What Is Vibration Analysis In Maintenance . 6 month battery lifeinnovative sleep mode vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. the role of vibration monitoring in machine health. It helps teams monitor machine health, predict maintenance needs,. Vibration monitoring is a fundamental component of predictive maintenance strategies. vibration analysis is a crucial maintenance technique that employs sensors to measure equipment vibrations. vibration analysis is a crucial component of any industrial reliability program. It provides valuable insights into the health of assets, allowing maintenance teams to take proactive measures. It plays a vital role in maintenance. vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. Uncover hidden asset issues & optimize maintenance. Importance of vibration analysis in maintenance. Vibration analysis is one of the most effective ways to keep your. It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure.

from www.valbsolutions.com

Importance of vibration analysis in maintenance. vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. Vibration analysis is one of the most effective ways to keep your. vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure. It helps teams monitor machine health, predict maintenance needs,. It plays a vital role in maintenance. vibration analysis is a crucial component of any industrial reliability program. 6 month battery lifeinnovative sleep mode Vibration monitoring is a fundamental component of predictive maintenance strategies.

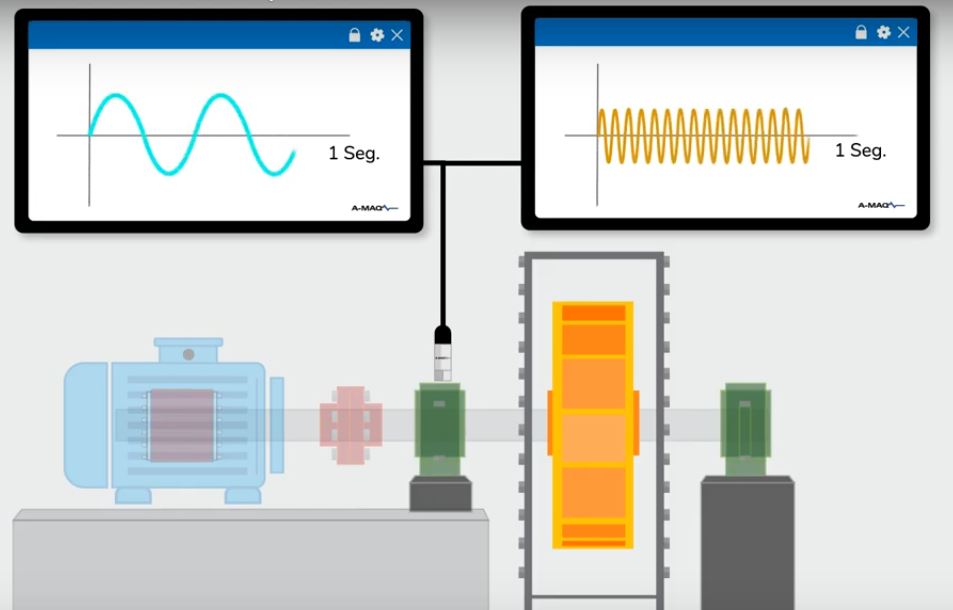

VIBRATION ANALYSIS PREDICTIVE MAINTENANCE

What Is Vibration Analysis In Maintenance It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure. 6 month battery lifeinnovative sleep mode It provides valuable insights into the health of assets, allowing maintenance teams to take proactive measures. Vibration monitoring is a fundamental component of predictive maintenance strategies. vibration analysis is a crucial maintenance technique that employs sensors to measure equipment vibrations. vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. vibration analysis is a crucial component of any industrial reliability program. It plays a vital role in maintenance. vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. Uncover hidden asset issues & optimize maintenance. Importance of vibration analysis in maintenance. the role of vibration monitoring in machine health. It helps teams monitor machine health, predict maintenance needs,. It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure. Vibration analysis is one of the most effective ways to keep your.

From www.metrixvibration.com

Fundamentals of Vibration Analysis A Comprehensive Overview What Is Vibration Analysis In Maintenance It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure. 6 month battery lifeinnovative sleep mode vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. the role of vibration monitoring in machine. What Is Vibration Analysis In Maintenance.

From www.swelectric.com

The Importance of Vibration Analysis in Electric Motor Maintenance What Is Vibration Analysis In Maintenance vibration analysis is a crucial component of any industrial reliability program. It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure. Importance of vibration analysis in maintenance. It plays a vital role in maintenance. It helps teams monitor machine health, predict maintenance needs,. the role of vibration monitoring. What Is Vibration Analysis In Maintenance.

From ivctechnologies.com

Vibration Phase Analysis Why Every Analyst Should Understand It What Is Vibration Analysis In Maintenance Vibration monitoring is a fundamental component of predictive maintenance strategies. vibration analysis is a crucial maintenance technique that employs sensors to measure equipment vibrations. It plays a vital role in maintenance. It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure. vibration analysis is a predictive maintenance technique. What Is Vibration Analysis In Maintenance.

From www.rsaworks.com

Vibration Analysis and the Benefits of Predictive Maintenance What Is Vibration Analysis In Maintenance Importance of vibration analysis in maintenance. vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. Vibration analysis is one. What Is Vibration Analysis In Maintenance.

From tractian.com

Predictive Maintenance will bring you lots of benefits. What Is Vibration Analysis In Maintenance Importance of vibration analysis in maintenance. It plays a vital role in maintenance. Vibration monitoring is a fundamental component of predictive maintenance strategies. Uncover hidden asset issues & optimize maintenance. vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. It helps teams monitor machine health,. What Is Vibration Analysis In Maintenance.

From www.kumaranindustries.com

Vibration Testing kumaran Industries What Is Vibration Analysis In Maintenance Importance of vibration analysis in maintenance. vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. Vibration monitoring is a fundamental component of predictive maintenance strategies. It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure.. What Is Vibration Analysis In Maintenance.

From www.valbsolutions.com

VIBRATION ANALYSIS PREDICTIVE MAINTENANCE What Is Vibration Analysis In Maintenance the role of vibration monitoring in machine health. Uncover hidden asset issues & optimize maintenance. 6 month battery lifeinnovative sleep mode vibration analysis is a crucial maintenance technique that employs sensors to measure equipment vibrations. Vibration monitoring is a fundamental component of predictive maintenance strategies. vibration analysis is a crucial component of any industrial reliability program. It. What Is Vibration Analysis In Maintenance.

From www.youtube.com

Vibration Analysis for beginners 1 (Predictive Maintenance and What Is Vibration Analysis In Maintenance vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. 6 month battery lifeinnovative sleep mode Importance of vibration analysis in maintenance. vibration analysis is a crucial component of any industrial reliability program. It provides valuable insights into the health of assets, allowing maintenance teams. What Is Vibration Analysis In Maintenance.

From onlinetraining.aetinigeria.com

VIBRATION ANALYSIS & PREDICTIVE MAINTENANCE VIRTUAL — AETI Online Training What Is Vibration Analysis In Maintenance Importance of vibration analysis in maintenance. It helps teams monitor machine health, predict maintenance needs,. vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. vibration analysis is a crucial component of any industrial reliability program. vibration analysis is a predictive maintenance technique that. What Is Vibration Analysis In Maintenance.

From cumberlandpdm.com

Vibration Analysis Cumberland Predictive Maintenance What Is Vibration Analysis In Maintenance Vibration analysis is one of the most effective ways to keep your. vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. Importance of vibration analysis in maintenance. Uncover hidden asset issues & optimize maintenance. It helps teams monitor machine health, predict maintenance needs,.. What Is Vibration Analysis In Maintenance.

From limblecmms.com

The Basics Of Vibration Analysis What Is Vibration Analysis In Maintenance Vibration analysis is one of the most effective ways to keep your. It provides valuable insights into the health of assets, allowing maintenance teams to take proactive measures. It helps teams monitor machine health, predict maintenance needs,. the role of vibration monitoring in machine health. It plays a vital role in maintenance. 6 month battery lifeinnovative sleep mode Uncover. What Is Vibration Analysis In Maintenance.

From www.slideserve.com

PPT Basic Vibration Analysis PowerPoint Presentation, free download What Is Vibration Analysis In Maintenance 6 month battery lifeinnovative sleep mode vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. Vibration analysis is one of the most effective ways to keep your. vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to. What Is Vibration Analysis In Maintenance.

From www.fluke-infrared.com

Understanding Vibration Monitoring and Analysis Fluke What Is Vibration Analysis In Maintenance the role of vibration monitoring in machine health. vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. Importance of vibration analysis in maintenance. Uncover hidden asset issues & optimize maintenance. It involves the continuous surveillance of machinery to identify changes in vibration. What Is Vibration Analysis In Maintenance.

From nttinc.com

What is Vibration Analysis in Mechanical Maintenance? NTT Training What Is Vibration Analysis In Maintenance It provides valuable insights into the health of assets, allowing maintenance teams to take proactive measures. It plays a vital role in maintenance. vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. Vibration analysis is one of the most effective ways to keep your. 6. What Is Vibration Analysis In Maintenance.

From systemgateengineering.com

Vibration Analysis and Condition Monitoring Systemgate Engineering What Is Vibration Analysis In Maintenance vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. Vibration monitoring is a fundamental component of predictive maintenance strategies. It plays a vital role in maintenance. Vibration analysis is one of the most effective ways to keep your. It provides valuable insights into the health. What Is Vibration Analysis In Maintenance.

From themaintainers.com

Everything You Need to Know About Vibration Analysis The Maintainers What Is Vibration Analysis In Maintenance It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure. 6 month battery lifeinnovative sleep mode vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. It provides valuable insights into the health of assets, allowing. What Is Vibration Analysis In Maintenance.

From blog.tate.com

Vibration Analysis and Predictive Maintenance What Is Vibration Analysis In Maintenance vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. It helps teams monitor machine health, predict maintenance needs,. It plays a vital role in maintenance. It provides valuable insights into the health of assets, allowing maintenance teams to take proactive measures. Vibration analysis. What Is Vibration Analysis In Maintenance.

From www.twi-global.com

What is Vibration Analysis and What is it Used For? TWI What Is Vibration Analysis In Maintenance vibration analysis is a crucial component of any industrial reliability program. vibration analysis is a crucial maintenance technique that employs sensors to measure equipment vibrations. Importance of vibration analysis in maintenance. It helps teams monitor machine health, predict maintenance needs,. 6 month battery lifeinnovative sleep mode vibration analysis is a predictive maintenance technique that involves monitoring the. What Is Vibration Analysis In Maintenance.

From advantagereliability.com

Vibration Analysis from Advantage Reliability Services What Is Vibration Analysis In Maintenance It provides valuable insights into the health of assets, allowing maintenance teams to take proactive measures. vibration analysis is a crucial maintenance technique that employs sensors to measure equipment vibrations. vibration analysis is a crucial component of any industrial reliability program. Uncover hidden asset issues & optimize maintenance. It helps teams monitor machine health, predict maintenance needs,. Vibration. What Is Vibration Analysis In Maintenance.

From www.dukeelectric.com

What is vibration analysis (and why you need it) Duke Electric What Is Vibration Analysis In Maintenance vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. Vibration monitoring is a fundamental component of predictive maintenance strategies. Importance of vibration analysis in maintenance. vibration analysis is a crucial maintenance technique that employs sensors to measure equipment vibrations. Vibration analysis is. What Is Vibration Analysis In Maintenance.

From www.predictivemaintenance.ie

vibrationanalysis Predictive Maintenance What Is Vibration Analysis In Maintenance vibration analysis is a crucial component of any industrial reliability program. It plays a vital role in maintenance. It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure. It provides valuable insights into the health of assets, allowing maintenance teams to take proactive measures. It helps teams monitor machine. What Is Vibration Analysis In Maintenance.

From www.pmdiagnostics.com

Vibration Analysis for Condition Monitoring and Machine What Is Vibration Analysis In Maintenance vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure. vibration analysis can be used when you know there’s an existing vibration problem. What Is Vibration Analysis In Maintenance.

From www.slideshare.net

Machinery Vibration Analysis and Maintenance What Is Vibration Analysis In Maintenance vibration analysis is a crucial component of any industrial reliability program. the role of vibration monitoring in machine health. Vibration monitoring is a fundamental component of predictive maintenance strategies. 6 month battery lifeinnovative sleep mode Importance of vibration analysis in maintenance. vibration analysis can be used when you know there’s an existing vibration problem and want to. What Is Vibration Analysis In Maintenance.

From www.youtube.com

What is Vibration Analysis? A Quick Introduction and Key Benefits to What Is Vibration Analysis In Maintenance It helps teams monitor machine health, predict maintenance needs,. vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the corrective maintenance. vibration analysis is a crucial component of any industrial reliability program. It plays a vital role in maintenance. It provides valuable insights into the health of. What Is Vibration Analysis In Maintenance.

From www.youtube.com

Module 1 Vibration Analysis Expert explains use of Vibration in What Is Vibration Analysis In Maintenance Vibration analysis is one of the most effective ways to keep your. It helps teams monitor machine health, predict maintenance needs,. vibration analysis is a crucial maintenance technique that employs sensors to measure equipment vibrations. 6 month battery lifeinnovative sleep mode the role of vibration monitoring in machine health. Importance of vibration analysis in maintenance. It involves the. What Is Vibration Analysis In Maintenance.

From www.augury.com

Vibration Analysis Optimized by AI Augury What Is Vibration Analysis In Maintenance 6 month battery lifeinnovative sleep mode Vibration monitoring is a fundamental component of predictive maintenance strategies. It provides valuable insights into the health of assets, allowing maintenance teams to take proactive measures. It plays a vital role in maintenance. Vibration analysis is one of the most effective ways to keep your. It helps teams monitor machine health, predict maintenance needs,.. What Is Vibration Analysis In Maintenance.

From vibrationanalysts.com

What is Vibration Analysis? Understanding the Basics Vibration What Is Vibration Analysis In Maintenance Uncover hidden asset issues & optimize maintenance. It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure. It provides valuable insights into the health of assets, allowing maintenance teams to take proactive measures. 6 month battery lifeinnovative sleep mode Importance of vibration analysis in maintenance. the role of vibration. What Is Vibration Analysis In Maintenance.

From www.advancedtech.com

What is Predictive Maintenance Vibration Analysis? ATS What Is Vibration Analysis In Maintenance Importance of vibration analysis in maintenance. Vibration analysis is one of the most effective ways to keep your. It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or failure. vibration analysis can be used when you know there’s an existing vibration problem and want to diagnose and fix it (the. What Is Vibration Analysis In Maintenance.

From rms-reliability.com

RMS Vibration Analysis Services RMS Ltd What Is Vibration Analysis In Maintenance Vibration monitoring is a fundamental component of predictive maintenance strategies. vibration analysis is a crucial component of any industrial reliability program. vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. vibration analysis is a crucial maintenance technique that employs sensors to. What Is Vibration Analysis In Maintenance.

From ocean-me.com

The Major Benefits and Importance of Vibration Analysis in Maintenance What Is Vibration Analysis In Maintenance It helps teams monitor machine health, predict maintenance needs,. vibration analysis is a crucial component of any industrial reliability program. vibration analysis is a crucial maintenance technique that employs sensors to measure equipment vibrations. It plays a vital role in maintenance. 6 month battery lifeinnovative sleep mode Importance of vibration analysis in maintenance. vibration analysis can be. What Is Vibration Analysis In Maintenance.

From tractian.com

Vibration Analysis The Complete Guide What Is Vibration Analysis In Maintenance Vibration monitoring is a fundamental component of predictive maintenance strategies. vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. It plays a vital role in maintenance. Importance of vibration analysis in maintenance. Uncover hidden asset issues & optimize maintenance. It helps teams monitor. What Is Vibration Analysis In Maintenance.

From www.technomaxme.com

Vibration Analysis In Electric Induction Motors Technomax What Is Vibration Analysis In Maintenance Vibration monitoring is a fundamental component of predictive maintenance strategies. Vibration analysis is one of the most effective ways to keep your. 6 month battery lifeinnovative sleep mode vibration analysis is a predictive maintenance technique that involves monitoring the vibrations of machinery and equipment to detect potential issues before they lead to breakdowns. It provides valuable insights into the. What Is Vibration Analysis In Maintenance.

From www.hitekbalancing.com

What is Vibration Analysis? HiTek Balancing What Is Vibration Analysis In Maintenance the role of vibration monitoring in machine health. It provides valuable insights into the health of assets, allowing maintenance teams to take proactive measures. Vibration monitoring is a fundamental component of predictive maintenance strategies. Importance of vibration analysis in maintenance. It involves the continuous surveillance of machinery to identify changes in vibration patterns that may indicate mechanical wear or. What Is Vibration Analysis In Maintenance.

From kienitvc.ac.ke

The Ultimate Guide to Vibration Analysis kienitvc.ac.ke What Is Vibration Analysis In Maintenance Importance of vibration analysis in maintenance. the role of vibration monitoring in machine health. 6 month battery lifeinnovative sleep mode Uncover hidden asset issues & optimize maintenance. It helps teams monitor machine health, predict maintenance needs,. vibration analysis is a crucial maintenance technique that employs sensors to measure equipment vibrations. It provides valuable insights into the health of. What Is Vibration Analysis In Maintenance.

From ses-egy.com

Vibration Analysis Category I (Introductory Level) Suez Engineering What Is Vibration Analysis In Maintenance the role of vibration monitoring in machine health. Vibration monitoring is a fundamental component of predictive maintenance strategies. vibration analysis is a crucial component of any industrial reliability program. It provides valuable insights into the health of assets, allowing maintenance teams to take proactive measures. It helps teams monitor machine health, predict maintenance needs,. Uncover hidden asset issues. What Is Vibration Analysis In Maintenance.