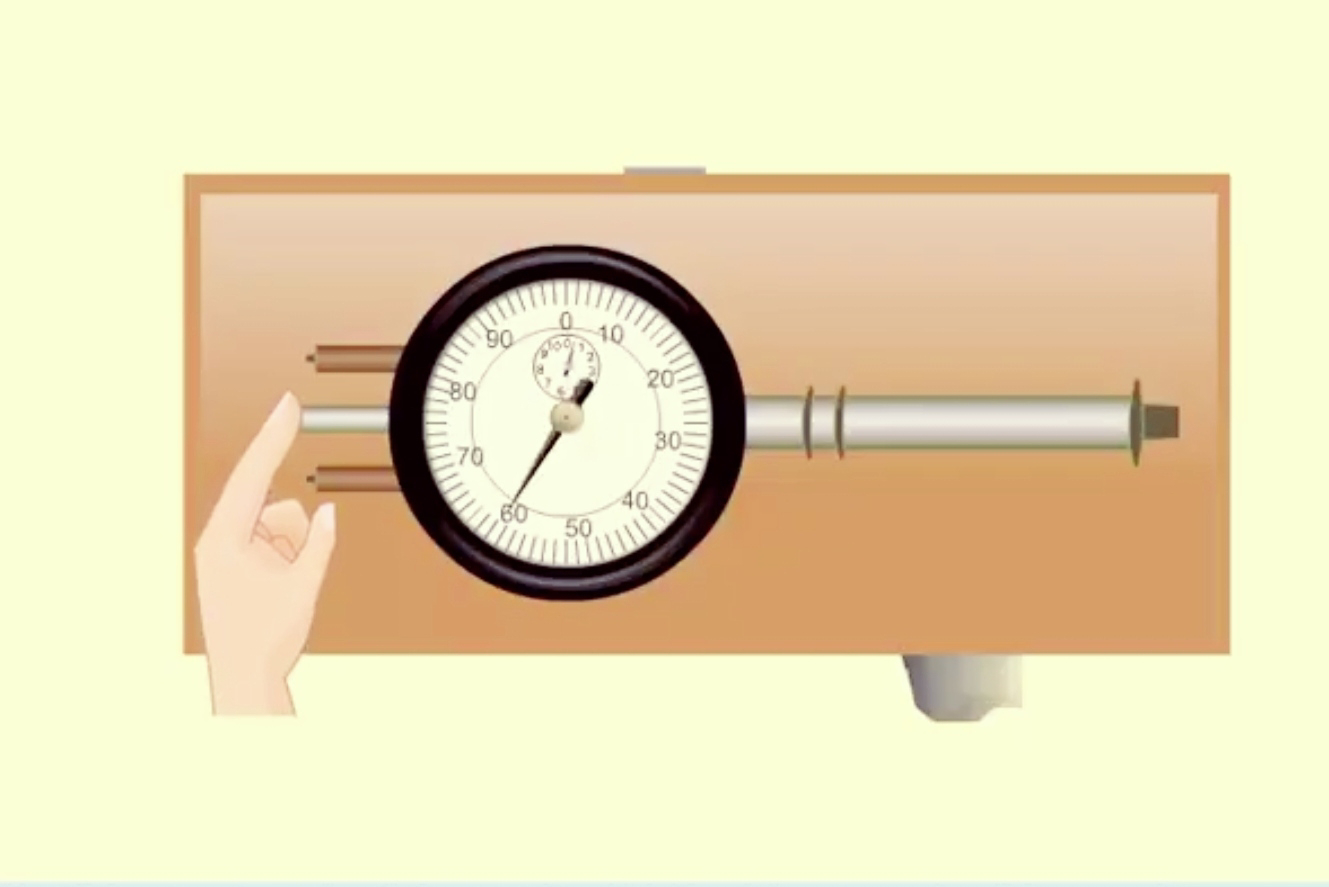

Engine Deflection Measurement . the measurements can be affected by: the amount of deflection of a crankshaft may be determined by the use of a straight gauge which is simple to apply. The engine temperature (so it might be stated if the engine is cold or at working temperature) vessel load condition; why do we need to measure crankshaft deflection? >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. crankshaft deflections are measured to detect the misalignment of main bearings. >the caveat to this is that. Ambient air and water temperature; The measurement is done by a dial indicator placed at a predefined location between crank webs. crankshaft deflections are measured by using deflection gauge. The misalignment occurs due to bearing wear or deflection. The deflection gauge is a dial gauge, which. the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings.

from www.marineengineersknowledge.com

Ambient air and water temperature; the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. The engine temperature (so it might be stated if the engine is cold or at working temperature) vessel load condition; why do we need to measure crankshaft deflection? crankshaft deflections are measured to detect the misalignment of main bearings. crankshaft deflections are measured by using deflection gauge. the amount of deflection of a crankshaft may be determined by the use of a straight gauge which is simple to apply. >the caveat to this is that. >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. The deflection gauge is a dial gauge, which.

Crankshaft Deflections Measurement Marine engineers knowledge

Engine Deflection Measurement The measurement is done by a dial indicator placed at a predefined location between crank webs. why do we need to measure crankshaft deflection? the measurements can be affected by: crankshaft deflections are measured by using deflection gauge. The measurement is done by a dial indicator placed at a predefined location between crank webs. crankshaft deflections are measured to detect the misalignment of main bearings. Ambient air and water temperature; >the caveat to this is that. >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. The misalignment occurs due to bearing wear or deflection. the amount of deflection of a crankshaft may be determined by the use of a straight gauge which is simple to apply. The deflection gauge is a dial gauge, which. the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. The engine temperature (so it might be stated if the engine is cold or at working temperature) vessel load condition;

From www.vrogue.co

What Is Crankshaft Deflection And Slippage Marine Eng vrogue.co Engine Deflection Measurement The deflection gauge is a dial gauge, which. crankshaft deflections are measured to detect the misalignment of main bearings. crankshaft deflections are measured by using deflection gauge. >the caveat to this is that. the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. the amount of deflection of. Engine Deflection Measurement.

From www.marineengineersknowledge.com

Crankshaft Deflections Measurement Marine engineers knowledge Engine Deflection Measurement the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. Ambient air and water temperature; The engine temperature (so it might be stated if the engine is cold or at working temperature) vessel load condition; The deflection gauge is a dial gauge, which. why do we need to measure crankshaft. Engine Deflection Measurement.

From www.scribd.com

Crankshaft Deflection Measurement Engines Rotating Machines Engine Deflection Measurement The engine temperature (so it might be stated if the engine is cold or at working temperature) vessel load condition; the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. the measurements can be affected by: crankshaft deflections are measured to detect the misalignment of main bearings. Ambient air. Engine Deflection Measurement.

From www.youtube.com

Crankshaft Deflection Measurement procedure YouTube Engine Deflection Measurement crankshaft deflections are measured to detect the misalignment of main bearings. The misalignment occurs due to bearing wear or deflection. >the caveat to this is that. the amount of deflection of a crankshaft may be determined by the use of a straight gauge which is simple to apply. The deflection gauge is a dial gauge, which. >a. Engine Deflection Measurement.

From workshopinsider.com

Engine Crankshaft Deflection Measurement Insider Engine Deflection Measurement >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. crankshaft deflections are measured to detect the misalignment of main bearings. why do we need to measure crankshaft deflection? The measurement is done by a dial indicator placed at a predefined location between crank webs. Ambient air. Engine Deflection Measurement.

From planm8.io

How to Conduct a Crankshaft Deflection Measurement Engine Deflection Measurement >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. The misalignment occurs due to bearing wear or deflection. the measurements can be affected by: The measurement is done by a dial indicator placed at a predefined location between crank webs. The engine temperature (so it might be. Engine Deflection Measurement.

From planm8.io

How to Conduct a Crankshaft Deflection Measurement Engine Deflection Measurement Ambient air and water temperature; the measurements can be affected by: why do we need to measure crankshaft deflection? The measurement is done by a dial indicator placed at a predefined location between crank webs. >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. the. Engine Deflection Measurement.

From workshopinsider.com

Engine Crankshaft Deflection Measurement Insider Engine Deflection Measurement Ambient air and water temperature; crankshaft deflections are measured to detect the misalignment of main bearings. the amount of deflection of a crankshaft may be determined by the use of a straight gauge which is simple to apply. the measurements can be affected by: The engine temperature (so it might be stated if the engine is cold. Engine Deflection Measurement.

From dxotkasfu.blob.core.windows.net

Crankshaft Deflection at William Newton blog Engine Deflection Measurement the measurements can be affected by: crankshaft deflections are measured to detect the misalignment of main bearings. The deflection gauge is a dial gauge, which. The measurement is done by a dial indicator placed at a predefined location between crank webs. The misalignment occurs due to bearing wear or deflection. the amount of deflection of a crankshaft. Engine Deflection Measurement.

From www.marineengineersknowledge.com

Crankshaft Deflections Measurement Marine engineers knowledge Engine Deflection Measurement >the caveat to this is that. The engine temperature (so it might be stated if the engine is cold or at working temperature) vessel load condition; The measurement is done by a dial indicator placed at a predefined location between crank webs. >a set of measurements taken from an engine will reveal this deflection which should be constant through. Engine Deflection Measurement.

From www.youtube.com

How to Measure Crankshaft Deflection YouTube Engine Deflection Measurement the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. the measurements can be affected by: >the caveat to this is that. The deflection gauge is a dial gauge,. Engine Deflection Measurement.

From www.youtube.com

DTI to measure deflection of splined shaft YouTube Engine Deflection Measurement the measurements can be affected by: the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. The measurement is done by a dial indicator placed at a predefined location between crank webs. The deflection gauge is a dial gauge, which. The misalignment occurs due to bearing wear or deflection. . Engine Deflection Measurement.

From dokumen.tips

(PDF) CRANkshAFT mEAsuREmENT DEFLECTION INDICATOR · PDF fileDEFLECTION Engine Deflection Measurement the measurements can be affected by: crankshaft deflections are measured by using deflection gauge. The misalignment occurs due to bearing wear or deflection. The engine temperature (so it might be stated if the engine is cold or at working temperature) vessel load condition; Ambient air and water temperature; >a set of measurements taken from an engine will. Engine Deflection Measurement.

From www.researchgate.net

Tool tip ellipse trajectory deflection measurement Download Engine Deflection Measurement crankshaft deflections are measured to detect the misalignment of main bearings. Ambient air and water temperature; the amount of deflection of a crankshaft may be determined by the use of a straight gauge which is simple to apply. The deflection gauge is a dial gauge, which. >a set of measurements taken from an engine will reveal this. Engine Deflection Measurement.

From www.scribd.com

Engine Crankshaft Deflection Measurement Guide IIMS PDF Bearing Engine Deflection Measurement crankshaft deflections are measured by using deflection gauge. crankshaft deflections are measured to detect the misalignment of main bearings. The measurement is done by a dial indicator placed at a predefined location between crank webs. >the caveat to this is that. The engine temperature (so it might be stated if the engine is cold or at working temperature). Engine Deflection Measurement.

From www.scribd.com

Crank Shaft & Its Deflection Measurement Engines Diesel Engine Engine Deflection Measurement why do we need to measure crankshaft deflection? crankshaft deflections are measured by using deflection gauge. The measurement is done by a dial indicator placed at a predefined location between crank webs. Ambient air and water temperature; The deflection gauge is a dial gauge, which. >the caveat to this is that. The misalignment occurs due to bearing wear. Engine Deflection Measurement.

From www.youtube.com

Crankshaft Deflection Measurement of Main Engine YouTube Engine Deflection Measurement crankshaft deflections are measured by using deflection gauge. Ambient air and water temperature; >the caveat to this is that. the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. The misalignment occurs due to bearing wear or deflection. The deflection gauge is a dial gauge, which. The measurement is done. Engine Deflection Measurement.

From planm8.io

How to Conduct a Crankshaft Deflection Measurement Engine Deflection Measurement >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. >the caveat to this is that. The measurement is done by a dial indicator placed at a predefined location between crank webs. The misalignment occurs due to bearing wear or deflection. crankshaft deflections are measured by using deflection. Engine Deflection Measurement.

From www.mdpi.com

Sensors Free FullText Remote Bridge Deflection Measurement Using Engine Deflection Measurement crankshaft deflections are measured by using deflection gauge. >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. crankshaft deflections are measured to detect the misalignment of main bearings. The misalignment occurs due to bearing wear or deflection. The deflection gauge is a dial gauge, which. . Engine Deflection Measurement.

From www.iims.org.uk

Engine Crankshaft Deflection Measurement Guide IIMS Engine Deflection Measurement why do we need to measure crankshaft deflection? crankshaft deflections are measured to detect the misalignment of main bearings. the amount of deflection of a crankshaft may be determined by the use of a straight gauge which is simple to apply. the document discusses measuring crankshaft deflection in large diesel engines to check for wear in. Engine Deflection Measurement.

From motionics.com

Wireless Crankshaft Deflection Test Kit Motionics LLC Engine Deflection Measurement the measurements can be affected by: The deflection gauge is a dial gauge, which. crankshaft deflections are measured to detect the misalignment of main bearings. the amount of deflection of a crankshaft may be determined by the use of a straight gauge which is simple to apply. why do we need to measure crankshaft deflection? The. Engine Deflection Measurement.

From www.vrogue.co

Simple Explanation Of Crankshaft Deflections Measurem vrogue.co Engine Deflection Measurement The engine temperature (so it might be stated if the engine is cold or at working temperature) vessel load condition; Ambient air and water temperature; the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. The misalignment occurs due to bearing wear or deflection. the measurements can be affected by:. Engine Deflection Measurement.

From marineandoffshoreinsight.com

Guide On How To Take Crankshaft Deflection Marine And Offshore Insight Engine Deflection Measurement >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. the measurements can be affected by: the amount of deflection of a crankshaft may be determined by the use of a straight gauge which is simple to apply. Ambient air and water temperature; The misalignment occurs due. Engine Deflection Measurement.

From www.youtube.com

how to measure crank shaft deflection large two stroke diesel engine Engine Deflection Measurement crankshaft deflections are measured by using deflection gauge. >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. >the caveat to this is that. the measurements can be affected by: the amount of deflection of a crankshaft may be determined by the use of a straight. Engine Deflection Measurement.

From www.youtube.com

How to measure Crankshaft Deflection of Main Engine using digital dial Engine Deflection Measurement The deflection gauge is a dial gauge, which. The misalignment occurs due to bearing wear or deflection. The engine temperature (so it might be stated if the engine is cold or at working temperature) vessel load condition; the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. >a set of. Engine Deflection Measurement.

From www.iims.org.uk

Engine Crankshaft Deflection Measurement Guide IIMS Engine Deflection Measurement crankshaft deflections are measured to detect the misalignment of main bearings. the measurements can be affected by: why do we need to measure crankshaft deflection? crankshaft deflections are measured by using deflection gauge. the amount of deflection of a crankshaft may be determined by the use of a straight gauge which is simple to apply.. Engine Deflection Measurement.

From www.youtube.com

HOW DO THEY DO.. HOW TO MEASURE CRANKSHAFT DEFLECTION ON GENERATOR Engine Deflection Measurement the measurements can be affected by: Ambient air and water temperature; the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. The misalignment occurs due to bearing wear or deflection. The measurement is done by a dial indicator placed at a predefined location between crank webs. crankshaft deflections are. Engine Deflection Measurement.

From www.scribd.com

March 11, 2016 News Hound Engine Crankshaft Deflection Measurement Engine Deflection Measurement The measurement is done by a dial indicator placed at a predefined location between crank webs. The misalignment occurs due to bearing wear or deflection. The engine temperature (so it might be stated if the engine is cold or at working temperature) vessel load condition; crankshaft deflections are measured to detect the misalignment of main bearings. The deflection gauge. Engine Deflection Measurement.

From www.vrogue.co

Simple Explanation Of Crankshaft Deflections Measurem vrogue.co Engine Deflection Measurement The engine temperature (so it might be stated if the engine is cold or at working temperature) vessel load condition; crankshaft deflections are measured to detect the misalignment of main bearings. The deflection gauge is a dial gauge, which. crankshaft deflections are measured by using deflection gauge. the measurements can be affected by: >a set of. Engine Deflection Measurement.

From www.researchgate.net

Diagram of the deflection measurement Download Scientific Diagram Engine Deflection Measurement crankshaft deflections are measured to detect the misalignment of main bearings. >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. The engine temperature (so it might be stated. Engine Deflection Measurement.

From chris-marine.com

Crankshaft Deflection Gauge / CONTROLmag® I&II ChrisMarine Engine Deflection Measurement crankshaft deflections are measured to detect the misalignment of main bearings. >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. The engine temperature (so it might be stated if the engine is cold or at working temperature) vessel load condition; crankshaft deflections are measured by using. Engine Deflection Measurement.

From www.vrogue.co

Simple Explanation Of Crankshaft Deflections Measurem vrogue.co Engine Deflection Measurement The misalignment occurs due to bearing wear or deflection. crankshaft deflections are measured to detect the misalignment of main bearings. >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. Ambient air and water temperature; The deflection gauge is a dial gauge, which. >the caveat to this is. Engine Deflection Measurement.

From dokumen.tips

(PDF) CRANkshAFT mEAsuREmENT DEFLECTION INDICATOR · PDF fileDEFLECTION Engine Deflection Measurement The measurement is done by a dial indicator placed at a predefined location between crank webs. >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. the measurements can be affected by: >the caveat to this is that. The engine temperature (so it might be stated if the. Engine Deflection Measurement.

From www.marineengineersknowledge.com

Crankshaft Deflections Measurement Marine engineers knowledge Engine Deflection Measurement why do we need to measure crankshaft deflection? The deflection gauge is a dial gauge, which. >a set of measurements taken from an engine will reveal this deflection which should be constant through each crank/piston unit. >the caveat to this is that. The engine temperature (so it might be stated if the engine is cold or at working. Engine Deflection Measurement.

From workshopinsider.com

Engine Crankshaft Deflection Measurement Insider Engine Deflection Measurement the document discusses measuring crankshaft deflection in large diesel engines to check for wear in the main bearings. the amount of deflection of a crankshaft may be determined by the use of a straight gauge which is simple to apply. Ambient air and water temperature; why do we need to measure crankshaft deflection? >a set of. Engine Deflection Measurement.