Crankshaft Hardness Limit . In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The variation in measurement of main journal and. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. Innovatest has designed an affordable near to fully automatic machine to measure the. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process.

from www.epi-eng.com

Innovatest has designed an affordable near to fully automatic machine to measure the. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. The variation in measurement of main journal and. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer.

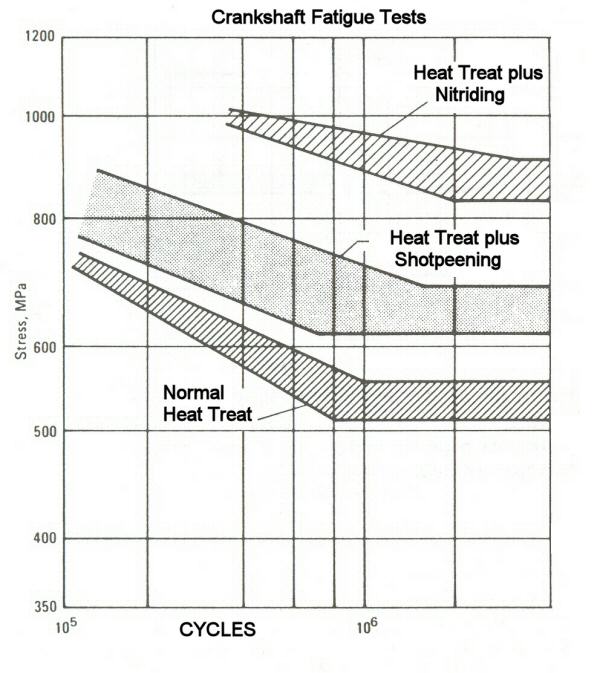

Crankshaft Design, Materials, Loads and Manufacturing, by EPI Inc.

Crankshaft Hardness Limit It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The variation in measurement of main journal and. Innovatest has designed an affordable near to fully automatic machine to measure the. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively.

From www.youtube.com

Crankshaft Hardness Testing YouTube Crankshaft Hardness Limit Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. Innovatest has designed an affordable near to fully automatic machine to measure the. The surface hardness, however, was 600 and 460 h v for the unground and. Crankshaft Hardness Limit.

From www.freepik.com

Premium Photo Master makes metal hardness measurement crankshaft Crankshaft Hardness Limit It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. Innovatest has designed an affordable near to fully automatic machine. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit The variation in measurement of main journal and. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft. Crankshaft Hardness Limit.

From www.vehiclespare-parts.com

High Hardness 6 Cylinder Auto Crankshaft 6SD1 960mm For Vehical Engine Crankshaft Hardness Limit The variation in measurement of main journal and. Innovatest has designed an affordable near to fully automatic machine to measure the. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. It was found that the material hardness of the crankshaft before and after grinding was 420 h v,. Crankshaft Hardness Limit.

From www.pinterest.ca

Metal Hardness Chart Rockwell Scale Crankshaft Hardness Limit The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. Hardness case depth represents important hardness criteria. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. Innovatest has designed an affordable near to fully automatic machine. Crankshaft Hardness Limit.

From www.freepik.com

Premium Photo Master makes metal hardness measurement crankshaft Crankshaft Hardness Limit In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. Innovatest has designed an affordable near to fully automatic machine to measure the. The variation in measurement of main journal and. The surface hardness, however, was 600 and. Crankshaft Hardness Limit.

From exocyebyz.blob.core.windows.net

What Is The Function Of A Crankshaft In A Car at Anna Nosal blog Crankshaft Hardness Limit It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. In order to salvage crankshaft at the. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. The surface hardness, however, was 600 and 460 h v for the unground. Crankshaft Hardness Limit.

From kartshop.com

Crankshaft measuring equipment, JHC Crankshaft Hardness Limit Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. Innovatest has designed an affordable near to fully automatic machine to measure the. It was found that the material hardness of the crankshaft before and after grinding. Crankshaft Hardness Limit.

From www.freepik.com

Premium Photo Master makes metal hardness measurement crankshaft Crankshaft Hardness Limit In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit Innovatest has designed an affordable near to fully automatic machine to measure the. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set. Crankshaft Hardness Limit.

From www.freepik.com

Premium Photo Master makes metal hardness measurement crankshaft Crankshaft Hardness Limit In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. The variation in measurement of main journal and. Innovatest has designed an affordable near to fully automatic machine to measure the.. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The variation in measurement of main. Crankshaft Hardness Limit.

From www.industrialmarinepower.com

5DK 20 CRANKSHAFT STD LIMIT 0.9MM Crankshaft Hardness Limit The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. Innovatest has designed an affordable near to fully automatic machine to measure the. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The variation in measurement of main journal and.. Crankshaft Hardness Limit.

From inchbyinch.de

INCH Technical English crankshaft Crankshaft Hardness Limit The variation in measurement of main journal and. Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. In order to salvage crankshaft. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit Innovatest has designed an affordable near to fully automatic machine to measure the. The variation in measurement of main journal and. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively.. Crankshaft Hardness Limit.

From www.freepik.com

Premium Photo Master makes metal hardness measurement crankshaft Crankshaft Hardness Limit The variation in measurement of main journal and. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal,. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit The variation in measurement of main journal and. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main. Crankshaft Hardness Limit.

From www.researchgate.net

Total alkalinity, total hardness, chloride content, BOD5, COD Crankshaft Hardness Limit Innovatest has designed an affordable near to fully automatic machine to measure the. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. In order to salvage crankshaft at the minimum undersize, goltens recommended. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The surface hardness, however, was 600 and 460 h v. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. Innovatest has designed an affordable near to fully automatic machine to measure the. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The variation in measurement of main journal and.. Crankshaft Hardness Limit.

From affri.com

Hardness Tester For Camshaft And Crankshaft Crankshaft Hardness Limit The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. In order to salvage crankshaft at the. Crankshaft Hardness Limit.

From www.researchgate.net

69 A large variation of hardness (FCD450) in the crankshaft. Download Crankshaft Hardness Limit Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. The variation in measurement of main journal and. Innovatest has designed an affordable near to fully automatic machine to measure the. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. It was found. Crankshaft Hardness Limit.

From www.researchgate.net

A large variation of hardness (FCD450) in crankshaft. Download Crankshaft Hardness Limit The variation in measurement of main journal and. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. Innovatest has. Crankshaft Hardness Limit.

From www.freepik.com

Premium Photo Master makes metal hardness measurement crankshaft Crankshaft Hardness Limit The variation in measurement of main journal and. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The variation in measurement of main journal and. Hardness case depth represents important hardness criteria achieved by the depth of induction. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. The variation in measurement of main journal and. Innovatest has. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The variation in measurement of main journal and. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. The surface. Crankshaft Hardness Limit.

From www.researchgate.net

A large variation of hardness (FCD450) in crankshaft. Download Crankshaft Hardness Limit The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. Innovatest has designed an affordable near to. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. The surface hardness, however, was 600 and 460 h v for the unground and ground crankshafts at the main journal, respectively. Hardness case depth represents important hardness criteria. Crankshaft Hardness Limit.

From www.epi-eng.com

Crankshaft Design, Materials, Loads and Manufacturing, by EPI Inc. Crankshaft Hardness Limit It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. The variation in measurement of main journal and. Innovatest has designed an affordable near to fully automatic machine to measure the. Hardness case depth represents important hardness criteria. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its class approved crankshaft annealing process. The variation in measurement of main journal and. Innovatest has designed an affordable near to fully automatic machine to measure the. The surface hardness, however, was 600. Crankshaft Hardness Limit.

From www.alamy.com

Master makes metal hardness measurement. Crankshaft Stock Photo Alamy Crankshaft Hardness Limit It was found that the material hardness of the crankshaft before and after grinding was 420 h v, which exceeds the minimum requirement of 300 h v limit set by the manufacturer. Hardness case depth represents important hardness criteria achieved by the depth of induction hardening process. In order to salvage crankshaft at the minimum undersize, goltens recommended applying its. Crankshaft Hardness Limit.