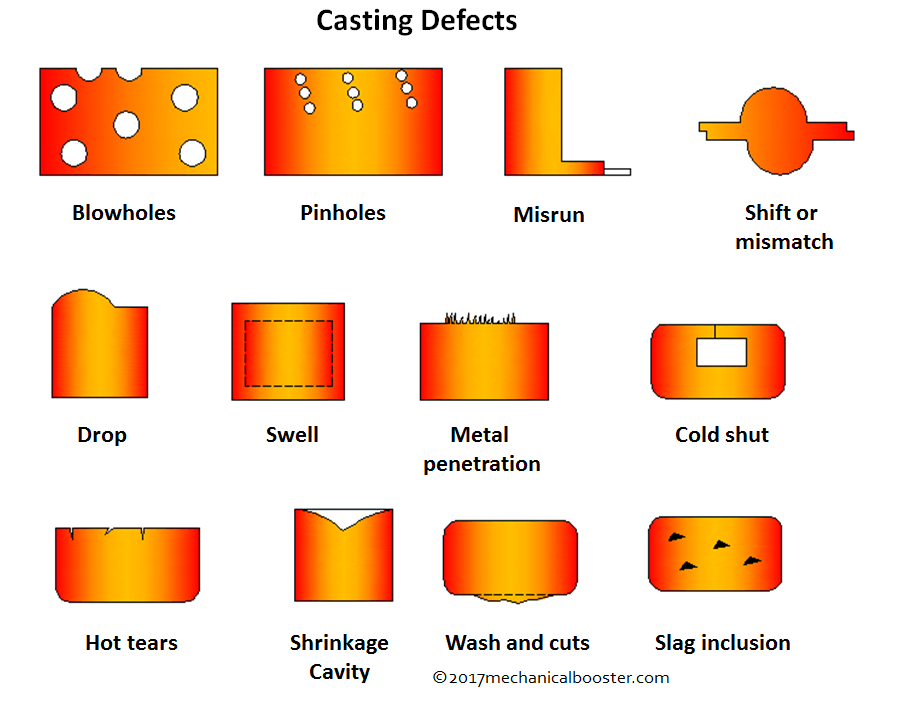

Casting Defects Mold Design . Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce the occurrence of hot. Some of the common casting defects are listed below (groover, 2010): The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Cast metal parts are prone to certain defects based on the type of process and material used. This defect is caused when the molten metal solidifies before. Some of the common defects are:

from www.mechanicalbooster.com

Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Some of the common defects are: Some of the common casting defects are listed below (groover, 2010): Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce the occurrence of hot. Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. Cast metal parts are prone to certain defects based on the type of process and material used. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. This defect is caused when the molten metal solidifies before.

What is Casting Defects Types, Causes and Remedies? Mechanical Booster

Casting Defects Mold Design This defect is caused when the molten metal solidifies before. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Some of the common casting defects are listed below (groover, 2010): This defect is caused when the molten metal solidifies before. Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce the occurrence of hot. Cast metal parts are prone to certain defects based on the type of process and material used. Some of the common defects are: Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage.

From plasticexpert.com

Plastic Molding Defects Failure Analysis in Plastic Manufacturing Casting Defects Mold Design The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Cast metal parts are prone to certain defects based on the type. Casting Defects Mold Design.

From justinfozone.blogspot.com

Sand Casting Defects Informational Encyclopedia Casting Defects Mold Design The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce the occurrence. Casting Defects Mold Design.

From www.youtube.com

Molding DefectsFlow marksProduct Review & Design YouTube Casting Defects Mold Design Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. This defect is caused when the molten metal solidifies before. Some of the common casting defects are listed below (groover, 2010): Some of the common defects are: The most common causes. Casting Defects Mold Design.

From www.vem-tooling.com

Molding Defects Sink Marks Casting Defects Mold Design Cast metal parts are prone to certain defects based on the type of process and material used. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. This defect is caused when the molten. Casting Defects Mold Design.

From sealectplastics.com

The Top 5 Plastic Injection Molding Defects (and How to Solve Them) Casting Defects Mold Design Some of the common casting defects are listed below (groover, 2010): This defect is caused when the molten metal solidifies before. Cast metal parts are prone to certain defects based on the type of process and material used. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. The most common causes of. Casting Defects Mold Design.

From www.fastradius.com

7 Injection Molding Defects and How to Avoid Casting Defects Mold Design Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Some of the common defects are: Cast metal parts are prone to certain defects based on the type of process and material used. This defect is caused when the molten metal. Casting Defects Mold Design.

From www.linkedin.com

Understanding Defects in Continuous Casting Billets Casting Defects Mold Design This defect is caused when the molten metal solidifies before. Cast metal parts are prone to certain defects based on the type of process and material used. Some of the common defects are: The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Understanding and addressing common casting defects is vital. Casting Defects Mold Design.

From narodnatribuna.info

What Is Casting Defects Types Causes And Remedies Mechanical Booster Casting Defects Mold Design Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Some of the common casting defects are listed below (groover, 2010): Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce the occurrence of hot. Some of the common defects are:. Casting Defects Mold Design.

From www.slideserve.com

PPT CASTING DEFECTS PowerPoint Presentation, free download ID9600903 Casting Defects Mold Design This defect is caused when the molten metal solidifies before. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce the occurrence of hot. Some of the common defects are: The. Casting Defects Mold Design.

From www.mechanicalbooster.com

What is Casting Defects Types, Causes and Remedies? Mechanical Booster Casting Defects Mold Design Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce the occurrence of hot. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Cast metal parts are prone to certain defects based on the type of process and material used.. Casting Defects Mold Design.

From www.pioneerplastics.com

Injection Molding Defects and How to Avoid Them Casting Defects Mold Design Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. This defect is caused when the molten metal solidifies before. Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce the occurrence of hot. The most common causes of casting defects. Casting Defects Mold Design.

From www.plastopialtd.com

6 tips on Cheap Injection Molding Plastopia Casting Defects Mold Design Some of the common defects are: The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Some of the common casting defects are listed below (groover, 2010): Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce the occurrence. Casting Defects Mold Design.

From www.zhycasting.com

Analysis of shrinkage casting defects of special alloy gray cast iron Casting Defects Mold Design The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Some of the common defects are: This defect is caused when the molten metal solidifies before. Cast metal parts are prone to certain defects based on the type of process and material used. Designing proper gating systems and ensuring even cooling. Casting Defects Mold Design.

From jp.pinterest.com

Different Types of Casting Defects Their Causes and Remedies It cast Casting Defects Mold Design The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Some of the common casting defects are listed below (groover, 2010): This defect is caused when the molten metal solidifies before. Some of the common defects are: Proper design of the casting geometry, use of suitable mold materials with good thermal. Casting Defects Mold Design.

From www.studocu.com

Casting Defects 1. WHAT IS CASTING DEFECTS? It is an unwanted Casting Defects Mold Design Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. This defect is caused when the molten metal solidifies before. Some of the common defects are: Some of the common casting defects are listed below (groover, 2010): The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Proper design. Casting Defects Mold Design.

From www.semanticscholar.org

[PDF] Transient FluidFlow Phenomena in the Continuous SteelSlab Casting Defects Mold Design Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Some of the common defects are: This defect is caused when the molten metal solidifies before. Understanding and addressing common casting defects is vital for maintaining product quality, reducing. Casting Defects Mold Design.

From precision-casting.co.id

What is Casting Defects? Gas Porosity and Shrinkage Zenith Allmart Casting Defects Mold Design Some of the common defects are: Cast metal parts are prone to certain defects based on the type of process and material used. This defect is caused when the molten metal solidifies before. Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment,. Casting Defects Mold Design.

From www.mdpi.com

Metals Free FullText The Impact of Process Factors on Creating Casting Defects Mold Design Some of the common casting defects are listed below (groover, 2010): Cast metal parts are prone to certain defects based on the type of process and material used. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Some of the common defects are: Understanding and addressing common casting defects is. Casting Defects Mold Design.

From www.slideserve.com

PPT Fundamentals of Casting PowerPoint Presentation, free download Casting Defects Mold Design Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. This defect is caused when the molten metal solidifies before. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Cast metal parts are prone to certain defects based on the type of process. Casting Defects Mold Design.

From joidreqze.blob.core.windows.net

Mold Control Hs Code at Blankenship blog Casting Defects Mold Design Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. Cast metal parts are prone to certain defects based on the type of process and material used. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Some of the common casting defects are listed below (groover, 2010): Proper. Casting Defects Mold Design.

From www.zdcpu.com

7 Plastic Injection Molding Defects Their Causes and Solutions Zhongde Casting Defects Mold Design Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Some of the common defects are: This defect is caused when the molten metal solidifies before. Some of the common casting defects are listed below (groover, 2010): Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and. Casting Defects Mold Design.

From www.giessereilexikon.com

Microporosity Casting Defects Mold Design The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. This defect is caused when the molten metal solidifies before. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Cast metal parts are prone to certain defects based on the type of process. Casting Defects Mold Design.

From www.slideserve.com

PPT CASTING DEFECTS PowerPoint Presentation, free download ID9600903 Casting Defects Mold Design Some of the common casting defects are listed below (groover, 2010): Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce the occurrence of hot. This defect is caused when the molten metal solidifies before. Understanding and addressing common casting defects is vital for maintaining product quality, reducing. Casting Defects Mold Design.

From helecu.com

17 Types of Casting Defects Understanding Their Causes and Remidies (2022) Casting Defects Mold Design This defect is caused when the molten metal solidifies before. Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce the occurrence of hot. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Designing proper gating systems and ensuring even. Casting Defects Mold Design.

From kehuimold.com

The Defects of Plastic Mold Shrinkage and Improvement MethodsKehui Casting Defects Mold Design This defect is caused when the molten metal solidifies before. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Some of the common casting defects are listed below (groover, 2010): Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Cast metal parts. Casting Defects Mold Design.

From ermak.com

Metal Casting Defects Ermak Foundry & Machining, Inc. Casting Defects Mold Design This defect is caused when the molten metal solidifies before. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Cast metal parts are prone to certain defects based on the type of process and material used. Some of the common defects are: Understanding and addressing common casting defects is vital. Casting Defects Mold Design.

From mechanicalinventions.blogspot.com

Different types of Castings defects Mechanical Engineering Casting Defects Mold Design Some of the common defects are: This defect is caused when the molten metal solidifies before. Cast metal parts are prone to certain defects based on the type of process and material used. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Proper design of the casting geometry, use of suitable mold. Casting Defects Mold Design.

From cejdwyrc.blob.core.windows.net

Typical Casting Defects at Jene Holub blog Casting Defects Mold Design Some of the common defects are: Cast metal parts are prone to certain defects based on the type of process and material used. Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. Some of the common casting defects are listed below (groover, 2010): Proper design of the casting geometry, use of suitable mold materials with good thermal. Casting Defects Mold Design.

From present5.com

IE 337 Materials Manufacturing Processes Lecture 9 Casting Defects Mold Design Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Cast metal parts are prone to certain defects based on the type of process and material used. Some of the common casting defects are listed below (groover, 2010): Some of the common defects are: This defect is caused when the molten metal solidifies. Casting Defects Mold Design.

From www.sunrise-metal.com

22 Types of Die Casting Defects Causes and Solutions Sunrise Metal Casting Defects Mold Design Cast metal parts are prone to certain defects based on the type of process and material used. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Some of the common defects are: Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. Some of the common casting defects are listed. Casting Defects Mold Design.

From gudmould.wordpress.com

Fifteen steps of molding design and design focus Gud Mould Casting Defects Mold Design This defect is caused when the molten metal solidifies before. Some of the common casting defects are listed below (groover, 2010): Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce. Casting Defects Mold Design.

From www.iqsdirectory.com

Urethane Casting What Is It? How Does It Work? Applications Casting Defects Mold Design Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Some of the common defects are: Proper design of the casting geometry,. Casting Defects Mold Design.

From vietnamcastiron.com

5 types of Sand casting defects and how to prevent to improve cast quality Casting Defects Mold Design Some of the common defects are: Cast metal parts are prone to certain defects based on the type of process and material used. Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques. Casting Defects Mold Design.

From www.steel-foundry.com

Description, Reasons and Remedies of Common Sand Casting Defects Casting Defects Mold Design Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. Some of the common defects are: Understanding and addressing common casting defects is vital for maintaining product quality, reducing waste, and optimizing production. Cast metal parts are prone to certain defects based on the type of process and material used. The most common causes of casting defects include. Casting Defects Mold Design.

From www.fastradius.com

7 Injection Molding Defects and How to Avoid Casting Defects Mold Design Some of the common casting defects are listed below (groover, 2010): Designing proper gating systems and ensuring even cooling to prevent uneven shrinkage. This defect is caused when the molten metal solidifies before. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate mold design. Some of the common defects are: Proper design. Casting Defects Mold Design.