Powder Metallurgy Porosity . The correct amount of porosity for your part really depends on how your part will. powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. the features of powder metallurgy porous materials include: porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. (1) controllable pore size and porosity; the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. porosity in powder metallurgy: in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material.

from www.semanticscholar.org

(1) controllable pore size and porosity; The correct amount of porosity for your part really depends on how your part will. the features of powder metallurgy porous materials include: powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. porosity in powder metallurgy:

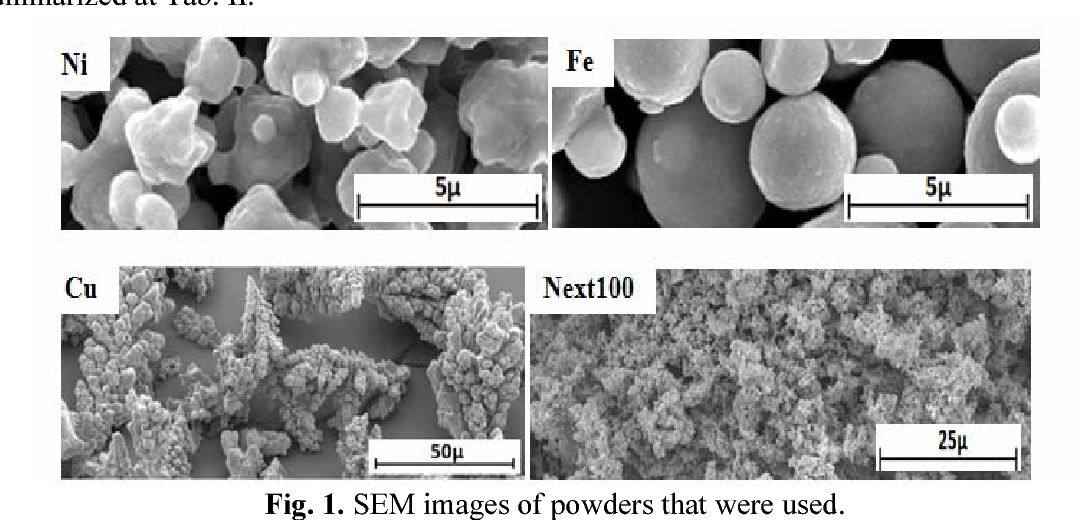

Figure 1 from The Effect of Porosity and Cu Rate on Microstructure and

Powder Metallurgy Porosity powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. the features of powder metallurgy porous materials include: (1) controllable pore size and porosity; powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. The correct amount of porosity for your part really depends on how your part will. porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. porosity in powder metallurgy:

From www.scribd.com

Powder Metallurgy Chapter 7 PDF Sintering Porosity Powder Metallurgy Porosity powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material.. Powder Metallurgy Porosity.

From www.researchgate.net

(PDF) Powder Metallurgy Aluminum Alloys Structure and Porosity Powder Metallurgy Porosity porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. (1) controllable pore size and porosity; porosity in powder metallurgy: powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. The correct amount of porosity for your part really depends on how your part will. in powder. Powder Metallurgy Porosity.

From www.scribd.com

Characterization of Powder Metallurgy An Overview of Engineering Powder Metallurgy Porosity powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. the features of powder metallurgy porous materials include: in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. (1) controllable pore size and porosity; powder metallurgy is now a. Powder Metallurgy Porosity.

From www.designworldonline.com

What does “porosity” mean in metal additive manufacturing? Powder Metallurgy Porosity The correct amount of porosity for your part really depends on how your part will. powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. (1) controllable pore size and porosity; the features of powder metallurgy porous materials include: porosity in powder metallurgy: powder metallurgy is the most common method to produce. Powder Metallurgy Porosity.

From www.tandfonline.com

THE EFFECT OF POROSITY ON SOME OF THE PHYSICAL PROPERTIES OF POWDER Powder Metallurgy Porosity in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. the features of powder metallurgy porous materials include: The correct amount of porosity for your part really depends on how your part will. . Powder Metallurgy Porosity.

From www.researchgate.net

(PDF) Powder Metallurgy Aluminum Alloys Structure and Porosity Powder Metallurgy Porosity powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. (1) controllable pore size and porosity; porosity in powder metallurgy: porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. the ability to achieve close control of porosity and pore size is the. Powder Metallurgy Porosity.

From www.semanticscholar.org

Figure 1 from Production and Characterization of High Porosity Ti6Al Powder Metallurgy Porosity powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. the features of powder metallurgy porous materials include: The correct amount of porosity for your part really depends on how your part will. . Powder Metallurgy Porosity.

From lrli.us.com

Powder Metallurgy Manufacturing LTS Powder Metallurgy Porosity the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. the features of powder metallurgy porous materials include: (1) controllable pore size and porosity; porous powder materials (ppm), porous fibrous materials of. Powder Metallurgy Porosity.

From slideplayer.com

POWDER METALLURGY The Characterization of Engineering Powders ppt Powder Metallurgy Porosity in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. porosity in powder metallurgy: (1) controllable pore size and porosity; powder metallurgy is now a mature commercial metalforming technology which frequently introduces. Powder Metallurgy Porosity.

From www.scribd.com

Powder Metallurgy Report PDF Sintering Porosity Powder Metallurgy Porosity powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. (1) controllable pore size and porosity; in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. The correct amount of porosity for your part really depends on how your part will. porosity in powder. Powder Metallurgy Porosity.

From www.mdpi.com

JMMP Free FullText Laser Powder Bed Fusion with Intentionally Powder Metallurgy Porosity the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. the features of. Powder Metallurgy Porosity.

From www.scribd.com

Powder Metallurgy Chapter 16 Sintering Porosity Powder Metallurgy Porosity porosity in powder metallurgy: in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. (1) controllable pore size and porosity; powder metallurgy is the most common method to produce porous metallic products, where. Powder Metallurgy Porosity.

From www.mdpi.com

Materials Free FullText Microstructure and Porosity Evolution of Powder Metallurgy Porosity powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. porosity in powder metallurgy: the features of powder metallurgy porous materials include: the ability to achieve close control of porosity and pore size is the main. Powder Metallurgy Porosity.

From www.scribd.com

Porosity in Powder Metallurgy Sintering Porosity Powder Metallurgy Porosity the features of powder metallurgy porous materials include: The correct amount of porosity for your part really depends on how your part will. porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material.. Powder Metallurgy Porosity.

From www.scribd.com

Powder Metallurgy (PM) Usual PM Production Sequence PDF Porosity Powder Metallurgy Porosity (1) controllable pore size and porosity; the features of powder metallurgy porous materials include: porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. The correct amount of porosity for your part really depends on how your part will. powder metallurgy is now a mature commercial metalforming technology which frequently introduces an. Powder Metallurgy Porosity.

From www.researchgate.net

(PDF) Causal Factors of Weld Porosity in Gas Tungsten Arc Welding of Powder Metallurgy Porosity The correct amount of porosity for your part really depends on how your part will. the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. powder metallurgy is. Powder Metallurgy Porosity.

From www.scribd.com

Powder Metallurgy PDF Sintering Porosity Powder Metallurgy Porosity porosity in powder metallurgy: the features of powder metallurgy porous materials include: The correct amount of porosity for your part really depends on how your part will. the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. powder metallurgy is the most common method to produce. Powder Metallurgy Porosity.

From www.academia.edu

(PDF) Effect of porosity on thermal response, hardness, hardenability Powder Metallurgy Porosity porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. the features of powder metallurgy porous materials include: powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. (1). Powder Metallurgy Porosity.

From www.metal-am.com

Understanding metal powder requirements for Additive Manufacturing Powder Metallurgy Porosity porosity in powder metallurgy: powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. the features of powder metallurgy porous materials include: The correct amount of porosity for your part really depends on. Powder Metallurgy Porosity.

From www.pinterest.com

Powder metallurgy Powder metallurgy, Porosity, Liquid metal Powder Metallurgy Porosity porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. The correct amount of porosity for your part really. Powder Metallurgy Porosity.

From www.researchgate.net

(PDF) Image Analysis Software for Porosity Measurements in Some Powder Powder Metallurgy Porosity powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. The correct amount of porosity. Powder Metallurgy Porosity.

From www.beyonddiscovery.org

Influence of Porosity on Case Depth Powder Metallurgy Powder Metallurgy Porosity the features of powder metallurgy porous materials include: porosity in powder metallurgy: in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. The correct amount of porosity for your part really depends on how your part will. (1) controllable pore size and porosity; powder metallurgy is the. Powder Metallurgy Porosity.

From www.iqsdirectory.com

Powder Metallurgy What Is It? Processes, Parts, Metals Used Powder Metallurgy Porosity powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. The correct amount of porosity for your part really depends on how your part will. powder metallurgy is the most common method to produce porous metallic products, where. Powder Metallurgy Porosity.

From www.nexamspro.com

Powder Metallurgy NEXAMS Powder Metallurgy Porosity The correct amount of porosity for your part really depends on how your part will. porosity in powder metallurgy: in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. the ability to. Powder Metallurgy Porosity.

From themech.in

MANUFACTURING PROCESS POWDER METALLURGY TheMech.in Powder Metallurgy Porosity porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. The correct amount of porosity for your part really depends on how your part will. the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. in powder metallurgy, porosity plays an important. Powder Metallurgy Porosity.

From www.semanticscholar.org

Figure 1 from Microstructure and Porosity Evolution of the Ti35Zr Powder Metallurgy Porosity powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. the features of powder metallurgy porous materials include: the ability to achieve close control of porosity and pore size is the main reason. Powder Metallurgy Porosity.

From www.mdpi.com

JMMP Free FullText Laser Powder Bed Fusion with Intentionally Powder Metallurgy Porosity The correct amount of porosity for your part really depends on how your part will. powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. the ability to achieve close. Powder Metallurgy Porosity.

From www.mdpi.com

Materials Free FullText Microstructure and Properties of Porous Powder Metallurgy Porosity porosity in powder metallurgy: porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. powder metallurgy. Powder Metallurgy Porosity.

From www.semanticscholar.org

Figure 1 from The Effect of Porosity and Cu Rate on Microstructure and Powder Metallurgy Porosity in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. (1) controllable pore size and porosity; porosity in powder metallurgy: powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. the features of powder metallurgy porous materials include: The correct amount of porosity. Powder Metallurgy Porosity.

From www.researchgate.net

(PDF) INFLUENCE OF POROSITY ON MECHANICAL PROPERTIES OF POWDER Powder Metallurgy Porosity in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. porous powder materials (ppm), porous. Powder Metallurgy Porosity.

From www.scribd.com

Powder Metallurgy PDF Sintering Porosity Powder Metallurgy Porosity powder metallurgy is the most common method to produce porous metallic products, where the level of porosity and. the features of powder metallurgy porous materials include: porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. in powder metallurgy, porosity plays an important role because pores act as linkage sites for. Powder Metallurgy Porosity.

From www.researchgate.net

Example involving powder metallurgy material optimization (porosity Powder Metallurgy Porosity in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. porosity in powder metallurgy: the features of powder metallurgy porous materials include: The correct amount of porosity for your part really depends on how your part will. powder metallurgy is the most common method to produce porous. Powder Metallurgy Porosity.

From www.studocu.com

Powder Metallurgy2 Complete notes on porosity Porosity Ratio of Powder Metallurgy Porosity in powder metallurgy, porosity plays an important role because pores act as linkage sites for crack propagations through material. powder metallurgy is now a mature commercial metalforming technology which frequently introduces an important. porosity in powder metallurgy: the features of powder metallurgy porous materials include: porous powder materials (ppm), porous fibrous materials of inorganic fibers. Powder Metallurgy Porosity.

From www.slideserve.com

PPT Powder Metallurgy PowerPoint Presentation, free download ID2604023 Powder Metallurgy Porosity porous powder materials (ppm), porous fibrous materials of inorganic fibers (pfm), porous mesh materials (pmm),. porosity in powder metallurgy: The correct amount of porosity for your part really depends on how your part will. the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. the features. Powder Metallurgy Porosity.

From www.horizontechnology.biz

Addressing Porosity in Powder Metallurgy Powder Metallurgy Porosity the features of powder metallurgy porous materials include: The correct amount of porosity for your part really depends on how your part will. the ability to achieve close control of porosity and pore size is the main reason that porous metallic materials are. in powder metallurgy, porosity plays an important role because pores act as linkage sites. Powder Metallurgy Porosity.