Resistance Spot Welding Stainless Steel . — in this paper, we aim to optimize welding parameters namely welding current and time in resistance spot. spot welding (also known as resistance spot welding) is a resistance welding process. If the sheets are steel, the resistance to the. This welding process is used primarily for welding two or more metal sheets. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. — resistance spot welding offers several advantages, such as high production rates, minimal need for filler materials, and the ability to weld various metals, including steel, aluminum, and stainless steel. spot welding stainless steel, spot welding copper, spot welding wire. However, it also presents some limitations, including restricted accessibility for complex joint geometries and the potential for electrode wear. — spot welding is a most popular technique in the welding industry, especially used for stainless steel. It involves the use of electrical resistance to. Images and videos of metal resistance welding applications. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. — resistance spot welding works on the principle of joule’s law of heating, where the heat generated is directly proportional to the square. — in this blog post, we’ll discuss why resistance spot welding stainless steel is difficult and how it can be done effectively. Stainless steel is known for being a tough material that is resistant to corrosion, making it an ideal choice for many applications.

from www.mdpi.com

Stainless steel is known for being a tough material that is resistant to corrosion, making it an ideal choice for many applications. However, it also presents some limitations, including restricted accessibility for complex joint geometries and the potential for electrode wear. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. — resistance spot welding offers several advantages, such as high production rates, minimal need for filler materials, and the ability to weld various metals, including steel, aluminum, and stainless steel. It involves the use of electrical resistance to. spot welding (also known as resistance spot welding) is a resistance welding process. — in this blog post, we’ll discuss why resistance spot welding stainless steel is difficult and how it can be done effectively. — in this paper, we aim to optimize welding parameters namely welding current and time in resistance spot. This welding process is used primarily for welding two or more metal sheets. — resistance spot welding works on the principle of joule’s law of heating, where the heat generated is directly proportional to the square.

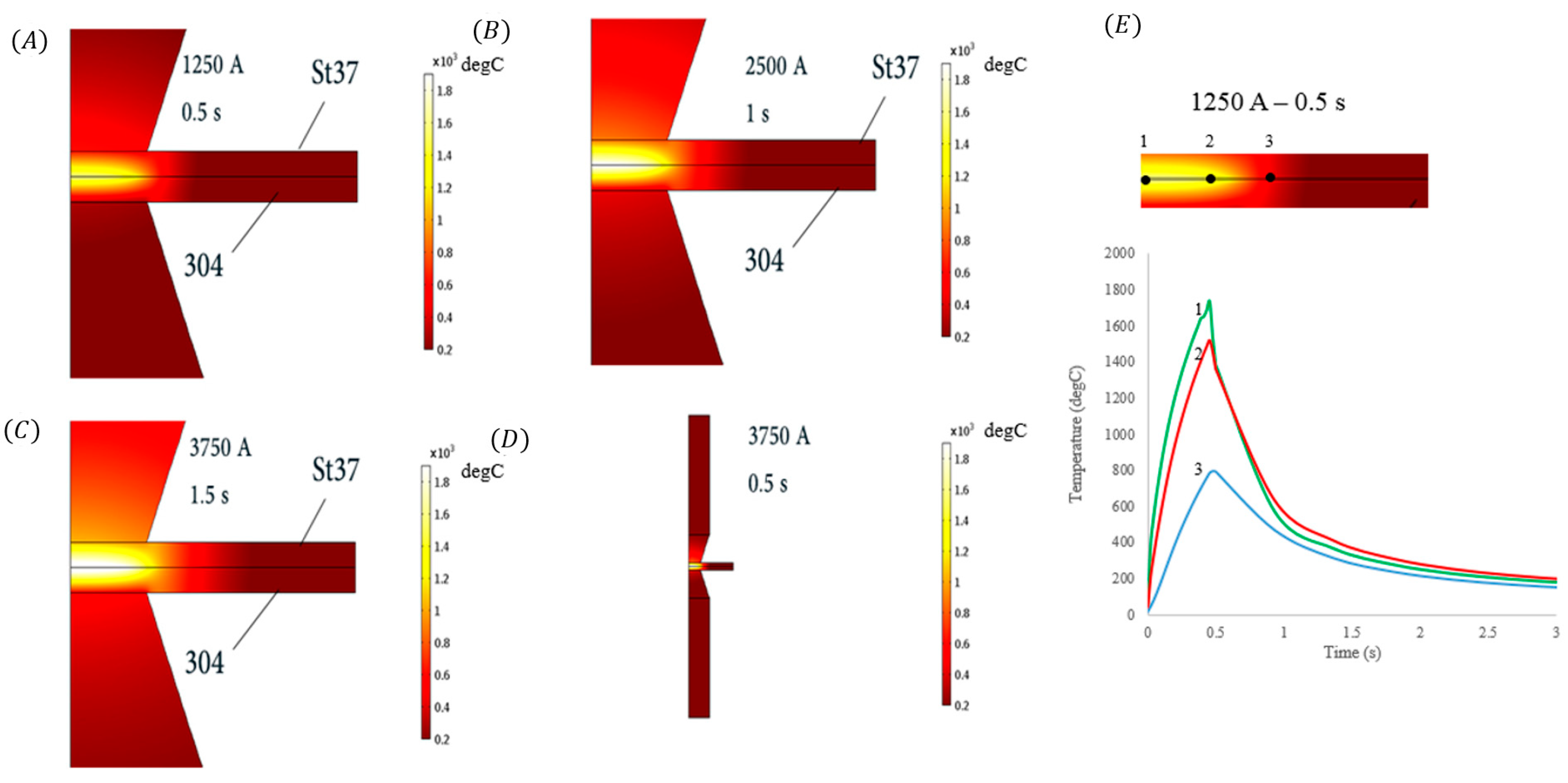

Metals Free FullText Simulation and Microstructure Prediction of

Resistance Spot Welding Stainless Steel — in this paper, we aim to optimize welding parameters namely welding current and time in resistance spot. — in this paper, we aim to optimize welding parameters namely welding current and time in resistance spot. Stainless steel is known for being a tough material that is resistant to corrosion, making it an ideal choice for many applications. — resistance spot welding offers several advantages, such as high production rates, minimal need for filler materials, and the ability to weld various metals, including steel, aluminum, and stainless steel. However, it also presents some limitations, including restricted accessibility for complex joint geometries and the potential for electrode wear. — spot welding is a most popular technique in the welding industry, especially used for stainless steel. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. spot welding stainless steel, spot welding copper, spot welding wire. Images and videos of metal resistance welding applications. It involves the use of electrical resistance to. If the sheets are steel, the resistance to the. This welding process is used primarily for welding two or more metal sheets. — in this blog post, we’ll discuss why resistance spot welding stainless steel is difficult and how it can be done effectively. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. spot welding (also known as resistance spot welding) is a resistance welding process. — resistance spot welding works on the principle of joule’s law of heating, where the heat generated is directly proportional to the square.

From www.alibaba.com

220v Battery Spot Welder Resistance Welding Machine Capacitive Energy Resistance Spot Welding Stainless Steel — in this paper, we aim to optimize welding parameters namely welding current and time in resistance spot. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. This welding process is used primarily for welding two or more metal sheets. If the sheets are steel,. Resistance Spot Welding Stainless Steel.

From blog.thepipingmart.com

What Does Resistance Welding Mean? ThePipingMart Blog Resistance Spot Welding Stainless Steel — resistance spot welding offers several advantages, such as high production rates, minimal need for filler materials, and the ability to weld various metals, including steel, aluminum, and stainless steel. — in this blog post, we’ll discuss why resistance spot welding stainless steel is difficult and how it can be done effectively. spot welding (also known as. Resistance Spot Welding Stainless Steel.

From blog.thepipingmart.com

Resistance Spot Welding Stainless Steel Resistance Spot Welding Stainless Steel — spot welding is a most popular technique in the welding industry, especially used for stainless steel. spot welding (also known as resistance spot welding) is a resistance welding process. — resistance spot welding offers several advantages, such as high production rates, minimal need for filler materials, and the ability to weld various metals, including steel, aluminum,. Resistance Spot Welding Stainless Steel.

From qdhanben.en.made-in-china.com

Inverter Resistance Automatic Spot Welding Machine for Stainless Steel Resistance Spot Welding Stainless Steel — in this paper, we aim to optimize welding parameters namely welding current and time in resistance spot. However, it also presents some limitations, including restricted accessibility for complex joint geometries and the potential for electrode wear. — in this blog post, we’ll discuss why resistance spot welding stainless steel is difficult and how it can be done. Resistance Spot Welding Stainless Steel.

From www.youtube.com

Spot Welding Steel & Stainless Steel YouTube Resistance Spot Welding Stainless Steel spot welding (also known as resistance spot welding) is a resistance welding process. Images and videos of metal resistance welding applications. — resistance spot welding works on the principle of joule’s law of heating, where the heat generated is directly proportional to the square. Stainless steel is known for being a tough material that is resistant to corrosion,. Resistance Spot Welding Stainless Steel.

From agerawelding.en.made-in-china.com

Mf DC Resistance Automatic Double Side Spot Welding Stainless Steel Resistance Spot Welding Stainless Steel — resistance spot welding offers several advantages, such as high production rates, minimal need for filler materials, and the ability to weld various metals, including steel, aluminum, and stainless steel. — spot welding is a most popular technique in the welding industry, especially used for stainless steel. — in this paper, we aim to optimize welding parameters. Resistance Spot Welding Stainless Steel.

From www.semanticscholar.org

Figure 1 from RESISTANCE SPOT WELDING STAINLESS STEEL FOIL BY THE Resistance Spot Welding Stainless Steel Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. — resistance spot welding works on the principle of joule’s law of heating, where the heat generated is directly proportional to the square. It involves the use of electrical resistance to. spot welding stainless. Resistance Spot Welding Stainless Steel.

From agerawelding.en.made-in-china.com

AC Medium Frequency Inverter Resistance Spot Welding Machine for Resistance Spot Welding Stainless Steel If the sheets are steel, the resistance to the. — in this paper, we aim to optimize welding parameters namely welding current and time in resistance spot. Stainless steel is known for being a tough material that is resistant to corrosion, making it an ideal choice for many applications. — spot welding is a most popular technique in. Resistance Spot Welding Stainless Steel.

From agerawelding.en.made-in-china.com

Stud Metal Spot Welder Resistance Inverter Spot Welding Machine for Resistance Spot Welding Stainless Steel Images and videos of metal resistance welding applications. — resistance spot welding offers several advantages, such as high production rates, minimal need for filler materials, and the ability to weld various metals, including steel, aluminum, and stainless steel. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the. Resistance Spot Welding Stainless Steel.

From www.youtube.com

Roll Spot Weld Stainless Steel Mesh Sunstone CD Resistance Welder and Resistance Spot Welding Stainless Steel Images and videos of metal resistance welding applications. However, it also presents some limitations, including restricted accessibility for complex joint geometries and the potential for electrode wear. — resistance spot welding offers several advantages, such as high production rates, minimal need for filler materials, and the ability to weld various metals, including steel, aluminum, and stainless steel. —. Resistance Spot Welding Stainless Steel.

From kiaind.en.made-in-china.com

Stainless Steel Resistance HandHeld Spot Welder Machine China Resistance Spot Welding Stainless Steel — spot welding is a most popular technique in the welding industry, especially used for stainless steel. If the sheets are steel, the resistance to the. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. Images and videos of metal resistance welding applications. . Resistance Spot Welding Stainless Steel.

From journals.uran.ua

Optimization of resistance spot welding with surface roughness Resistance Spot Welding Stainless Steel Images and videos of metal resistance welding applications. — spot welding is a most popular technique in the welding industry, especially used for stainless steel. spot welding (also known as resistance spot welding) is a resistance welding process. — resistance spot welding offers several advantages, such as high production rates, minimal need for filler materials, and the. Resistance Spot Welding Stainless Steel.

From www.metalsupermarkets.co.uk

Resistance Welding Processes What is Spot Welding? Metal Supermarkets UK Resistance Spot Welding Stainless Steel Stainless steel is known for being a tough material that is resistant to corrosion, making it an ideal choice for many applications. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. spot welding (also known as resistance spot welding) is a resistance welding process. . Resistance Spot Welding Stainless Steel.

From www.mdpi.com

Metals Free FullText Simulation and Microstructure Prediction of Resistance Spot Welding Stainless Steel — spot welding is a most popular technique in the welding industry, especially used for stainless steel. It involves the use of electrical resistance to. If the sheets are steel, the resistance to the. spot welding stainless steel, spot welding copper, spot welding wire. Stainless steel is known for being a tough material that is resistant to corrosion,. Resistance Spot Welding Stainless Steel.

From agerawelding.en.made-in-china.com

Agera Resistance 2mm Stainless Steel Capacitor Storage Spot Welding Resistance Spot Welding Stainless Steel — in this blog post, we’ll discuss why resistance spot welding stainless steel is difficult and how it can be done effectively. If the sheets are steel, the resistance to the. However, it also presents some limitations, including restricted accessibility for complex joint geometries and the potential for electrode wear. Figure 1 shows a standard resistance spot welding arrangement. Resistance Spot Welding Stainless Steel.

From www.mdpi.com

Metals Free FullText Liquid Metal Embrittlement of Galvanized TRIP Resistance Spot Welding Stainless Steel — resistance spot welding works on the principle of joule’s law of heating, where the heat generated is directly proportional to the square. spot welding stainless steel, spot welding copper, spot welding wire. It involves the use of electrical resistance to. the resistance spot welding (rsw) process is often used as a model to explain the fundamental. Resistance Spot Welding Stainless Steel.

From www.xwwelding.com

Resistance Welders China Stainless Steel Aluminium Inverter Spot Resistance Spot Welding Stainless Steel Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. If the sheets are steel, the resistance to the. — spot welding is a most popular technique in the welding industry, especially used for stainless steel. spot welding stainless steel, spot welding copper, spot. Resistance Spot Welding Stainless Steel.

From sheetstainlesssteel.com

Expert Tips for Spot Welding Stainless Steel like a Pro Resistance Spot Welding Stainless Steel Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. However, it also presents some limitations, including restricted accessibility for complex joint geometries and the potential for electrode wear. spot welding stainless steel, spot welding copper, spot welding wire. — in this paper, we. Resistance Spot Welding Stainless Steel.

From www.mdpi.com

Metals Free FullText Simulation and Microstructure Prediction of Resistance Spot Welding Stainless Steel It involves the use of electrical resistance to. However, it also presents some limitations, including restricted accessibility for complex joint geometries and the potential for electrode wear. Images and videos of metal resistance welding applications. Stainless steel is known for being a tough material that is resistant to corrosion, making it an ideal choice for many applications. — resistance. Resistance Spot Welding Stainless Steel.

From agerawelding.en.made-in-china.com

Stainless Steel Galvanized Sheet Nuts Resistance Spot Projection Resistance Spot Welding Stainless Steel Stainless steel is known for being a tough material that is resistant to corrosion, making it an ideal choice for many applications. — resistance spot welding offers several advantages, such as high production rates, minimal need for filler materials, and the ability to weld various metals, including steel, aluminum, and stainless steel. the resistance spot welding (rsw) process. Resistance Spot Welding Stainless Steel.

From www.mdpi.com

Metals Free FullText Resistance Spot Welding of Aluminum Alloy and Resistance Spot Welding Stainless Steel — resistance spot welding offers several advantages, such as high production rates, minimal need for filler materials, and the ability to weld various metals, including steel, aluminum, and stainless steel. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. — in this blog. Resistance Spot Welding Stainless Steel.

From www.thefabricator.com

Resistance spot welding and what to know about the technology Resistance Spot Welding Stainless Steel — in this paper, we aim to optimize welding parameters namely welding current and time in resistance spot. — resistance spot welding offers several advantages, such as high production rates, minimal need for filler materials, and the ability to weld various metals, including steel, aluminum, and stainless steel. — resistance spot welding works on the principle of. Resistance Spot Welding Stainless Steel.

From agerawelding.en.made-in-china.com

Easy to Operate Mfdc Resistance Spot Welding Spot Welder for Stainless Resistance Spot Welding Stainless Steel — resistance spot welding works on the principle of joule’s law of heating, where the heat generated is directly proportional to the square. If the sheets are steel, the resistance to the. However, it also presents some limitations, including restricted accessibility for complex joint geometries and the potential for electrode wear. Figure 1 shows a standard resistance spot welding. Resistance Spot Welding Stainless Steel.

From www.intechopen.com

Resistance Spot Welding Principles and Its Applications IntechOpen Resistance Spot Welding Stainless Steel Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. If the sheets are steel, the resistance to the. — resistance spot welding works on the principle of joule’s law of heating, where the heat generated is directly proportional to the square. However, it also. Resistance Spot Welding Stainless Steel.

From blog.thepipingmart.com

How to Spot Weld Stainless Steel A Complete Guide Resistance Spot Welding Stainless Steel — resistance spot welding works on the principle of joule’s law of heating, where the heat generated is directly proportional to the square. Images and videos of metal resistance welding applications. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. — resistance spot. Resistance Spot Welding Stainless Steel.

From www.thestructuralsteeldetailing.com

Demystifying resistance spot welding technology Resistance Spot Welding Stainless Steel Images and videos of metal resistance welding applications. — spot welding is a most popular technique in the welding industry, especially used for stainless steel. It involves the use of electrical resistance to. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. — in. Resistance Spot Welding Stainless Steel.

From blog.thepipingmart.com

What is Resistance Spot Welding? Working and Uses Resistance Spot Welding Stainless Steel It involves the use of electrical resistance to. spot welding (also known as resistance spot welding) is a resistance welding process. — resistance spot welding works on the principle of joule’s law of heating, where the heat generated is directly proportional to the square. — in this blog post, we’ll discuss why resistance spot welding stainless steel. Resistance Spot Welding Stainless Steel.

From www.alibaba.com

Small Movable Sheet Metal Spot Welding Machine Of Stainless Steel Iron Resistance Spot Welding Stainless Steel Images and videos of metal resistance welding applications. It involves the use of electrical resistance to. — resistance spot welding works on the principle of joule’s law of heating, where the heat generated is directly proportional to the square. — spot welding is a most popular technique in the welding industry, especially used for stainless steel. Stainless steel. Resistance Spot Welding Stainless Steel.

From www.mdpi.com

Metals Free FullText Resistance Spot Welding of SUS316L Austenitic Resistance Spot Welding Stainless Steel Images and videos of metal resistance welding applications. It involves the use of electrical resistance to. This welding process is used primarily for welding two or more metal sheets. spot welding (also known as resistance spot welding) is a resistance welding process. — spot welding is a most popular technique in the welding industry, especially used for stainless. Resistance Spot Welding Stainless Steel.

From www.researchgate.net

AISI2304 duplex stainless steel resistance spot weld ATypical Resistance Spot Welding Stainless Steel If the sheets are steel, the resistance to the. It involves the use of electrical resistance to. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. spot welding (also known as resistance spot welding) is a resistance welding process. — resistance spot welding. Resistance Spot Welding Stainless Steel.

From www.mdpi.com

Metals Free FullText Weldability of Additive Manufactured Resistance Spot Welding Stainless Steel — resistance spot welding works on the principle of joule’s law of heating, where the heat generated is directly proportional to the square. If the sheets are steel, the resistance to the. — spot welding is a most popular technique in the welding industry, especially used for stainless steel. — in this paper, we aim to optimize. Resistance Spot Welding Stainless Steel.

From pdkjwelder.en.made-in-china.com

Dtn Pneumatic Resistance Spot Welding Machine for Stainless Steel&Non Resistance Spot Welding Stainless Steel spot welding stainless steel, spot welding copper, spot welding wire. However, it also presents some limitations, including restricted accessibility for complex joint geometries and the potential for electrode wear. Stainless steel is known for being a tough material that is resistant to corrosion, making it an ideal choice for many applications. Images and videos of metal resistance welding applications.. Resistance Spot Welding Stainless Steel.

From www.researchgate.net

(PDF) Improvement of SingleSided Resistance Spot Welding of Austenitic Resistance Spot Welding Stainless Steel spot welding stainless steel, spot welding copper, spot welding wire. Stainless steel is known for being a tough material that is resistant to corrosion, making it an ideal choice for many applications. This welding process is used primarily for welding two or more metal sheets. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes. Resistance Spot Welding Stainless Steel.

From www.precisionengineering.com

Welding Precision Engineering Resistance Spot Welding Stainless Steel Images and videos of metal resistance welding applications. — in this paper, we aim to optimize welding parameters namely welding current and time in resistance spot. spot welding stainless steel, spot welding copper, spot welding wire. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets. Resistance Spot Welding Stainless Steel.

From sfjuntengfa.en.made-in-china.com

Resistance Stainless Steel Spot Welding Machine China Stainless Steel Resistance Spot Welding Stainless Steel Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. It involves the use of electrical resistance to. This welding process is used. Resistance Spot Welding Stainless Steel.