Engine Misalignment . Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Inspect engine mounts and alignment to. Misalignment between a motor and its driven. Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Check and replace any loose or damaged mounting bolts. Replace the affected engine mounts to correct the misalignment. Failed engine mounts and loose or damaged bolts are the primary causes of engine misalignment. Ensure proper installation and alignment during the replacement process to avoid further issues. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Recognizing these symptoms early can help prevent further damage and costly repairs. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine.

from blog.slsbearings.com

Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine. Check and replace any loose or damaged mounting bolts. Misalignment between a motor and its driven. Failed engine mounts and loose or damaged bolts are the primary causes of engine misalignment. Inspect engine mounts and alignment to. Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Recognizing these symptoms early can help prevent further damage and costly repairs. Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Replace the affected engine mounts to correct the misalignment.

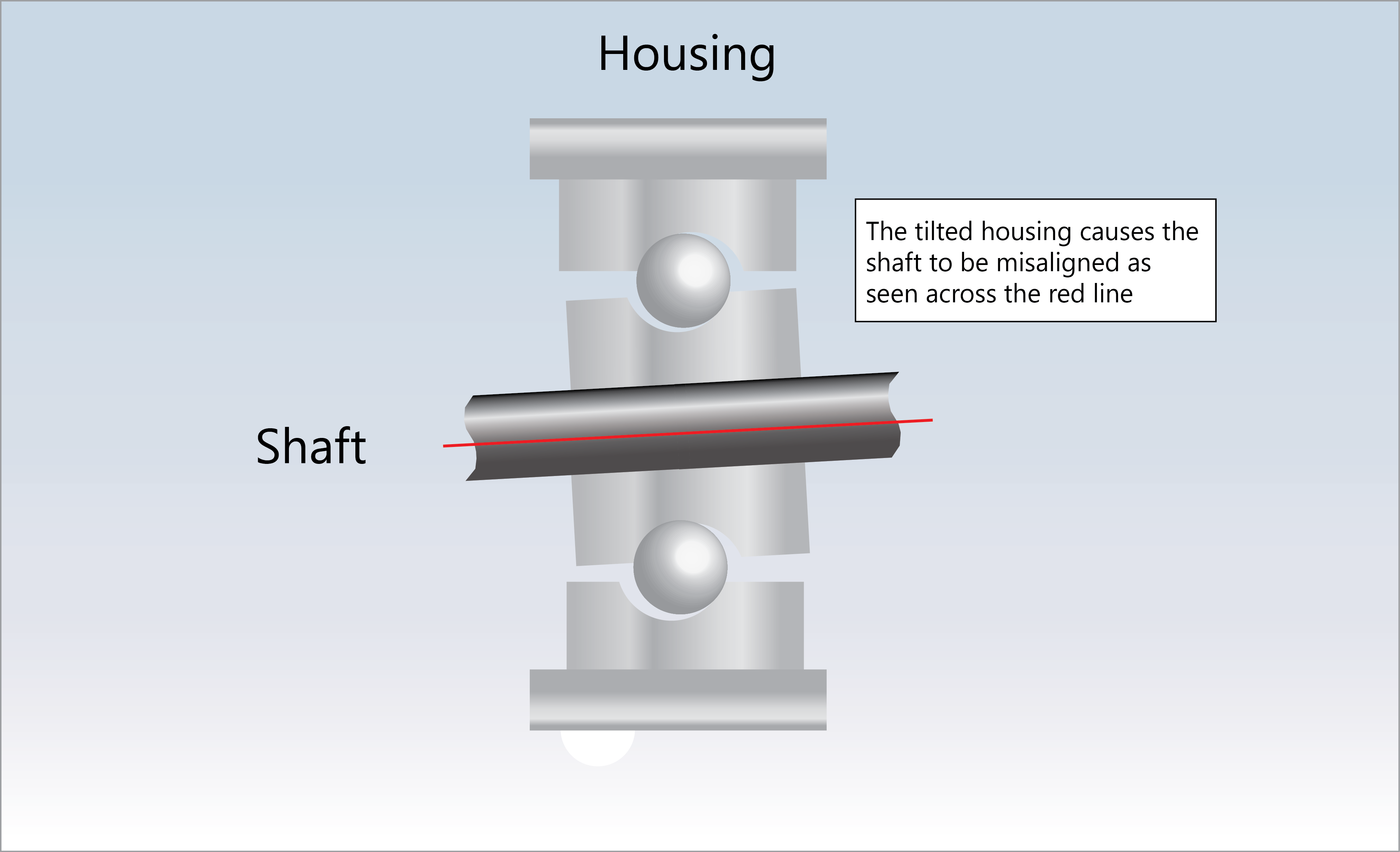

Understanding Shaft and Housing Alignment & Fits (to Prevent Bearing

Engine Misalignment Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine. Replace the affected engine mounts to correct the misalignment. Ensure proper installation and alignment during the replacement process to avoid further issues. Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Recognizing these symptoms early can help prevent further damage and costly repairs. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Check and replace any loose or damaged mounting bolts. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine. Failed engine mounts and loose or damaged bolts are the primary causes of engine misalignment. Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Inspect engine mounts and alignment to. Misalignment between a motor and its driven.

From power-mi.com

Misalignment PowerMI Engine Misalignment Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Replace the affected engine mounts to correct the misalignment. Misalignment between a motor and its driven. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to. Engine Misalignment.

From www.fluke.com

13 Common Causes of Motor Failure Fluke Engine Misalignment Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Recognizing these symptoms early can help prevent further damage and costly repairs. Ensure proper installation and alignment during the replacement process to avoid further issues. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine.. Engine Misalignment.

From www.cbmconnect.com

Procedure To Detect Misalignment CBM CONNECT® Engine Misalignment Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Check and replace any loose or damaged mounting bolts. Misalignment between a motor and its driven. Ensure proper installation and alignment during the replacement process to avoid further issues. Replace the affected engine mounts to correct the misalignment. Failed engine mounts and loose or. Engine Misalignment.

From www.technomaxme.com

Detecting Misalignment Between Ic Engines & Gas Compressors Engine Misalignment Inspect engine mounts and alignment to. Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Check and replace any loose or damaged mounting bolts. Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Replace the affected engine mounts to correct the misalignment. Its primary function is to dampen torsional. Engine Misalignment.

From themachine.science

Mastering Engine Misalignment and Noise A Comprehensive DIY Guide Engine Misalignment Misalignment between a motor and its driven. Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Recognizing these symptoms early can help prevent further damage and costly repairs. Ensure proper installation and alignment during the replacement process to avoid further issues. Check and replace any loose or damaged mounting bolts. Failed engine mounts and loose or. Engine Misalignment.

From www.davidaltmejd.com

TellTale Signs Your Motor Mounts Are Going Bad and How to Replace Them Engine Misalignment Failed engine mounts and loose or damaged bolts are the primary causes of engine misalignment. Replace the affected engine mounts to correct the misalignment. Recognizing these symptoms early can help prevent further damage and costly repairs. Check and replace any loose or damaged mounting bolts. Ensure proper installation and alignment during the replacement process to avoid further issues. Bad motor. Engine Misalignment.

From www.marineinsight.com

Reasons for Failure and Misalignment of Crankshaft in Marine Engines Engine Misalignment Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine. Ensure proper installation and alignment during the replacement process to avoid further issues. Symptoms of engine misalignment include a continuous noise that worsens. Engine Misalignment.

From blog.slsbearings.com

Understanding Shaft and Housing Alignment & Fits (to Prevent Bearing Engine Misalignment Recognizing these symptoms early can help prevent further damage and costly repairs. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine. Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Engine misalignment. Engine Misalignment.

From www.designworldonline.com

inar Motion couplings and misalignment Design approaches for Engine Misalignment Ensure proper installation and alignment during the replacement process to avoid further issues. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Recognizing these symptoms early can help prevent further damage and costly repairs. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Proper motor alignment. Engine Misalignment.

From www.amesolutions.com

A 225m tanker wiped a stern tube bearing due to an engine misalignment. Engine Misalignment Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Recognizing these symptoms early can help prevent further damage and costly repairs. Replace the affected engine mounts to correct the misalignment. Ensure proper installation and alignment during the replacement process to avoid further issues. Inspect engine mounts and alignment to. Bad motor mount symptoms. Engine Misalignment.

From www.cbmconnect.com

Misalignments in a System How To Diagnose and Detect Them Engine Misalignment Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Inspect engine mounts and alignment to. Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Its primary function is to dampen torsional vibrations that can occur. Engine Misalignment.

From dreisilker.com

Laser Shaft Alignment Dreisilker Electric Motors Engine Misalignment Misalignment between a motor and its driven. Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Inspect engine mounts and alignment to. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Check and replace any loose or damaged mounting bolts. Engine misalignment occurs when the engine’s components, such as the crankshaft,. Engine Misalignment.

From techiescience.com

Engine Pulley Misalignment Noise A Comprehensive Guide Engine Misalignment Recognizing these symptoms early can help prevent further damage and costly repairs. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine. Ensure proper installation and alignment during the replacement process to avoid further issues. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not. Engine Misalignment.

From www.power-mi.com

Misalignment PowerMI Engine Misalignment Inspect engine mounts and alignment to. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Recognizing these symptoms early can help prevent further damage and costly repairs. Misalignment between a motor and its driven. Ensure proper installation. Engine Misalignment.

From www.researchgate.net

Induced generator misalignment Download Scientific Diagram Engine Misalignment Recognizing these symptoms early can help prevent further damage and costly repairs. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are. Engine Misalignment.

From themachine.science

Engine Misalignment Vibrations A Comprehensive Guide Engine Misalignment Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine. Failed engine mounts and loose or damaged bolts are the primary causes of engine misalignment. Misalignment between a motor and its driven. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Check. Engine Misalignment.

From acurazine.com

Engine Misalignment (Side Mount won't Bolt Up) AcuraZine Acura Engine Misalignment Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine. Replace the affected engine mounts to correct the misalignment. Inspect engine mounts and alignment to. Failed engine mounts and loose or damaged bolts are the. Engine Misalignment.

From www.reddit.com

Misaligned belt on N47 engine r/BmwTech Engine Misalignment Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Inspect engine mounts and alignment to. Replace the affected engine mounts to correct the misalignment. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Ensure proper installation and alignment during the replacement process to avoid further issues. Recognizing these symptoms early can. Engine Misalignment.

From www.amesolutions.com

A 225m tanker wiped a stern tube bearing due to an engine misalignment. Engine Misalignment Recognizing these symptoms early can help prevent further damage and costly repairs. Replace the affected engine mounts to correct the misalignment. Failed engine mounts and loose or damaged bolts are the primary causes of engine misalignment. Check and replace any loose or damaged mounting bolts. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing. Engine Misalignment.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Engine Misalignment Failed engine mounts and loose or damaged bolts are the primary causes of engine misalignment. Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Inspect engine mounts and alignment to. Ensure proper installation and alignment during the replacement. Engine Misalignment.

From www.jeepforum.com

Is my engine misaligned? Jeep Enthusiast Forums Engine Misalignment Check and replace any loose or damaged mounting bolts. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Recognizing these symptoms early can help prevent further damage and costly repairs. Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Inspect engine mounts and alignment to. Its primary function. Engine Misalignment.

From www.amesolutions.com

A 225m tanker wiped a stern tube bearing due to an engine misalignment. Engine Misalignment Inspect engine mounts and alignment to. Replace the affected engine mounts to correct the misalignment. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Recognizing these symptoms early can help prevent further. Engine Misalignment.

From blender.stackexchange.com

cycles render engine Misalignment of depth map when projecting two Engine Misalignment Misalignment between a motor and its driven. Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Failed engine mounts and loose or damaged bolts are the primary causes of engine misalignment. Check and replace any loose or damaged mounting bolts. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage. Engine Misalignment.

From www.researchgate.net

Spline shaft of the a.c. generator of the GT40PCz6 type after Engine Misalignment Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Recognizing these symptoms early can help prevent further damage and costly repairs. Ensure proper installation and alignment during the replacement process to avoid further issues. Misalignment between a motor and its driven. Check and replace any loose or damaged mounting bolts. Inspect engine mounts and alignment. Engine Misalignment.

From www.amesolutions.com

A 225m tanker wiped a stern tube bearing due to an engine misalignment. Engine Misalignment Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Failed engine mounts and loose or damaged bolts are the primary causes of engine misalignment. Misalignment between a motor and its driven. Check and replace any. Engine Misalignment.

From www.kmotorshop.com

Causes and possible consequences of valve failures in the engine K Engine Misalignment Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Its primary function is to dampen torsional vibrations that can occur in the crankshaft, preventing damage to the engine. Check and replace any loose or damaged mounting bolts. Inspect engine mounts and alignment to. Misalignment between a motor and its driven. Bad. Engine Misalignment.

From www.couplingtips.com

Reaction forces from couplings How to prevent or mitigate? Engine Misalignment Failed engine mounts and loose or damaged bolts are the primary causes of engine misalignment. Check and replace any loose or damaged mounting bolts. Misalignment between a motor and its driven. Replace the affected engine mounts to correct the misalignment. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Its primary function is to dampen. Engine Misalignment.

From www.f150forum.com

Engine light. Misalignment of engine parts. Ford F150 Forum Engine Misalignment Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Inspect engine mounts and alignment to. Misalignment between a motor and its driven. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Its primary function is to dampen torsional vibrations that can occur in the. Engine Misalignment.

From www.amesolutions.com

A 225m tanker wiped a stern tube bearing due to an engine misalignment. Engine Misalignment Recognizing these symptoms early can help prevent further damage and costly repairs. Misalignment between a motor and its driven. Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Replace the affected engine mounts to correct the misalignment. Failed engine. Engine Misalignment.

From www.pinterest.com

Reasons for Failure and Misalignment of Crankshaft in Marine Engines Engine Misalignment Misalignment between a motor and its driven. Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Failed engine mounts and loose or damaged bolts are the primary causes of engine misalignment. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Recognizing these symptoms early can help prevent further damage and costly. Engine Misalignment.

From www.youtube.com

Engine Belt Misalignment YouTube Engine Misalignment Misalignment between a motor and its driven. Replace the affected engine mounts to correct the misalignment. Check and replace any loose or damaged mounting bolts. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Ensure proper installation and alignment during the replacement process to avoid further issues. Bad motor mount symptoms. Engine Misalignment.

From www.reddit.com

2019 3.5 Ecoboost engine misalignment code r/f150 Engine Misalignment Inspect engine mounts and alignment to. Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Bad motor mount symptoms include excessive engine vibration, abnormal noises, and misaligned engine components. Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Failed engine mounts and loose or damaged bolts are the primary. Engine Misalignment.

From www.vwvortex.com

HELP Misaligned engine mount (right side) VW Vortex Volkswagen Forum Engine Misalignment Symptoms of engine misalignment include a continuous noise that worsens with engine speed. Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Misalignment between a motor and its driven. Check and replace any loose or damaged mounting bolts. Replace the affected engine mounts to correct the misalignment. Ensure proper installation and. Engine Misalignment.

From www.amesolutions.com

A 225m tanker wiped a stern tube bearing due to an engine misalignment. Engine Misalignment Ensure proper installation and alignment during the replacement process to avoid further issues. Inspect engine mounts and alignment to. Failed engine mounts and loose or damaged bolts are the primary causes of engine misalignment. Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Recognizing these symptoms early can help prevent further damage and. Engine Misalignment.

From www.technomaxme.com

Types Of Misalignment In Machines Detection & Correction Engine Misalignment Engine misalignment occurs when the engine’s components, such as the crankshaft, camshaft, and flywheel, are not properly aligned. Check and replace any loose or damaged mounting bolts. Misalignment between a motor and its driven. Proper motor alignment is a fundamental aspect of maintaining and optimising the performance of rotating equipment. Ensure proper installation and alignment during the replacement process to. Engine Misalignment.