Flux On Brazing . For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Function and performance requirements of brazing flux: Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. In this article, we will discuss common brazing filler metals and fluxes and their use. Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Below are some key features of castolin. 1) eliminate oxide films on metal surfaces, creating optimal.

from www.superiorflux.com

For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. In this article, we will discuss common brazing filler metals and fluxes and their use. Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Function and performance requirements of brazing flux: 1) eliminate oxide films on metal surfaces, creating optimal. Below are some key features of castolin. Quality fluxes prevent surface oxidation as the temperature rises during the brazing process.

Superior Flux Home Page Superior Flux & Mfg. Co.

Flux On Brazing Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Function and performance requirements of brazing flux: In this article, we will discuss common brazing filler metals and fluxes and their use. 1) eliminate oxide films on metal surfaces, creating optimal. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Below are some key features of castolin.

From www.contractormag.com

Common Brazing Mistakes and How to Avoid Them Contractor Flux On Brazing Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Function and performance requirements of brazing flux: In this article, we will discuss common brazing filler metals and fluxes and their use.. Flux On Brazing.

From www.thewelderswarehouse.com

500g Brazing Flux for most Grades of Brazing Alloys Flux On Brazing In this article, we will discuss common brazing filler metals and fluxes and their use. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Function and performance requirements of brazing flux: Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. White. Flux On Brazing.

From www.aluminium-brazing.com

Sil Flux Brazing « to Aluminium Brazing Blog Flux On Brazing For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Function and performance requirements of brazing flux: Below are some key features of castolin. Quality fluxes. Flux On Brazing.

From www.mathuremetalworks.com

Brazing and Soldering Fluxes Mathure Metal Works Flux On Brazing Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. For manual torch brazing applications, welding distributors typically handle. Flux On Brazing.

From www.indiamart.com

Brass Brazing Flux Powder at Rs 650/kg Brazing Fluxes in Mumbai ID Flux On Brazing Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. In this article, we will discuss common brazing filler metals and fluxes and their use. 1) eliminate oxide films on metal surfaces, creating. Flux On Brazing.

From www.alibaba.com

White Brazing Flux Noncorrosive Qj208 Aluminum Brazing Flux Powder Flux On Brazing For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. Below are some key features of castolin. In this article, we will discuss common brazing filler metals and fluxes and their use. White flux is useful for. Flux On Brazing.

From www.focusweld.com

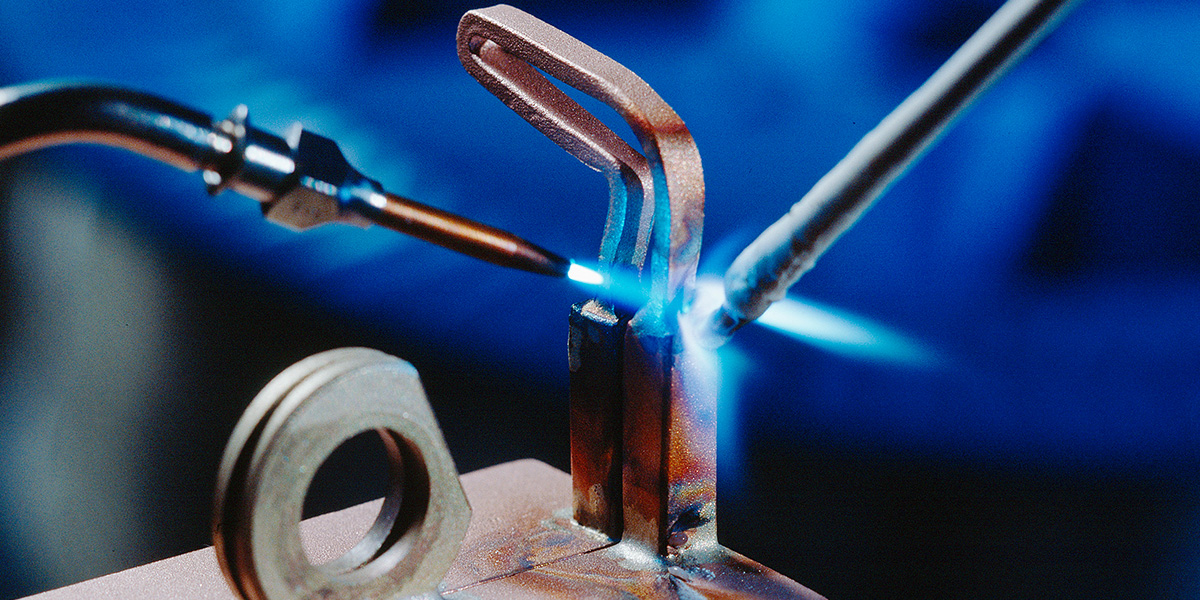

Brazing is a traditional metal joining process in which two or more Flux On Brazing White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface. Flux On Brazing.

From www.mingledorffs.com

Soldering, Brazing, and Welding Mingledorff's Flux On Brazing For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. 1) eliminate oxide films on metal surfaces, creating optimal. Below are some key features of castolin.. Flux On Brazing.

From www.slideserve.com

PPT Brazing PowerPoint Presentation, free download ID5761358 Flux On Brazing In this article, we will discuss common brazing filler metals and fluxes and their use. Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. White flux is useful for brazing copper, brass,. Flux On Brazing.

From www.farmandfleet.com

KT Industries Brazing Flux 22750 Blain's Farm & Fleet Flux On Brazing White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Function and performance requirements of brazing flux: Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. In this article, we will discuss common brazing filler metals and fluxes and their use.. Flux On Brazing.

From www.superiorflux.com

Superior Flux Home Page Superior Flux & Mfg. Co. Flux On Brazing In this article, we will discuss common brazing filler metals and fluxes and their use. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Below are some key features of castolin. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Function and performance requirements. Flux On Brazing.

From www.indiamart.com

Aluminum Brazing Flux Paste at Rs 1200/kg Brazing Fluxes in Pune ID Flux On Brazing Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. In this article, we will discuss common brazing filler metals and fluxes and their use. Below are some key features of castolin. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. White. Flux On Brazing.

From weldcote.com

brazing flux white anti borax fluxes Weldcote Welding For WellBeing Flux On Brazing In this article, we will discuss common brazing filler metals and fluxes and their use. Below are some key features of castolin. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. 1) eliminate oxide films. Flux On Brazing.

From www.indiamart.com

Brass Flux Brass Brazing Flux Powder at Rs 1200/kg Nanded Pune ID Flux On Brazing Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. Below are some key features of castolin. In this article, we will discuss common brazing filler metals and fluxes and their use. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Flux is a chemical compound applied to the joint surfaces before. Flux On Brazing.

From www.hobbyistgeek.com

What Is Brazing Flux And How To Use It? Flux On Brazing Function and performance requirements of brazing flux: In this article, we will discuss common brazing filler metals and fluxes and their use. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing.. Flux On Brazing.

From www.superradiatorcoils.com

Brazing Defects Flux Entrapment Overview and Causes The Super Blog Flux On Brazing 1) eliminate oxide films on metal surfaces, creating optimal. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. Flux is a chemical compound applied to the joint surfaces before brazing that. Flux On Brazing.

From www.superradiatorcoils.com

Brazing Defects Flux Entrapment Overview and Causes The Super Blog Flux On Brazing Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. In this article, we will discuss common brazing filler metals and fluxes and their use. Below. Flux On Brazing.

From fractory.com

Brazing Explained Definition, Process, Types Fractory Flux On Brazing Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Function and performance requirements of brazing flux: White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys. Flux On Brazing.

From www.takealot.com

MTS Brazing Flux 500g Shop Today. Get it Tomorrow! Flux On Brazing Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. 1) eliminate. Flux On Brazing.

From blog.thepipingmart.com

Brazing Flux vs Soldering Flux What's the Difference Flux On Brazing Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Function and performance requirements of brazing flux: In this article, we will discuss common brazing filler metals and fluxes and their use. 1) eliminate oxide films on metal surfaces, creating optimal. Below are some key features. Flux On Brazing.

From www.youtube.com

Brazing Copper to Brass with SilFos® YouTube Flux On Brazing Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. 1) eliminate oxide films on metal surfaces, creating optimal. Function and performance requirements of brazing flux: For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. In this article, we will discuss common brazing filler metals and. Flux On Brazing.

From www.castolin.com

Paste flux for braze welding with Brazing Alloy 18. Brass/ Bronze flux Flux On Brazing 1) eliminate oxide films on metal surfaces, creating optimal. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. In this article, we will discuss common brazing filler metals and fluxes and their use. White flux is useful for brazing copper, brass, steel, stainless steel, and. Flux On Brazing.

From www.cashbuildonline.co.za

Brazing Flux Cashbuild Flux On Brazing Function and performance requirements of brazing flux: White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Oxides are the result of chemical combination between the hot metal and oxygen in the. Flux On Brazing.

From www.walmart.com

Brazing Flux Powder, 8Ounce Flux On Brazing Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Below are some key features of castolin. 1) eliminate oxide films on metal surfaces, creating optimal. In this article, we will discuss. Flux On Brazing.

From www.youtube.com

brazing flux removal YouTube Flux On Brazing Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. White flux is useful for brazing copper, brass, steel, stainless steel, and. Flux On Brazing.

From www.thewelderswarehouse.com

100g Brazing Flux for most Grades of Brazing Alloys Flux On Brazing Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Below are some key features of castolin. Function and performance requirements of brazing flux: 1) eliminate oxide films on metal surfaces, creating optimal. In this article, we. Flux On Brazing.

From www.cashbuildonline.co.za

Brazing Flux Cashbuild Flux On Brazing White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. In this article, we will discuss common brazing filler metals and fluxes and their use. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Quality fluxes prevent surface oxidation as the. Flux On Brazing.

From www.indiamart.com

Braze Flux Copper Alloy Brazing Fluxes at Rs 950/kilogram Brazing Flux On Brazing Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. Function and performance requirements of brazing flux: Below are some key features of castolin. Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. For manual torch brazing applications, welding distributors typically handle. Flux On Brazing.

From www.harrisproductsgroup.com.au

Brazing Harris Products Group Flux On Brazing Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Function and performance requirements of brazing flux: Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. 1) eliminate. Flux On Brazing.

From technotes.alconox.com

Removing Brazing Flux Residue TechNotes Critical Cleaning Advice Flux On Brazing 1) eliminate oxide films on metal surfaces, creating optimal. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Below are some key features of castolin. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing.. Flux On Brazing.

From engineeringlearner.com

Types of Brazing Definition, Principle, Applications, Advantages Flux On Brazing Function and performance requirements of brazing flux: Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. White flux is useful for. Flux On Brazing.

From weldingpros.net

Brazing Filler Metals And Fluxes Explained In Detail Flux On Brazing Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. Below are some key features of castolin. 1) eliminate oxide films on metal surfaces, creating optimal. For manual torch brazing applications, welding distributors. Flux On Brazing.

From www.huaguangwelding.com

Fundamentals of Brazing Flux Flux On Brazing For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. Oxides are the result of chemical combination between the hot metal and oxygen in the air and form when a metal surface is heated. Flux is. Flux On Brazing.

From blog.thepipingmart.com

What is Brazing Fluxes? Uses and Working Flux On Brazing Quality fluxes prevent surface oxidation as the temperature rises during the brazing process. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. Function and performance requirements of brazing flux: Oxides are the result of chemical combination between the hot metal and oxygen in the air. Flux On Brazing.

From www.amazon.in

Hot Max 24000 Brazing Flux Powder, 8Ounce Amazon.in Industrial Flux On Brazing In this article, we will discuss common brazing filler metals and fluxes and their use. Flux is a chemical compound applied to the joint surfaces before brazing that prevents oxides from forming and inhibiting the metallurgical bond in brazing. White flux is useful for brazing copper, brass, steel, stainless steel, and nickel alloys. 1) eliminate oxide films on metal surfaces,. Flux On Brazing.