Hobbing Machine Differential Gearing . The profile is formed by the equally spaced cutting. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. The hob is a series of racks positioned around the circumference of a cylindrical tool. Each successive rack is shifted axially to create a. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling.

from engineeringlearn.com

Each successive rack is shifted axially to create a. The profile is formed by the equally spaced cutting. Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. The hob is a series of racks positioned around the circumference of a cylindrical tool.

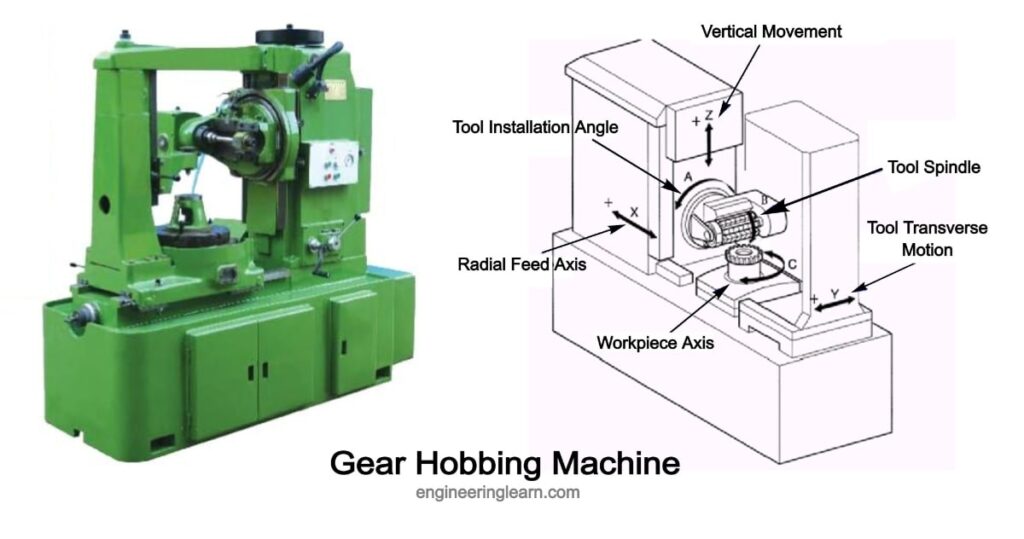

Gear Hobbing Machine Definition, Types, Uses, Working & Construction

Hobbing Machine Differential Gearing Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling. Each successive rack is shifted axially to create a. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. The profile is formed by the equally spaced cutting. The hob is a series of racks positioned around the circumference of a cylindrical tool. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the.

From mechanicaltalks.in

Gear Hobbing Parts, Working, Diagram, Advantages, Disadvantages Hobbing Machine Differential Gearing Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling. The profile is formed by the equally spaced cutting. The hob is a series of racks positioned around the circumference of a cylindrical tool. Gear hobbing is a process in which gear is cut by a generating process by rotating. Hobbing Machine Differential Gearing.

From www.youtube.com

Gear Hobbing Machine Differential Rev 2UPDATE! YouTube Hobbing Machine Differential Gearing The profile is formed by the equally spaced cutting. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the.. Hobbing Machine Differential Gearing.

From www.emag.com

Gear Hobbing Machine K 160 Gear Hobbing at the Highest Level Hobbing Machine Differential Gearing Each successive rack is shifted axially to create a. The hob is a series of racks positioned around the circumference of a cylindrical tool. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear. Hobbing Machine Differential Gearing.

From www.emag.com

VL 4 H Gear Hobbing Machine for Fast Gear Cutting Hobbing Machine Differential Gearing The hob is a series of racks positioned around the circumference of a cylindrical tool. Each successive rack is shifted axially to create a. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. The profile is formed by the equally. Hobbing Machine Differential Gearing.

From www.youtube.com

Prime Time Making a Differential for a Gear Hobbing Machine. YouTube Hobbing Machine Differential Gearing Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. The hob is a series of racks positioned around the circumference of a cylindrical tool. The profile is formed by the equally spaced cutting. Hobbing is a. Hobbing Machine Differential Gearing.

From www.emag.com

Gear Hobbing Machines for Precise Gear Hobbing Hobbing Machine Differential Gearing Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling. The hob is a series of racks positioned around the circumference of a cylindrical tool. Each successive rack is shifted axially to create a. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism. Hobbing Machine Differential Gearing.

From dxokfgzch.blob.core.windows.net

Internal Gear Hobbing Machine at Billy Martinez blog Hobbing Machine Differential Gearing Each successive rack is shifted axially to create a. Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. The profile is formed by the equally spaced cutting. Rather, the hobbing machine. Hobbing Machine Differential Gearing.

From asthegearturns.com

The Hobbing Process, Part 1 As the Gear Turns Hobbing Machine Differential Gearing Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a. Hobbing Machine Differential Gearing.

From koepferamerica.com

Koepfer America Introduces CLC Vertical Gear Hobbing Machines Koepfer Hobbing Machine Differential Gearing The profile is formed by the equally spaced cutting. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. The hob is a series of racks positioned around the circumference of a cylindrical tool. Hobbing is a. Hobbing Machine Differential Gearing.

From www.youtube.com

Gear Hobbing Process Compilation Kompilasi Proses Gear Hobbing Hobbing Machine Differential Gearing Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Each successive rack is shifted axially to create a. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the.. Hobbing Machine Differential Gearing.

From www.hotonmachinery.com

Gear Hobbing Machines Y3150 Hobbing Machine Differential Gearing The hob is a series of racks positioned around the circumference of a cylindrical tool. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. The profile is formed by the equally spaced cutting. Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a. Hobbing Machine Differential Gearing.

From www.youtube.com

Liebherr Gear Hobbing and profile Hobbing Machine LC 4000 YouTube Hobbing Machine Differential Gearing Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. The hob is a series of racks positioned around the circumference of a cylindrical tool. Each successive rack is shifted axially to create a. Robert hermann pfauter. Hobbing Machine Differential Gearing.

From www.liebherr.com

Gear hobbing machines Liebherr Liebherr Hobbing Machine Differential Gearing Each successive rack is shifted axially to create a. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter. Hobbing Machine Differential Gearing.

From www.kishanind.com

Gear Hobbing Machines 6 Module Kishan Industries Hobbing Machine Differential Gearing Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling. Robert hermann pfauter (rhp) invented the method of hobbing helical gears. Hobbing Machine Differential Gearing.

From www.zhygear.com

Hobbing of helical gear installation of hob ZHY Gear Hobbing Machine Differential Gearing Each successive rack is shifted axially to create a. The profile is formed by the equally spaced cutting. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Hobbing is a machining process for gear cutting, cutting. Hobbing Machine Differential Gearing.

From koepferamerica.com

Koepfer America Introduces CLC Vertical Gear Hobbing Machines Koepfer Hobbing Machine Differential Gearing The profile is formed by the equally spaced cutting. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative. Hobbing Machine Differential Gearing.

From www.liebherr.com

Gear hobbing machines Liebherr Liebherr Hobbing Machine Differential Gearing The profile is formed by the equally spaced cutting. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling. The hob is a series of racks positioned around the circumference of a. Hobbing Machine Differential Gearing.

From www.youtube.com

Mechanism of Gear Hobbing Machine YouTube Hobbing Machine Differential Gearing Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. Hobbing is a machining process for gear cutting, cutting. Hobbing Machine Differential Gearing.

From www.equipment-trader.co.uk

Sykes Hv14A Vertical Gear Hobbing Machine Equipment Trader Hobbing Machine Differential Gearing Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. The profile is formed by the equally spaced cutting.. Hobbing Machine Differential Gearing.

From www.m3.tuc.gr

m3 Gear Hobbing Hobbing Machine Differential Gearing Each successive rack is shifted axially to create a. Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. The profile. Hobbing Machine Differential Gearing.

From www.liebherr.com

Gear hobbing machines Liebherr Liebherr Hobbing Machine Differential Gearing Each successive rack is shifted axially to create a. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. The profile is formed by the equally spaced cutting. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect. Hobbing Machine Differential Gearing.

From www.motorgearengineer.com

Gear Hobbing Service Introduction, Working, and Applications Hobbing Machine Differential Gearing Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. The profile is formed by the equally spaced cutting. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the. Hobbing Machine Differential Gearing.

From learnmech.com

Gear Hobbing Parts, Working, Diagram, Advantages, Disadvantages Hobbing Machine Differential Gearing Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. The profile is formed by the equally spaced cutting. The hob is a series of racks positioned around the circumference of a cylindrical tool. Robert hermann pfauter. Hobbing Machine Differential Gearing.

From www.liebherr.com

LC 2000 12000 Gear hobbing machines Liebherr Liebherr Hobbing Machine Differential Gearing Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. Each successive rack is shifted axially to create a. The profile is formed. Hobbing Machine Differential Gearing.

From heliosgearproducts.com

Helios Introduces Hera 350 CNC Gear Hobbing Machine Helios Gear Products Hobbing Machine Differential Gearing The hob is a series of racks positioned around the circumference of a cylindrical tool. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism. Hobbing Machine Differential Gearing.

From www.researchgate.net

a Schematic diagram of the gear hobbing machine (source authors). b Hobbing Machine Differential Gearing Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Each successive rack is shifted axially to create a. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative. Hobbing Machine Differential Gearing.

From www.pli-international.com

CNC Gear Hobbing Machine LIEBHERR LC802 PLI International Hobbing Machine Differential Gearing The hob is a series of racks positioned around the circumference of a cylindrical tool. The profile is formed by the equally spaced cutting. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative. Hobbing Machine Differential Gearing.

From www.first-gear.com

Gear Hobbing — First Gear Hobbing Machine Differential Gearing Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling. Each successive rack is shifted axially to create a. The hob is a series of racks positioned around the circumference of a cylindrical tool. The profile is formed by the equally spaced cutting. Robert hermann pfauter (rhp) invented the method. Hobbing Machine Differential Gearing.

From engineeringlearn.com

Gear Hobbing Machine Definition, Types, Uses, Working & Construction Hobbing Machine Differential Gearing The profile is formed by the equally spaced cutting. The hob is a series of racks positioned around the circumference of a cylindrical tool. Each successive rack is shifted axially to create a. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the. Hobbing Machine Differential Gearing.

From www.riderbraces.com

Helios Introduces Hera 500 CNC Gear Hobbing Machine Helios, 53 OFF Hobbing Machine Differential Gearing Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets using a hobbing machine, a specialized milling. The hob is a series of racks positioned around the circumference of a cylindrical tool. The profile is formed by the equally spaced cutting. Gear hobbing is a process in which gear is cut by a generating process by rotating. Hobbing Machine Differential Gearing.

From www.youtube.com

Liebherr Gear Hobbing Machine LC 380500 YouTube Hobbing Machine Differential Gearing The profile is formed by the equally spaced cutting. Each successive rack is shifted axially to create a. Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a. Hobbing Machine Differential Gearing.

From www.eng-tips.com

Build Your Own Hobbing Machine. Gear & Pulley engineering EngTips Hobbing Machine Differential Gearing Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed. Hobbing Machine Differential Gearing.

From www.lathes.co.uk

Jacobe Gear Hobber Hobbing Machine Differential Gearing Robert hermann pfauter (rhp) invented the method of hobbing helical gears by adding a differential mechanism to the. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. The hob is a series of racks positioned around the circumference of a. Hobbing Machine Differential Gearing.

From www.youtube.com

Gear Hobbing Machine YouTube Hobbing Machine Differential Gearing The hob is a series of racks positioned around the circumference of a cylindrical tool. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. Gear hobbing is a process in which gear is cut by a generating process by rotating. Hobbing Machine Differential Gearing.

From www.youtube.com

Gear Hobbing Machine TOS FO6 YouTube Hobbing Machine Differential Gearing The hob is a series of racks positioned around the circumference of a cylindrical tool. Each successive rack is shifted axially to create a. Rather, the hobbing machine provides an accurate differential mechanism that gradually offsets the rotation of the hob relative to the work piece with respect to the feed of the. The profile is formed by the equally. Hobbing Machine Differential Gearing.