Molding Of Foam . Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. The foaming agent used in the process. In this article, we discuss the. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Eco friendly materialsprevent injury & damage Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts.

from innovativefoam.com

The foaming agent used in the process. Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. In this article, we discuss the. Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. Eco friendly materialsprevent injury & damage

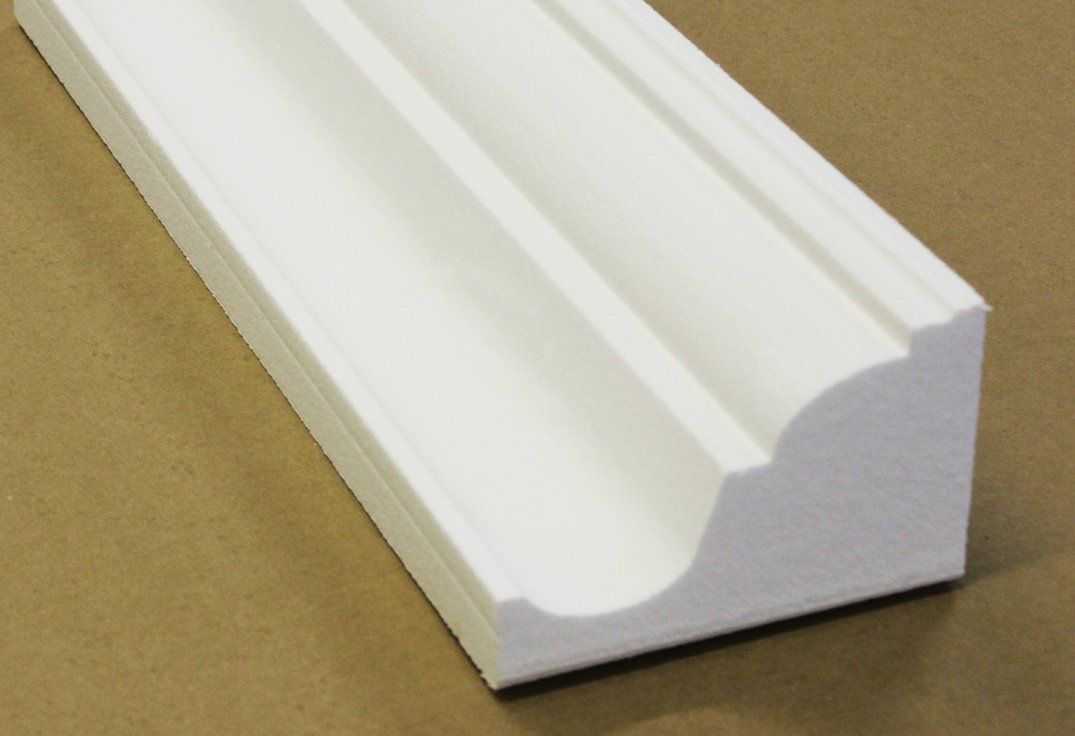

Architectural Foam Molding Innovative Foam

Molding Of Foam The foaming agent used in the process. In this article, we discuss the. Eco friendly materialsprevent injury & damage Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. The foaming agent used in the process. Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert.

From www.immould.com

The Basics Of Foam Injection Molding FOW Mould Molding Of Foam This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. In this article, we discuss the. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. Eco friendly materialsprevent injury & damage The foaming. Molding Of Foam.

From www.mdpi.com

Polymers Free FullText Compression Molding of Thermoplastic Molding Of Foam Eco friendly materialsprevent injury & damage Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. The foaming agent used in the process. Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. Structural foam is a composite material produced when. Molding Of Foam.

From www.slideserve.com

PPT Foaming PowerPoint Presentation, free download ID142570 Molding Of Foam Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. In this article, we discuss the. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Eco friendly materialsprevent injury & damage Today, structural. Molding Of Foam.

From www.mdpi.com

Polymers Free FullText Compression Molding of Thermoplastic Molding Of Foam The foaming agent used in the process. Eco friendly materialsprevent injury & damage In this article, we discuss the. Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. This article will explore in detail the principles of injection molding foam, the process flow, and application. Molding Of Foam.

From innovativefoam.com

Architectural Foam Molding Innovative Foam Molding Of Foam Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. The foaming agent used in the process. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. Structural foam molding allows for producing much. Molding Of Foam.

From www.structuralfoammolding.net

Structural Foam Molding LowPressure Plastic Injection Molding Molding Of Foam Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. Eco friendly materialsprevent injury & damage Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and. Molding Of Foam.

From www.slideserve.com

PPT KEY BENEFITS OF THE STRUCTURAL FOAM INJECTION MOLDING PROCESS Molding Of Foam Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. Eco friendly materialsprevent injury & damage The foaming agent used in the process. In. Molding Of Foam.

From milesproducts.com

Introducing the Structural Foam Molding Design Guide Miles Products Molding Of Foam Eco friendly materialsprevent injury & damage Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is. Molding Of Foam.

From decopro.com.ph

Decopro Source of HighQuality Building & Construction Materials Molding Of Foam The foaming agent used in the process. Eco friendly materialsprevent injury & damage Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. In. Molding Of Foam.

From www.dekalbplastics.com

Structural Foam Molding DeKALB Molded Plastics Molding Of Foam This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Eco friendly materialsprevent injury & damage Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. Structural foam is a composite material produced when. Molding Of Foam.

From www.immould.com

The Basics Of Foam Injection Molding FOW Mould Molding Of Foam Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. In this article, we discuss the. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Eco friendly materialsprevent injury & damage Today, structural. Molding Of Foam.

From www.iqsdirectory.com

Polyurethane Molding What Is It? How Does It Work? Uses, Types Of Molding Of Foam In this article, we discuss the. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. Eco friendly materialsprevent injury & damage Structural foam molding allows. Molding Of Foam.

From www.houzz.com

Foam Molding Home Design Ideas, Pictures, Remodel and Decor Molding Of Foam Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. Structural foam molding allows for producing much lighter parts with excellent strength and structural. Molding Of Foam.

From www.researchgate.net

Schematic of foam injection molding process with variable volume cavity Molding Of Foam This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. Structural foam is a composite material produced when a polymer, usually thermoset (but can. Molding Of Foam.

From www.wtm.tf.fau.eu

Integral foam molding Chair of Materials Science and Engineering for Molding Of Foam Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. In this article, we discuss the. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. The foaming agent used in the process. Structural. Molding Of Foam.

From polytek.com

Casting Foam in Polyurethane Rubber Molds Polytek Development Corp. Molding Of Foam The foaming agent used in the process. Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. In this article, we discuss the. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Eco friendly materialsprevent injury & damage Structural foam is a. Molding Of Foam.

From polytek.com

Casting Foam in Polyurethane Rubber Molds Polytek Development Corp. Molding Of Foam Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Structural foam molding allows for producing much lighter parts with excellent strength and structural. Molding Of Foam.

From proleantech.com

Foam Injection Molding Types, Process, and Applications Molding Of Foam The foaming agent used in the process. Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. Eco friendly materialsprevent injury & damage In this article, we discuss the. Structural foam. Molding Of Foam.

From www.slideserve.com

PPT Comparison of Structural Foam Molding With Traditional Molding Molding Of Foam Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. Eco friendly materialsprevent injury & damage Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. The foaming agent used in the process. Structural. Molding Of Foam.

From www.slideserve.com

PPT KEY BENEFITS OF THE STRUCTURAL FOAM INJECTION MOLDING PROCESS Molding Of Foam Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. The foaming agent used in the process. Structural foam is a composite material produced. Molding Of Foam.

From www.structuralfoammolder.com

Structural Foam Molding S&A Molders Molding Of Foam In this article, we discuss the. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. The foaming agent used in the process. Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. Eco friendly materialsprevent injury & damage Structural foam. Molding Of Foam.

From www.structuralfoammolder.com

Structural Foam Molding S&A Molders Molding Of Foam The foaming agent used in the process. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. Today, structural foam molding is a highly. Molding Of Foam.

From clintonmachine.com

PU Foam Mold Automation Clinton Machine Molding Of Foam Eco friendly materialsprevent injury & damage In this article, we discuss the. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. The foaming agent used in the process. Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is. Molding Of Foam.

From www.youtube.com

FoamCore Advanced Basics Tutorial Guide FoamBoard model making Molding Of Foam Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Today, structural foam molding is a highly evolved technique that can create lighter, stronger,. Molding Of Foam.

From www.castlegroupusa.com

Architectural foam moldings in soffit / vane area Architectural Foam Molding Of Foam Eco friendly materialsprevent injury & damage Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. The foaming agent used in the process. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Structural foam is a composite material produced when a polymer,. Molding Of Foam.

From knaufautomotive.com

Foam Molding Technology Knauf Automotive Molding Of Foam Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. Today, structural foam molding is a highly evolved technique that can create lighter, stronger,. Molding Of Foam.

From innovativefoam.com

Architectural Foam Molding Innovative Foam Molding Of Foam In this article, we discuss the. Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. The foaming agent used in the process. Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. Today,. Molding Of Foam.

From foamcrownmolding.com

Decorative Foam Crown Molding 18003156311 Molding Of Foam Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. Eco friendly materialsprevent injury & damage Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. The foaming agent used in the process. In. Molding Of Foam.

From www.thecraftpatchblog.com

The Craft Patch Everything You Want To Know About FOAM Crown Molding Molding Of Foam This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. Today, structural foam molding is a highly evolved technique that can create lighter, stronger,. Molding Of Foam.

From structuralfoammolding.net

What is Structural Foam Molding? Structural Foam Molding Molding Of Foam Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Today, structural foam molding is a highly evolved technique that can create lighter, stronger,. Molding Of Foam.

From coremt.com

Structural Foam Molding CORE Molding Technologies Molding Of Foam In this article, we discuss the. Structural foam molding is a specialized form of injection molding used for producing parts that have a cellular or foam core surrounded by a. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. Structural foam is a composite material. Molding Of Foam.

From custommolding.com

Custom Molding Structural Foam Molding Low Pressure Gas Assist Molding Of Foam The foaming agent used in the process. Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more. Molding Of Foam.

From www.youtube.com

Installation of Styrofoam DIY Crown Moldings YouTube Molding Of Foam Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. In this article, we discuss the. The foaming agent used in the process. Today, structural foam molding is a highly evolved technique that can create lighter, stronger, and more resilient plastic parts than traditional injection molded parts. This article will explore in detail the principles. Molding Of Foam.

From www.youtube.com

Making a mold from foam YouTube Molding Of Foam The foaming agent used in the process. Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. This article will explore in detail the principles of injection molding foam, the process flow, and application examples, providing a reference for. Eco friendly materialsprevent injury & damage Structural foam molding. Molding Of Foam.

From www.iqsdirectory.com

Polyurethane Foam What Is It? How Is It Made? Applications Molding Of Foam The foaming agent used in the process. Structural foam is a composite material produced when a polymer, usually thermoset (but can be thermoplastic), is combined with either an inert. In this article, we discuss the. Structural foam molding allows for producing much lighter parts with excellent strength and structural integrity. Today, structural foam molding is a highly evolved technique that. Molding Of Foam.