Eddy Current Testing Turbine Blade . this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object.

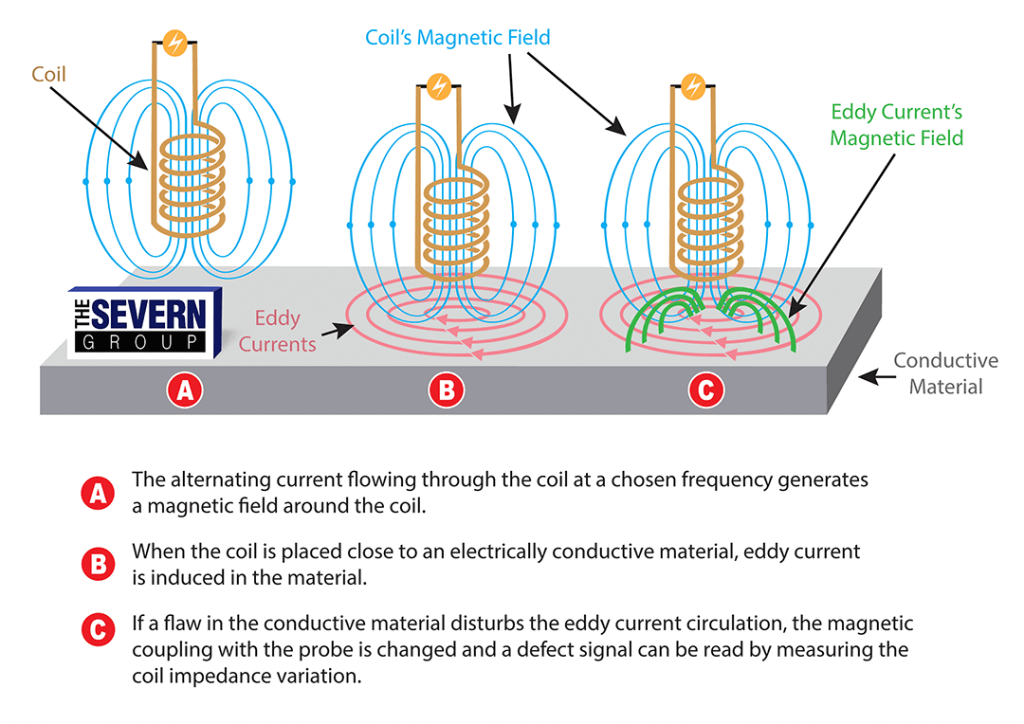

from www.theseverngroup.com

the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted.

Eddy Current Testing 101 The Severn Group

Eddy Current Testing Turbine Blade eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed.

From tecscan.ca

Automated Eddy Current Testing for Aeroengine Components TecScan Eddy Current Testing Turbine Blade this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. more than a. Eddy Current Testing Turbine Blade.

From fsmerdunordhtschematic.z21.web.core.windows.net

Eddy Current Break System Eddy Current Testing Turbine Blade more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. eddy. Eddy Current Testing Turbine Blade.

From www.youtube.com

Turbine Blade Inspection YouTube Eddy Current Testing Turbine Blade more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. the quantitative evaluation. Eddy Current Testing Turbine Blade.

From www.victor-aviation.com

Eddy Current Testing Aircraft Engine Overhaul Eddy Current Testing Turbine Blade in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. this paper has simulated a rotating bladed. Eddy Current Testing Turbine Blade.

From www.zetec.com

Employing Ultrasonic or Eddy Current Inspection of Turbine Blades Ensuring Flight Safety Zetec Eddy Current Testing Turbine Blade eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. the quantitative evaluation. Eddy Current Testing Turbine Blade.

From www.reddit.com

First post here. Gas turbine bucket dovetails have passed eddy current and fluorescent dye pen Eddy Current Testing Turbine Blade eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. in order to find. Eddy Current Testing Turbine Blade.

From www.researchgate.net

(PDF) Frequency Scanning Eddy Current testing (FSECT) for Condition Assessment of Multiple Eddy Current Testing Turbine Blade eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. the quantitative evaluation of blade. Eddy Current Testing Turbine Blade.

From www.theseverngroup.com

Eddy Current Testing 101 The Severn Group Eddy Current Testing Turbine Blade this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. the quantitative evaluation of blade surface fatigue. Eddy Current Testing Turbine Blade.

From www.integrityndt.com

Eddy Current Tube Inspection Integrity NDT Eddy Current Testing Turbine Blade eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. in order to find the early cracks of. Eddy Current Testing Turbine Blade.

From www.mdpi.com

Sensors Free FullText Eddy Current Sensor System for Blade Tip Clearance Measurement Based Eddy Current Testing Turbine Blade eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. eddy current is able to detect surface flaws with 200µm in. Eddy Current Testing Turbine Blade.

From www.youtube.com

Eddy Current Bore Hole Inspection YouTube Eddy Current Testing Turbine Blade this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. the quantitative evaluation of blade surface. Eddy Current Testing Turbine Blade.

From tiat.nl

Eddy Current Testing Tiat Europe B.V. Eddy Current Testing Turbine Blade it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. eddy current is able to detect surface flaws with. Eddy Current Testing Turbine Blade.

From dynesystems.com

Custom Eddy Current Dyno Testing Dyne Systems Eddy Current Testing Turbine Blade eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. it is quite important to nondestructively comprehend. Eddy Current Testing Turbine Blade.

From www.twi-global.com

Eddy Current Testing A Definitive Guide (Includes Eddy Current Array) TWI Eddy Current Testing Turbine Blade in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. the quantitative evaluation of blade surface. Eddy Current Testing Turbine Blade.

From deltatest.de

Turbine blades Delta Test GmbH Eddy Current Testing Turbine Blade eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. more than a decade later, innovative new. Eddy Current Testing Turbine Blade.

From www.semanticscholar.org

Figure 5 from High resolution crack detection on turbine blade roots by the use of eddy current Eddy Current Testing Turbine Blade more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. the quantitative evaluation of. Eddy Current Testing Turbine Blade.

From www.kalva.net

Kalva Home Eddy Current Testing Turbine Blade eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. this paper has simulated. Eddy Current Testing Turbine Blade.

From www.youtube.com

Eddy Current Testing (NDT) YouTube Eddy Current Testing Turbine Blade this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. the quantitative evaluation of blade surface fatigue cracks is. Eddy Current Testing Turbine Blade.

From www.sciencephoto.com

Technician testing aircraft engine turbine blades Stock Image T612/0120 Science Photo Library Eddy Current Testing Turbine Blade it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. in order to find the early cracks of steam turbine. Eddy Current Testing Turbine Blade.

From simutechgroup.com

Turbine Blade Testing Services Ansys Consulting Eddy Current Testing Turbine Blade the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. this paper has simulated a rotating bladed disk. Eddy Current Testing Turbine Blade.

From www.researchgate.net

(PDF) Eddy Current Testing Basics Eddy Current Testing Turbine Blade this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. eddy current is able to detect surface flaws with 200µm in depth. Eddy Current Testing Turbine Blade.

From www.youtube.com

Eddycon C for aircraft testing using eddy current YouTube Eddy Current Testing Turbine Blade this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. the quantitative evaluation of. Eddy Current Testing Turbine Blade.

From dynesystems.com

Custom Eddy Current Dyno Testing Dyne Systems Eddy Current Testing Turbine Blade eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. it is quite important. Eddy Current Testing Turbine Blade.

From www.ndt.org

Eddy Current Testing in Wind Turbines Eddy Current Testing Turbine Blade the quantitative evaluation of blade surface fatigue cracks is extremely significant to hdgt. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. eddy current sensors are increasingly being used. Eddy Current Testing Turbine Blade.

From www.qualitymag.com

Eddy Current Inspection of InService Aircraft Structure Quality Magazine Eddy Current Testing Turbine Blade eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. the quantitative evaluation of blade surface fatigue. Eddy Current Testing Turbine Blade.

From www.victor-aviation.com

Eddy Current Testing Aircraft Engine Overhaul Eddy Current Testing Turbine Blade it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. in order to find the early cracks of steam. Eddy Current Testing Turbine Blade.

From www.aerospacendtservices.com

METHODS Aerospace NDT Services Eddy Current Testing Turbine Blade eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. the quantitative evaluation of blade surface fatigue. Eddy Current Testing Turbine Blade.

From www.victor-aviation.com

Eddy Current Testing Aircraft Engine Overhaul Eddy Current Testing Turbine Blade eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. more than a. Eddy Current Testing Turbine Blade.

From www.bol.com

Eddy Current Pulsed Thermography of Cfrp for Wind Turbine Blades 9783659486043 Eddy Current Testing Turbine Blade more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. eddy current is. Eddy Current Testing Turbine Blade.

From www.qualitymag.com

Automated Eddy Current Testing Solution for Aeroengine Discs 20190708 Quality Magazine Eddy Current Testing Turbine Blade eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. the. Eddy Current Testing Turbine Blade.

From exofodgsv.blob.core.windows.net

Eddy Current Testing Kit at John Ford blog Eddy Current Testing Turbine Blade eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. this paper has. Eddy Current Testing Turbine Blade.

From exoxwufee.blob.core.windows.net

Eddy Current Testing Method Corrosion at Louie Rushing blog Eddy Current Testing Turbine Blade eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. eddy current is able to detect surface flaws with 200µm. Eddy Current Testing Turbine Blade.

From www.tecscan.ca

Turbine Blade Inspection TecScan Eddy Current Testing Turbine Blade more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. eddy current is able to detect surface flaws with 200µm in depth on a material with relative barely conductivity. this paper has simulated a rotating bladed. Eddy Current Testing Turbine Blade.

From simutechgroup.com

Turbine Blade Testing Services Ansys Consulting Eddy Current Testing Turbine Blade in order to find the early cracks of steam turbine blade, 2cr12nimowv stainless steel was taken as the research object. this paper has simulated a rotating bladed disk monitored by passive and active eddy current sensors mounted. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. the quantitative evaluation. Eddy Current Testing Turbine Blade.

From exovouukk.blob.core.windows.net

Eddy Current Testing at Timothy Kincaid blog Eddy Current Testing Turbine Blade it is quite important to nondestructively comprehend the depths of surface‐breaking cracks in blades. more than a decade later, innovative new eddy current array (eca) solutions are constantly being developed. eddy current sensors are increasingly being used to measure the dynamic blade tip clearance in turbines. this paper has simulated a rotating bladed disk monitored by. Eddy Current Testing Turbine Blade.