How To Cut Helical Gears . Installing & setting up the universal headsupport. Read on to learn more about the different cutting methods. The teeth of a helical gear are cut using a gear hobbing machine or a gear shaping machine. Turn the given ci bank to required diameter in centre lathe. Gear cutting allows you to make worm, bevel, spur, helical, or herringbone gears, but there isn’t just one way of doing it. Cutting helical gears on the horizontal mill 3: Sliding velocity increases as the distance from the pitch point increases in the line of action. Helical gears can be produced from. The points of contact furthest from the pitch point are the sap and eap. Drill a hole in the blank of diameter. Cutting a helical gear is just like cutting a spur gear except for some key differences: 81k views 1 year ago. Procedure of helical gear cutting : Cutting helical gears on the horizontal mill 6: Sliding is of greatest concern at the sap and eap, when a pair of helical gear teeth are entering or exiting the mesh cycle.

from www.transmissions-gears.com

In cases of high profile shift, the pitch point may. Gear cutting allows you to make worm, bevel, spur, helical, or herringbone gears, but there isn’t just one way of doing it. A whilst the gear is being cut, the milling table moves by. Sliding velocity increases as the distance from the pitch point increases in the line of action. Drill a hole in the blank of diameter. Cutting helical gears on the horizontal mill 6: Sliding is of greatest concern at the sap and eap, when a pair of helical gear teeth are entering or exiting the mesh cycle. Turn the given ci bank to required diameter in centre lathe. Helical gears can be produced from. 81k views 1 year ago.

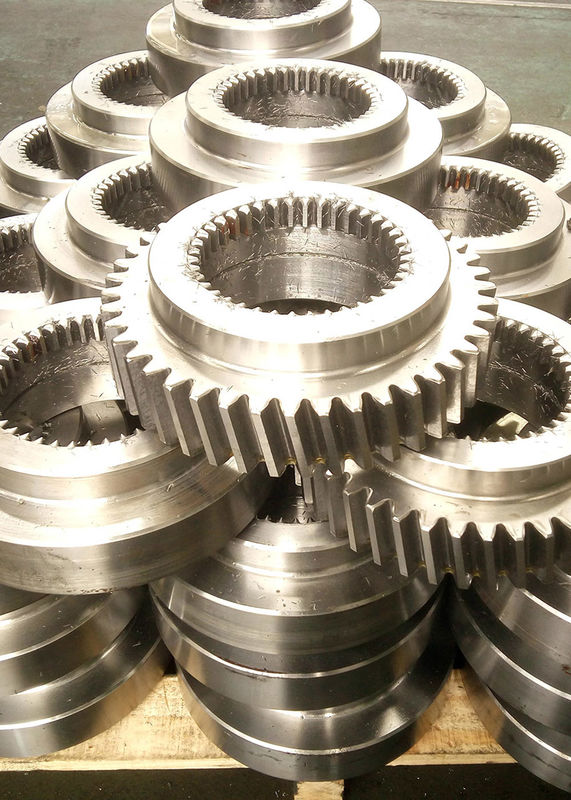

External Helical Cut Gears With Internal Spur Gear Involute Splines

How To Cut Helical Gears Sliding velocity increases as the distance from the pitch point increases in the line of action. Cutting helical gears on the horizontal mill 3: Cutting a helical gear is just like cutting a spur gear except for some key differences: A whilst the gear is being cut, the milling table moves by. Sliding velocity increases as the distance from the pitch point increases in the line of action. Helical gears can be produced from. Procedure of helical gear cutting : The points of contact furthest from the pitch point are the sap and eap. Turn the given ci bank to required diameter in centre lathe. In cases of high profile shift, the pitch point may. Sliding is of greatest concern at the sap and eap, when a pair of helical gear teeth are entering or exiting the mesh cycle. Installing & setting up the universal headsupport. 81k views 1 year ago. Gear cutting allows you to make worm, bevel, spur, helical, or herringbone gears, but there isn’t just one way of doing it. Drill a hole in the blank of diameter. Read on to learn more about the different cutting methods.

From www.drivetrainhub.com

Helical Gears Geometry of helical gears and gear meshes How To Cut Helical Gears The teeth of a helical gear are cut using a gear hobbing machine or a gear shaping machine. Helical gears can be produced from. A whilst the gear is being cut, the milling table moves by. Cutting helical gears on the horizontal mill 3: Sliding velocity increases as the distance from the pitch point increases in the line of action.. How To Cut Helical Gears.

From www.youtube.com

Cutting Helical Gears on the Horizontal Milling Machine Setting up the How To Cut Helical Gears Read on to learn more about the different cutting methods. Drill a hole in the blank of diameter. Cutting helical gears on the horizontal mill 3: Sliding is of greatest concern at the sap and eap, when a pair of helical gear teeth are entering or exiting the mesh cycle. 81k views 1 year ago. Cutting a helical gear is. How To Cut Helical Gears.

From www.rapiddirect.com

Gear Manufacturing 101 A Comolete Guide on Gear Production Processes How To Cut Helical Gears Helical gears can be produced from. Installing & setting up the universal headsupport. Procedure of helical gear cutting : In cases of high profile shift, the pitch point may. Turn the given ci bank to required diameter in centre lathe. Gear cutting allows you to make worm, bevel, spur, helical, or herringbone gears, but there isn’t just one way of. How To Cut Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations How To Cut Helical Gears In cases of high profile shift, the pitch point may. Turn the given ci bank to required diameter in centre lathe. The points of contact furthest from the pitch point are the sap and eap. Helical gears can be produced from. Cutting helical gears on the horizontal mill 6: Cutting a helical gear is just like cutting a spur gear. How To Cut Helical Gears.

From www.youtube.com

Gear cutting Helical gear repair (free hobbing technique) YouTube How To Cut Helical Gears Cutting helical gears on the horizontal mill 3: Read on to learn more about the different cutting methods. Cutting a helical gear is just like cutting a spur gear except for some key differences: Procedure of helical gear cutting : Installing & setting up the universal headsupport. Cutting helical gears on the horizontal mill 6: Sliding is of greatest concern. How To Cut Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations How To Cut Helical Gears 81k views 1 year ago. Gear cutting allows you to make worm, bevel, spur, helical, or herringbone gears, but there isn’t just one way of doing it. In cases of high profile shift, the pitch point may. Installing & setting up the universal headsupport. Read on to learn more about the different cutting methods. Helical gears can be produced from.. How To Cut Helical Gears.

From www.alamy.com

Gear hobbing of helical gear Hobbing process to cut a helical gear with How To Cut Helical Gears Sliding velocity increases as the distance from the pitch point increases in the line of action. Cutting helical gears on the horizontal mill 6: Helical gears can be produced from. Turn the given ci bank to required diameter in centre lathe. A whilst the gear is being cut, the milling table moves by. Cutting helical gears on the horizontal mill. How To Cut Helical Gears.

From www.youtube.com

helical gear cutting on milling YouTube How To Cut Helical Gears 81k views 1 year ago. Gear cutting allows you to make worm, bevel, spur, helical, or herringbone gears, but there isn’t just one way of doing it. In cases of high profile shift, the pitch point may. Procedure of helical gear cutting : Turn the given ci bank to required diameter in centre lathe. Drill a hole in the blank. How To Cut Helical Gears.

From www.youtube.com

Thick Helical Gear Cutting with the 5Axis CMS Waterjet YouTube How To Cut Helical Gears The teeth of a helical gear are cut using a gear hobbing machine or a gear shaping machine. Turn the given ci bank to required diameter in centre lathe. Read on to learn more about the different cutting methods. Helical gears can be produced from. In cases of high profile shift, the pitch point may. A whilst the gear is. How To Cut Helical Gears.

From www.youtube.com

Helical Gear 4 axis milling YouTube How To Cut Helical Gears Sliding is of greatest concern at the sap and eap, when a pair of helical gear teeth are entering or exiting the mesh cycle. The points of contact furthest from the pitch point are the sap and eap. In cases of high profile shift, the pitch point may. Procedure of helical gear cutting : 81k views 1 year ago. Cutting. How To Cut Helical Gears.

From www.youtube.com

Tutorial How to Model Screw (Crossed Helical) Gears in Blender YouTube How To Cut Helical Gears The points of contact furthest from the pitch point are the sap and eap. Read on to learn more about the different cutting methods. Sliding velocity increases as the distance from the pitch point increases in the line of action. 81k views 1 year ago. In cases of high profile shift, the pitch point may. Helical gears can be produced. How To Cut Helical Gears.

From learnsolidworks.com

Creating Spur and Helical Gears in SolidWorks How To Cut Helical Gears Cutting helical gears on the horizontal mill 3: The teeth of a helical gear are cut using a gear hobbing machine or a gear shaping machine. The points of contact furthest from the pitch point are the sap and eap. Read on to learn more about the different cutting methods. Procedure of helical gear cutting : Cutting helical gears on. How To Cut Helical Gears.

From www.youtube.com

Design Of Helical Gear with Equation in SolidWorks YouTube How To Cut Helical Gears Helical gears can be produced from. The points of contact furthest from the pitch point are the sap and eap. Turn the given ci bank to required diameter in centre lathe. Read on to learn more about the different cutting methods. Drill a hole in the blank of diameter. Cutting helical gears on the horizontal mill 6: Installing & setting. How To Cut Helical Gears.

From www.youtube.com

How to create a Helical gear in solidworks using design library. YouTube How To Cut Helical Gears 81k views 1 year ago. Cutting helical gears on the horizontal mill 6: Installing & setting up the universal headsupport. The teeth of a helical gear are cut using a gear hobbing machine or a gear shaping machine. Helical gears can be produced from. Drill a hole in the blank of diameter. Cutting a helical gear is just like cutting. How To Cut Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations How To Cut Helical Gears The points of contact furthest from the pitch point are the sap and eap. Installing & setting up the universal headsupport. Procedure of helical gear cutting : Read on to learn more about the different cutting methods. Sliding is of greatest concern at the sap and eap, when a pair of helical gear teeth are entering or exiting the mesh. How To Cut Helical Gears.

From www.hkdivedi.com

BASIC OF HELICAL GEAR Mechanical Engineering Professionals How To Cut Helical Gears The teeth of a helical gear are cut using a gear hobbing machine or a gear shaping machine. In cases of high profile shift, the pitch point may. Gear cutting allows you to make worm, bevel, spur, helical, or herringbone gears, but there isn’t just one way of doing it. Cutting helical gears on the horizontal mill 3: Helical gears. How To Cut Helical Gears.

From www.youtube.com

Helical gear cutting YouTube How To Cut Helical Gears Installing & setting up the universal headsupport. Drill a hole in the blank of diameter. In cases of high profile shift, the pitch point may. Cutting helical gears on the horizontal mill 3: Cutting a helical gear is just like cutting a spur gear except for some key differences: Procedure of helical gear cutting : Gear cutting allows you to. How To Cut Helical Gears.

From low-offset.com

Helical vs Straight Cut Gears Difference Explained Low Offset How To Cut Helical Gears Gear cutting allows you to make worm, bevel, spur, helical, or herringbone gears, but there isn’t just one way of doing it. In cases of high profile shift, the pitch point may. 81k views 1 year ago. The points of contact furthest from the pitch point are the sap and eap. Cutting helical gears on the horizontal mill 3: Turn. How To Cut Helical Gears.

From mentoredengineer.com

How to Easily Calculate Tooth Forces on Spur and Helical Gears How To Cut Helical Gears Sliding velocity increases as the distance from the pitch point increases in the line of action. Procedure of helical gear cutting : Cutting helical gears on the horizontal mill 6: Cutting a helical gear is just like cutting a spur gear except for some key differences: Read on to learn more about the different cutting methods. Sliding is of greatest. How To Cut Helical Gears.

From www.youtube.com

Cutting of Helical gear on Hobbing machine YouTube How To Cut Helical Gears Cutting helical gears on the horizontal mill 3: Turn the given ci bank to required diameter in centre lathe. The teeth of a helical gear are cut using a gear hobbing machine or a gear shaping machine. A whilst the gear is being cut, the milling table moves by. The points of contact furthest from the pitch point are the. How To Cut Helical Gears.

From www.nst.com.my

All hail the helical cut gear New Straits Times Malaysia General How To Cut Helical Gears Sliding velocity increases as the distance from the pitch point increases in the line of action. A whilst the gear is being cut, the milling table moves by. Read on to learn more about the different cutting methods. Installing & setting up the universal headsupport. Cutting helical gears on the horizontal mill 3: Sliding is of greatest concern at the. How To Cut Helical Gears.

From grabcad.com

how to create a helical gear GrabCAD Tutorials How To Cut Helical Gears Cutting a helical gear is just like cutting a spur gear except for some key differences: Read on to learn more about the different cutting methods. Helical gears can be produced from. The points of contact furthest from the pitch point are the sap and eap. Sliding velocity increases as the distance from the pitch point increases in the line. How To Cut Helical Gears.

From www.transmissions-gears.com

External Helical Cut Gears With Internal Spur Gear Involute Splines How To Cut Helical Gears 81k views 1 year ago. A whilst the gear is being cut, the milling table moves by. In cases of high profile shift, the pitch point may. The points of contact furthest from the pitch point are the sap and eap. Sliding velocity increases as the distance from the pitch point increases in the line of action. Cutting helical gears. How To Cut Helical Gears.

From grabcad.com

Tutorial Creating Helical Gear in SolidWorks? GrabCAD Tutorials How To Cut Helical Gears The points of contact furthest from the pitch point are the sap and eap. Gear cutting allows you to make worm, bevel, spur, helical, or herringbone gears, but there isn’t just one way of doing it. 81k views 1 year ago. Cutting helical gears on the horizontal mill 3: Sliding is of greatest concern at the sap and eap, when. How To Cut Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations How To Cut Helical Gears 81k views 1 year ago. Cutting a helical gear is just like cutting a spur gear except for some key differences: In cases of high profile shift, the pitch point may. A whilst the gear is being cut, the milling table moves by. Sliding is of greatest concern at the sap and eap, when a pair of helical gear teeth. How To Cut Helical Gears.

From www.youtube.com

Design of Helical Gears An Example (English) YouTube How To Cut Helical Gears Procedure of helical gear cutting : 81k views 1 year ago. The teeth of a helical gear are cut using a gear hobbing machine or a gear shaping machine. In cases of high profile shift, the pitch point may. Turn the given ci bank to required diameter in centre lathe. A whilst the gear is being cut, the milling table. How To Cut Helical Gears.

From 3dcadmodel.blogspot.com

3D CAD Model Tutorial Use Cut Swept to Draw Helical Gear How To Cut Helical Gears Turn the given ci bank to required diameter in centre lathe. Procedure of helical gear cutting : The points of contact furthest from the pitch point are the sap and eap. Cutting helical gears on the horizontal mill 3: Cutting a helical gear is just like cutting a spur gear except for some key differences: The teeth of a helical. How To Cut Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations How To Cut Helical Gears Helical gears can be produced from. Turn the given ci bank to required diameter in centre lathe. Cutting helical gears on the horizontal mill 6: A whilst the gear is being cut, the milling table moves by. Read on to learn more about the different cutting methods. Gear cutting allows you to make worm, bevel, spur, helical, or herringbone gears,. How To Cut Helical Gears.

From www.youtube.com

HELICAL VS. STRAIGHT CUT GEARS Donut Media YouTube How To Cut Helical Gears Cutting helical gears on the horizontal mill 6: Cutting helical gears on the horizontal mill 3: Sliding is of greatest concern at the sap and eap, when a pair of helical gear teeth are entering or exiting the mesh cycle. Turn the given ci bank to required diameter in centre lathe. Procedure of helical gear cutting : Installing & setting. How To Cut Helical Gears.

From mechanicbokobokov3m.z21.web.core.windows.net

Helical Cut Gears Vs Straight Cut How To Cut Helical Gears Sliding is of greatest concern at the sap and eap, when a pair of helical gear teeth are entering or exiting the mesh cycle. Gear cutting allows you to make worm, bevel, spur, helical, or herringbone gears, but there isn’t just one way of doing it. Cutting helical gears on the horizontal mill 3: 81k views 1 year ago. Drill. How To Cut Helical Gears.

From www.youtube.com

Helical Gear with Animation (Video Tutorial) SolidWorks YouTube How To Cut Helical Gears Installing & setting up the universal headsupport. The points of contact furthest from the pitch point are the sap and eap. Cutting a helical gear is just like cutting a spur gear except for some key differences: Turn the given ci bank to required diameter in centre lathe. Sliding is of greatest concern at the sap and eap, when a. How To Cut Helical Gears.

From engineblogfpc8is.z21.web.core.windows.net

Straight Cut Gears Vs Helical Gears How To Cut Helical Gears Cutting helical gears on the horizontal mill 6: In cases of high profile shift, the pitch point may. Cutting helical gears on the horizontal mill 3: Cutting a helical gear is just like cutting a spur gear except for some key differences: Procedure of helical gear cutting : The teeth of a helical gear are cut using a gear hobbing. How To Cut Helical Gears.

From grabcad.com

how to create a helical gear GrabCAD Tutorials How To Cut Helical Gears Procedure of helical gear cutting : Turn the given ci bank to required diameter in centre lathe. A whilst the gear is being cut, the milling table moves by. Cutting helical gears on the horizontal mill 3: Cutting a helical gear is just like cutting a spur gear except for some key differences: Sliding velocity increases as the distance from. How To Cut Helical Gears.

From www.youtube.com

helical gears axial load YouTube How To Cut Helical Gears Cutting a helical gear is just like cutting a spur gear except for some key differences: Read on to learn more about the different cutting methods. The points of contact furthest from the pitch point are the sap and eap. The teeth of a helical gear are cut using a gear hobbing machine or a gear shaping machine. Drill a. How To Cut Helical Gears.

From www.researchgate.net

Assembly of the helicalgear set (a) layout sketch;(b) mating of teeth How To Cut Helical Gears Turn the given ci bank to required diameter in centre lathe. Drill a hole in the blank of diameter. Cutting helical gears on the horizontal mill 3: Read on to learn more about the different cutting methods. Cutting helical gears on the horizontal mill 6: The teeth of a helical gear are cut using a gear hobbing machine or a. How To Cut Helical Gears.