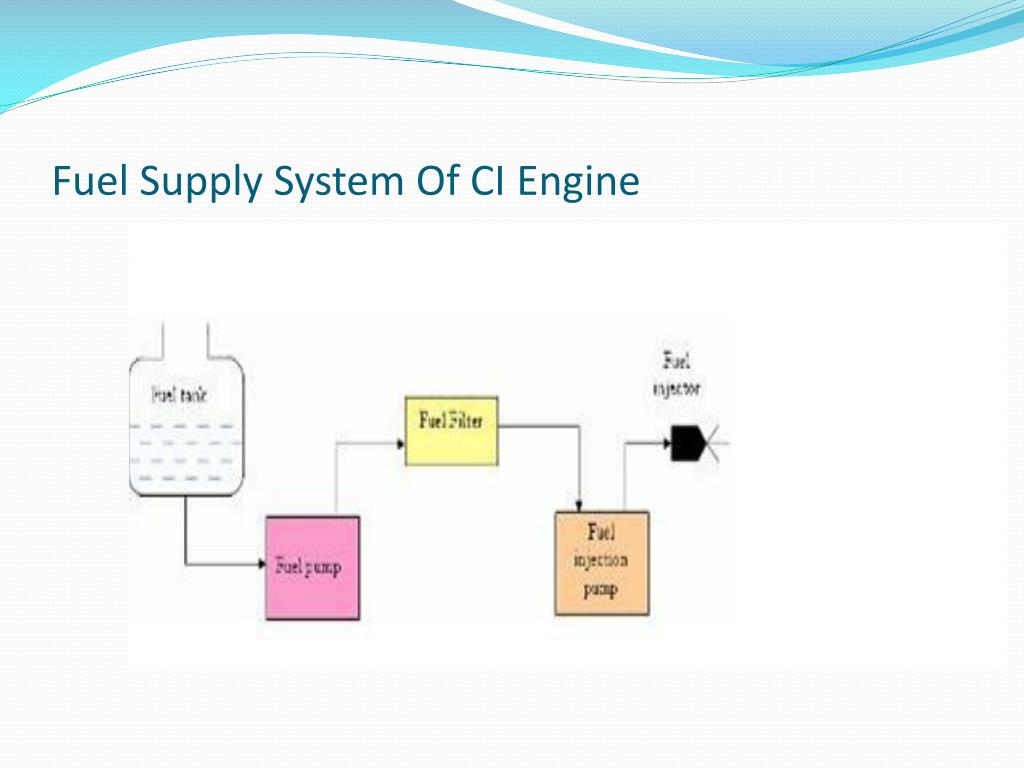

Ci Engine Fuel Injection System . The fuel supply system of a diesel engine can be called as the heart of the engine, since the. Introduction to fuel supply system for ci engines: When the combustion cycle is exactly right, the injector atomizes the fuel and forces it into the combustion chamber. For supplying high pressure air multistage air compressors are required, which are very much costly and. During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. The function of a fuel injection system is to meter the appropriate quantity of fuel for the given engine speed and load to each cylinder, each. A ci engine uses a fuel injector to atomize and inject fuel. A fuel injection system is a critical component in modern ic engines, responsible for precisely delivering fuel to the engine's combustion chamber. Recent injection systems are capable of delivering up to nine injection events per cycle [10, 26]. Thus, a high number of. In this case fuel is injected under the pressure of air.

from www.slideserve.com

Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. A fuel injection system is a critical component in modern ic engines, responsible for precisely delivering fuel to the engine's combustion chamber. For supplying high pressure air multistage air compressors are required, which are very much costly and. During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. Introduction to fuel supply system for ci engines: In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. Recent injection systems are capable of delivering up to nine injection events per cycle [10, 26]. A ci engine uses a fuel injector to atomize and inject fuel. Thus, a high number of. The function of a fuel injection system is to meter the appropriate quantity of fuel for the given engine speed and load to each cylinder, each.

PPT FUEL SUPPLY SYSTEMS PowerPoint Presentation, free download ID

Ci Engine Fuel Injection System When the combustion cycle is exactly right, the injector atomizes the fuel and forces it into the combustion chamber. Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. A ci engine uses a fuel injector to atomize and inject fuel. Introduction to fuel supply system for ci engines: A fuel injection system is a critical component in modern ic engines, responsible for precisely delivering fuel to the engine's combustion chamber. When the combustion cycle is exactly right, the injector atomizes the fuel and forces it into the combustion chamber. The function of a fuel injection system is to meter the appropriate quantity of fuel for the given engine speed and load to each cylinder, each. Recent injection systems are capable of delivering up to nine injection events per cycle [10, 26]. In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. The fuel supply system of a diesel engine can be called as the heart of the engine, since the. During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. For supplying high pressure air multistage air compressors are required, which are very much costly and. Thus, a high number of. In this case fuel is injected under the pressure of air.

From www.pinterest.com.mx

What Is Direct Fuel Injection, and How Does It Work? Fuel injection Ci Engine Fuel Injection System In this case fuel is injected under the pressure of air. Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. In ci engines, the air. Ci Engine Fuel Injection System.

From www.samarins.com

Direct Injection in a car How it works, pros and cons, maintenance Ci Engine Fuel Injection System The fuel supply system of a diesel engine can be called as the heart of the engine, since the. The function of a fuel injection system is to meter the appropriate quantity of fuel for the given engine speed and load to each cylinder, each. Direct injection of the fuel into the combustion chamber provided high resistance to knock, which. Ci Engine Fuel Injection System.

From www.slideserve.com

PPT FUEL SUPPLY SYSTEMS PowerPoint Presentation, free download ID Ci Engine Fuel Injection System During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. In this case fuel is injected under the pressure of air. Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. When the combustion cycle is. Ci Engine Fuel Injection System.

From www.researchgate.net

Schematic diagram of a typical automotive fuel system Download Ci Engine Fuel Injection System For supplying high pressure air multistage air compressors are required, which are very much costly and. The function of a fuel injection system is to meter the appropriate quantity of fuel for the given engine speed and load to each cylinder, each. Introduction to fuel supply system for ci engines: Thus, a high number of. In ci engines, the air. Ci Engine Fuel Injection System.

From www.aircraftsystemstech.com

Aircraft Systems Reciprocating Engine Fuel Injection Systems Ci Engine Fuel Injection System Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. Recent injection systems are capable of delivering up to nine injection events per cycle [10, 26].. Ci Engine Fuel Injection System.

From www.slideserve.com

PPT Fuel Injection System PowerPoint Presentation, free download ID Ci Engine Fuel Injection System The fuel supply system of a diesel engine can be called as the heart of the engine, since the. For supplying high pressure air multistage air compressors are required, which are very much costly and. Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark. Ci Engine Fuel Injection System.

From www.ingenieriaymecanicaautomotriz.com

INJECTION SYSTEM COMPONENTS, TYPES AND WORKING PRINCIPLES INGENIERÍA Ci Engine Fuel Injection System In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. Introduction to fuel supply system for ci engines: Recent injection systems are capable of delivering up to nine injection events per cycle [10, 26]. In this case fuel is injected under the pressure of air. During. Ci Engine Fuel Injection System.

From innovationdiscoveries.space

KJetronic Fuel Injection System Ci Engine Fuel Injection System For supplying high pressure air multistage air compressors are required, which are very much costly and. During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. A fuel injection system is a critical component in modern ic engines, responsible for precisely delivering fuel to the engine's combustion chamber. When the combustion cycle. Ci Engine Fuel Injection System.

From www.newkidscar.com

FUEL SYSTEM Car Anatomy Ci Engine Fuel Injection System A ci engine uses a fuel injector to atomize and inject fuel. In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. The function of a fuel injection system is to meter the appropriate quantity of fuel for the given engine speed and load to each. Ci Engine Fuel Injection System.

From www.carsguide.com.au

Fuel Injector How a Fuel Injected Engine Works CarsGuide Ci Engine Fuel Injection System In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. A ci engine uses a fuel injector to atomize and. Ci Engine Fuel Injection System.

From enggsiksha.blogspot.com

Technology Fuel Injection System Ci Engine Fuel Injection System During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. For supplying high pressure air multistage air compressors are required, which are very much costly and. A ci engine uses a fuel injector to atomize and inject fuel. A fuel injection system is a critical component in modern ic engines, responsible for. Ci Engine Fuel Injection System.

From www.howacarworks.com

How a fuel injection system works How a Car Works Ci Engine Fuel Injection System When the combustion cycle is exactly right, the injector atomizes the fuel and forces it into the combustion chamber. The fuel supply system of a diesel engine can be called as the heart of the engine, since the. Thus, a high number of. Introduction to fuel supply system for ci engines: Direct injection of the fuel into the combustion chamber. Ci Engine Fuel Injection System.

From speed.academy

Direct InjectionHow It Works And Why It’s A Game Changer (For Better Ci Engine Fuel Injection System When the combustion cycle is exactly right, the injector atomizes the fuel and forces it into the combustion chamber. In this case fuel is injected under the pressure of air. A fuel injection system is a critical component in modern ic engines, responsible for precisely delivering fuel to the engine's combustion chamber. A ci engine uses a fuel injector to. Ci Engine Fuel Injection System.

From skill-lync.com

All You Need to Know about Fuel Injection Systems in SI Engines Ci Engine Fuel Injection System When the combustion cycle is exactly right, the injector atomizes the fuel and forces it into the combustion chamber. The function of a fuel injection system is to meter the appropriate quantity of fuel for the given engine speed and load to each cylinder, each. Thus, a high number of. For supplying high pressure air multistage air compressors are required,. Ci Engine Fuel Injection System.

From dokumen.tips

(PPTX) Fuel injection system in c.i engines DOKUMEN.TIPS Ci Engine Fuel Injection System For supplying high pressure air multistage air compressors are required, which are very much costly and. A ci engine uses a fuel injector to atomize and inject fuel. In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. In this case fuel is injected under the. Ci Engine Fuel Injection System.

From www.spinny.com

Explore the different types of fuel injectors at Spinny Ci Engine Fuel Injection System In this case fuel is injected under the pressure of air. For supplying high pressure air multistage air compressors are required, which are very much costly and. Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. A fuel injection system is a critical. Ci Engine Fuel Injection System.

From www.alamy.com

Common rail direct fuel injection is a direct fuel injection system for Ci Engine Fuel Injection System A fuel injection system is a critical component in modern ic engines, responsible for precisely delivering fuel to the engine's combustion chamber. Thus, a high number of. During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. The fuel supply system of a diesel engine can be called as the heart of. Ci Engine Fuel Injection System.

From www.mdpi.com

Applied Sciences Free FullText Experimental Study on the Effects Ci Engine Fuel Injection System When the combustion cycle is exactly right, the injector atomizes the fuel and forces it into the combustion chamber. A ci engine uses a fuel injector to atomize and inject fuel. Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. The fuel supply. Ci Engine Fuel Injection System.

From www.theengineerspost.com

Fuel Injection System Diagram, Parts, Working, Types [PDF] Ci Engine Fuel Injection System In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. Thus, a high number of. Introduction to fuel supply system for ci engines: A fuel injection system is a critical component in modern ic engines, responsible for precisely delivering fuel to the engine's combustion chamber. Direct. Ci Engine Fuel Injection System.

From www.dieseltechmag.com

Fuel Under Pressure Diesel fuel injectors make things work Diesel Ci Engine Fuel Injection System During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. A ci engine uses a fuel injector to atomize and inject fuel. Recent injection systems are capable of delivering up to nine injection events per cycle [10, 26]. Thus, a high number of. A fuel injection system is a critical component in. Ci Engine Fuel Injection System.

From learnmech.com

Electronic fuel injection System Parts ,Types, Working , Advantages Ci Engine Fuel Injection System Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. Thus, a high number of. In this case fuel is injected under the pressure of air.. Ci Engine Fuel Injection System.

From www.youtube.com

CI Engine CRDI Fuel Injection System M2.42 Thermal Engineering in Ci Engine Fuel Injection System Introduction to fuel supply system for ci engines: Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. Recent injection systems are capable of delivering up to nine injection events per cycle [10, 26]. The fuel supply system of a diesel engine can be. Ci Engine Fuel Injection System.

From www.youtube.com

PETROL INJECTION SYSTEM,TYPES OF FUEL INJECTION YouTube Ci Engine Fuel Injection System In this case fuel is injected under the pressure of air. A fuel injection system is a critical component in modern ic engines, responsible for precisely delivering fuel to the engine's combustion chamber. When the combustion cycle is exactly right, the injector atomizes the fuel and forces it into the combustion chamber. During the compression of air, a fuel injector. Ci Engine Fuel Injection System.

From www.howacarworks.com

How a fuel injection system works How a Car Works Ci Engine Fuel Injection System Introduction to fuel supply system for ci engines: In this case fuel is injected under the pressure of air. In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. The function of a fuel injection system is to meter the appropriate quantity of fuel for the. Ci Engine Fuel Injection System.

From www.youtube.com

Fuel Injection Systems in SI Engines SkillLync YouTube Ci Engine Fuel Injection System Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. In this case fuel is injected under the pressure of air. The function of a fuel. Ci Engine Fuel Injection System.

From www.researchgate.net

(PDF) CI Diesel Engine Fuel Injection System Ci Engine Fuel Injection System Thus, a high number of. A ci engine uses a fuel injector to atomize and inject fuel. In this case fuel is injected under the pressure of air. For supplying high pressure air multistage air compressors are required, which are very much costly and. Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits. Ci Engine Fuel Injection System.

From www.pinterest.com

How a Fuel Injection System Works Car Fuel Injection System Fuel Ci Engine Fuel Injection System Recent injection systems are capable of delivering up to nine injection events per cycle [10, 26]. The fuel supply system of a diesel engine can be called as the heart of the engine, since the. In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. When. Ci Engine Fuel Injection System.

From skill-lync.com

Combustion simulation of Port Fuel Injection SI engine Full Ci Engine Fuel Injection System Thus, a high number of. During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. For supplying high pressure air multistage air compressors are required, which are very much costly and. In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70. Ci Engine Fuel Injection System.

From www.youtube.com

Types of Fuel Injection System Direct Fuel Injection, Indirect Fuel Ci Engine Fuel Injection System A fuel injection system is a critical component in modern ic engines, responsible for precisely delivering fuel to the engine's combustion chamber. A ci engine uses a fuel injector to atomize and inject fuel. Thus, a high number of. In this case fuel is injected under the pressure of air. For supplying high pressure air multistage air compressors are required,. Ci Engine Fuel Injection System.

From www.cars24.com

Fuel Injection Types A Quick Guide by CARS24 Ci Engine Fuel Injection System During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. Thus, a high number of. When the combustion cycle is exactly right, the injector atomizes the fuel and forces it into the combustion chamber. Introduction to fuel supply system for ci engines: Direct injection of the fuel into the combustion chamber provided. Ci Engine Fuel Injection System.

From store5603150.ecwid.com

MultiPort Fuel Injection System for 350 CI Small Block Ci Engine Fuel Injection System Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. During the compression of air, a fuel injector injects fuel into the cylinder, allowing it to be burned. In ci engines, the air is taken in during the suction stroke and compressed to a. Ci Engine Fuel Injection System.

From learntoflyblog.com

Aircraft Systems Fuel Injection Systems Learn to Fly Blog ASA Ci Engine Fuel Injection System In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. Recent injection systems are capable of delivering up to nine injection events per cycle [10, 26]. A ci engine uses a fuel injector to atomize and inject fuel. When the combustion cycle is exactly right, the. Ci Engine Fuel Injection System.

From asecertificationtraining.com

Diesel Engine Injection Pump ASE Certification Training HQ Ci Engine Fuel Injection System A fuel injection system is a critical component in modern ic engines, responsible for precisely delivering fuel to the engine's combustion chamber. In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. The function of a fuel injection system is to meter the appropriate quantity of. Ci Engine Fuel Injection System.

From www.researchgate.net

A typical Common rail diesel fuel injection system. Download Ci Engine Fuel Injection System A ci engine uses a fuel injector to atomize and inject fuel. In this case fuel is injected under the pressure of air. In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. Thus, a high number of. When the combustion cycle is exactly right, the. Ci Engine Fuel Injection System.

From gomechanic.in

Types Of Diesel Injection Systems Explained Ci Engine Fuel Injection System In ci engines, the air is taken in during the suction stroke and compressed to a high pressure (28 to 70 bar) and high. Direct injection of the fuel into the combustion chamber provided high resistance to knock, which limits the compression ratio and ultimately, the efficiency of spark ignition. The function of a fuel injection system is to meter. Ci Engine Fuel Injection System.