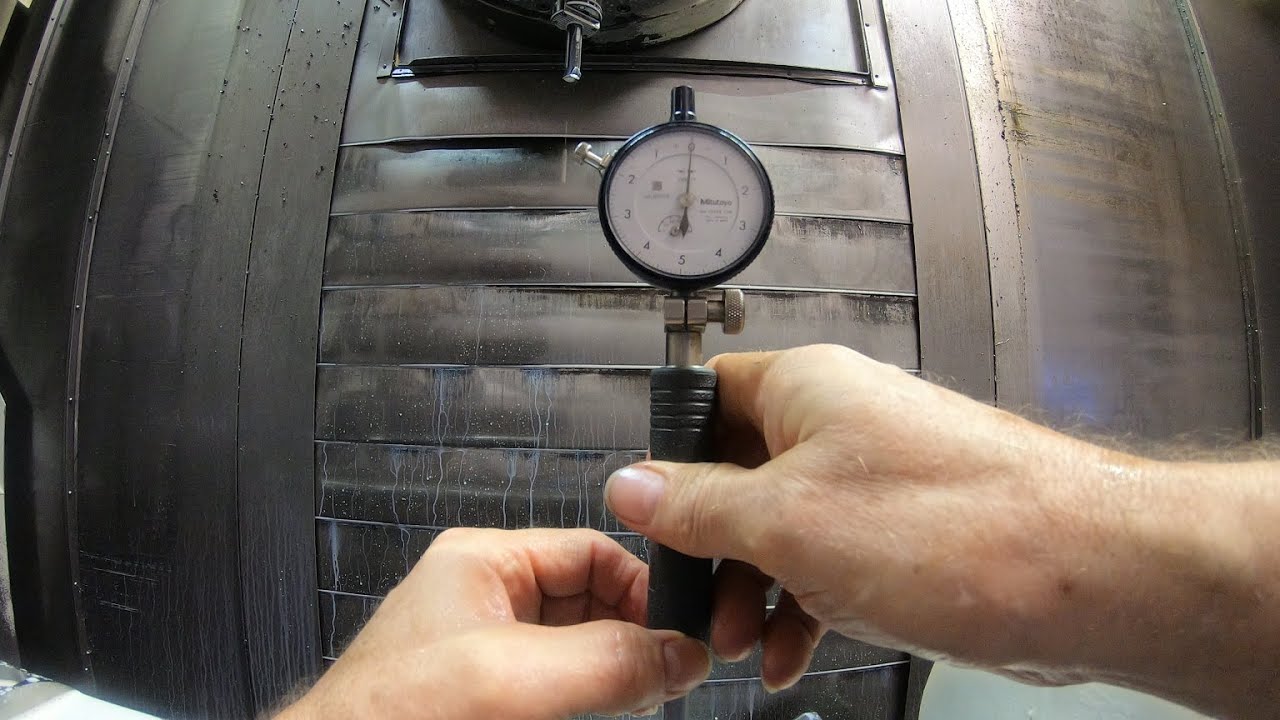

How To Read Bore Dial Gauge . How to take accurate measurements. Tresna instruments says the cost associated with bore gauges. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. Here then are some tips on how to read a dial bore gage when taking measurements of a bore or cylinder. When taking measurements, you start. Dial bore gauges are typically used by machinists to measure the inner diameter of bores in motor engines. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out.

from www.youtube.com

When taking measurements, you start. When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. How to take accurate measurements. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. Dial bore gauges are typically used by machinists to measure the inner diameter of bores in motor engines. Here then are some tips on how to read a dial bore gage when taking measurements of a bore or cylinder. Tresna instruments says the cost associated with bore gauges.

Setup A Dial Bore Gauge And Bore YouTube

How To Read Bore Dial Gauge A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. How to take accurate measurements. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. Here then are some tips on how to read a dial bore gage when taking measurements of a bore or cylinder. Dial bore gauges are typically used by machinists to measure the inner diameter of bores in motor engines. When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. When taking measurements, you start. Tresna instruments says the cost associated with bore gauges.

From ikki-group.com

Bore Gauge บอร์เกจ (Split ball) ใช้ในการวัดและตรวจสอบไดมิเตอร์ ID How To Read Bore Dial Gauge When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch. How To Read Bore Dial Gauge.

From appu.com.uy

Different Types Of Measuring Tools And Gauges Used On Ships, 41 OFF How To Read Bore Dial Gauge Dial bore gauges are typically used by machinists to measure the inner diameter of bores in motor engines. Here then are some tips on how to read a dial bore gage when taking measurements of a bore or cylinder. How to take accurate measurements. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025. How To Read Bore Dial Gauge.

From www.youtube.com

HOW TO USE A BORE DIAL GAUGE TO MEASURE CYLINDER YouTube How To Read Bore Dial Gauge Dial bore gauges are typically used by machinists to measure the inner diameter of bores in motor engines. Tresna instruments says the cost associated with bore gauges. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. When you are measuring any cylinder bore. How To Read Bore Dial Gauge.

From extrudesign.com

Dial Indicator Dial Gauge Types Of Dial Indicators Working How To Read Bore Dial Gauge A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. Here then are some tips on how to read a dial bore gage when taking measurements of a bore or cylinder. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter),. How To Read Bore Dial Gauge.

From mechdieselengine.blogspot.com

HOW TO MEASURE WITH A BORE DIAL GAUGE How To Read Bore Dial Gauge A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. Using a bore gauge involves inserting the measuring head into the bore to be measured and then. How To Read Bore Dial Gauge.

From exykdbezj.blob.core.windows.net

Measuring Bore Of A Cylinder at Diana Wallace blog How To Read Bore Dial Gauge How to take accurate measurements. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. When taking measurements, you start. When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. Tresna instruments says the cost associated with bore gauges. Dial. How To Read Bore Dial Gauge.

From exongijzs.blob.core.windows.net

How To Read A Dial Bore Gauge .0001 at Frank Robinson blog How To Read Bore Dial Gauge Here then are some tips on how to read a dial bore gage when taking measurements of a bore or cylinder. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully. How To Read Bore Dial Gauge.

From www.cottandco.com

Bore Gauges and Dial Gauges How To Read Bore Dial Gauge Dial bore gauges are typically used by machinists to measure the inner diameter of bores in motor engines. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. A demonstration of how to set up, use, and read a dial bore gauge to check. How To Read Bore Dial Gauge.

From exongijzs.blob.core.windows.net

How To Read A Dial Bore Gauge .0001 at Frank Robinson blog How To Read Bore Dial Gauge Dial bore gauges are typically used by machinists to measure the inner diameter of bores in motor engines. How to take accurate measurements. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. Using a bore gauge involves inserting the measuring head into the bore to be measured and. How To Read Bore Dial Gauge.

From www.banggood.com

50160mm accuracy 0.01mm indicator inner diameter dial bore gauge Sale How To Read Bore Dial Gauge Tresna instruments says the cost associated with bore gauges. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. Here then are some tips on how to. How To Read Bore Dial Gauge.

From goodson.com

GA4141 Sunnen .0001" Reading Dial Bore Gauge Goodson Tools & Supplies How To Read Bore Dial Gauge A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. Dial bore gauges are typically used by machinists to measure the inner diameter of bores in motor engines. When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. Using. How To Read Bore Dial Gauge.

From www.youtube.com

Setup A Dial Bore Gauge And Bore YouTube How To Read Bore Dial Gauge When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. Dial bore gauges are typically used by machinists to measure the inner diameter of bores in motor engines. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they. How To Read Bore Dial Gauge.

From www.diymotofix.com

Precision Measuring For The AtHome Mechanic DIY Moto Fix How To Read Bore Dial Gauge A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. Here then are some tips on how to read a dial bore gage when taking measurements of a bore or cylinder. Dial bore gauges are typically used by machinists to measure the inner diameter of bores in motor engines.. How To Read Bore Dial Gauge.

From exongijzs.blob.core.windows.net

How To Read A Dial Bore Gauge .0001 at Frank Robinson blog How To Read Bore Dial Gauge Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. When taking measurements, you start. Here then are some tips on how. How To Read Bore Dial Gauge.

From exyhoxzie.blob.core.windows.net

Bore Gauge Terminology at Esther Crivello blog How To Read Bore Dial Gauge When taking measurements, you start. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. How to take accurate measurements. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. Here then. How To Read Bore Dial Gauge.

From bearingtoolscentre.com

Dial Bore Gauge How To Read Bore Dial Gauge Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. Here then are some tips on how to read a dial bore gage when taking measurements of a bore or cylinder. When taking measurements, you start. When you are measuring any cylinder bore you. How To Read Bore Dial Gauge.

From www.puritoolsandsteel.com

Dial Gauge Insize PURI Tools & Steel Trader Mumbai India📞9920880039 How To Read Bore Dial Gauge When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. Tresna instruments says the cost associated with bore gauges. Here then are some tips on how to read a dial. How To Read Bore Dial Gauge.

From www.mrclab.com

DIAL BORE GAUGES 1835MM/0.01MM How To Read Bore Dial Gauge Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. Tresna instruments says the cost associated with bore gauges. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. How to take. How To Read Bore Dial Gauge.

From www.mmsonline.com

Reading What the Dial Indicator Is Saying Modern Machine Shop How To Read Bore Dial Gauge Tresna instruments says the cost associated with bore gauges. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. How to take accurate measurements. When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. A. How To Read Bore Dial Gauge.

From cme-tools.myshopify.com

Dial Bore Gauges CME Tools How To Read Bore Dial Gauge Here then are some tips on how to read a dial bore gage when taking measurements of a bore or cylinder. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully. How To Read Bore Dial Gauge.

From www.klassikats.com

How to Measure With A Dial Indicator Correctly Klassik ATS How To Read Bore Dial Gauge When taking measurements, you start. When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. Using a bore gauge involves inserting the measuring head into the bore to be. How To Read Bore Dial Gauge.

From tagumdoctors.edu.ph

Automotive Graduation 0.0005" Dial Bore Gauge Set Brand New Range 2.0 How To Read Bore Dial Gauge A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the. How To Read Bore Dial Gauge.

From neoteck.cn

Neoteck Bore Gage Set Digital Indicator Dial Bore Gauge (2"6"/0.0005" How To Read Bore Dial Gauge When taking measurements, you start. Dial bore gauges are typically used by machinists to measure the inner diameter of bores in motor engines. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. Tresna instruments says the cost associated with bore gauges. Using a bore gauge involves inserting. How To Read Bore Dial Gauge.

From www.huttie.com

Dual Reading Digital Dial Bore Gauge Huttie How To Read Bore Dial Gauge Here then are some tips on how to read a dial bore gage when taking measurements of a bore or cylinder. How to take accurate measurements. Tresna instruments says the cost associated with bore gauges. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. Using a bore gauge. How To Read Bore Dial Gauge.

From www.youtube.com

LINKS 4" 6.5" Jeweled Dial Bore Gauge .0005" Graduations YouTube How To Read Bore Dial Gauge Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. How to take accurate measurements. When you are measuring any cylinder bore you. How To Read Bore Dial Gauge.

From www.youtube.com

Dial Gauge Indicator(Working Principle) YouTube How To Read Bore Dial Gauge When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. How to take accurate measurements. Tresna instruments says the cost associated with bore gauges. When taking measurements, you start. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until. How To Read Bore Dial Gauge.

From www.kaefer-messuhren.com

Precision Dial Gauges analogue metric / inch Käfer dial gauges How To Read Bore Dial Gauge A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. Here then are some tips on how to read a dial bore gage when taking measurements of a bore. How To Read Bore Dial Gauge.

From www.basicmechaniccourse.com

Cara Membaca Dan MenggunakanInsideDialGauge ( Bore Gauge ) How To Read Bore Dial Gauge Here then are some tips on how to read a dial bore gage when taking measurements of a bore or cylinder. How to take accurate measurements. When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. Dial bore gauges are typically used by machinists to measure the inner diameter of bores. How To Read Bore Dial Gauge.

From www.grainger.com

MITUTOYO Bore Gauge Set with Dial Indicator, Operation Type Mechanical How To Read Bore Dial Gauge Here then are some tips on how to read a dial bore gage when taking measurements of a bore or cylinder. How to take accurate measurements. Tresna instruments says the cost associated with bore gauges. When taking measurements, you start. When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. A. How To Read Bore Dial Gauge.

From www.wikihow.com

How to Read a Dial Indicator 15 Steps (with Pictures) wikiHow How To Read Bore Dial Gauge Tresna instruments says the cost associated with bore gauges. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. How to take accurate measurements. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make. How To Read Bore Dial Gauge.

From cme-tools.myshopify.com

Dial Bore Gauges CME Tools How To Read Bore Dial Gauge Tresna instruments says the cost associated with bore gauges. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. How to take accurate measurements. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. Using a bore. How To Read Bore Dial Gauge.

From www.alibaba.com

50160mm Dial Bore Gauge Buy Mitutoyo Dial Bore Gauges,Dial Gauge How To Read Bore Dial Gauge A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. A dial bore gauge is a special tool, calibrated in.001 inch (.0025. How To Read Bore Dial Gauge.

From automotifnewstrend.blogspot.co.id

Bagianbaagian,fungsi,Cara membaca Cylinder Bore Gauge dan cara How To Read Bore Dial Gauge When taking measurements, you start. Using a bore gauge involves inserting the measuring head into the bore to be measured and then carefully expanding the arms until they make contact with. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. A demonstration of how to set up, use,. How To Read Bore Dial Gauge.

From www.vlr.eng.br

Bore Dial Gauge Diagram vlr.eng.br How To Read Bore Dial Gauge Dial bore gauges are typically used by machinists to measure the inner diameter of bores in motor engines. When you are measuring any cylinder bore you are looking for three things, bore size, taper, and out of. Tresna instruments says the cost associated with bore gauges. When taking measurements, you start. Using a bore gauge involves inserting the measuring head. How To Read Bore Dial Gauge.

From www.indiamart.com

Dial Bore Gauge at Rs 8000/unit dial bore gauge in Coimbatore ID How To Read Bore Dial Gauge How to take accurate measurements. A demonstration of how to set up, use, and read a dial bore gauge to check for cylinder wear, taper, and out. Tresna instruments says the cost associated with bore gauges. A dial bore gauge is a special tool, calibrated in.001 inch (.0025 centimeter) or.0001 inch (.00025 centimeter), which is used to. Dial bore gauges. How To Read Bore Dial Gauge.