Carbon Fiber In Jet Engine . The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. That engine is being developed for the boeing 777x passenger airplanes that are. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. While that represents only about 2. Enhancements in fiber properties can be gained from the historical data presented in table 2.

from www.semanticscholar.org

Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. That engine is being developed for the boeing 777x passenger airplanes that are. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. While that represents only about 2. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. Enhancements in fiber properties can be gained from the historical data presented in table 2.

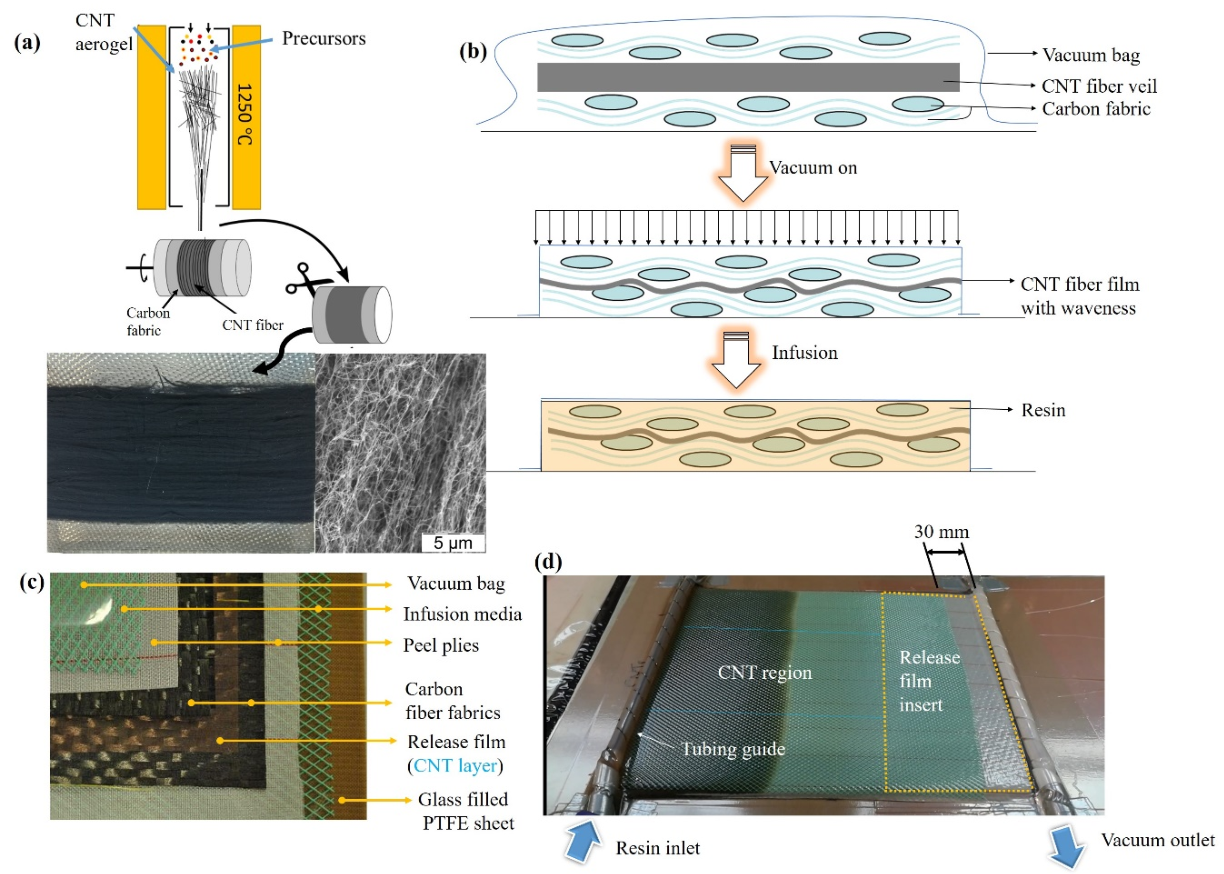

Figure 1 from Interlaminar toughening in structural carbon fiber/epoxy

Carbon Fiber In Jet Engine While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. That engine is being developed for the boeing 777x passenger airplanes that are. Enhancements in fiber properties can be gained from the historical data presented in table 2. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. While that represents only about 2. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric.

From www.jeccomposites.com

Filament winding process based on jet engine nozzle geometry for Carbon Fiber In Jet Engine That engine is being developed for the boeing 777x passenger airplanes that are. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. Ge aviation says the new blades will be redesigned using a carbon composite with. Carbon Fiber In Jet Engine.

From usa.exportersindia.com

Carbonfiber composite fan blades Buy carbonfiber composite fan blades Carbon Fiber In Jet Engine The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. While that represents only about 2. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. That engine is being developed for the. Carbon Fiber In Jet Engine.

From www.xccarbonfiber.com

Flexible carbon fiber sheet China Dongguan xccarbon Carbon Fiber In Jet Engine We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. Enhancements in fiber properties can be gained from the historical data presented in table 2. The commercial aviation industry emits. Carbon Fiber In Jet Engine.

From www.wallpaperflare.com

HD wallpaper engine schematics wallpaper, diagrams, engines, aircraft Carbon Fiber In Jet Engine The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. That engine is being developed for the. Carbon Fiber In Jet Engine.

From www.alibaba.com

Quality Supplier Prepreg Carbon Fiber Molded Parts Oem Carbon Fiber Carbon Fiber In Jet Engine We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. Enhancements in fiber properties can be gained from the historical data presented in table 2. That engine is being developed for the boeing 777x passenger airplanes that are. While that represents only about 2. Ge aviation says the new blades will be redesigned. Carbon Fiber In Jet Engine.

From www.wevolver.com

How to Produce a Jet Engine Blade via Automated Fiber Placement (AFP)? Carbon Fiber In Jet Engine Enhancements in fiber properties can be gained from the historical data presented in table 2. That engine is being developed for the boeing 777x passenger airplanes that are. While that represents only about 2. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. Ge aviation says the new blades will be redesigned using a carbon. Carbon Fiber In Jet Engine.

From theawesomer.com

Jet Engine Ceiling Fan 2.0 Carbon Fiber In Jet Engine Enhancements in fiber properties can be gained from the historical data presented in table 2. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. We found that demand for composite. Carbon Fiber In Jet Engine.

From www.nccuk.com

DigiProp Developing the next generation of composite propeller blades Carbon Fiber In Jet Engine That engine is being developed for the boeing 777x passenger airplanes that are. While that represents only about 2. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. We found that demand. Carbon Fiber In Jet Engine.

From www.nccuk.com

DigiProp Developing the next generation of composite propeller blades Carbon Fiber In Jet Engine Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. That engine is being developed for. Carbon Fiber In Jet Engine.

From analyzing-testing.netzsch.com

Characterization of FiberReinforced Composites by Means of DMA Carbon Fiber In Jet Engine While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. Enhancements in fiber properties can be gained from the historical data presented in table 2. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. The commercial aviation industry emits 705 million metric tons of carbon dioxide. Carbon Fiber In Jet Engine.

From www.ge.com

The Art of Engineering The World’s Largest Jet Engine Shows Off Carbon Fiber In Jet Engine Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. That engine is being developed for the boeing 777x passenger airplanes that are. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. Enhancements in fiber properties can be gained from the historical. Carbon Fiber In Jet Engine.

From wallpapers.com

Download Carbon Fiber Pictures Carbon Fiber In Jet Engine While that represents only about 2. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. That engine is being developed for the boeing 777x passenger airplanes that are. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. The commercial. Carbon Fiber In Jet Engine.

From www.motorbiscuit.com

Nissan Wants to Build Engines Completely Out of Carbon Fiber Carbon Fiber In Jet Engine While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. Enhancements in fiber properties can be gained from the historical data presented in table 2. Ge aviation says the new blades will be redesigned using a carbon. Carbon Fiber In Jet Engine.

From www.designworldonline.com

The World's Largest Jet Engine Shows Off Composite Curves Carbon Fiber In Jet Engine We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. While that represents only about 2.. Carbon Fiber In Jet Engine.

From www.semanticscholar.org

Figure 1 from Interlaminar toughening in structural carbon fiber/epoxy Carbon Fiber In Jet Engine While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. That engine is being developed for the boeing 777x passenger airplanes that are. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. While that represents only about 2. Enhancements in fiber properties can be gained from the historical data. Carbon Fiber In Jet Engine.

From formlabs.com

How to Manufacture Carbon Fiber Parts Carbon Fiber In Jet Engine We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. Enhancements in fiber properties. Carbon Fiber In Jet Engine.

From www.mdpi.com

JMSE Free FullText Carbon Fiber Composites for LargeScale Wind Carbon Fiber In Jet Engine While that represents only about 2. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. Enhancements in fiber properties can be gained from the historical data presented in table 2. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. Ge aviation says the new blades will be. Carbon Fiber In Jet Engine.

From www.cfmaeroengines.com

LEAP Engines CFM International Jet Engines CFM International Carbon Fiber In Jet Engine While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. While that represents only about 2. Ge aviation says the new blades will. Carbon Fiber In Jet Engine.

From www.compositestoday.com

Rolls Royce Tests Composite Fan Systems for New Engine Designs Carbon Fiber In Jet Engine Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. That engine is being developed for. Carbon Fiber In Jet Engine.

From www.youtube.com

This BMW S1000RRPowered Airplane Will Blow Your Mind YouTube Carbon Fiber In Jet Engine Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. Enhancements in fiber properties can be gained from the historical data presented in table 2. While that represents only about 2. That engine. Carbon Fiber In Jet Engine.

From www.smicomposites.com

Can Carbon Fiber Help Improve Fighter Jet Aerodynamics? Carbon Fiber In Jet Engine The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. That engine is being developed for the boeing 777x passenger airplanes that are. While that represents only about 2. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. Enhancements in fiber properties. Carbon Fiber In Jet Engine.

From www.fiberdyne1.com

Carbon Fiber Automotive Applications Fiberdyne Carbon Fiber In Jet Engine While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. Ge aviation says the new blades will be redesigned using a carbon composite. Carbon Fiber In Jet Engine.

From www.motortrend.com

Carbon Fiber DualPlenum LS3 Intake Carbon Fiber In Jet Engine While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. That engine is being developed for the boeing 777x passenger airplanes that are. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. We found that demand for composite engine structures. Carbon Fiber In Jet Engine.

From www.youtube.com

Carbon Fiber Jet Engine YouTube Carbon Fiber In Jet Engine While that represents only about 2. That engine is being developed for the boeing 777x passenger airplanes that are. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. We found. Carbon Fiber In Jet Engine.

From www.compositesworld.com

Automated Preforming, Part 1 Numbers and Landscape CompositesWorld Carbon Fiber In Jet Engine Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. Enhancements in fiber properties can be gained from the historical data presented in table 2. That engine is being developed for the boeing 777x passenger airplanes that are. We found that demand for composite engine structures during. Carbon Fiber In Jet Engine.

From www.wpafb.af.mil

Light carbonfiber structure protects heavy space cargo > Wright Carbon Fiber In Jet Engine While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. That engine is being developed for the boeing 777x passenger airplanes that are.. Carbon Fiber In Jet Engine.

From www.aircraftnerds.com

GEnx Boeing 787 and Boeing 7478 Aircraft Engine Aircraft Nerds Carbon Fiber In Jet Engine We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. That engine is being developed for the boeing 777x passenger airplanes that are. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. While that represents only about 2. The. Carbon Fiber In Jet Engine.

From www.turbosquid.com

3d model pratt f100 afterburning turbofan engine Carbon Fiber In Jet Engine Enhancements in fiber properties can be gained from the historical data presented in table 2. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. While that represents only about 2. While titanium,. Carbon Fiber In Jet Engine.

From www.compositestoday.com

GE's Composite Blade Project Turns 20 Years Old Carbon Fiber In Jet Engine While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. While that represents only. Carbon Fiber In Jet Engine.

From www.dreamstime.com

Jet Engine Royalty Free Stock Photography Image 38126117 Carbon Fiber In Jet Engine Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. That engine is being developed for the boeing 777x passenger airplanes that are. While titanium, aluminum and continuous fiber reinforced thermosetting composites and. Carbon Fiber In Jet Engine.

From www.addcomposites.com

Producing a Jet Engine Blade via Automated Fiber Placement Carbon Fiber In Jet Engine While that represents only about 2. Enhancements in fiber properties can be gained from the historical data presented in table 2. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber.. Carbon Fiber In Jet Engine.

From www.youtube.com

Carbon Fiber Ramjet (RC) YouTube Carbon Fiber In Jet Engine Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. Enhancements in fiber properties can be gained from the historical data presented in table 2. While that represents only about 2.. Carbon Fiber In Jet Engine.

From technology.nasa.gov

Silicon Carbide (SiC) FiberReinforced SiC Matrix Composites T2 Portal Carbon Fiber In Jet Engine While that represents only about 2. That engine is being developed for the boeing 777x passenger airplanes that are. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. While. Carbon Fiber In Jet Engine.

From www.reddit.com

Straight on shot of a CFM LEAP jet engine. Fun fact Each fan blade Carbon Fiber In Jet Engine We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. While titanium, aluminum and continuous fiber reinforced thermosetting composites and superalloys prevail in the current material. Enhancements in fiber properties can be gained from the historical data presented in table 2. The commercial aviation industry emits 705 million metric tons of carbon dioxide. Carbon Fiber In Jet Engine.

From www.nitprocomposites.com

5 Uses of Carbon Fiber in the Medical Industry Carbon Fiber In Jet Engine While that represents only about 2. We found that demand for composite engine structures during 2007 totaled approximately 1.49 million lb (675.85 metric. The commercial aviation industry emits 705 million metric tons of carbon dioxide each year. Ge aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber.. Carbon Fiber In Jet Engine.