Lead Casting Process . ever think about casting your own lead bullets? Smelting wheel weights into ingots. for those contemplating venturing into bullet casting, certain aspects need careful attention. release some lead onto the spurce plate in between the two mold cavities, allowing the molten lead alloy to flow into the cavities and form a small puddle on top of the. by understanding the lead casting process, you'll be able to create. in this video, you'll learn about the lead casting process in detail and see. It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. Maybe you’re already a member of our growing ranks of diy bullet.

from schematicmoha39.z22.web.core.windows.net

ever think about casting your own lead bullets? release some lead onto the spurce plate in between the two mold cavities, allowing the molten lead alloy to flow into the cavities and form a small puddle on top of the. Smelting wheel weights into ingots. I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. in this video, you'll learn about the lead casting process in detail and see. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. for those contemplating venturing into bullet casting, certain aspects need careful attention. Maybe you’re already a member of our growing ranks of diy bullet. by understanding the lead casting process, you'll be able to create.

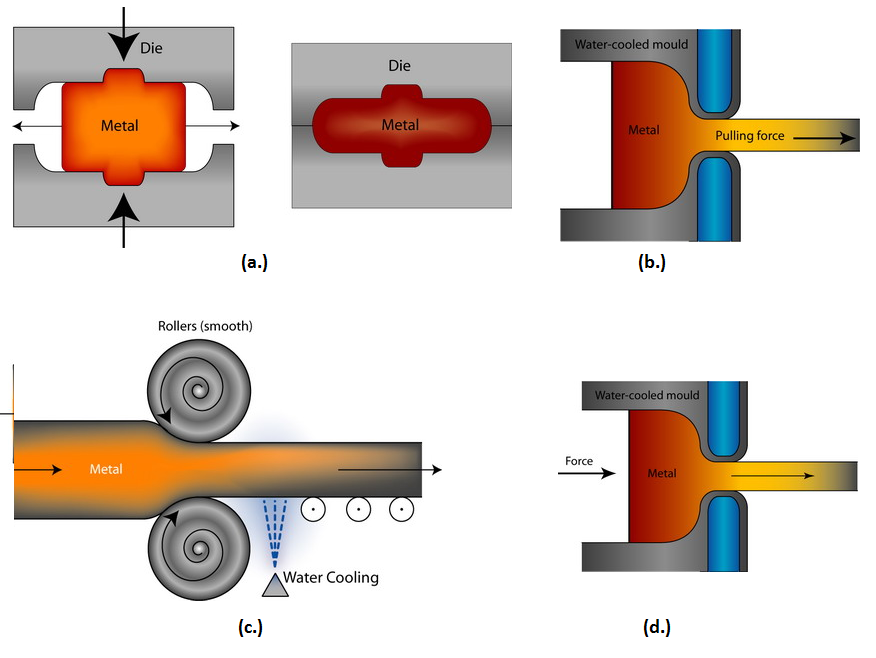

What Is Forming In The Diagram

Lead Casting Process It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. for those contemplating venturing into bullet casting, certain aspects need careful attention. in this video, you'll learn about the lead casting process in detail and see. release some lead onto the spurce plate in between the two mold cavities, allowing the molten lead alloy to flow into the cavities and form a small puddle on top of the. Smelting wheel weights into ingots. by understanding the lead casting process, you'll be able to create. Maybe you’re already a member of our growing ranks of diy bullet. ever think about casting your own lead bullets?

From dxomwelfk.blob.core.windows.net

Expendable Mold Casting Process at Kathleen Bickerstaff blog Lead Casting Process It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. in this video, you'll learn about the lead casting process in detail and see. Smelting wheel weights into ingots. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. I procured a natural gas burner, regulator,. Lead Casting Process.

From www.youtube.com

Metal casting process in manufacturing / Metal casting business ideas Lead Casting Process I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. Maybe you’re already a member of our growing ranks of diy bullet. for those contemplating venturing into bullet casting, certain aspects need careful attention. in this video, you'll learn about the lead casting process in detail and see.. Lead Casting Process.

From www.diecastingcompany.com

Ten Kinds Casting Processes In Foundries Minghe Casting Lead Casting Process I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. in this video, you'll learn about the lead casting process in detail and see. Maybe you’re already a member of our growing ranks of diy bullet. It then measures the dimple’s diameter and compares that number to a supplied. Lead Casting Process.

From www.researchgate.net

Preparation of active films via solvent casting method Download Lead Casting Process I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. in this video, you'll learn about the lead casting process in detail and see. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. for those contemplating venturing into bullet casting, certain aspects. Lead Casting Process.

From fluids.leeds.ac.uk

Fluid Dynamics of the Continuous Casting of Steel Leeds Institute for Lead Casting Process It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. release some lead onto the spurce plate in between the two mold cavities, allowing the molten lead alloy to flow into the cavities and form a small puddle on top of the. The bullet casting procedure is pretty simple, really…you just. Lead Casting Process.

From www.researchgate.net

Schematic illustration of the solution casting process.... Download Lead Casting Process ever think about casting your own lead bullets? for those contemplating venturing into bullet casting, certain aspects need careful attention. Smelting wheel weights into ingots. in this video, you'll learn about the lead casting process in detail and see. It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness.. Lead Casting Process.

From blog.transvalorusa.com

How Casting Process Simulation Software Improves Manufacturing Efficiency Lead Casting Process ever think about casting your own lead bullets? It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. for those contemplating venturing into bullet casting, certain aspects need careful attention. release some lead onto. Lead Casting Process.

From www.youtube.com

Hot Chamber and Cold Chamber Die Casting Process Working Animation Lead Casting Process by understanding the lead casting process, you'll be able to create. in this video, you'll learn about the lead casting process in detail and see. ever think about casting your own lead bullets? release some lead onto the spurce plate in between the two mold cavities, allowing the molten lead alloy to flow into the cavities. Lead Casting Process.

From exomwgvze.blob.core.windows.net

Permanent Mold Casting Process Ppt at Donna Lehto blog Lead Casting Process I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. Smelting wheel weights into ingots. release some lead onto the spurce plate in between the two mold cavities, allowing the molten. Lead Casting Process.

From www.deancast.com

Gravity Die Casting Precision Aluminium Castings Lead Casting Process for those contemplating venturing into bullet casting, certain aspects need careful attention. I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. in this video, you'll learn about the lead casting process in detail and see. ever think about casting your own lead bullets? Smelting wheel weights. Lead Casting Process.

From www.worthyhardware.com

Exploring 11 Unique Casting Process Types A Comprehensive Guide CNC Lead Casting Process I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. for those contemplating venturing into bullet casting, certain aspects need careful attention. by understanding the lead casting process, you'll be able to create. ever think about casting your own lead bullets? release some lead onto the. Lead Casting Process.

From intercast.com

The Many Benefits of Steel Casting Steel Casting Process Intercast Lead Casting Process I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. Smelting wheel weights into ingots. in this video, you'll learn about the lead casting process in detail and see. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. It then measures the dimple’s. Lead Casting Process.

From news.ewmfg.com

Investment Casting vs. Die Casting 7 Considerations When Choosing a Lead Casting Process Smelting wheel weights into ingots. for those contemplating venturing into bullet casting, certain aspects need careful attention. in this video, you'll learn about the lead casting process in detail and see. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. It then measures the dimple’s diameter and compares that number to a. Lead Casting Process.

From hanmetallurgy.com

Continuous Casting Machine Process Hani Metallurgy Lead Casting Process I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. Maybe you’re already a member of our growing ranks of diy bullet. by understanding the lead casting process, you'll be able to create. in this video, you'll learn about the lead casting process in detail and see. . Lead Casting Process.

From www.pinterest.com

Continuous Casting Process It cast, Continuity, Under pressure Lead Casting Process by understanding the lead casting process, you'll be able to create. in this video, you'll learn about the lead casting process in detail and see. I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. ever think about casting your own lead bullets? Smelting wheel weights into. Lead Casting Process.

From wetronindustrial.com

High Pressure of Four Processes of High Pressure Lead Casting Process by understanding the lead casting process, you'll be able to create. Smelting wheel weights into ingots. Maybe you’re already a member of our growing ranks of diy bullet. It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. in this video, you'll learn about the lead casting process in detail. Lead Casting Process.

From www.youtube.com

Casting Lead YouTube Lead Casting Process by understanding the lead casting process, you'll be able to create. It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. Smelting wheel weights into ingots. I procured a natural gas burner, regulator, and a cast. Lead Casting Process.

From ppcpinc.com

Pennsylvania Precision Cast Parts Investment Casting Process Lead Casting Process ever think about casting your own lead bullets? for those contemplating venturing into bullet casting, certain aspects need careful attention. release some lead onto the spurce plate in between the two mold cavities, allowing the molten lead alloy to flow into the cavities and form a small puddle on top of the. The bullet casting procedure is. Lead Casting Process.

From www.researchgate.net

Diagrammatic representation of solvent casting and particulate leaching Lead Casting Process for those contemplating venturing into bullet casting, certain aspects need careful attention. ever think about casting your own lead bullets? I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness.. Lead Casting Process.

From www.mdpi.com

Materials Free FullText A Novel Approach to Improve the Lead Casting Process The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. Smelting wheel weights into ingots. for those contemplating venturing into bullet casting, certain aspects need careful attention. ever think about casting your own lead bullets? in this video, you'll learn about the lead casting process in detail and see. Maybe you’re already. Lead Casting Process.

From www.pedowitzgroup.com

Strong Lead Management Process = More Revenue. Follow These Steps! Lead Casting Process Smelting wheel weights into ingots. by understanding the lead casting process, you'll be able to create. in this video, you'll learn about the lead casting process in detail and see. I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. ever think about casting your own lead. Lead Casting Process.

From americancastingco.com

Investment Casting Process Steps and Flow Chart American Casting Company Lead Casting Process Maybe you’re already a member of our growing ranks of diy bullet. in this video, you'll learn about the lead casting process in detail and see. ever think about casting your own lead bullets? by understanding the lead casting process, you'll be able to create. release some lead onto the spurce plate in between the two. Lead Casting Process.

From www.researchgate.net

Schematic representation of the casting process of A preformed Lead Casting Process release some lead onto the spurce plate in between the two mold cavities, allowing the molten lead alloy to flow into the cavities and form a small puddle on top of the. by understanding the lead casting process, you'll be able to create. I procured a natural gas burner, regulator, and a cast iron frying pan for smelting. Lead Casting Process.

From www.slideserve.com

PPT Metal Casting Processes PowerPoint Presentation, free download Lead Casting Process release some lead onto the spurce plate in between the two mold cavities, allowing the molten lead alloy to flow into the cavities and form a small puddle on top of the. by understanding the lead casting process, you'll be able to create. for those contemplating venturing into bullet casting, certain aspects need careful attention. Maybe you’re. Lead Casting Process.

From www.researchgate.net

(PDF) Analyzing the casting defects in small scale casting industry Lead Casting Process I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. ever think about casting your own. Lead Casting Process.

From www.theengineerspost.com

15 Different Types of Casting Process Explained [with PDF] Lead Casting Process Maybe you’re already a member of our growing ranks of diy bullet. in this video, you'll learn about the lead casting process in detail and see. I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. by understanding the lead casting process, you'll be able to create. Smelting. Lead Casting Process.

From www.researchgate.net

Lead sheet sand casting process workflow. Download Scientific Diagram Lead Casting Process ever think about casting your own lead bullets? Smelting wheel weights into ingots. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. by understanding the lead casting process, you'll be able to create. . Lead Casting Process.

From mungfali.com

Die Casting Process Flow Chart Lead Casting Process for those contemplating venturing into bullet casting, certain aspects need careful attention. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. in this video, you'll learn about the lead casting process in detail and see. Maybe you’re already a member of our growing ranks of diy bullet. I procured a natural gas. Lead Casting Process.

From www.slideserve.com

PPT Metal Casting Processes PowerPoint Presentation, free download Lead Casting Process for those contemplating venturing into bullet casting, certain aspects need careful attention. It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. The bullet casting procedure is pretty simple, really…you just. Lead Casting Process.

From www.btscl.com

Gravity casting what is it and how to know if it is right for you? Lead Casting Process I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights into ingots. Maybe you’re already a member of our growing ranks of diy bullet. ever think about casting your own lead bullets? The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. for those contemplating. Lead Casting Process.

From www.sputtertargets.net

An Introduction to Metal Casting Process Stanford Advanced Materials Lead Casting Process by understanding the lead casting process, you'll be able to create. in this video, you'll learn about the lead casting process in detail and see. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. I procured a natural gas burner, regulator, and a cast iron frying pan for smelting the wheel weights. Lead Casting Process.

From www.comsol.com

Optimizing the Continuous Casting Process with Simulation COMSOL Blog Lead Casting Process Maybe you’re already a member of our growing ranks of diy bullet. It then measures the dimple’s diameter and compares that number to a supplied chart to get the hardness. by understanding the lead casting process, you'll be able to create. release some lead onto the spurce plate in between the two mold cavities, allowing the molten lead. Lead Casting Process.

From www.youtube.com

Lead casting YouTube Lead Casting Process ever think about casting your own lead bullets? in this video, you'll learn about the lead casting process in detail and see. by understanding the lead casting process, you'll be able to create. release some lead onto the spurce plate in between the two mold cavities, allowing the molten lead alloy to flow into the cavities. Lead Casting Process.

From civilguidelines.com

A Brief Guide to the RCC Slab Casting Process Lead Casting Process Smelting wheel weights into ingots. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. ever think about casting your own lead bullets? Maybe you’re already a member of our growing ranks of diy bullet. for those contemplating venturing into bullet casting, certain aspects need careful attention. It then measures the dimple’s diameter. Lead Casting Process.

From schematicmoha39.z22.web.core.windows.net

What Is Forming In The Diagram Lead Casting Process for those contemplating venturing into bullet casting, certain aspects need careful attention. Maybe you’re already a member of our growing ranks of diy bullet. The bullet casting procedure is pretty simple, really…you just melt lead until it flows like. by understanding the lead casting process, you'll be able to create. I procured a natural gas burner, regulator, and. Lead Casting Process.