How To Minimize Vibration . And by that, we mean. By identifying and addressing these. 9 strategies to eliminate machining vibrations. This unwanted vibration can be reduced using the following five tips : Techniques for vibration reduction and control. When it comes to keeping engine vibrations in check, it pays to start with a solid foundation. The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. Looseness can be rotating or mechanically generated. The most efficient way to curb the effects of vibrations on mechanical. Adjusting cutting parameters such as speed, feed rate, and depth. There are three types of mechanical looseness to consider: Understanding the root causes of vibration is the foundation for any effective control strategy. Ways to reduce or prevent vibration.

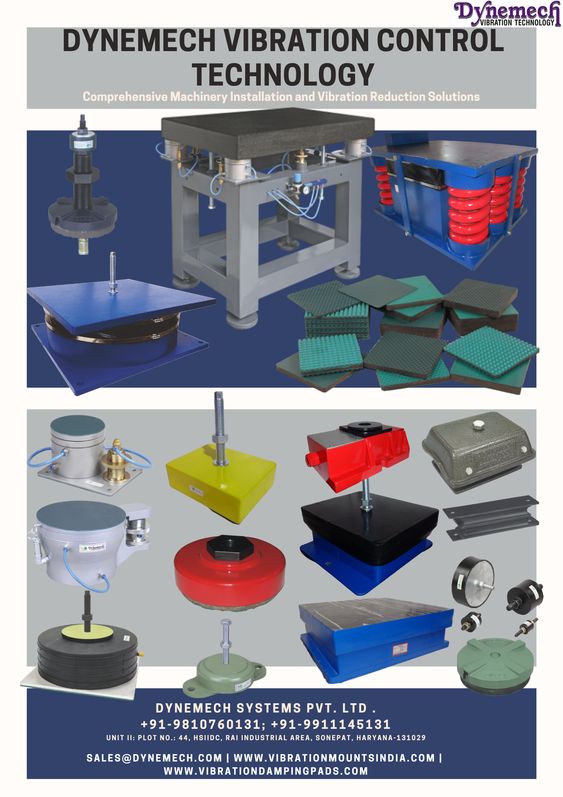

from www.vibrationmountsindia.com

The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. Techniques for vibration reduction and control. Ways to reduce or prevent vibration. There are three types of mechanical looseness to consider: 9 strategies to eliminate machining vibrations. Looseness can be rotating or mechanically generated. Understanding the root causes of vibration is the foundation for any effective control strategy. By identifying and addressing these. This unwanted vibration can be reduced using the following five tips : And by that, we mean.

Vibration Reduction Techniques in Machines

How To Minimize Vibration Understanding the root causes of vibration is the foundation for any effective control strategy. 9 strategies to eliminate machining vibrations. The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. By identifying and addressing these. Techniques for vibration reduction and control. When it comes to keeping engine vibrations in check, it pays to start with a solid foundation. The most efficient way to curb the effects of vibrations on mechanical. Looseness can be rotating or mechanically generated. Ways to reduce or prevent vibration. Adjusting cutting parameters such as speed, feed rate, and depth. And by that, we mean. This unwanted vibration can be reduced using the following five tips : Understanding the root causes of vibration is the foundation for any effective control strategy. There are three types of mechanical looseness to consider:

From giownpvko.blob.core.windows.net

How To Reduce Vibration In Lathe Machine at Bettye White blog How To Minimize Vibration By identifying and addressing these. This unwanted vibration can be reduced using the following five tips : Adjusting cutting parameters such as speed, feed rate, and depth. 9 strategies to eliminate machining vibrations. Ways to reduce or prevent vibration. Looseness can be rotating or mechanically generated. The most efficient way to curb the effects of vibrations on mechanical. There are. How To Minimize Vibration.

From www.youtube.com

Introduction to Mechanical Vibrations Ch.1 Basic Concepts (1/7 How To Minimize Vibration Ways to reduce or prevent vibration. Adjusting cutting parameters such as speed, feed rate, and depth. There are three types of mechanical looseness to consider: Understanding the root causes of vibration is the foundation for any effective control strategy. 9 strategies to eliminate machining vibrations. This unwanted vibration can be reduced using the following five tips : And by that,. How To Minimize Vibration.

From giownpvko.blob.core.windows.net

How To Reduce Vibration In Lathe Machine at Bettye White blog How To Minimize Vibration This unwanted vibration can be reduced using the following five tips : The most efficient way to curb the effects of vibrations on mechanical. Ways to reduce or prevent vibration. Adjusting cutting parameters such as speed, feed rate, and depth. Looseness can be rotating or mechanically generated. Understanding the root causes of vibration is the foundation for any effective control. How To Minimize Vibration.

From www.youtube.com

How To Reduce Vibration On Rough Roads GCN Tech Clinic AskGCNTech How To Minimize Vibration And by that, we mean. Looseness can be rotating or mechanically generated. 9 strategies to eliminate machining vibrations. By identifying and addressing these. Understanding the root causes of vibration is the foundation for any effective control strategy. The most efficient way to curb the effects of vibrations on mechanical. The biggest concern with unbalance is that it can cause unnecessary. How To Minimize Vibration.

From www.youtube.com

How to reduce vibrations YouTube How To Minimize Vibration Ways to reduce or prevent vibration. And by that, we mean. Understanding the root causes of vibration is the foundation for any effective control strategy. There are three types of mechanical looseness to consider: The most efficient way to curb the effects of vibrations on mechanical. 9 strategies to eliminate machining vibrations. Techniques for vibration reduction and control. Adjusting cutting. How To Minimize Vibration.

From www.linkedin.com

5 Effective Ways To Reduce Vibration In Machines How To Minimize Vibration When it comes to keeping engine vibrations in check, it pays to start with a solid foundation. Techniques for vibration reduction and control. The most efficient way to curb the effects of vibrations on mechanical. This unwanted vibration can be reduced using the following five tips : And by that, we mean. 9 strategies to eliminate machining vibrations. By identifying. How To Minimize Vibration.

From www.youtube.com

How to reduce vibrations in Royal Enfield YouTube How To Minimize Vibration Looseness can be rotating or mechanically generated. Ways to reduce or prevent vibration. The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. When it comes to keeping engine vibrations in check, it pays to start with a solid foundation. Adjusting cutting parameters such as speed, feed rate, and depth.. How To Minimize Vibration.

From www.mecanocaucho.com

VIBRATION ISOLATION OF INDUSTRIAL MACHINERY. MOTION CONTROL USING How To Minimize Vibration The most efficient way to curb the effects of vibrations on mechanical. This unwanted vibration can be reduced using the following five tips : Understanding the root causes of vibration is the foundation for any effective control strategy. Looseness can be rotating or mechanically generated. 9 strategies to eliminate machining vibrations. And by that, we mean. Ways to reduce or. How To Minimize Vibration.

From www.youtube.com

Torsional Vibration Damperhow Torsional Vibration Damper fittedhow How To Minimize Vibration 9 strategies to eliminate machining vibrations. And by that, we mean. Techniques for vibration reduction and control. Understanding the root causes of vibration is the foundation for any effective control strategy. Ways to reduce or prevent vibration. By identifying and addressing these. The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life. How To Minimize Vibration.

From www.reddit.com

Best way to minimize vibrations/skipping r/vintageaudio How To Minimize Vibration The most efficient way to curb the effects of vibrations on mechanical. This unwanted vibration can be reduced using the following five tips : The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. 9 strategies to eliminate machining vibrations. Adjusting cutting parameters such as speed, feed rate, and depth.. How To Minimize Vibration.

From cuddlyplushly.com

How to Reduce Vibration Tips and Strategies for a Smooth Ride Cuddly How To Minimize Vibration By identifying and addressing these. The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. This unwanted vibration can be reduced using the following five tips : Looseness can be rotating or mechanically generated. Ways to reduce or prevent vibration. Understanding the root causes of vibration is the foundation for. How To Minimize Vibration.

From www.youtube.com

How to reduce vibrations and resonances in a highend audio system How To Minimize Vibration This unwanted vibration can be reduced using the following five tips : Ways to reduce or prevent vibration. The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. Adjusting cutting parameters such as speed, feed rate, and depth. Techniques for vibration reduction and control. By identifying and addressing these. There. How To Minimize Vibration.

From www.vibrationmountsindia.com

Vibration Reduction Techniques in Machines How To Minimize Vibration There are three types of mechanical looseness to consider: This unwanted vibration can be reduced using the following five tips : Looseness can be rotating or mechanically generated. 9 strategies to eliminate machining vibrations. Understanding the root causes of vibration is the foundation for any effective control strategy. The most efficient way to curb the effects of vibrations on mechanical.. How To Minimize Vibration.

From www.youtube.com

Vibration Hangers YouTube How To Minimize Vibration When it comes to keeping engine vibrations in check, it pays to start with a solid foundation. Ways to reduce or prevent vibration. Understanding the root causes of vibration is the foundation for any effective control strategy. And by that, we mean. The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life. How To Minimize Vibration.

From www.slideserve.com

PPT Noise and Vibration Control PowerPoint Presentation, free How To Minimize Vibration Adjusting cutting parameters such as speed, feed rate, and depth. Ways to reduce or prevent vibration. The most efficient way to curb the effects of vibrations on mechanical. This unwanted vibration can be reduced using the following five tips : 9 strategies to eliminate machining vibrations. By identifying and addressing these. Looseness can be rotating or mechanically generated. Understanding the. How To Minimize Vibration.

From www.pinterest.com

Keeping your vibration high is very important. Try not to listen to too How To Minimize Vibration And by that, we mean. 9 strategies to eliminate machining vibrations. Understanding the root causes of vibration is the foundation for any effective control strategy. The most efficient way to curb the effects of vibrations on mechanical. Looseness can be rotating or mechanically generated. Ways to reduce or prevent vibration. Adjusting cutting parameters such as speed, feed rate, and depth.. How To Minimize Vibration.

From www.scribd.com

Application Data Minimizing Line Vibration To How To Minimize Vibration This unwanted vibration can be reduced using the following five tips : Techniques for vibration reduction and control. Ways to reduce or prevent vibration. And by that, we mean. 9 strategies to eliminate machining vibrations. The most efficient way to curb the effects of vibrations on mechanical. The biggest concern with unbalance is that it can cause unnecessary vibration and. How To Minimize Vibration.

From www.youtube.com

How to reduce Vibration and noise YouTube How To Minimize Vibration There are three types of mechanical looseness to consider: The most efficient way to curb the effects of vibrations on mechanical. The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. Adjusting cutting parameters such as speed, feed rate, and depth. Techniques for vibration reduction and control. 9 strategies to. How To Minimize Vibration.

From soundproofinghacks.com

How To Reduce Floor Vibrations? 2 Different Solutions That Works How To Minimize Vibration When it comes to keeping engine vibrations in check, it pays to start with a solid foundation. Techniques for vibration reduction and control. The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. This unwanted vibration can be reduced using the following five tips : Looseness can be rotating or. How To Minimize Vibration.

From www.youtube.com

GoPro How to Reduce Vibration YouTube How To Minimize Vibration The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. 9 strategies to eliminate machining vibrations. There are three types of mechanical looseness to consider: Looseness can be rotating or mechanically generated. Ways to reduce or prevent vibration. Techniques for vibration reduction and control. Adjusting cutting parameters such as speed,. How To Minimize Vibration.

From soundproofinghacks.com

How To Reduce Floor Vibrations? 2 Different Solutions That Works How To Minimize Vibration The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. And by that, we mean. Adjusting cutting parameters such as speed, feed rate, and depth. This unwanted vibration can be reduced using the following five tips : Techniques for vibration reduction and control. When it comes to keeping engine vibrations. How To Minimize Vibration.

From www.youtube.com

An Animated Introduction to Vibration Analysis by Mobius Institute How To Minimize Vibration When it comes to keeping engine vibrations in check, it pays to start with a solid foundation. Ways to reduce or prevent vibration. Adjusting cutting parameters such as speed, feed rate, and depth. Techniques for vibration reduction and control. The most efficient way to curb the effects of vibrations on mechanical. Looseness can be rotating or mechanically generated. Understanding the. How To Minimize Vibration.

From power-technique.cp.com

How to reduce the risks of handarm vibration syndrome when using How To Minimize Vibration This unwanted vibration can be reduced using the following five tips : The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. Understanding the root causes of vibration is the foundation for any effective control strategy. Techniques for vibration reduction and control. By identifying and addressing these. 9 strategies to. How To Minimize Vibration.

From giownpvko.blob.core.windows.net

How To Reduce Vibration In Lathe Machine at Bettye White blog How To Minimize Vibration There are three types of mechanical looseness to consider: The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. When it comes to keeping engine vibrations in check, it pays to start with a solid foundation. Adjusting cutting parameters such as speed, feed rate, and depth. Understanding the root causes. How To Minimize Vibration.

From www.youtube.com

Control to Vibration.Vibration Control.How to safe by Vibration How To Minimize Vibration Adjusting cutting parameters such as speed, feed rate, and depth. This unwanted vibration can be reduced using the following five tips : Understanding the root causes of vibration is the foundation for any effective control strategy. There are three types of mechanical looseness to consider: When it comes to keeping engine vibrations in check, it pays to start with a. How To Minimize Vibration.

From www.reddit.com

How to reduce vibrations here? The upper bracket mounts to our living How To Minimize Vibration When it comes to keeping engine vibrations in check, it pays to start with a solid foundation. The most efficient way to curb the effects of vibrations on mechanical. Adjusting cutting parameters such as speed, feed rate, and depth. The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. Understanding. How To Minimize Vibration.

From www.youtube.com

How to reduce vibration in Discover 125( In Hindi )/In any bike How To Minimize Vibration By identifying and addressing these. There are three types of mechanical looseness to consider: The most efficient way to curb the effects of vibrations on mechanical. Looseness can be rotating or mechanically generated. 9 strategies to eliminate machining vibrations. And by that, we mean. The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the. How To Minimize Vibration.

From www.youtube.com

Vibration Reducing Motor Mounts YouTube How To Minimize Vibration When it comes to keeping engine vibrations in check, it pays to start with a solid foundation. Adjusting cutting parameters such as speed, feed rate, and depth. Ways to reduce or prevent vibration. The most efficient way to curb the effects of vibrations on mechanical. And by that, we mean. There are three types of mechanical looseness to consider: By. How To Minimize Vibration.

From www.youtube.com

How to reduce Vibrations in Royal Enfield (தமிழில்) Taper Roller How To Minimize Vibration The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. 9 strategies to eliminate machining vibrations. The most efficient way to curb the effects of vibrations on mechanical. Understanding the root causes of vibration is the foundation for any effective control strategy. This unwanted vibration can be reduced using the. How To Minimize Vibration.

From control.com

Vibration Physics Introduction to Machine Vibration Measurement How To Minimize Vibration Looseness can be rotating or mechanically generated. By identifying and addressing these. Ways to reduce or prevent vibration. The most efficient way to curb the effects of vibrations on mechanical. Adjusting cutting parameters such as speed, feed rate, and depth. This unwanted vibration can be reduced using the following five tips : 9 strategies to eliminate machining vibrations. Understanding the. How To Minimize Vibration.

From www.youtube.com

How to Reduce Vibration Noise YouTube How To Minimize Vibration And by that, we mean. Ways to reduce or prevent vibration. There are three types of mechanical looseness to consider: The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. 9 strategies to eliminate machining vibrations. By identifying and addressing these. The most efficient way to curb the effects of. How To Minimize Vibration.

From www.eptyres.com

Balancing Minimize the Vibration Eptyres How To Minimize Vibration This unwanted vibration can be reduced using the following five tips : When it comes to keeping engine vibrations in check, it pays to start with a solid foundation. And by that, we mean. 9 strategies to eliminate machining vibrations. By identifying and addressing these. Adjusting cutting parameters such as speed, feed rate, and depth. The most efficient way to. How To Minimize Vibration.

From www.youtube.com

How To Reduce Vibration And Add Comfort To Any Motorcycle Or Scooter How To Minimize Vibration When it comes to keeping engine vibrations in check, it pays to start with a solid foundation. There are three types of mechanical looseness to consider: Understanding the root causes of vibration is the foundation for any effective control strategy. By identifying and addressing these. 9 strategies to eliminate machining vibrations. The most efficient way to curb the effects of. How To Minimize Vibration.

From www.walmart.com

XMARK Adjustable Speed Bag Platform with 15" Height Adjustment and How To Minimize Vibration Ways to reduce or prevent vibration. This unwanted vibration can be reduced using the following five tips : Adjusting cutting parameters such as speed, feed rate, and depth. Techniques for vibration reduction and control. Understanding the root causes of vibration is the foundation for any effective control strategy. The biggest concern with unbalance is that it can cause unnecessary vibration. How To Minimize Vibration.

From kienitvc.ac.ke

How to Easily Increase your Rooms Vibration kienitvc.ac.ke How To Minimize Vibration The biggest concern with unbalance is that it can cause unnecessary vibration and drastically reduce the operational life of bearings. There are three types of mechanical looseness to consider: Understanding the root causes of vibration is the foundation for any effective control strategy. When it comes to keeping engine vibrations in check, it pays to start with a solid foundation.. How To Minimize Vibration.