Hydraulic Machine Efficiency . There are three categories of efficiency used to describe hydraulic pumps (and motors): Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace applications. The average efficiency of these fluid power systems is 21%. The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. That's 61 percent, not including losses through valves. A gear pump or motor in good condition is 85 percent efficient. The use of variable speed technology can dramatically increase hydraulic efficiency. Here, the new green hydraulic. Η = 0.7 to 0.75 / circuits. Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. The energy is lost in two main forms.

from www.studiesaddict.com

There are three categories of efficiency used to describe hydraulic pumps (and motors): That's 61 percent, not including losses through valves. A gear pump or motor in good condition is 85 percent efficient. Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. Η = 0.7 to 0.75 / circuits. Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. The average efficiency of these fluid power systems is 21%. The energy is lost in two main forms. The use of variable speed technology can dramatically increase hydraulic efficiency.

The applications of Hydraulic Systems in Industrial sector, Automobiles

Hydraulic Machine Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): A gear pump or motor in good condition is 85 percent efficient. Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. Η = 0.7 to 0.75 / circuits. The use of variable speed technology can dramatically increase hydraulic efficiency. The energy is lost in two main forms. The average efficiency of these fluid power systems is 21%. That's 61 percent, not including losses through valves. Here, the new green hydraulic. That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace applications. There are three categories of efficiency used to describe hydraulic pumps (and motors):

From hosebox.com

Part 3 Optimal Output The Synergy of Hydraulic Components Hydraulic Machine Efficiency That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace applications. The average efficiency of these fluid power systems is 21%. The use of variable speed technology can dramatically increase hydraulic efficiency. Here, the new green hydraulic. Hydraulic machine efficiency can vary, which means that making the right decisions can be the. Hydraulic Machine Efficiency.

From www.youtube.com

Hydraulic Machines 29 Pelton Turbine Efficiencies YouTube Hydraulic Machine Efficiency Η = 0.7 to 0.75 / circuits. That's 61 percent, not including losses through valves. That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace applications. The energy is lost in two main forms. Here, the new green hydraulic. There are three categories of efficiency used to describe hydraulic pumps (and motors):. Hydraulic Machine Efficiency.

From bullpowertrain.com

4 Ways To Improve Your Hydraulic System’s Energy Efficiency Hydraulic Machine Efficiency Here, the new green hydraulic. A gear pump or motor in good condition is 85 percent efficient. The use of variable speed technology can dramatically increase hydraulic efficiency. Η = 0.7 to 0.75 / circuits. The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. The average efficiency of these fluid power systems is 21%. Hydraulic machine. Hydraulic Machine Efficiency.

From www.pinterest.com

Working Principle of Hydraulic Jack Hydraulic systems, Engineering Hydraulic Machine Efficiency The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. The energy is lost in two main forms. There are three categories of efficiency used to describe hydraulic pumps (and motors): A gear pump or motor in good condition is 85 percent efficient. Η = 0.7 to 0.75 / circuits. Hydraulic machine efficiency can vary, which means. Hydraulic Machine Efficiency.

From extrudesign.com

Characteristic curves of Hydraulic Turbines ExtruDesign Hydraulic Machine Efficiency The use of variable speed technology can dramatically increase hydraulic efficiency. A gear pump or motor in good condition is 85 percent efficient. The energy is lost in two main forms. Here, the new green hydraulic. The average efficiency of these fluid power systems is 21%. There are three categories of efficiency used to describe hydraulic pumps (and motors): That's. Hydraulic Machine Efficiency.

From www.hyspecs.com.au

Hydraulic Power Hyspecs Hydraulics Australia Hydraulic Machine Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. A gear pump or motor in good condition is 85 percent efficient. The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. Η = 0.7. Hydraulic Machine Efficiency.

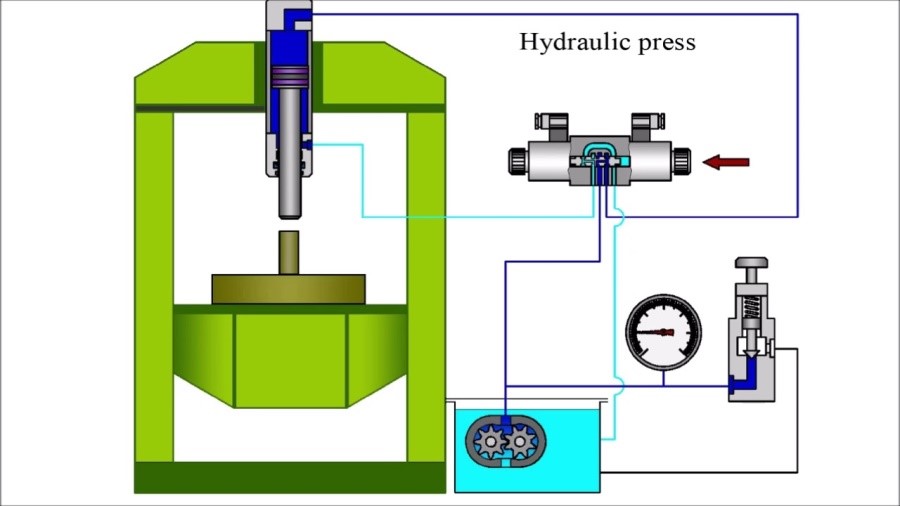

From blog.dakecorp.com

Hydraulic Press Terminology Hydraulic Machine Efficiency The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. Here, the new green hydraulic. That's 61 percent, not including losses through valves. There are three categories of efficiency used to describe hydraulic pumps (and motors): Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. That breaks down to roughly 1.2 quadrillion for mobile applications,. Hydraulic Machine Efficiency.

From www.theengineerspost.com

Hydraulic Press Diagram, Working, Types & Application [PDF] Hydraulic Machine Efficiency The average efficiency of these fluid power systems is 21%. The use of variable speed technology can dramatically increase hydraulic efficiency. That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace applications. A gear pump or motor in good condition is 85 percent efficient. Η = 0.7 to 0.75 / circuits. The. Hydraulic Machine Efficiency.

From learnchannel-tv.com

Hydraulic Pumps Hydraulic Machine Efficiency The average efficiency of these fluid power systems is 21%. The energy is lost in two main forms. There are three categories of efficiency used to describe hydraulic pumps (and motors): The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. A gear pump or motor in good condition is 85 percent efficient. Hydraulic machine efficiency can. Hydraulic Machine Efficiency.

From www.hydraulicsupermarket.com

What’s Your Hydraulic System’s Standby Efficiency? Brendan Casey's Hydraulic Machine Efficiency The use of variable speed technology can dramatically increase hydraulic efficiency. Here, the new green hydraulic. There are three categories of efficiency used to describe hydraulic pumps (and motors): The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. A gear pump or motor in good condition is 85 percent efficient. That's 61 percent, not including losses. Hydraulic Machine Efficiency.

From hydraulicpumpwopakura.blogspot.com

Hydraulic Pump Hydraulic Pump Power Calculation Hydraulic Machine Efficiency The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. A gear pump or motor in good condition is 85 percent efficient. The use of variable speed. Hydraulic Machine Efficiency.

From info.texasfinaldrive.com

Hydraulic Motor Efficiency Hydraulic Machine Efficiency A gear pump or motor in good condition is 85 percent efficient. That's 61 percent, not including losses through valves. That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace applications. The average efficiency of these fluid power systems is 21%. The use of variable speed technology can dramatically increase hydraulic efficiency.. Hydraulic Machine Efficiency.

From www.studiesaddict.com

The applications of Hydraulic Systems in Industrial sector, Automobiles Hydraulic Machine Efficiency The average efficiency of these fluid power systems is 21%. That's 61 percent, not including losses through valves. Here, the new green hydraulic. There are three categories of efficiency used to describe hydraulic pumps (and motors): A gear pump or motor in good condition is 85 percent efficient. That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for. Hydraulic Machine Efficiency.

From www.hkdivedi.com

INTRODUCTION TO HYDRAULIC MACHINES Mechanical Engineering Professionals Hydraulic Machine Efficiency Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. A gear pump or motor in good condition is 85 percent efficient. The energy is lost in two main forms. Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. The theoretical efficiency would now be 0.85 x 0.85 x. Hydraulic Machine Efficiency.

From www.youtube.com

Hydraulic machines//Hydraulic lift//Mechanical advantage//Class 11 Hydraulic Machine Efficiency Η = 0.7 to 0.75 / circuits. A gear pump or motor in good condition is 85 percent efficient. Here, the new green hydraulic. That's 61 percent, not including losses through valves. There are three categories of efficiency used to describe hydraulic pumps (and motors): Hydraulic machine efficiency can vary, which means that making the right decisions can be the. Hydraulic Machine Efficiency.

From www.youtube.com

Fluid Mechanics And Hydraulic Machines A Basic Introduction YouTube Hydraulic Machine Efficiency That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace applications. Here, the new green hydraulic. That's 61 percent, not including losses through valves. Η = 0.7 to 0.75 / circuits. The use of variable speed technology can dramatically increase hydraulic efficiency. The theoretical efficiency would now be 0.85 x 0.85 x. Hydraulic Machine Efficiency.

From issuu.com

Types and Uses of a Hydraulic Machine by HYDRAULIC & ENGINEERING Hydraulic Machine Efficiency Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace applications. Here, the new green hydraulic. A gear pump or motor in good condition is 85 percent efficient. The energy is lost in two main forms. There are three categories of. Hydraulic Machine Efficiency.

From www.hydac.co.nz

Efficient Hydraulics for EMobility HYDAC News News Hydraulic Machine Efficiency Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. The energy is lost in two main forms. The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. Here, the new green hydraulic. The average efficiency of these fluid power systems is 21%. The use of variable speed. Hydraulic Machine Efficiency.

From www.elliottrentalandequipment.com

Hydraulic Efficiency Why it Matters? Elliott Hydraulics Hydraulic Machine Efficiency That's 61 percent, not including losses through valves. There are three categories of efficiency used to describe hydraulic pumps (and motors): Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. Hydraulic machine efficiency can vary, which means that making the right decisions can be the. Hydraulic Machine Efficiency.

From www.youtube.com

ISO EFFICIENCY CURVE OF HYDRAULIC TURBINE HYDRAULIC MACHINES Hydraulic Machine Efficiency The energy is lost in two main forms. There are three categories of efficiency used to describe hydraulic pumps (and motors): A gear pump or motor in good condition is 85 percent efficient. The average efficiency of these fluid power systems is 21%. That's 61 percent, not including losses through valves. Fluid power systems consume between 2.25 and 3.0 quadrillion. Hydraulic Machine Efficiency.

From heicoin.com

Is Your Hydraulic Machine Efficient? Hydraulic Machine Efficiency The average efficiency of these fluid power systems is 21%. Η = 0.7 to 0.75 / circuits. Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. The energy is lost in two main forms. There are three categories of. Hydraulic Machine Efficiency.

From 360.lubrizol.com

Manufacturing Hydraulic Machine Efficiency Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. The average efficiency of these fluid power systems is 21%. Here, the new green hydraulic. There are three categories of efficiency used to describe hydraulic pumps (and motors): A gear pump or motor in good condition is 85 percent efficient. That's. Hydraulic Machine Efficiency.

From slideplayer.com

Turbo Machinery Energy transfer from a fluid to a rotor ppt download Hydraulic Machine Efficiency That's 61 percent, not including losses through valves. Here, the new green hydraulic. Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. Η = 0.7 to 0.75 / circuits. The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. The average efficiency of these fluid power systems is 21%. There are three categories of efficiency. Hydraulic Machine Efficiency.

From research.tuni.fi

Digital Hydraulics IHA Innovative Hydraulics and Automation Hydraulic Machine Efficiency A gear pump or motor in good condition is 85 percent efficient. Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. That's 61 percent, not including losses through valves. Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. The average efficiency of these fluid power systems is 21%.. Hydraulic Machine Efficiency.

From www.powermotiontech.com

Efficient Hydraulic Systems Deliver The Power Power & Motion Hydraulic Machine Efficiency That's 61 percent, not including losses through valves. Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. The average efficiency of these fluid power systems is 21%. There are three categories of efficiency used to describe hydraulic pumps (and motors): That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace. Hydraulic Machine Efficiency.

From www.iqsdirectory.com

Hydraulic Lift What is it, How it Works, Types, Application Hydraulic Machine Efficiency Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. Η = 0.7 to 0.75 / circuits. There are three categories of efficiency used to describe hydraulic pumps (and motors): Fluid power systems consume between 2.25 and 3.0. Hydraulic Machine Efficiency.

From www.stle.org

Machinery Hydraulic Machine Efficiency Here, the new green hydraulic. The energy is lost in two main forms. A gear pump or motor in good condition is 85 percent efficient. Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace applications. The theoretical efficiency would now. Hydraulic Machine Efficiency.

From www.hydraulicspneumatics.com

Efficient Hydraulic Systems Deliver The Power Hydraulics & Pneumatics Hydraulic Machine Efficiency That's 61 percent, not including losses through valves. Η = 0.7 to 0.75 / circuits. Here, the new green hydraulic. A gear pump or motor in good condition is 85 percent efficient. There are three categories of efficiency used to describe hydraulic pumps (and motors): Hydraulic machine efficiency can vary, which means that making the right decisions can be the. Hydraulic Machine Efficiency.

From microhydrotechnic.co.in

Maximizing Efficiency with Hydraulic Press Machines Micro HydroTechnic Hydraulic Machine Efficiency The average efficiency of these fluid power systems is 21%. Η = 0.7 to 0.75 / circuits. The energy is lost in two main forms. The use of variable speed technology can dramatically increase hydraulic efficiency. That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace applications. That's 61 percent, not including. Hydraulic Machine Efficiency.

From www.youtube.com

chapter 1 Hydraulic Efficiency part 2 YouTube Hydraulic Machine Efficiency The use of variable speed technology can dramatically increase hydraulic efficiency. That's 61 percent, not including losses through valves. The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. Here, the new green hydraulic. Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. That breaks down to. Hydraulic Machine Efficiency.

From www.mdpi.com

Energies Free FullText Energy Efficiency Comparison of Hydraulic Hydraulic Machine Efficiency The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace applications. There are three categories of efficiency used to describe. Hydraulic Machine Efficiency.

From engineeringdiscoveries.com

Hydraulic Turbine Working, Types, Advantages And Disadvantages Hydraulic Machine Efficiency A gear pump or motor in good condition is 85 percent efficient. Here, the new green hydraulic. Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. Η = 0.7 to 0.75 / circuits. There are three categories of efficiency used to describe hydraulic pumps (and motors): Hydraulic machine efficiency can vary, which means that making the right decisions. Hydraulic Machine Efficiency.

From extrudesign.com

Hydraulic Turbines Heads, Efficiencies and Classification ExtruDesign Hydraulic Machine Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): The average efficiency of these fluid power systems is 21%. That's 61 percent, not including losses through valves. The theoretical efficiency would now be 0.85 x 0.85 x 0.85 = 0.61. Η = 0.7 to 0.75 / circuits. Here, the new green hydraulic. That breaks down to. Hydraulic Machine Efficiency.

From fluidpowerjournal.com

Efficient Hydraulic Systems Fluid Power Journal Hydraulic Machine Efficiency A gear pump or motor in good condition is 85 percent efficient. Here, the new green hydraulic. Fluid power systems consume between 2.25 and 3.0 quadrillion btus annually. Hydraulic machine efficiency can vary, which means that making the right decisions can be the difference between an economical. The average efficiency of these fluid power systems is 21%. That breaks down. Hydraulic Machine Efficiency.

From www.aircraftsystemstech.com

Aircraft Hydraulic Systems and Hydraulic Power Systems Aircraft Systems Hydraulic Machine Efficiency That's 61 percent, not including losses through valves. Here, the new green hydraulic. Η = 0.7 to 0.75 / circuits. That breaks down to roughly 1.2 quadrillion for mobile applications, 1.7 for industrial applications and 0.1 for aerospace applications. The average efficiency of these fluid power systems is 21%. The energy is lost in two main forms. The theoretical efficiency. Hydraulic Machine Efficiency.