End Mill Slotting Depth Of Cut . I was given the recommended speeds and feed of 300sfm and.002. The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. When slotting with an end mill the only variable is the axial depth of cut (a p). Full slotting with an end mill is a demanding operation. Get accurate results with cnc cookbook. Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. For smaller taper machining centers or less rigid conditions, please adjust parameters. The tougher the material the shallower the cut. I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless steel. Machine rigidity and chip evacuation should also be. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. The above recommendations are based on ideal conditions; The axial cutting depth should be generally reduced to around 70% of the edge length.

from www.mscdirect.com

The tougher the material the shallower the cut. The above recommendations are based on ideal conditions; The axial cutting depth should be generally reduced to around 70% of the edge length. Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. For smaller taper machining centers or less rigid conditions, please adjust parameters. The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. Full slotting with an end mill is a demanding operation. Machine rigidity and chip evacuation should also be. When slotting with an end mill the only variable is the axial depth of cut (a p).

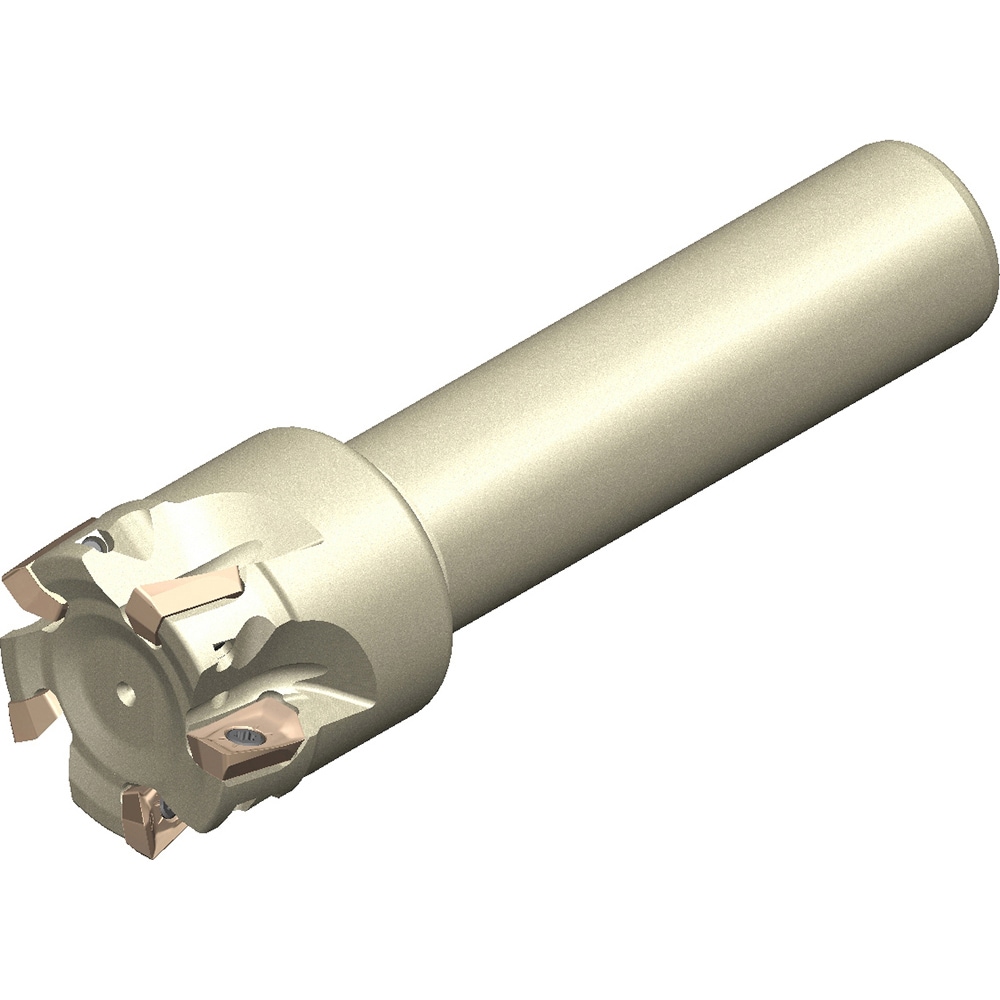

Sumitomo Indexable SquareShoulder End Mill WEZ17040EL02, 40 mm Cut

End Mill Slotting Depth Of Cut I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless steel. For smaller taper machining centers or less rigid conditions, please adjust parameters. Get accurate results with cnc cookbook. Full slotting with an end mill is a demanding operation. Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. Machine rigidity and chip evacuation should also be. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. The tougher the material the shallower the cut. When slotting with an end mill the only variable is the axial depth of cut (a p). I was given the recommended speeds and feed of 300sfm and.002. I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless steel. The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. The axial cutting depth should be generally reduced to around 70% of the edge length. The above recommendations are based on ideal conditions;

From stepcraft.com.au

END MILLS Undercut Slotting Bit 1/4" End Mill Slotting Depth Of Cut Machine rigidity and chip evacuation should also be. The axial cutting depth should be generally reduced to around 70% of the edge length. Get accurate results with cnc cookbook. The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. I ordered a couple 5 flute carbide end mills from. End Mill Slotting Depth Of Cut.

From www.walmart.com

T Slot End Mill Milling Cutter 8 Flutes 20mm Cutting Dia 4mm Depth End Mill Slotting Depth Of Cut Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. The tougher the material the shallower the cut. I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless steel. The cutting speed varies with the amount of radial depth of cut when profiling and. End Mill Slotting Depth Of Cut.

From riverdeposit.mystrikingly.com

Slot Milling Depth Of Cut End Mill Slotting Depth Of Cut I was given the recommended speeds and feed of 300sfm and.002. Machine rigidity and chip evacuation should also be. Get accurate results with cnc cookbook. I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless steel. When slotting with an end mill the only variable is the axial depth of cut (a p).. End Mill Slotting Depth Of Cut.

From www.minaprem.com

What is Depth of Cut in Machining? Its Unit, Value, Effects and Selection End Mill Slotting Depth Of Cut Get accurate results with cnc cookbook. When slotting with an end mill the only variable is the axial depth of cut (a p). Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless. End Mill Slotting Depth Of Cut.

From bluelightballroom.com

Best T Slot End Mill For Your End Mill Slotting Depth Of Cut Full slotting with an end mill is a demanding operation. The tougher the material the shallower the cut. The above recommendations are based on ideal conditions; Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. Machine rigidity and chip evacuation should also be. The cutting speed varies with the. End Mill Slotting Depth Of Cut.

From www.walmart.com

T Slot End Mill Milling Cutter 6 Flutes 16mm Cutting Dia 4mm Depth End Mill Slotting Depth Of Cut The tougher the material the shallower the cut. Machine rigidity and chip evacuation should also be. The above recommendations are based on ideal conditions; Get accurate results with cnc cookbook. Full slotting with an end mill is a demanding operation. For smaller taper machining centers or less rigid conditions, please adjust parameters. I was given the recommended speeds and feed. End Mill Slotting Depth Of Cut.

From edwardocooley.blogspot.com

roughing end mill cutter diagram Edwardo Cooley End Mill Slotting Depth Of Cut The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. The above recommendations are based on ideal conditions; Get accurate results with cnc cookbook. Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. I ordered a couple 5. End Mill Slotting Depth Of Cut.

From www.walmart.com

T Slot End Mill Milling Cutter 8 Flutes 32mm Cutting Dia 6mm Depth End Mill Slotting Depth Of Cut I was given the recommended speeds and feed of 300sfm and.002. Get accurate results with cnc cookbook. The above recommendations are based on ideal conditions; Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. The cutting speed varies with the amount of radial depth of cut when profiling and. End Mill Slotting Depth Of Cut.

From my.misumi-ec.com

Milling Tips / Holders Ball End Mills Technical Information Tools End Mill Slotting Depth Of Cut I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless steel. Get accurate results with cnc cookbook. For smaller taper machining centers or less rigid conditions, please adjust parameters. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. When slotting with an end. End Mill Slotting Depth Of Cut.

From www.carbideanddiamondtooling.com

Slotting Cutters High Speed Steel, Cobalt, Cutting Tools End Mill Slotting Depth Of Cut For smaller taper machining centers or less rigid conditions, please adjust parameters. Machine rigidity and chip evacuation should also be. Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. The above recommendations are based on ideal conditions; I ordered a couple 5 flute carbide end mills from lakeshore carbide. End Mill Slotting Depth Of Cut.

From www.ctemag.com

Going deep into slotting Cutting Tool Engineering End Mill Slotting Depth Of Cut When slotting with an end mill the only variable is the axial depth of cut (a p). Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless steel. Full slotting with an end. End Mill Slotting Depth Of Cut.

From www.amazon.com

6mm Dia 19mm Cutting Depth Four Flute Slotting End Mill End Mill Slotting Depth Of Cut The axial cutting depth should be generally reduced to around 70% of the edge length. The above recommendations are based on ideal conditions; Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. I was given the recommended speeds and feed of 300sfm and.002. Get accurate results with cnc cookbook.. End Mill Slotting Depth Of Cut.

From www.slideserve.com

PPT ME 350 Lecture 5 Chapter 22 PowerPoint Presentation, free End Mill Slotting Depth Of Cut I was given the recommended speeds and feed of 300sfm and.002. I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless steel. The tougher the material the shallower the cut. The axial cutting depth should be generally reduced to around 70% of the edge length. The cutting speed varies with the amount of. End Mill Slotting Depth Of Cut.

From toolnotes.com

Cutting Parameters for Milling ToolNotes End Mill Slotting Depth Of Cut The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless steel. Full slotting with an end mill is a demanding operation. The above recommendations are based on ideal conditions; Take control of. End Mill Slotting Depth Of Cut.

From bluelightballroom.com

Best T Slot End Mill For Your End Mill Slotting Depth Of Cut The axial cutting depth should be generally reduced to around 70% of the edge length. When slotting with an end mill the only variable is the axial depth of cut (a p). Get accurate results with cnc cookbook. The above recommendations are based on ideal conditions; Slotting with an end mill angle of engagement (or arc of contact) the angle. End Mill Slotting Depth Of Cut.

From chenriprecision.en.made-in-china.com

Deep Slotting Cutting Mills Altin Coated Carbide End Mills for CNC End Mill Slotting Depth Of Cut When slotting with an end mill the only variable is the axial depth of cut (a p). Get accurate results with cnc cookbook. Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. Machine rigidity and chip evacuation should also be. Take control of your cnc machining projects with two. End Mill Slotting Depth Of Cut.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools End Mill Slotting Depth Of Cut Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. The tougher the material the shallower the cut. The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. The axial cutting depth should be generally reduced to around 70% of. End Mill Slotting Depth Of Cut.

From blog.tormach.com

The Anatomy of an End Mill End Mill Slotting Depth Of Cut Machine rigidity and chip evacuation should also be. Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. The tougher the material the shallower the cut. For smaller taper machining centers or less rigid conditions, please adjust parameters. When slotting with an end mill the only variable is the axial. End Mill Slotting Depth Of Cut.

From toolnotes.com

Cutting Parameters for Milling ToolNotes End Mill Slotting Depth Of Cut Get accurate results with cnc cookbook. The tougher the material the shallower the cut. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. For smaller taper machining centers or less rigid conditions, please adjust parameters. The axial cutting depth should be generally reduced to around 70% of the edge length.. End Mill Slotting Depth Of Cut.

From femjoy-virtuagirl-hd-25.blogspot.com

roughing end mill depth of cut Big History Blogger Photography End Mill Slotting Depth Of Cut The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. Get accurate results with cnc cookbook. I ordered a couple 5 flute carbide end mills from lakeshore carbide that were. End Mill Slotting Depth Of Cut.

From toolnotes.com

Milling Operations ToolNotes End Mill Slotting Depth Of Cut The tougher the material the shallower the cut. The axial cutting depth should be generally reduced to around 70% of the edge length. For smaller taper machining centers or less rigid conditions, please adjust parameters. The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. Take control of your. End Mill Slotting Depth Of Cut.

From endmill.com.au

Choosing the right end mill for the job Adam's Bits End Mill Slotting Depth Of Cut The above recommendations are based on ideal conditions; Full slotting with an end mill is a demanding operation. The axial cutting depth should be generally reduced to around 70% of the edge length. The tougher the material the shallower the cut. Machine rigidity and chip evacuation should also be. I ordered a couple 5 flute carbide end mills from lakeshore. End Mill Slotting Depth Of Cut.

From www.aliexpress.com

UXCELL 25Mm Cutting Dia 6Mm Depth Hss Al 8 Flutes T Slot End Mill End Mill Slotting Depth Of Cut The tougher the material the shallower the cut. The axial cutting depth should be generally reduced to around 70% of the edge length. The above recommendations are based on ideal conditions; I was given the recommended speeds and feed of 300sfm and.002. Get accurate results with cnc cookbook. When slotting with an end mill the only variable is the axial. End Mill Slotting Depth Of Cut.

From www.aliexpress.com

10 mm cutting depth 20 mm Dia 6 flutes HSS T slot end mill toolin End Mill Slotting Depth Of Cut Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. I was given the recommended speeds and feed of 300sfm and.002. The tougher the material the shallower the cut. The above. End Mill Slotting Depth Of Cut.

From www.youtube.com

Axial and radial depth of cut in milling operations YouTube End Mill Slotting Depth Of Cut I was given the recommended speeds and feed of 300sfm and.002. The axial cutting depth should be generally reduced to around 70% of the edge length. I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless steel. The tougher the material the shallower the cut. Machine rigidity and chip evacuation should also be.. End Mill Slotting Depth Of Cut.

From toolnotes.com

Cutting Parameters for Milling ToolNotes End Mill Slotting Depth Of Cut For smaller taper machining centers or less rigid conditions, please adjust parameters. The tougher the material the shallower the cut. Machine rigidity and chip evacuation should also be. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. I ordered a couple 5 flute carbide end mills from lakeshore carbide that. End Mill Slotting Depth Of Cut.

From www.transtutors.com

(Solved) Question 1 By using a labelled diagram describe the function End Mill Slotting Depth Of Cut The axial cutting depth should be generally reduced to around 70% of the edge length. I was given the recommended speeds and feed of 300sfm and.002. For smaller taper machining centers or less rigid conditions, please adjust parameters. Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. The above. End Mill Slotting Depth Of Cut.

From www.mscdirect.com

Kyocera Indexable SquareShoulder End Mill MEC18S1611T, 18 mm Cut End Mill Slotting Depth Of Cut Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. When slotting with an end mill the only variable is the axial depth of cut (a p). Full slotting with an end mill is a demanding operation. I was given the recommended speeds and feed of 300sfm and.002. The cutting speed. End Mill Slotting Depth Of Cut.

From www.speedtigertools.com

The Beginners Guide of CNC End Mill (2023 Edition)SPEED TIGER End Mill Slotting Depth Of Cut When slotting with an end mill the only variable is the axial depth of cut (a p). Get accurate results with cnc cookbook. The axial cutting depth should be generally reduced to around 70% of the edge length. I was given the recommended speeds and feed of 300sfm and.002. For smaller taper machining centers or less rigid conditions, please adjust. End Mill Slotting Depth Of Cut.

From www.mscdirect.com

Sumitomo Indexable SquareShoulder End Mill WEZ17040EL02, 40 mm Cut End Mill Slotting Depth Of Cut I was given the recommended speeds and feed of 300sfm and.002. I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless steel. The above recommendations are based on ideal conditions; Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. The tougher the material. End Mill Slotting Depth Of Cut.

From www.harveyperformance.com

Diving Into the Depth of Cut In The Loupe Machinist Blog End Mill Slotting Depth Of Cut Machine rigidity and chip evacuation should also be. The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. I was given the recommended speeds and feed of 300sfm and.002. When slotting with an end mill the only variable is the axial depth of cut (a p). For smaller taper. End Mill Slotting Depth Of Cut.

From www.davehylands.com

Charts End Mill Slotting Depth Of Cut The tougher the material the shallower the cut. Full slotting with an end mill is a demanding operation. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. Get accurate results with cnc cookbook. The above recommendations are based on ideal conditions; I was given the recommended speeds and feed of. End Mill Slotting Depth Of Cut.

From www.researchgate.net

Discretization of the ballend mill cutting edge (a), scheme of cutting End Mill Slotting Depth Of Cut For smaller taper machining centers or less rigid conditions, please adjust parameters. Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. I ordered a couple 5 flute carbide end mills from lakeshore carbide that were made for stainless steel. The above recommendations are based on ideal conditions; The cutting. End Mill Slotting Depth Of Cut.

From engineeringlearn.com

Types of Milling Cutter Tools and Their Uses [with Pictures End Mill Slotting Depth Of Cut The tougher the material the shallower the cut. The axial cutting depth should be generally reduced to around 70% of the edge length. Slotting with an end mill angle of engagement (or arc of contact) the angle of engagement is a function of. The above recommendations are based on ideal conditions; I was given the recommended speeds and feed of. End Mill Slotting Depth Of Cut.

From www.youtube.com

E140HX D10 Multipurpose End Mills(Slotting Milling)超微粒鎢鋼塗層多用途立铣刀(溝铣 End Mill Slotting Depth Of Cut Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. The tougher the material the shallower the cut. The axial cutting depth should be generally reduced to around 70% of the edge length. Get accurate results with cnc cookbook. Full slotting with an end mill is a demanding operation. Slotting with. End Mill Slotting Depth Of Cut.