Surface Roughness Using Image Processing . The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical.

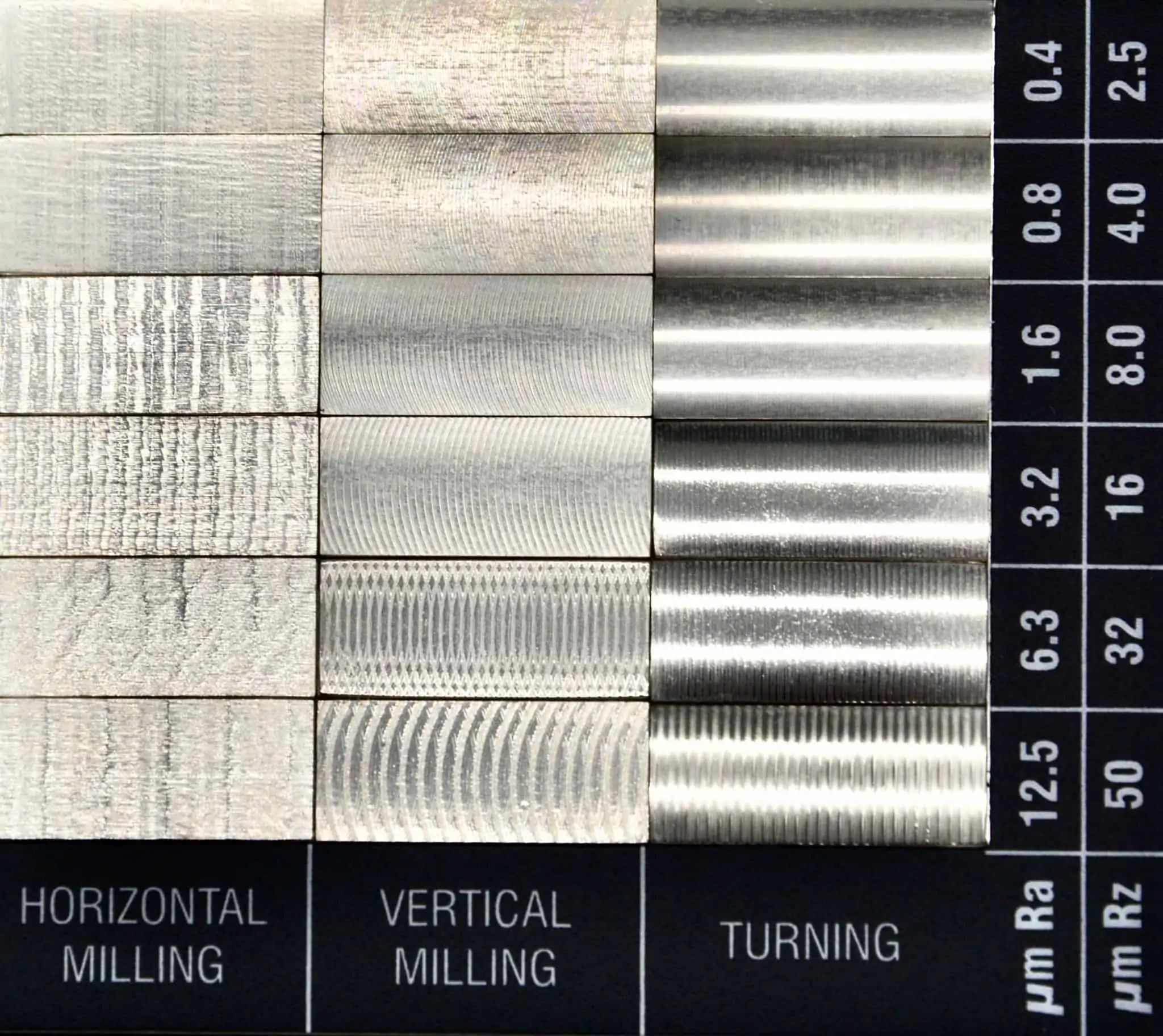

from xometry.eu

The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing.

Selecting right surface roughness for CNC machining Xometry Europe

Surface Roughness Using Image Processing A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for.

From www.coventor.com

Modeling of Line and Surface Roughness in Semiconductor Processing Coventor Surface Roughness Using Image Processing Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. The roughness of the bottom. Surface Roughness Using Image Processing.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Roughness Using Image Processing A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. The roughness of the bottom. Surface Roughness Using Image Processing.

From vdocuments.mx

Surface Roughness Measurement Based on Image · PDF fileSurface Roughness Measurement Based on Surface Roughness Using Image Processing This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. Two novel industrial implementation. Surface Roughness Using Image Processing.

From www.researchgate.net

(PDF) Surface roughness characterisation of turned surfaces using image processing Surface Roughness Using Image Processing The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. The roughness of the bottom surface of. Surface Roughness Using Image Processing.

From www.engineeringtoolbox.com

Mechanical Processing and Surface Roughness Surface Roughness Using Image Processing The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. This paper. Surface Roughness Using Image Processing.

From wa.nlcs.gov.bt

Surface roughness chart Surface Roughness Using Image Processing This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. The roughness of the bottom surface of. Surface Roughness Using Image Processing.

From www.imagemet.com

Roughness, Hardness & Surface Analysis Image Metrology Surface Roughness Using Image Processing This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. The hamming distance between the reference. Surface Roughness Using Image Processing.

From newsroom.lamresearch.com

Modeling of Line and Surface Roughness in Semiconductor Processing Jan. 13, 2023 Surface Roughness Using Image Processing This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. From the perspective of. Surface Roughness Using Image Processing.

From newsroom.lamresearch.com

Modeling of Line and Surface Roughness in Semiconductor Processing Jan. 13, 2023 Surface Roughness Using Image Processing This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. A surface roughness measurement technique, based. Surface Roughness Using Image Processing.

From manufactur3dmag.com

Surface Roughness A Guide To Metal Additive Manufacturing By Digital Alloys Manufactur3D Surface Roughness Using Image Processing The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. Evaluation using experimental data shows that the. Surface Roughness Using Image Processing.

From imagesee.biz

Surface Finish Machinng Chart Pdf Surface Roughness Machining IMAGESEE Surface Roughness Using Image Processing A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. The hamming distance between. Surface Roughness Using Image Processing.

From edmontonrealestateinvestmentblog.com

Surface Roughness Explained Get It Made (2022) Surface Roughness Using Image Processing Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. The hamming distance between the reference signals and. Surface Roughness Using Image Processing.

From www.keyence.com

Roughness Measurement Examples Introduction To Roughness KEYENCE America Surface Roughness Using Image Processing The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. From the perspective of. Surface Roughness Using Image Processing.

From dokumen.tips

(PDF) Surface roughness classification using image processing DOKUMEN.TIPS Surface Roughness Using Image Processing This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. A surface roughness measurement technique, based on an. Surface Roughness Using Image Processing.

From www.researchgate.net

Comparison of surface roughness value evaluated by imageprocessing and... Download Scientific Surface Roughness Using Image Processing Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. This paper aims to present a methodology to. Surface Roughness Using Image Processing.

From mavink.com

Rms Surface Roughness Chart Surface Roughness Using Image Processing Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. From the perspective of image acquisition,. Surface Roughness Using Image Processing.

From github.com

GitHub AdrianRvzz/SurfaceRoughnessImageAnalysis Python program for analyzing surface Surface Roughness Using Image Processing The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing.. Surface Roughness Using Image Processing.

From www.scientific.net

Monitoring Surface Roughness of Turning by Using Image Processing Technology Surface Roughness Using Image Processing From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. A surface roughness measurement technique, based on an. Surface Roughness Using Image Processing.

From www.suginocorp.com

Surface Roughness for Lathe Turning Surface Roughness Using Image Processing The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. A surface roughness measurement technique,. Surface Roughness Using Image Processing.

From www.researchgate.net

(PDF) SOFTWARE APPLICATION FOR DETERMINING THE SURFACE ROUGHNESS USING IMAGE PROCESSING WITH Surface Roughness Using Image Processing This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. Evaluation using experimental data. Surface Roughness Using Image Processing.

From www.mdpi.com

Micromachines Free FullText Effect of Milling Processing Parameters on the Surface Surface Roughness Using Image Processing The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. Evaluation using experimental data. Surface Roughness Using Image Processing.

From www.researchgate.net

Microscopic image (enlargement 50) of the surface roughness obtained by... Download Scientific Surface Roughness Using Image Processing From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. The roughness of the bottom surface of each cavity was. Surface Roughness Using Image Processing.

From www.semanticscholar.org

Figure 1 from Surface roughness prediction of machined components using gray level cooccurrence Surface Roughness Using Image Processing This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. A surface roughness. Surface Roughness Using Image Processing.

From www.techscience.com

CMES Free FullText Surface Characteristics Measurement Using Computer Vision A Review Surface Roughness Using Image Processing Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. The roughness of the bottom surface of each cavity. Surface Roughness Using Image Processing.

From www.azonano.com

How to Measure the Roughness of Very Smooth Surfaces Surface Roughness Using Image Processing The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. The roughness of the. Surface Roughness Using Image Processing.

From www.researchgate.net

Areal surface roughness measured by noncontact optical profilometer; a... Download Scientific Surface Roughness Using Image Processing The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. Two novel industrial implementation methods. Surface Roughness Using Image Processing.

From xometry.eu

Selecting right surface roughness for CNC machining Xometry Europe Surface Roughness Using Image Processing The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. From the. Surface Roughness Using Image Processing.

From www.edmundoptics.com

Understanding Surface Roughness Edmund Optics Surface Roughness Using Image Processing The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. Evaluation using experimental data shows that the developed method predicts surface roughness with an error of 0.5%, outperforming existing. Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. From the perspective of. Surface Roughness Using Image Processing.

From www.researchgate.net

Typical examples of surface roughness of smooth Al cold rolled foil... Download Scientific Diagram Surface Roughness Using Image Processing A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. Two. Surface Roughness Using Image Processing.

From www.researchgate.net

(PDF) Surface roughness characterization using digital image processing technique Surface Roughness Using Image Processing From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. Two novel industrial implementation methods. Surface Roughness Using Image Processing.

From www.researchgate.net

(PDF) On Line Surface Roughness Measurement Using Image Processing and Machine Vision. Surface Roughness Using Image Processing The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. This paper aims to present a. Surface Roughness Using Image Processing.

From www.mdpi.com

Machines Free FullText Contactless Method for Measurement of Surface Roughness Based on a Surface Roughness Using Image Processing The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. From the perspective of image acquisition, preprocessing, and detection algorithms, this paper summarizes the existing typical. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. A surface roughness measurement technique, based on. Surface Roughness Using Image Processing.

From www.mdpi.com

Machines Free FullText A GANBPNNBased Surface Roughness Measurement Method for Robotic Surface Roughness Using Image Processing The roughness of the bottom surface of each cavity was measured with the line profiling method using a contact stylus surface. The hamming distance between the reference signals and test signal was used to estimate the surface roughness of test image. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. Evaluation. Surface Roughness Using Image Processing.

From www.semanticscholar.org

Figure 1 from Surface roughness classification using image processing Semantic Scholar Surface Roughness Using Image Processing Two novel industrial implementation methods are introduced in this paper to estimate, quantitatively, the concrete surface roughness. A surface roughness measurement technique, based on an optical method using a computer vision system, was investigated for. This paper aims to present a methodology to predict surface roughness using image processing, computer vision, and. From the perspective of image acquisition, preprocessing, and. Surface Roughness Using Image Processing.