemer Converter.

From www.hagley.org

to Hagley Museum & Library What Is A Bessemer Converter Air is blown in through openings (tuyeres). The conversion process was rapid, typically taking around 20 minutes. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. The method involved steelmakers heating pig. What Is A Bessemer Converter.

From www.youtube.com

The Bessemer Process and Bessemer Converter How They Work YouTube What Is A Bessemer Converter Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. They. What Is A Bessemer Converter.

From smallworkshop.co.uk

The Bessemer Process What Is A Bessemer Converter Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. They place iron in the furnace. Air is blown in through openings (tuyeres). The method involved steelmakers. What Is A Bessemer Converter.

From www.alamy.com

Bessemer converter, 1900 Stock Photo Alamy What Is A Bessemer Converter The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. They place iron in the furnace. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. The conversion process was rapid, typically taking around 20 minutes. Air is blown in through openings (tuyeres). Henry bessemer's. What Is A Bessemer Converter.

From www.alamy.com

Bessemer converter Stock Photo 29106259 Alamy What Is A Bessemer Converter The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. They place iron in the furnace. Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. The conversion process was rapid, typically taking around 20 minutes. Air. What Is A Bessemer Converter.

From smallworkshop.co.uk

The Bessemer Process What Is A Bessemer Converter Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. They place iron in the furnace. Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing. What Is A Bessemer Converter.

From www.alamy.com

Bessemer Converter Stock Photos & Bessemer Converter Stock Images Alamy What Is A Bessemer Converter The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. Air is blown in through openings (tuyeres). The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery. What Is A Bessemer Converter.

From smallworkshop.co.uk

The Bessemer Process What Is A Bessemer Converter Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. Air is blown in through openings (tuyeres). Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. The method involved steelmakers heating pig iron in a furnace to reach a specific. What Is A Bessemer Converter.

From www.britannica.com

Bessemer converter metallurgy Britannica What Is A Bessemer Converter Air is blown in through openings (tuyeres). Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. They place iron in the furnace. Once the burning iron became molten, it was transferred to. What Is A Bessemer Converter.

From journals.sagepub.com

Historical overview on the development of converter steelmaking from What Is A Bessemer Converter The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. The conversion process was rapid, typically taking around 20 minutes. Air is blown in through openings (tuyeres).. What Is A Bessemer Converter.

From interestingengineering.com

The Fascinating History and Inventions of Henry Bessemer What Is A Bessemer Converter The conversion process was rapid, typically taking around 20 minutes. They place iron in the furnace. Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. The bessemer converter is a. What Is A Bessemer Converter.

From www.alamy.com

An engraving depicting the Bessemer movable converter used in the What Is A Bessemer Converter They place iron in the furnace. The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove.. What Is A Bessemer Converter.

From www.doubtnut.com

Bessemer converter. What Is A Bessemer Converter Air is blown in through openings (tuyeres). Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. They place iron in the furnace. The conversion process was rapid, typically taking around 20 minutes. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory.. What Is A Bessemer Converter.

From wblog.wiki

proceso de Bessemer What Is A Bessemer Converter Air is blown in through openings (tuyeres). Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. The conversion process was rapid, typically taking around 20 minutes. The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. They place iron in the. What Is A Bessemer Converter.

From www.alamy.com

This illustration dates to the 1870s and shows a Bessemer converter What Is A Bessemer Converter Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. The conversion process was rapid, typically taking around 20 minutes. They place iron in the furnace. Once the burning iron became molten, it. What Is A Bessemer Converter.

From etc.usf.edu

Bessemer Converter ClipArt ETC What Is A Bessemer Converter Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. They place iron in the furnace. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Steel manufacturers use a special furnace, known as a bessemer converter, to. What Is A Bessemer Converter.

From www.flickr.com

Sheffield Bessemer Converter, Kelham Island Museum Besseme… Flickr What Is A Bessemer Converter The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. The conversion process was rapid, typically taking around 20 minutes. Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. Steel manufacturers use a special furnace, known as. What Is A Bessemer Converter.

From www.sheffieldmuseums.org.uk

Bessemer Converter Sheffield Museums Trust What Is A Bessemer Converter They place iron in the furnace. Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally. What Is A Bessemer Converter.

From www.alamy.com

Bessemer Converter, Kelham Island Museum, Sheffield Stock Photo Alamy What Is A Bessemer Converter Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten. What Is A Bessemer Converter.

From www.dreamstime.com

Bessemer Converter at Kelham Island Museum Editorial Photography What Is A Bessemer Converter Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. Air is blown in through openings (tuyeres). Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. The conversion process was rapid, typically taking around. What Is A Bessemer Converter.

From www.alamy.com

Section of a bessemer converter Stock Photo Alamy What Is A Bessemer Converter They place iron in the furnace. The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. The conversion process was rapid, typically taking around 20 minutes. Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. Air is blown in through openings. What Is A Bessemer Converter.

From www.geograph.org.uk

Bessemer Converter, Kelham Island Museum © David Dixon Geograph What Is A Bessemer Converter Air is blown in through openings (tuyeres). The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. The conversion process was rapid, typically taking around 20 minutes. Once the burning iron became molten,. What Is A Bessemer Converter.

From www.studenthandouts.com

Diagram of a Bessemer Converter 1867 Student Handouts What Is A Bessemer Converter Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. The conversion process was rapid, typically taking around 20 minutes. Steel manufacturers use a special furnace, known as. What Is A Bessemer Converter.

From steelmillmodelerssupply.com

Bessemer Converter Steel Mill What Is A Bessemer Converter Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. The conversion process was rapid, typically taking around 20 minutes. Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. The method involved steelmakers heating. What Is A Bessemer Converter.

From www.sciencephoto.com

Bessemer Converter Stock Image C012/9098 Science Photo Library What Is A Bessemer Converter Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. Air is blown in through openings (tuyeres). The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. Once the burning iron became molten, it was transferred to the bessemer converter, which was like. What Is A Bessemer Converter.

From www.alamy.com

Bessemer steel hires stock photography and images Alamy What Is A Bessemer Converter The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. They place iron in the furnace. Air is. What Is A Bessemer Converter.

From www.deviantart.com

Bessemer Converter at Sheffield by bobswin on DeviantArt What Is A Bessemer Converter The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. Steel manufacturers. What Is A Bessemer Converter.

From www.sheffieldmuseums.org.uk

Bessemer Converter Sheffield Museums Trust What Is A Bessemer Converter Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique.. What Is A Bessemer Converter.

From www.gettyimages.com.au

Bessemer Converter Photos and Premium High Res Pictures Getty Images What Is A Bessemer Converter Air is blown in through openings (tuyeres). Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery battleground where molten iron transformed. The conversion process was rapid, typically taking around 20 minutes. The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. Steel manufacturers use a special. What Is A Bessemer Converter.

From www.garmendale.co.uk

Building a Bessemer Converter using traditional methods Garmendale What Is A Bessemer Converter The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. Air is blown in through openings (tuyeres). The conversion process was rapid, typically taking around 20 minutes. The. What Is A Bessemer Converter.

From www.howitworksdaily.com

[fototag id=”Bessemer”] What Is A Bessemer Converter The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. Steel manufacturers use. What Is A Bessemer Converter.

From www.discoverwalks.com

Top 10 Facts About The Bessemer Process Discover Walks Blog What Is A Bessemer Converter The method involved steelmakers heating pig iron in a furnace to reach a specific temperature. Air is blown in through openings (tuyeres). The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Once the burning iron became molten, it was transferred to the bessemer converter, which was like a fiery. What Is A Bessemer Converter.

From www.alamy.com

Bessemer converter hires stock photography and images Alamy What Is A Bessemer Converter Steel manufacturers use a special furnace, known as a bessemer converter, to produce steel using this technique. The bessemer converter is a cylindrical steel pot approximately 6 metres (20 feet) high, originally lined with a siliceous refractory. Henry bessemer's converter method is a process developed in the 1850s for producing steel by blowing air through molten iron to remove. They. What Is A Bessemer Converter.