Raw Material Ordering Process . The raw material procurement process involves. The goal of this process is to streamline raw materials estimation, making it more efficient and accurate. Raw material inventory management is the process of managing the material goods used to create a product. The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. Raw materials are the fundamental building blocks in production processes, representing the unprocessed materials that are transformed into finished goods. Material procurement includes researching, selecting, ordering, and paying for the raw materials that are required for manufacturing. Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. Raw material procurement (direct procurement) is a complex and critical aspect of supply chain management. It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational lost time. The process of ‘raw material procurement’ includes identifying, acquiring, and securing materials that are necessary for manufacturing the parts. These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. In the blog today, we are going to provide two examples of how you can capture raw materials from the solidworks project and count them in openbom.

from kyloot.com

The goal of this process is to streamline raw materials estimation, making it more efficient and accurate. Raw materials are the fundamental building blocks in production processes, representing the unprocessed materials that are transformed into finished goods. Raw material inventory management is the process of managing the material goods used to create a product. The process of ‘raw material procurement’ includes identifying, acquiring, and securing materials that are necessary for manufacturing the parts. The raw material procurement process involves. Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. Material procurement includes researching, selecting, ordering, and paying for the raw materials that are required for manufacturing. It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational lost time. In the blog today, we are going to provide two examples of how you can capture raw materials from the solidworks project and count them in openbom. Raw material procurement (direct procurement) is a complex and critical aspect of supply chain management.

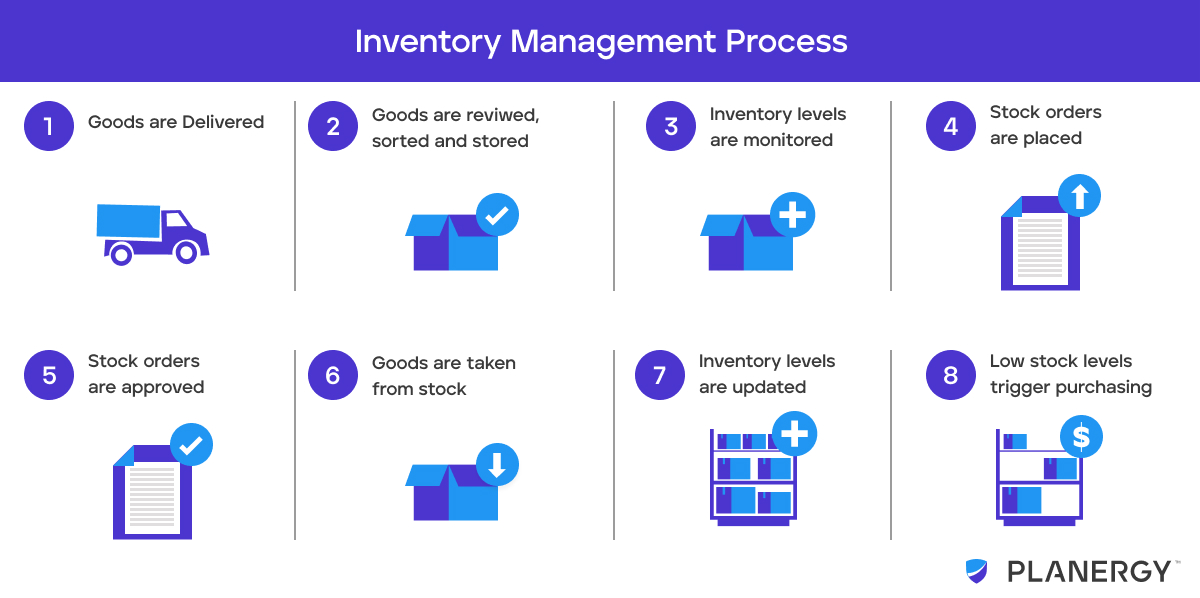

What Is Inventory Management Process? Flow Explained PLANERGY

Raw Material Ordering Process The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. Material procurement includes researching, selecting, ordering, and paying for the raw materials that are required for manufacturing. The goal of this process is to streamline raw materials estimation, making it more efficient and accurate. In the blog today, we are going to provide two examples of how you can capture raw materials from the solidworks project and count them in openbom. Raw material inventory management is the process of managing the material goods used to create a product. The process of ‘raw material procurement’ includes identifying, acquiring, and securing materials that are necessary for manufacturing the parts. It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational lost time. The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. The raw material procurement process involves. Raw materials are the fundamental building blocks in production processes, representing the unprocessed materials that are transformed into finished goods. Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. Raw material procurement (direct procurement) is a complex and critical aspect of supply chain management. These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production.

From www.smartdraw.com

Supply Ordering Process Map Raw Material Ordering Process The process of ‘raw material procurement’ includes identifying, acquiring, and securing materials that are necessary for manufacturing the parts. These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. Material. Raw Material Ordering Process.

From www.bluecart.com

Warehouse Management Process Flow Raw Material Ordering Process The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. The goal of this process is to streamline raw materials estimation, making it more efficient and accurate. Raw material inventory. Raw Material Ordering Process.

From craftybase.com

Complete Guide to Raw Material Inventory Management Craftybase Raw Material Ordering Process The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. Raw materials are the fundamental building blocks in production processes, representing the unprocessed materials that are transformed into finished goods. Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are.. Raw Material Ordering Process.

From www.researchgate.net

Lifecycle phases Raw material extraction includes the processes Raw Material Ordering Process It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational lost time. The goal of this process is to streamline raw materials estimation, making it more efficient and accurate. Raw materials are the fundamental building blocks in production processes, representing the unprocessed materials that are transformed into finished goods.. Raw Material Ordering Process.

From www.slideteam.net

Five Stages Of Procurement Process Flow Chart PPT PowerPoint Raw Material Ordering Process Raw materials are the fundamental building blocks in production processes, representing the unprocessed materials that are transformed into finished goods. These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. The raw material procurement process involves. Raw material inventory management is the process of managing the material goods used to create a. Raw Material Ordering Process.

From www.openbom.com

Ordering Raw Materials Using OpenBOM (with SOLIDWORKS Examples) OpenBOM Raw Material Ordering Process The raw material procurement process involves. In the blog today, we are going to provide two examples of how you can capture raw materials from the solidworks project and count them in openbom. Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. These materials are integral to supply chain management (scm). Raw Material Ordering Process.

From kfknowledgebank.kaplan.co.uk

Ordering and issuing inventory Raw Material Ordering Process The raw material procurement process involves. The goal of this process is to streamline raw materials estimation, making it more efficient and accurate. In the blog today, we are going to provide two examples of how you can capture raw materials from the solidworks project and count them in openbom. The process of ‘raw material procurement’ includes identifying, acquiring, and. Raw Material Ordering Process.

From www.wallstreetmojo.com

Material Flow What Is It, Types, Examples, Importance Raw Material Ordering Process These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. Material procurement includes researching, selecting, ordering, and paying for the raw materials that are required for manufacturing. It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational lost time. Raw material. Raw Material Ordering Process.

From www.researchgate.net

Procurement Process from Material Requirement Planning (MRP) to Sales Raw Material Ordering Process Raw material inventory management is the process of managing the material goods used to create a product. The goal of this process is to streamline raw materials estimation, making it more efficient and accurate. Raw materials are the fundamental building blocks in production processes, representing the unprocessed materials that are transformed into finished goods. The process of ‘raw material procurement’. Raw Material Ordering Process.

From mungfali.com

Manufacturing Procurement Process Flow Chart Raw Material Ordering Process Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. The raw material procurement process involves. Raw material procurement (direct procurement) is a complex and critical aspect of supply chain management. It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational. Raw Material Ordering Process.

From mungfali.com

Raw Material Process Flow Chart Raw Material Ordering Process Raw material procurement (direct procurement) is a complex and critical aspect of supply chain management. Raw materials are the fundamental building blocks in production processes, representing the unprocessed materials that are transformed into finished goods. These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. The goal of a raw material sourcing. Raw Material Ordering Process.

From www.researchgate.net

The raw material procurement flow chart of pharmaceutical companies Raw Material Ordering Process In the blog today, we are going to provide two examples of how you can capture raw materials from the solidworks project and count them in openbom. Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. These materials are integral to supply chain management (scm) as they influence every stage, from. Raw Material Ordering Process.

From researchforecast.com

Raw Material Procurement Sourcing Strategy Ken Research Raw Material Ordering Process Raw material inventory management is the process of managing the material goods used to create a product. The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. The process of. Raw Material Ordering Process.

From www.vem-tooling.com

Raw Material Procurement in Manufacturing Raw Material Ordering Process Material procurement includes researching, selecting, ordering, and paying for the raw materials that are required for manufacturing. It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational lost time. The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials. Raw Material Ordering Process.

From www.slideserve.com

PPT Chapter 3 Strategy and Information Systems PowerPoint Raw Material Ordering Process Raw material inventory management is the process of managing the material goods used to create a product. The process of ‘raw material procurement’ includes identifying, acquiring, and securing materials that are necessary for manufacturing the parts. Raw material procurement (direct procurement) is a complex and critical aspect of supply chain management. Raw materials inventory is the total cost of a. Raw Material Ordering Process.

From wiki.processmaker.com

3.0 3.4 Enterprise Trial Material Ordering Process Raw Material Ordering Process It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational lost time. Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. Raw materials are the fundamental building blocks in production processes, representing the unprocessed materials that are transformed into finished. Raw Material Ordering Process.

From www.slideteam.net

Production Process Preparation Raw Material Set Machine Store Product Raw Material Ordering Process It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational lost time. The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. The goal of this process is to streamline raw materials estimation, making it more efficient. Raw Material Ordering Process.

From mungfali.com

Purchase Order Flow Chart Raw Material Ordering Process The process of ‘raw material procurement’ includes identifying, acquiring, and securing materials that are necessary for manufacturing the parts. Raw material procurement (direct procurement) is a complex and critical aspect of supply chain management. Raw material inventory management is the process of managing the material goods used to create a product. In the blog today, we are going to provide. Raw Material Ordering Process.

From www.asprova.jp

Order Material Planning MRP glossary of Production scheduler Asprova Raw Material Ordering Process Raw material procurement (direct procurement) is a complex and critical aspect of supply chain management. The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. The process of ‘raw material. Raw Material Ordering Process.

From www.slideserve.com

PPT Chapter 4 PowerPoint Presentation, free download ID3290879 Raw Material Ordering Process Raw material inventory management is the process of managing the material goods used to create a product. The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. Material procurement includes researching, selecting, ordering, and paying for the raw materials that are required for manufacturing. Raw materials are the. Raw Material Ordering Process.

From www.researchgate.net

a) Manufacturing floor plan showing the location of the raw materials Raw Material Ordering Process The raw material procurement process involves. Raw material procurement (direct procurement) is a complex and critical aspect of supply chain management. It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational lost time. Material procurement includes researching, selecting, ordering, and paying for the raw materials that are required for. Raw Material Ordering Process.

From www.vem-tooling.com

Raw Material Procurement in Manufacturing Raw Material Ordering Process The goal of this process is to streamline raw materials estimation, making it more efficient and accurate. The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. The process of ‘raw material procurement’ includes identifying, acquiring, and securing materials that are necessary for manufacturing the parts. These materials. Raw Material Ordering Process.

From www.conceptdraw.com

Flow chart Example. Warehouse Flowchart How well does Your Purchase Raw Material Ordering Process Raw material procurement (direct procurement) is a complex and critical aspect of supply chain management. These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. The process of ‘raw material procurement’ includes identifying, acquiring, and securing materials that are necessary for manufacturing the parts. Raw materials inventory is the total cost of. Raw Material Ordering Process.

From www.asprova.jp

Order Material Planning MRP glossary of Production scheduler Asprova Raw Material Ordering Process The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. Raw materials are the fundamental building blocks in production processes, representing the unprocessed materials that are transformed into finished goods.. Raw Material Ordering Process.

From kyloot.com

What Is Inventory Management Process? Flow Explained PLANERGY Raw Material Ordering Process These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational lost time. Material. Raw Material Ordering Process.

From kr.pinterest.com

Manufacturing Order Process Flowchart Template Raw Material Ordering Process The raw material procurement process involves. Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational lost time. These materials are integral to supply chain management (scm) as they influence every. Raw Material Ordering Process.

From www.vem-tooling.com

Raw Material Procurement in Manufacturing Raw Material Ordering Process The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. The raw material procurement process involves. In the blog today, we are going to provide two examples of how you can capture raw materials from the solidworks project and count them in openbom. Raw material inventory management is. Raw Material Ordering Process.

From www.skunexus.com

The Ultimate Guide to Order Management Raw Material Ordering Process These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. The process of ‘raw material procurement’ includes identifying, acquiring, and securing materials that are necessary for manufacturing the parts. Material procurement includes researching, selecting, ordering, and paying for the raw materials that are required for manufacturing. Raw material inventory management is the. Raw Material Ordering Process.

From moqups.com

Manufacturing Order Process Flowchart Template Moqups Raw Material Ordering Process In the blog today, we are going to provide two examples of how you can capture raw materials from the solidworks project and count them in openbom. The raw material procurement process involves. These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. The goal of a raw material sourcing and procurement. Raw Material Ordering Process.

From www.deskera.com

Raw Materials Inventory Management Guide Raw Material Ordering Process Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. Raw material procurement (direct procurement) is a complex and critical aspect of supply chain management. These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. The goal of a raw material sourcing and procurement. Raw Material Ordering Process.

From www.erp-information.com

What is Manufacturing Order Management? (Order Template and Order Raw Material Ordering Process The goal of this process is to streamline raw materials estimation, making it more efficient and accurate. Raw materials inventory is the total cost of a manufacturer's components, subassemblies, and supplies in stock that are. The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. The raw material. Raw Material Ordering Process.

From www.researchgate.net

Flow chart process of ordering goods/services. Download Scientific Raw Material Ordering Process It aims to ensure you always have enough raw materials available to meet demand and maintain production levels while avoiding operational lost time. The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. Material procurement includes researching, selecting, ordering, and paying for the raw materials that are required. Raw Material Ordering Process.

From flowchart.ghkates.com

warehouse receiving procedures flowchart flowchart in word Raw Material Ordering Process The process of ‘raw material procurement’ includes identifying, acquiring, and securing materials that are necessary for manufacturing the parts. These materials are integral to supply chain management (scm) as they influence every stage, from procurement to production. Raw materials are the fundamental building blocks in production processes, representing the unprocessed materials that are transformed into finished goods. The raw material. Raw Material Ordering Process.

From mavink.com

Material Management Process Flow Chart Raw Material Ordering Process The goal of this process is to streamline raw materials estimation, making it more efficient and accurate. The goal of a raw material sourcing and procurement efficiency analysis is to optimize the process of acquiring raw materials to ensure. Raw material inventory management is the process of managing the material goods used to create a product. Raw materials are the. Raw Material Ordering Process.

From fitsmallbusiness.com

What Is Order Fulfillment? Processes & Strategies Raw Material Ordering Process In the blog today, we are going to provide two examples of how you can capture raw materials from the solidworks project and count them in openbom. Raw material inventory management is the process of managing the material goods used to create a product. Raw material procurement (direct procurement) is a complex and critical aspect of supply chain management. Material. Raw Material Ordering Process.