Material Jetting Process . Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. A printhead (similar to those used in standard inkjet printing) sprays droplets of a photosensitive. Material is deposited from a nozzle which moves horizontally across the build. Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. Material jetting involves heating the material and then jetting it through a nozzle onto the build. The material jetting manufacturing process allows different materials to be 3d printed within the same part. In material jetting, a printhead (similar to the printheads used for standard inkjet printing). These “inks” can be pure photopolymer or pure waxes, or. Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. Overview of material jetting process.

from plantecuador.com

Material jetting involves heating the material and then jetting it through a nozzle onto the build. These “inks” can be pure photopolymer or pure waxes, or. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. Overview of material jetting process. Material is deposited from a nozzle which moves horizontally across the build. The material jetting manufacturing process allows different materials to be 3d printed within the same part. In material jetting, a printhead (similar to the printheads used for standard inkjet printing).

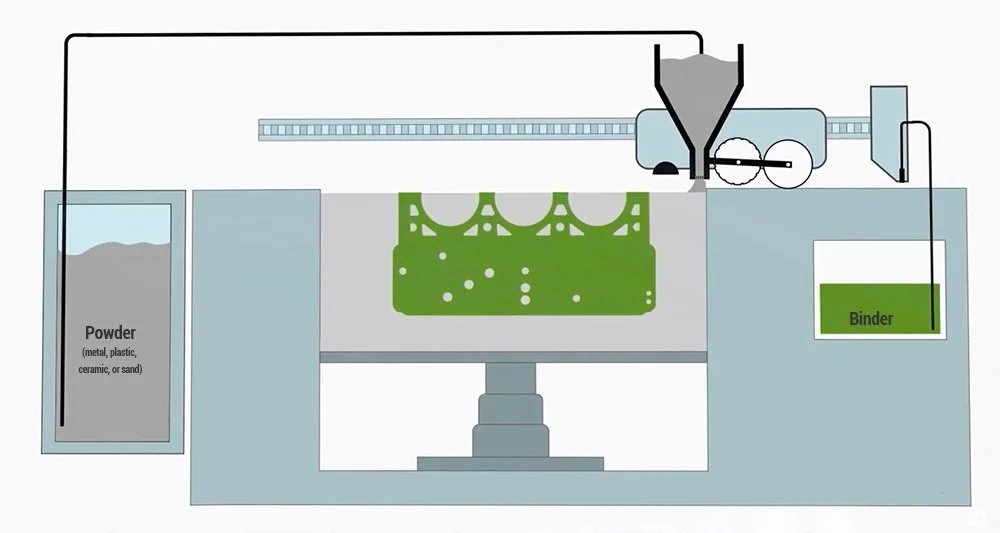

The Basics of Binder Jetting, binder material

Material Jetting Process The material jetting manufacturing process allows different materials to be 3d printed within the same part. Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. Overview of material jetting process. Material jetting involves heating the material and then jetting it through a nozzle onto the build. These “inks” can be pure photopolymer or pure waxes, or. Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. In material jetting, a printhead (similar to the printheads used for standard inkjet printing). A printhead (similar to those used in standard inkjet printing) sprays droplets of a photosensitive. Material is deposited from a nozzle which moves horizontally across the build. The material jetting manufacturing process allows different materials to be 3d printed within the same part. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer.

From www.metal-am.com

Binder Jetting and FDM vs Powder Bed Fusion and Injection Moulding Material Jetting Process Material jetting involves heating the material and then jetting it through a nozzle onto the build. Overview of material jetting process. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. In material jetting, a. Material Jetting Process.

From plantecuador.com

The Basics of Binder Jetting, binder material Material Jetting Process Material jetting involves heating the material and then jetting it through a nozzle onto the build. Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. The material jetting manufacturing process allows different materials to be 3d printed within the same part. A printhead (similar to those used in standard inkjet printing) sprays. Material Jetting Process.

From 3dprintingindustry.com

The Free Beginner’s Guide Processes 3D Printing Industry Material Jetting Process Material is deposited from a nozzle which moves horizontally across the build. Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. In material jetting, a printhead (similar to the printheads used for standard inkjet printing). The material jetting manufacturing process allows different materials to be 3d printed within the same part. Material jetting (mj) is an additive manufacturing. Material Jetting Process.

From facfox.com

All You Need to Know About Metal Binder Jetting FacFox Docs Material Jetting Process In material jetting, a printhead (similar to the printheads used for standard inkjet printing). Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. Overview of material jetting process. Material jetting involves heating the material and then jetting it through a nozzle onto the build. The material jetting manufacturing process allows different materials to be. Material Jetting Process.

From www.mkstechgroup.com

Binder Jetting Process MKS Technologies Pvt Ltd. Material Jetting Process These “inks” can be pure photopolymer or pure waxes, or. Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. In material jetting, a printhead (similar to the printheads used for standard inkjet printing). Material is jetted onto the build surface or. Material Jetting Process.

From www.researchgate.net

Principle of Material jetting process Download Scientific Diagram Material Jetting Process Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. Material jetting involves heating the material and then jetting it through a nozzle onto the build. A printhead (similar to those used in standard inkjet printing) sprays droplets of a photosensitive. These “inks” can be pure photopolymer or pure waxes, or. Material is deposited from a nozzle which moves. Material Jetting Process.

From www.researchgate.net

Illustration of the binder jet additive manufacturing process showing Material Jetting Process Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. The material jetting manufacturing process allows different materials to be 3d printed within the same part. In material jetting, a printhead (similar to the printheads used for standard inkjet printing). These “inks” can be pure photopolymer or pure waxes, or. A printhead (similar to those. Material Jetting Process.

From www.researchgate.net

Material jetting process overview [28]. Download Scientific Diagram Material Jetting Process Material jetting involves heating the material and then jetting it through a nozzle onto the build. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. The material jetting manufacturing process allows different. Material Jetting Process.

From engineeringproductdesign.com

What is Binder Jetting and how does binder jetting work Material Jetting Process In material jetting, a printhead (similar to the printheads used for standard inkjet printing). Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. These “inks” can be pure photopolymer or pure waxes, or. Overview of material jetting. Material Jetting Process.

From www.3ds.com

Material Jetting, What is it and how does it work? Dassault Systèmes® Material Jetting Process Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. These “inks” can be pure photopolymer or pure waxes, or. A printhead (similar to those used in standard inkjet printing) sprays droplets of a photosensitive.. Material Jetting Process.

From www.3ds.com

3DDruck, was ist das und wie funktioniert er? Dassault Systèmes® Material Jetting Process The material jetting manufacturing process allows different materials to be 3d printed within the same part. These “inks” can be pure photopolymer or pure waxes, or. Material is deposited from a nozzle which moves horizontally across the build. Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. Overview of material jetting process. A printhead. Material Jetting Process.

From www.researchgate.net

Material jetting process Download Scientific Diagram Material Jetting Process Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. A printhead (similar to those used in standard inkjet printing) sprays droplets of a photosensitive. Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. The material jetting manufacturing process allows different materials to be 3d printed within. Material Jetting Process.

From www.engineersgarage.com

3D Printing Processes Material Jetting (Part 7/8) Material Jetting Process Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. Material is deposited from a nozzle which moves. Material Jetting Process.

From mechguru.com

Additive Manufacturing Material Jetting mechGuru Material Jetting Process Material jetting involves heating the material and then jetting it through a nozzle onto the build. Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. The material jetting manufacturing process allows different materials to be 3d printed within the same part.. Material Jetting Process.

From www.researchgate.net

Schematic illustration of material jetting or multijet modelling Material Jetting Process Overview of material jetting process. A printhead (similar to those used in standard inkjet printing) sprays droplets of a photosensitive. Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. The material jetting manufacturing process allows different materials to be 3d printed within the same part. Material is deposited from a nozzle which. Material Jetting Process.

From www.youtube.com

Material Jetting Process in Additive Manufacturing. YouTube Material Jetting Process Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. These “inks” can be pure photopolymer or pure waxes, or. In material jetting, a printhead (similar to the printheads used for standard inkjet printing). Material jetting involves heating the. Material Jetting Process.

From www.researchgate.net

Material jetting process Download Scientific Diagram Material Jetting Process Material is deposited from a nozzle which moves horizontally across the build. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. A printhead (similar to those used in standard inkjet printing) sprays droplets of a photosensitive. In material jetting, a printhead (similar to the printheads used for standard inkjet. Material Jetting Process.

From 3dprinting.com

What is 3D printing? How does a 3D printer work? Learn 3D printing Material Jetting Process A printhead (similar to those used in standard inkjet printing) sprays droplets of a photosensitive. Material jetting involves heating the material and then jetting it through a nozzle onto the build. These “inks” can be pure photopolymer or pure waxes, or. Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. In material. Material Jetting Process.

From www.metal-am.com

Binder Jetting and FDM vs Powder Bed Fusion and Injection Moulding Material Jetting Process These “inks” can be pure photopolymer or pure waxes, or. Overview of material jetting process. Material jetting involves heating the material and then jetting it through a nozzle onto the build. Material is deposited from a nozzle which moves horizontally across the build. The material jetting manufacturing process allows different materials to be 3d printed within the same part. Material. Material Jetting Process.

From www.researchgate.net

Material Jetting. Source Download Scientific Diagram Material Jetting Process Overview of material jetting process. These “inks” can be pure photopolymer or pure waxes, or. The material jetting manufacturing process allows different materials to be 3d printed within the same part. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. A printhead (similar to those used in standard inkjet. Material Jetting Process.

From www.researchgate.net

Steps of binder jetting process [63] Download Scientific Diagram Material Jetting Process Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. In material jetting, a printhead (similar to the printheads used for standard inkjet printing).. Material Jetting Process.

From dreams.mii.vt.edu

Material Jetting Design, Research, and Education for Additive Material Jetting Process Overview of material jetting process. Material is deposited from a nozzle which moves horizontally across the build. Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. Material jetting involves heating the material and then jetting it through a nozzle onto the build. These “inks” can be pure photopolymer or pure waxes, or.. Material Jetting Process.

From www.researchgate.net

Material Jetting process Download Scientific Diagram Material Jetting Process These “inks” can be pure photopolymer or pure waxes, or. Material jetting involves heating the material and then jetting it through a nozzle onto the build. The material jetting manufacturing process allows different materials to be 3d printed within the same part. Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. Material is jetted onto the build surface. Material Jetting Process.

From engineeringproductdesign.com

What is Material Jetting? How does material jetting work? Material Jetting Process In material jetting, a printhead (similar to the printheads used for standard inkjet printing). Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. A printhead (similar to those used in standard inkjet printing) sprays droplets of a photosensitive. Material is deposited from a nozzle which moves horizontally across the. Material Jetting Process.

From dreams.mii.vt.edu

Material Jetting Design, Research, and Education for Additive Material Jetting Process Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. In material jetting, a printhead (similar to the printheads used for standard inkjet printing). Material jetting involves heating the material and then jetting it through a nozzle onto. Material Jetting Process.

From theadditivemanufacturing.com

The Power of Precision Exploring the Benefits of Material Jetting Material Jetting Process Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. The material jetting manufacturing process allows different materials to be 3d printed within the same part. Material jetting involves heating the material and then jetting it through a nozzle onto the build. Material is jetted onto the build surface or platform, where it. Material Jetting Process.

From theadditivemanufacturing.com

Material Jetting A Comprehensive Definition and Working Principle Material Jetting Process Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. Material jetting involves heating the material and then jetting it through a nozzle onto the build. Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. A. Material Jetting Process.

From www.researchgate.net

2. Schematic of material jetting process [12] Download Scientific Diagram Material Jetting Process The material jetting manufacturing process allows different materials to be 3d printed within the same part. Overview of material jetting process. In material jetting, a printhead (similar to the printheads used for standard inkjet printing). Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. Material is deposited from a nozzle which moves horizontally across the build. Material jetting. Material Jetting Process.

From journals.innovareacademics.in

Fig. 2 Material jetting process [25] Material Jetting Process Material is deposited from a nozzle which moves horizontally across the build. Material jetting involves heating the material and then jetting it through a nozzle onto the build. Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. These “inks” can be pure photopolymer. Material Jetting Process.

From www.3dhubs.com

Introduction to Material Jetting 3D Printing 3D Hubs Material Jetting Process Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. A printhead (similar to those used in standard inkjet printing) sprays droplets of a. Material Jetting Process.

From wohlersassociates.com

The Seven AM Processes Wohlers Associates Material Jetting Process Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. Material jetting (mj) is a type of additive manufacturing that works similarly to 2d printers. Material jetting involves heating the material and then jetting it through a nozzle onto. Material Jetting Process.

From www.additively.com

Material Jetting Additively Material Jetting Process Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. Material is deposited from a nozzle which moves horizontally across the build. These “inks” can be pure photopolymer or pure waxes, or. Overview of material jetting process. Material jetting involves heating the material and then jetting it through a nozzle. Material Jetting Process.

From pick3dprinter.com

Metal Binder Jetting (MBJ) 3D Printing Simply Explained Pick 3D Printer Material Jetting Process These “inks” can be pure photopolymer or pure waxes, or. Material is deposited from a nozzle which moves horizontally across the build. Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. The material jetting manufacturing process allows different materials to be 3d printed within the same part. In material jetting, a printhead. Material Jetting Process.

From www.metal-am.com

Effective metal powder specifications for Binder Jet Additive Manufacturing Material Jetting Process Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. Material is jetted onto the build surface or platform, where it solidifies and the model is built layer by layer. A printhead (similar to those used in standard inkjet printing) sprays droplets of a photosensitive. Material jetting dispenses a photopolymer from hundreds of. Material Jetting Process.

From sohaibwrites.com

What is binder jetting? (step by step, materials, advantages and Material Jetting Process The material jetting manufacturing process allows different materials to be 3d printed within the same part. In material jetting, a printhead (similar to the printheads used for standard inkjet printing). Material jetting (mj) is an additive manufacturing process that operates in a similar fashion to 2d printers. Material jetting dispenses a photopolymer from hundreds of tiny nozzles in. Material jetting. Material Jetting Process.