Electroplating Copper Deposition Rate . for advanced packaging applications, it is important to carefully control the copper plating rate and. the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed.

from www.comsol.de

in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. for advanced packaging applications, it is important to carefully control the copper plating rate and. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50.

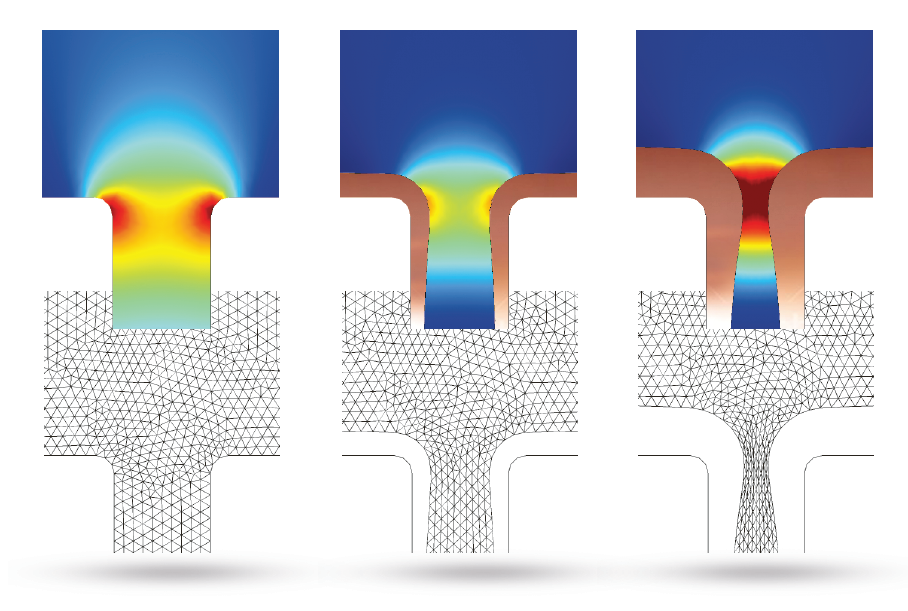

Modeling Copper Electrodeposition on a Circuit Board COMSOL Blog

Electroplating Copper Deposition Rate in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. for advanced packaging applications, it is important to carefully control the copper plating rate and. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed.

From www.comsol.de

Electrodeposition Modeling Inspiration COMSOL Blog Electroplating Copper Deposition Rate the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. for advanced packaging applications, it is important to carefully control the copper plating rate and. the effects of the inlet flow. Electroplating Copper Deposition Rate.

From www.comsol.de

Modeling Copper Electrodeposition on a Circuit Board COMSOL Blog Electroplating Copper Deposition Rate the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the ce is the ratio of charge. Electroplating Copper Deposition Rate.

From www.researchgate.net

of copper deposition in the presence of accelerator Electroplating Copper Deposition Rate for advanced packaging applications, it is important to carefully control the copper plating rate and. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the effects of the inlet flow. Electroplating Copper Deposition Rate.

From www.oatext.com

Modeling and simulation of electrodeposition effect of electrolyte Electroplating Copper Deposition Rate the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. for advanced packaging applications, it is important to carefully control the copper plating rate and. the laser‐jet electroplating technique has been applied to the high‐speed. Electroplating Copper Deposition Rate.

From www.frontiersin.org

Frontiers A Review on the Electroless Deposition of Functional Electroplating Copper Deposition Rate the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. for advanced packaging applications, it is important to. Electroplating Copper Deposition Rate.

From www.researchgate.net

(PDF) AspectRatioDependent Copper Electrodeposition Technique for Electroplating Copper Deposition Rate the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. for advanced packaging applications, it is important to carefully control the copper plating rate and. the laser‐jet electroplating technique has been applied to the high‐speed. Electroplating Copper Deposition Rate.

From www.mdpi.com

Materials Free FullText Effect of Copper Sulfate and Sulfuric Acid Electroplating Copper Deposition Rate in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. for advanced packaging applications,. Electroplating Copper Deposition Rate.

From www.chemedx.org

An Easy Copper Electroplating Demo for Your Redox Unit Chemical Electroplating Copper Deposition Rate the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. for advanced packaging applications, it is important to. Electroplating Copper Deposition Rate.

From www.comsol.it

Modeling Copper Electrodeposition on a Circuit Board COMSOL Blog Electroplating Copper Deposition Rate in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. for advanced packaging applications, it is important. Electroplating Copper Deposition Rate.

From sensorex.com

Electroplating The Process & Uses in Liquid Analysis Explained Sensorex Electroplating Copper Deposition Rate for advanced packaging applications, it is important to carefully control the copper plating rate and. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the effects of the inlet flow. Electroplating Copper Deposition Rate.

From www.semanticscholar.org

Figure 13 from Copper Electrodeposition in Mesoscale ThroughSilicon Electroplating Copper Deposition Rate in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. for advanced packaging applications,. Electroplating Copper Deposition Rate.

From exoidtmyy.blob.core.windows.net

Electroplating Deposition Rate at Lindsay James blog Electroplating Copper Deposition Rate the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. for advanced packaging applications, it is important to carefully control the copper plating rate and. the ce is the ratio of charge consumed toward. Electroplating Copper Deposition Rate.

From ietresearch.onlinelibrary.wiley.com

Development of seed layer deposition and fast copper electroplating Electroplating Copper Deposition Rate for advanced packaging applications, it is important to carefully control the copper plating rate and. the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. the laser‐jet electroplating technique has been applied to the high‐speed. Electroplating Copper Deposition Rate.

From www.youtube.com

What is Electroplating? Copper Electroplating YouTube Electroplating Copper Deposition Rate the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. for advanced packaging applications, it is important to carefully control the copper plating rate and. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. the ce is the ratio of charge consumed toward. Electroplating Copper Deposition Rate.

From studylib.net

Electrodeposition of Copper Electroplating Copper Deposition Rate the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. for advanced packaging applications, it is important to. Electroplating Copper Deposition Rate.

From www.pnas.org

Electrodeposition of metals from supercritical fluids PNAS Electroplating Copper Deposition Rate the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. in this study, we report on copper. Electroplating Copper Deposition Rate.

From www.comsol.fr

Electrodeposition Software Controlling Electrodeposition Processes Electroplating Copper Deposition Rate the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the ce is the ratio of charge. Electroplating Copper Deposition Rate.

From www.comsol.de

Modeling Copper Electrodeposition on a Circuit Board COMSOL Blog Electroplating Copper Deposition Rate the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. in this study, we report on copper. Electroplating Copper Deposition Rate.

From ietresearch.onlinelibrary.wiley.com

Development of seed layer deposition and fast copper electroplating Electroplating Copper Deposition Rate the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. for advanced packaging applications, it is important to carefully control the copper plating rate and. the effects of the inlet flow velocity,. Electroplating Copper Deposition Rate.

From www.researchgate.net

Copper electroplating deposition equipment (STMicroelectronics, Catania Electroplating Copper Deposition Rate the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. for advanced packaging applications, it is important to carefully control the copper plating rate and. the effects of the inlet flow. Electroplating Copper Deposition Rate.

From www.mdpi.com

Coatings Free FullText Electrodeposition of Copper Oxides as Cost Electroplating Copper Deposition Rate the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. for advanced packaging applications, it is important to. Electroplating Copper Deposition Rate.

From www.mdpi.com

Metals Free FullText Progress on Electrodeposition of Metals and Electroplating Copper Deposition Rate the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the laser‐jet electroplating technique has been applied to. Electroplating Copper Deposition Rate.

From www.researchgate.net

7 Methods for copper electrode deposition [1] (a) throughmask Electroplating Copper Deposition Rate the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. for advanced packaging applications, it is important to carefully control the copper plating rate and. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the ce is the ratio of charge consumed toward the. Electroplating Copper Deposition Rate.

From encyclopedia.pub

Recent Trends in Copper Metallization Encyclopedia MDPI Electroplating Copper Deposition Rate the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. in this study, we report on copper. Electroplating Copper Deposition Rate.

From www.researchgate.net

Effect of copper ions concentration on the deposition rate Download Electroplating Copper Deposition Rate for advanced packaging applications, it is important to carefully control the copper plating rate and. the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. in this study, we report on copper deposition mechanism and. Electroplating Copper Deposition Rate.

From www.mdpi.com

Metals Free FullText Impurity Effects in ElectroplatedCopper Electroplating Copper Deposition Rate for advanced packaging applications, it is important to carefully control the copper plating rate and. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the ce is the ratio of charge consumed toward the. Electroplating Copper Deposition Rate.

From www.mdpi.com

Applied Sciences Free FullText Electroplated Functional Materials Electroplating Copper Deposition Rate for advanced packaging applications, it is important to carefully control the copper plating rate and. the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the effects of the inlet flow velocity,. Electroplating Copper Deposition Rate.

From www.researchgate.net

b. Copper deposition is more uniform when low current density is used Electroplating Copper Deposition Rate the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. for advanced packaging applications, it is important. Electroplating Copper Deposition Rate.

From mantavya.com

What Is Electroplating & How does it work 2021 Guide Mantavya Electroplating Copper Deposition Rate the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. in this study, we report on copper. Electroplating Copper Deposition Rate.

From www.mdpi.com

Metals Free FullText Progress on Electrodeposition of Metals and Electroplating Copper Deposition Rate for advanced packaging applications, it is important to carefully control the copper plating rate and. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. in this study, we report on copper deposition mechanism. Electroplating Copper Deposition Rate.

From www.researchgate.net

Schematic diagram of the (a) conventional electroless copper deposition Electroplating Copper Deposition Rate the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. for advanced packaging applications, it is important to carefully control the copper plating rate and. in this study, we report on. Electroplating Copper Deposition Rate.

From www.researchgate.net

Does agitation effect the deposition rate in Electrodeposition of Electroplating Copper Deposition Rate in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. the ce is the ratio of charge. Electroplating Copper Deposition Rate.

From www.mdpi.com

Micromachines Free FullText Study of Copper Electrodeposition at a Electroplating Copper Deposition Rate the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. the ce is the ratio of charge. Electroplating Copper Deposition Rate.

From www.researchgate.net

a Bottomup electroplatinguniform metal deposition as metal starts Electroplating Copper Deposition Rate the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the effects of the inlet flow velocity, potential, electrolyte concentration, and microchannel geometry are. for advanced packaging applications, it is important to carefully control the copper plating rate and. in this study, we report on copper deposition mechanism and. Electroplating Copper Deposition Rate.

From criticalmaterials.org

2022 TECHCET News Critical Materials Council Electroplating Copper Deposition Rate the ce is the ratio of charge consumed toward the deposition reaction to the total charge consumed. the laser‐jet electroplating technique has been applied to the high‐speed deposition of copper at rates up to 50. in this study, we report on copper deposition mechanism and direct fine pattering process by applying sed. the effects of the. Electroplating Copper Deposition Rate.