End Mill Ramp Angle . Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. A recommended range of 3° to 10° ensures optimal. Another key consideration for effective ramp milling processes is starting ramp angles. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Considering the helix angle is essential since it influences.

from www.driverknowledgetests.com

The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. A recommended range of 3° to 10° ensures optimal. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Another key consideration for effective ramp milling processes is starting ramp angles. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Considering the helix angle is essential since it influences.

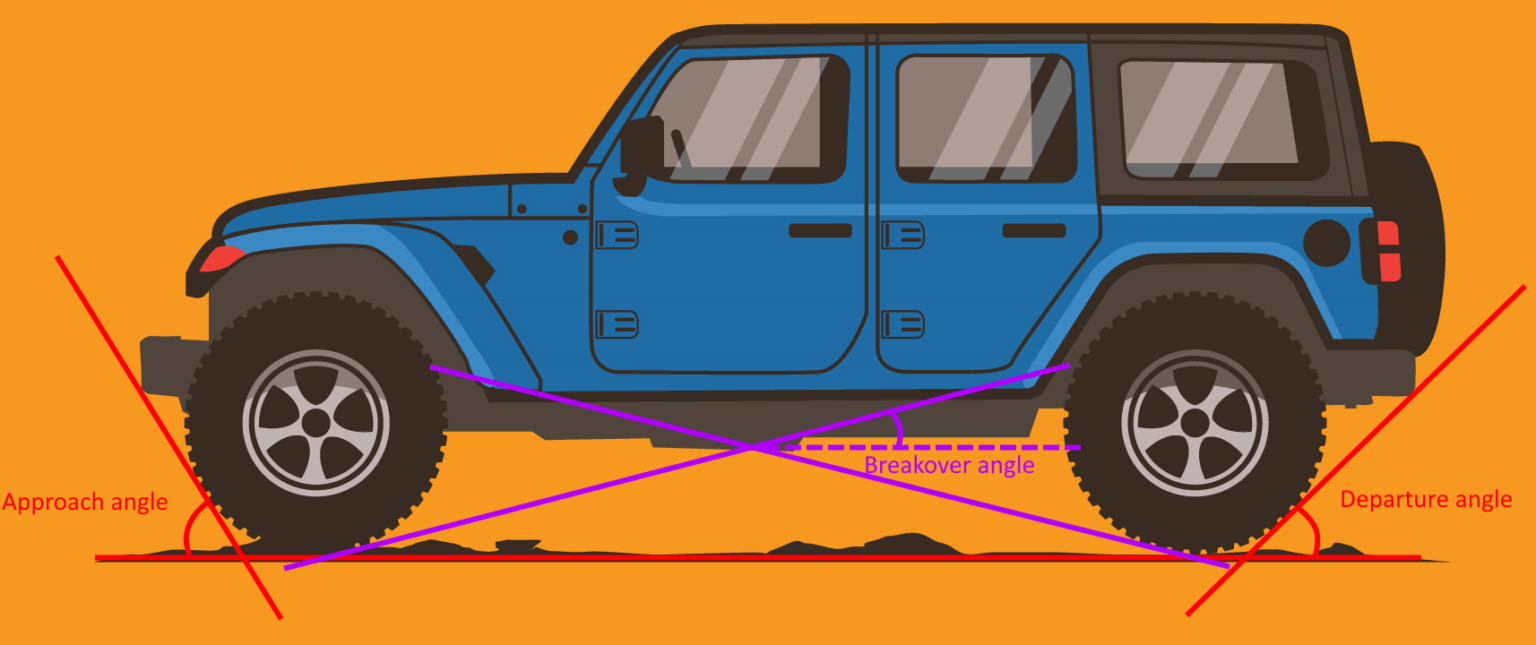

What are approach, departure and ramp breakover angles? Driver

End Mill Ramp Angle Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. A recommended range of 3° to 10° ensures optimal. Considering the helix angle is essential since it influences. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Another key consideration for effective ramp milling processes is starting ramp angles. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities.

From www.practicalmachinist.com

Calculating Ramp Angles Swift Carb Ramp Mill End Mill Ramp Angle Considering the helix angle is essential since it influences. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. Another key consideration for effective ramp milling processes is starting ramp angles. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count.. End Mill Ramp Angle.

From www.youtube.com

DoubleSided Square Shoulder 90Degree Milling Profiling, Ramp End Mill Ramp Angle When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. A recommended range of 3° to 10° ensures optimal. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. The helix angle is based on the idea that the endmill will achieve the depth of cut. End Mill Ramp Angle.

From leeta.com.tr

Ramp Angle Calculation Leeta End Mill Ramp Angle Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. A recommended range of 3° to 10° ensures optimal. Another key consideration for effective ramp milling processes is starting ramp angles. The helix angle is based. End Mill Ramp Angle.

From support.shapertools.com

Adjusting the ramp angle (plunge speed) Shaper End Mill Ramp Angle Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Considering the helix angle is essential since it influences. Another key consideration for effective ramp milling processes is starting ramp angles. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. When choosing. End Mill Ramp Angle.

From wiremanualbrianne.z13.web.core.windows.net

What Is Ramp Down In Cnc End Mill Ramp Angle Another key consideration for effective ramp milling processes is starting ramp angles. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. When choosing a tool for a machining process, machinists routinely consider. End Mill Ramp Angle.

From www.mscdirect.com

Tungaloy Indexable SquareShoulder End Mill EPA04R012M12.002, 12 mm End Mill Ramp Angle Considering the helix angle is essential since it influences. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. A recommended range of 3° to 10° ensures optimal. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. When choosing a tool for. End Mill Ramp Angle.

From www.rehabmart.com

EZAccess Pathway 3G Modular Expanded Metal Wheelchair Ramp System End Mill Ramp Angle Considering the helix angle is essential since it influences. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. A recommended range of 3° to 10° ensures optimal. The helix angle is based on the idea. End Mill Ramp Angle.

From www.onallcylinders.com

Quick Guide to Choosing the Right Race Ramps Car Ramp OnAllCylinders End Mill Ramp Angle Another key consideration for effective ramp milling processes is starting ramp angles. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Considering the helix angle is essential since it influences. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. A recommended. End Mill Ramp Angle.

From prototool.com

Ramping Milling In CNC Machining Operation End Mill Ramp Angle Considering the helix angle is essential since it influences. Another key consideration for effective ramp milling processes is starting ramp angles. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. The helix angle is based. End Mill Ramp Angle.

From loaids.com

How To Determine The Right Wheelchair Ramp Angle [Guide] End Mill Ramp Angle The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. Considering the helix angle is essential since it influences. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Another key consideration for effective ramp milling processes is starting ramp angles.. End Mill Ramp Angle.

From www.youtube.com

Worlds First Carbide Indexable End Mill, That Can Mill Any Angle! YouTube End Mill Ramp Angle Considering the helix angle is essential since it influences. Another key consideration for effective ramp milling processes is starting ramp angles. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. A recommended range of 3° to 10° ensures optimal. Linear ramping is a commonly used, efficient way of approaching the workpiece. End Mill Ramp Angle.

From www.surfanywhere.ca

Ramp angles for waves Surf Anywhere End Mill Ramp Angle Another key consideration for effective ramp milling processes is starting ramp angles. Considering the helix angle is essential since it influences. A recommended range of 3° to 10° ensures optimal. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. When choosing a tool for a machining process, machinists. End Mill Ramp Angle.

From joiqizqyh.blob.core.windows.net

Pitch Angle Chart at Julian McClelland blog End Mill Ramp Angle Another key consideration for effective ramp milling processes is starting ramp angles. Considering the helix angle is essential since it influences. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. When choosing. End Mill Ramp Angle.

From dave2.freeshell.org

1911 feed ramps End Mill Ramp Angle Another key consideration for effective ramp milling processes is starting ramp angles. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Considering the helix angle is essential since it influences. When choosing. End Mill Ramp Angle.

From www.youtube.com

PCD Twisted Helical End Mill features reduced cutting resistance End Mill Ramp Angle Another key consideration for effective ramp milling processes is starting ramp angles. A recommended range of 3° to 10° ensures optimal. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Considering the helix angle is essential since it influences. When choosing a tool for a machining process, machinists routinely consider the material, tooling. End Mill Ramp Angle.

From www.driverknowledgetests.com

What are approach, departure and ramp breakover angles? Driver End Mill Ramp Angle The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Another key consideration for effective ramp milling processes is starting ramp angles. Linear ramping is a commonly used, efficient way of. End Mill Ramp Angle.

From dave2.freeshell.org

Ramp angle and depth, How to Measure? End Mill Ramp Angle When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Considering the helix angle is essential since it influences. Another key consideration for effective ramp milling processes is starting ramp angles. A recommended range of 3° to 10° ensures optimal. The helix angle is based on the idea that the endmill will. End Mill Ramp Angle.

From diynetworkideas.blogspot.com

How To Cut Angle For Ramp DIY End Mill Ramp Angle When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Considering the helix angle is essential since it influences. A recommended range of 3° to 10° ensures optimal. Another key consideration for effective ramp milling processes. End Mill Ramp Angle.

From www.chegg.com

Solved As modeled in the diagram below, an access ramp End Mill Ramp Angle Another key consideration for effective ramp milling processes is starting ramp angles. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Considering the helix angle is essential since it influences. The helix angle is based. End Mill Ramp Angle.

From www.spruceandfjell.com

Building Instructions Shed Ramp — Spruce & Fjell End Mill Ramp Angle The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Considering the helix angle is essential since it influences. When choosing a tool for a machining process, machinists routinely consider the material, tooling. End Mill Ramp Angle.

From www.goldstarbuildings.com

How To Build A Shed Ramp Goldstar Buildings End Mill Ramp Angle A recommended range of 3° to 10° ensures optimal. Considering the helix angle is essential since it influences. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. Another key consideration for effective ramp milling processes is starting ramp angles. Linear ramping is a commonly used, efficient way of. End Mill Ramp Angle.

From www.etmm-online.com

End mill is suitable for drilling, ramping, roughing, finishing End Mill Ramp Angle When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Another key consideration for effective ramp milling processes is starting ramp angles. Considering the helix angle is essential since it influences. The helix angle is based. End Mill Ramp Angle.

From loaids.com

How To Determine The Right Wheelchair Ramp Angle [Guide] End Mill Ramp Angle The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. Considering the helix angle is essential since it influences. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. When choosing a tool for a machining process, machinists routinely consider the material, tooling. End Mill Ramp Angle.

From www.patienthandling.com.au

Decpac Multipurpose Ramp End Mill Ramp Angle A recommended range of 3° to 10° ensures optimal. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. Considering the helix angle is essential since it influences. Another key consideration for effective ramp milling processes is starting ramp angles. When choosing a tool for a machining process, machinists. End Mill Ramp Angle.

From www.numerade.com

SOLVED Flow at M = 3 enters an inlet with a ramp deflection angle Î End Mill Ramp Angle Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. A recommended range of 3° to 10° ensures optimal. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Another key consideration for effective ramp milling processes is starting ramp angles. The helix angle is based. End Mill Ramp Angle.

From www.big-daishowa.com

FULLCUT MILL FCR Type BIG DAISHOWA SEIKI CO., LTD. End Mill Ramp Angle A recommended range of 3° to 10° ensures optimal. Considering the helix angle is essential since it influences. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Another key consideration for effective ramp milling processes is starting ramp angles. Linear ramping is a commonly used, efficient way of approaching the workpiece. End Mill Ramp Angle.

From www.qualitytechtool.com

General Purpose End Mills Inch Quality Tech Tool End Mill Ramp Angle When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Another key consideration for effective ramp milling processes is starting ramp angles. Considering the helix angle is essential since it influences. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. A recommended range of 3°. End Mill Ramp Angle.

From www.hkptuning.com

Race Ramps SET OF TWO SCALE RAMPS 7.8 DEGREE APPROACH ANGLE End Mill Ramp Angle Another key consideration for effective ramp milling processes is starting ramp angles. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Considering the helix angle is essential since it influences. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. When choosing. End Mill Ramp Angle.

From www.amanatool.com

RC3400 CNC Solid Carbide 4Flute Insert Face Milling for NonFerrous End Mill Ramp Angle The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. A recommended range of 3° to 10° ensures optimal. Another key consideration for effective ramp milling processes is starting ramp angles. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Considering the. End Mill Ramp Angle.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools End Mill Ramp Angle When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. Another key consideration for effective ramp milling processes is starting ramp angles. A recommended range of 3° to 10° ensures optimal.. End Mill Ramp Angle.

From www.pinterest.com

Comprehensive Guide And Details About Ramp Slopes Design Ramp design End Mill Ramp Angle The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. A recommended range of 3° to 10° ensures optimal. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Considering the helix angle is essential since it influences. Another key consideration for effective. End Mill Ramp Angle.

From www.hobby-machinist.com

What end mill for brass? Copper? Page 2 The HobbyMachinist End Mill Ramp Angle Another key consideration for effective ramp milling processes is starting ramp angles. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Considering the helix angle is essential since it influences. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation.. End Mill Ramp Angle.

From www.youtube.com

Fullcut Mill FCR Type BIG DAISHOWA—Americas YouTube End Mill Ramp Angle Another key consideration for effective ramp milling processes is starting ramp angles. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. A recommended range of 3° to 10° ensures optimal. The helix angle is based. End Mill Ramp Angle.

From www.yumpu.com

Large ramp angle Angle of End Mill Ramp Angle Considering the helix angle is essential since it influences. A recommended range of 3° to 10° ensures optimal. The helix angle is based on the idea that the endmill will achieve the depth of cut specified in one rotation. When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Linear ramping is. End Mill Ramp Angle.

From www.harveyperformance.com

Ramping to Success In The Loupe Machinist Blog End Mill Ramp Angle When choosing a tool for a machining process, machinists routinely consider the material, tooling dimensions, and flute count. Linear ramping is a commonly used, efficient way of approaching the workpiece when machining closed slots/pockets/cavities. Considering the helix angle is essential since it influences. The helix angle is based on the idea that the endmill will achieve the depth of cut. End Mill Ramp Angle.