Raw Material Requirements Definition . It consists of three primary. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. It identifies necessary materials, estimates quantities, determines when. Mrp helps develop a production plan for finished goods by. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A material requirements planning (mrp) system accelerates the. Mrp converts the master schedule of production. A computerised planning and decision tool that focuses on what materials are needed,. Mrp is a system designed to plan manufacturing production. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and.

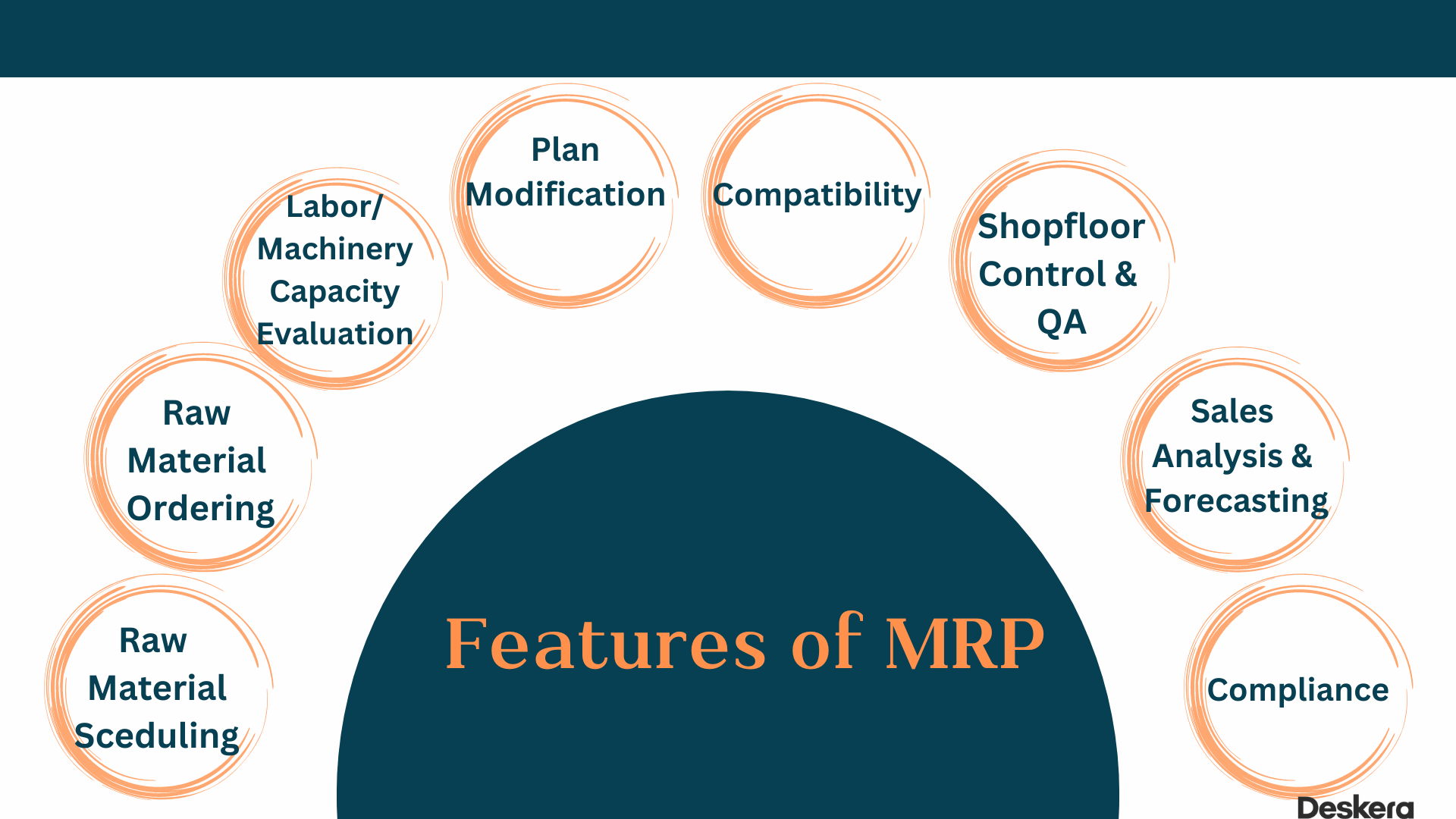

from www.deskera.com

It identifies necessary materials, estimates quantities, determines when. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. A computerised planning and decision tool that focuses on what materials are needed,. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. Mrp is a system designed to plan manufacturing production. A material requirements planning (mrp) system accelerates the. Mrp converts the master schedule of production. It consists of three primary. Mrp helps develop a production plan for finished goods by. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling.

What is Material Requirements Planning (MRP)?

Raw Material Requirements Definition It consists of three primary. It identifies necessary materials, estimates quantities, determines when. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. Mrp converts the master schedule of production. Mrp is a system designed to plan manufacturing production. A computerised planning and decision tool that focuses on what materials are needed,. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Mrp helps develop a production plan for finished goods by. A material requirements planning (mrp) system accelerates the. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. It consists of three primary.

From billofmaterialsmanagement.blogspot.com

Raw Material Requirement Planning Raw Material Requirements Definition It consists of three primary. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp helps develop a production plan for finished goods by. It identifies necessary materials, estimates quantities, determines when. A material requirements planning. Raw Material Requirements Definition.

From collectionperformance.com

Managing Raw Materials Logistics and Classification! Raw Material Requirements Definition Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Mrp helps develop a production plan for finished goods by. It consists of three primary. Mrp is a system designed to plan manufacturing production. A material requirements planning (mrp) system accelerates the. Material requirements planning (mrp) is a planning and control system. Raw Material Requirements Definition.

From www.researchgate.net

Raw Material Requirement for Various Explosive Products Download Table Raw Material Requirements Definition A material requirements planning (mrp) system accelerates the. It consists of three primary. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A computerised planning and decision tool that focuses on what materials are needed,. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and.. Raw Material Requirements Definition.

From present5.com

LESSON 21 MATERIAL REQUIREMENTS PLANNING Outline Raw Material Requirements Definition Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. A material requirements planning (mrp) system accelerates the. Mrp converts the master schedule of production. Mrp helps develop a production plan for finished. Raw Material Requirements Definition.

From www.vem-tooling.com

Raw Material Procurement in Manufacturing Raw Material Requirements Definition Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. It consists of three primary. A material requirements planning (mrp) system accelerates the. Mrp helps develop a production plan for finished goods by. Mrp is a system. Raw Material Requirements Definition.

From www.youtube.com

Raw Materials Definition for Kids YouTube Raw Material Requirements Definition Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A computerised planning and decision tool that focuses on what materials are needed,. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Material requirements planning is a methodical approach used by manufacturers to plan and control. Raw Material Requirements Definition.

From www.researchgate.net

Unit costs and material requirements for the raw materials used in the Raw Material Requirements Definition Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. It identifies necessary materials, estimates quantities, determines when. Mrp helps develop a production plan for finished goods by. It consists of three primary. Mrp converts the master schedule of production. Material requirements planning (mrp) is a system for calculating the materials. Raw Material Requirements Definition.

From www.vem-tooling.com

Raw Material Procurement in Manufacturing Raw Material Requirements Definition It consists of three primary. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. It identifies necessary materials, estimates quantities, determines when. Mrp helps develop a production plan for finished goods by. Mrp converts the master schedule of production. Mrp is a system designed to plan manufacturing production. A material requirements planning (mrp) system. Raw Material Requirements Definition.

From www.bluecart.com

Raw Materials Inventory Definition, Formula, and Turnover Raw Material Requirements Definition Mrp helps develop a production plan for finished goods by. It consists of three primary. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp converts the master schedule of production. Material requirements planning (mrp). Raw Material Requirements Definition.

From www.researchgate.net

Raw Material Requirements (MP = purified MAb). Download Scientific Raw Material Requirements Definition Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp helps develop a production plan for finished goods by. It consists of three primary. Mrp converts the master schedule of production. A material requirements planning (mrp) system accelerates the. Material requirements planning is a methodical approach used by manufacturers to plan and control the. Raw Material Requirements Definition.

From www.slideserve.com

PPT CHAPTER 5 OPERATIONS MANAGEMENT PowerPoint Presentation, free Raw Material Requirements Definition Mrp helps develop a production plan for finished goods by. It consists of three primary. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A material requirements planning (mrp) system accelerates the. A computerised planning and decision tool that focuses on what materials are needed,. Mrp converts the master schedule of production. Mrp is. Raw Material Requirements Definition.

From www.izba.co

Optimizing Supply Planning with Material Requirements Planning (MRP Raw Material Requirements Definition A computerised planning and decision tool that focuses on what materials are needed,. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. Mrp converts the master schedule of production. Mrp helps develop a production plan for finished goods by. Material requirements planning (mrp) is a system for calculating the materials. Raw Material Requirements Definition.

From www.researchgate.net

Raw Material Requirement for Various Explosive Products Download Table Raw Material Requirements Definition Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. Mrp converts the master schedule of production. It consists of three primary. A material requirements planning (mrp) system accelerates the. Mrp is a. Raw Material Requirements Definition.

From www.youtube.com

Raw Materials Inventory in Cost Accounting Definition, Formula Raw Material Requirements Definition Mrp is a system designed to plan manufacturing production. Mrp helps develop a production plan for finished goods by. A computerised planning and decision tool that focuses on what materials are needed,. Mrp converts the master schedule of production. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. Material requirements. Raw Material Requirements Definition.

From ansi.ph

6 Benefits Material Requirement Planning Brings to Manufacturers Raw Material Requirements Definition It consists of three primary. Mrp helps develop a production plan for finished goods by. Mrp is a system designed to plan manufacturing production. Mrp converts the master schedule of production. A material requirements planning (mrp) system accelerates the. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. It identifies necessary materials, estimates quantities,. Raw Material Requirements Definition.

From www.researchgate.net

Raw material requirements (1 batch = 11.5 kg MP) Download Table Raw Material Requirements Definition Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Mrp helps develop a production plan for finished goods by. Mrp is a system designed to plan manufacturing production. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A material requirements planning (mrp) system accelerates the.. Raw Material Requirements Definition.

From www.investopedia.com

Manufacturing Definition, Types, Examples, and Use as Indicator Raw Material Requirements Definition It identifies necessary materials, estimates quantities, determines when. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A material requirements planning (mrp) system accelerates the. Mrp converts the master schedule of production. Material requirements planning is. Raw Material Requirements Definition.

From www.toppers4u.com

Material Requirement Planning (MRP) Definition, Objectives, System Raw Material Requirements Definition It consists of three primary. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. Mrp is a system designed to plan manufacturing production. Mrp converts the master schedule of production. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp helps develop a production. Raw Material Requirements Definition.

From www.slideserve.com

PPT CHAPTER 5 OPERATIONS MANAGEMENT PowerPoint Presentation, free Raw Material Requirements Definition Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. It identifies necessary materials, estimates quantities, determines when. It consists of three primary. Mrp is a system designed to plan manufacturing production. A material requirements planning. Raw Material Requirements Definition.

From paksupplychain.blogspot.com

Material Requirements Planning Process Flow SAP PP Implementation Raw Material Requirements Definition It identifies necessary materials, estimates quantities, determines when. A computerised planning and decision tool that focuses on what materials are needed,. A material requirements planning (mrp) system accelerates the. Mrp is a system designed to plan manufacturing production. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp helps develop a production plan for. Raw Material Requirements Definition.

From www.educba.com

Raw Materials Meaning Types, Sources & Examples EDUCBA Raw Material Requirements Definition Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. It identifies necessary materials, estimates quantities, determines when. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product.. Raw Material Requirements Definition.

From www.researchgate.net

Raw material requirements (1 batch = 11.5 kg MP) Download Table Raw Material Requirements Definition Mrp is a system designed to plan manufacturing production. Mrp helps develop a production plan for finished goods by. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. It consists of three primary. A computerised planning and decision tool that focuses on what materials are needed,. Material requirements planning is a methodical approach used. Raw Material Requirements Definition.

From www.wallstreetmojo.com

Material Requirement Planning (MRP) Examples, Pros, Cons Raw Material Requirements Definition It identifies necessary materials, estimates quantities, determines when. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp helps develop a production plan for finished goods by. A computerised planning and decision tool that focuses on what materials are needed,. Mrp converts the master schedule of production. Mrp is a system designed to plan. Raw Material Requirements Definition.

From www.vrogue.co

Raw Materials Inventory Management Guide vrogue.co Raw Material Requirements Definition Mrp helps develop a production plan for finished goods by. It consists of three primary. Mrp converts the master schedule of production. Mrp is a system designed to plan manufacturing production. A material requirements planning (mrp) system accelerates the. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Material requirements planning. Raw Material Requirements Definition.

From www.researchgate.net

Raw material requirements and costs. Download Scientific Diagram Raw Material Requirements Definition Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. A material requirements planning (mrp) system accelerates the. It consists of three primary. Mrp is a system designed to plan manufacturing production. Mrp helps develop a production plan for finished goods by. It identifies necessary materials, estimates quantities, determines when. A computerised. Raw Material Requirements Definition.

From www.youtube.com

What are Raw Materials ? Define Raw Materials what is raw material Raw Material Requirements Definition It consists of three primary. Mrp helps develop a production plan for finished goods by. Mrp converts the master schedule of production. A computerised planning and decision tool that focuses on what materials are needed,. A material requirements planning (mrp) system accelerates the. Mrp is a system designed to plan manufacturing production. Material requirements planning is a methodical approach used. Raw Material Requirements Definition.

From www.deskera.com

What is Material Requirements Planning (MRP)? Raw Material Requirements Definition It consists of three primary. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp helps develop a production plan for finished goods by. A computerised planning and decision tool that focuses on what materials are needed,. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production. Raw Material Requirements Definition.

From www.erp-information.com

Material Requirements Planning (MRP) A Comprehensive Guide Raw Material Requirements Definition Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. It identifies necessary materials, estimates quantities, determines when. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. It consists of three primary. Mrp helps develop a production plan for finished goods by. Material requirements planning is. Raw Material Requirements Definition.

From www.youtube.com

How to make Material Requirement Planning? PPC Raw Material Raw Material Requirements Definition Mrp is a system designed to plan manufacturing production. A material requirements planning (mrp) system accelerates the. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. A computerised planning and decision tool that focuses on what. Raw Material Requirements Definition.

From www.slideserve.com

PPT Source of Raw Material PowerPoint Presentation, free download Raw Material Requirements Definition A computerised planning and decision tool that focuses on what materials are needed,. It consists of three primary. It identifies necessary materials, estimates quantities, determines when. A material requirements planning (mrp) system accelerates the. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Mrp helps develop a production plan for finished. Raw Material Requirements Definition.

From www.slideshare.net

Raw material Raw Material Requirements Definition It identifies necessary materials, estimates quantities, determines when. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. It consists of three primary. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. Mrp is a system designed to plan manufacturing production. Material requirements planning (mrp). Raw Material Requirements Definition.

From www.slideteam.net

Analyzing Future Raw Material Requirements And Accessibility Promoting Raw Material Requirements Definition It identifies necessary materials, estimates quantities, determines when. A computerised planning and decision tool that focuses on what materials are needed,. Mrp converts the master schedule of production. Mrp helps develop a production plan for finished goods by. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Mrp is a system. Raw Material Requirements Definition.

From www.scribd.com

Raw Material Requirement For You PDF Raw Material Requirements Definition Mrp is a system designed to plan manufacturing production. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. It consists of three primary. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp converts the master schedule of production. Material requirements planning (mrp) is. Raw Material Requirements Definition.

From ar.inspiredpencil.com

Raw Materials Examples Raw Material Requirements Definition Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp helps develop a production plan for finished goods by. It consists of three primary. A material requirements planning (mrp) system accelerates the. A computerised planning and decision tool that focuses on what materials are needed,. Material requirements planning (mrp) is a system for calculating. Raw Material Requirements Definition.

From www.colegiosantainescampestre.edu.co

Raw Materials Meaning, Types, Examples, Accounting, 41 OFF Raw Material Requirements Definition Mrp converts the master schedule of production. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Material requirements planning is a methodical approach used by manufacturers to plan and control the inventory, production scheduling and. Mrp helps develop a production plan for finished goods by. Mrp is a system designed to plan manufacturing production.. Raw Material Requirements Definition.