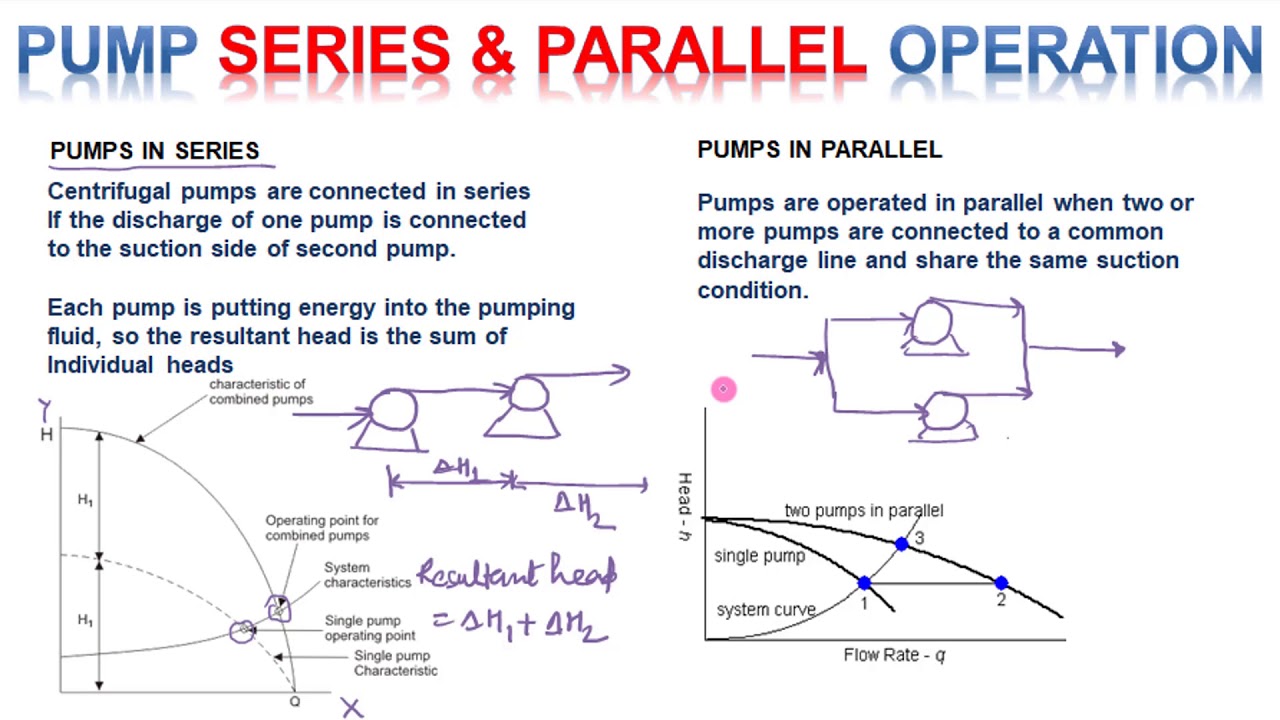

Pumps In Parallel Head Calculation . The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of head which is the same for both pumps, i.e. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. See the performance curves and examples of. Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. With pumps in parallel, the flow rates are additive with a common head. H 1 = h 2. If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. The flowrate qt is split between the inlet into q1. Learn how to connect pumps in parallel or serial to increase head or flow rate capacity. Examples in this book will show how to employ pumps in parallel or in series while avoiding the pitfalls that sometimes entrap a careless. As a general rule, always start the weaker pump first.

from circuitengineeclair.z21.web.core.windows.net

Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. H 1 = h 2. See the performance curves and examples of. The flowrate qt is split between the inlet into q1. With pumps in parallel, the flow rates are additive with a common head. As a general rule, always start the weaker pump first. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of head which is the same for both pumps, i.e. Learn how to connect pumps in parallel or serial to increase head or flow rate capacity.

Pd Pumps In Parallel

Pumps In Parallel Head Calculation In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. As a general rule, always start the weaker pump first. The flowrate qt is split between the inlet into q1. With pumps in parallel, the flow rates are additive with a common head. If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. H 1 = h 2. The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of head which is the same for both pumps, i.e. See the performance curves and examples of. Learn how to connect pumps in parallel or serial to increase head or flow rate capacity. Examples in this book will show how to employ pumps in parallel or in series while avoiding the pitfalls that sometimes entrap a careless.

From www.ctgclean.com

Pumps Pump Performance Curves CTG Cleaning Technologies, Inc. Pumps In Parallel Head Calculation If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. As a general rule, always start the weaker pump first. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined. Pumps In Parallel Head Calculation.

From electrical-engineering-portal.com

The essentials of pumping, pump speed and flow rate control that Pumps In Parallel Head Calculation H 1 = h 2. The flowrate qt is split between the inlet into q1. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and. Pumps In Parallel Head Calculation.

From mavink.com

Pump Head Calculation Pumps In Parallel Head Calculation If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. H 1 = h 2. Learn how to connect pumps in parallel or serial to increase head or flow rate capacity. Examples in this book will show how to employ pumps in. Pumps In Parallel Head Calculation.

From hollandapt.blog

What is Pump Head? How is it Different than Pressure? Holland Applied Pumps In Parallel Head Calculation The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of head which is the same for both pumps, i.e. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. The flowrate qt is split between. Pumps In Parallel Head Calculation.

From www.researchgate.net

8 Pump curve for 2 pumps in parallel Download Scientific Diagram Pumps In Parallel Head Calculation With pumps in parallel, the flow rates are additive with a common head. Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. Examples in this book will show how to employ pumps in parallel or in series while avoiding the pitfalls that sometimes entrap a careless. See the performance curves and examples of.. Pumps In Parallel Head Calculation.

From www.pumpsandsystems.com

Calculating the Performance of Multistage Pumps Operating in Parallel Pumps In Parallel Head Calculation H 1 = h 2. If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. With pumps in parallel, the flow rates are additive with a common head. See the performance curves and examples of. The total system performance curve for parallel. Pumps In Parallel Head Calculation.

From www.youtube.com

Pumps in series and parallel with solved examples YouTube Pumps In Parallel Head Calculation With pumps in parallel, the flow rates are additive with a common head. Learn how to connect pumps in parallel or serial to increase head or flow rate capacity. The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of head which is the same for both pumps, i.e.. Pumps In Parallel Head Calculation.

From www.pumps.org

Five Keys to Understanding Parallel Pump Optimization Pumps In Parallel Head Calculation The flowrate qt is split between the inlet into q1. Learn how to connect pumps in parallel or serial to increase head or flow rate capacity. Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given. Pumps In Parallel Head Calculation.

From theengineeringmindset.com

Pump calculations The Engineering Mindset Pumps In Parallel Head Calculation The flowrate qt is split between the inlet into q1. Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. Learn how to connect pumps in parallel or serial to increase head or flow rate capacity. If the system is designed for parallel pumps, determine which pump is the stronger one by running one. Pumps In Parallel Head Calculation.

From theengineeringmindset.com

Pump calculations The Engineering Mindset Pumps In Parallel Head Calculation As a general rule, always start the weaker pump first. The flowrate qt is split between the inlet into q1. If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. Examples in this book will show how to employ pumps in parallel. Pumps In Parallel Head Calculation.

From hassanelbanhawi.com

Pumps Classification, governing Equations and Calculation Tools. Pumps In Parallel Head Calculation H 1 = h 2. Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. Learn how to connect pumps in parallel or serial to increase head or flow rate capacity. As a general rule, always start the weaker pump first. If the system is designed for parallel pumps, determine which pump is the. Pumps In Parallel Head Calculation.

From www.pumpsandsystems.com

Calculating the Performance of Multistage Pumps Operating in Parallel Pumps In Parallel Head Calculation In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. Examples in this book will show how to employ pumps in parallel or in series while avoiding the pitfalls that sometimes entrap a careless. Learn how to connect pumps in parallel or serial to increase head or. Pumps In Parallel Head Calculation.

From www.thetechedvocate.org

How to calculate pump head The Tech Edvocate Pumps In Parallel Head Calculation See the performance curves and examples of. H 1 = h 2. Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of head which is the same for both pumps, i.e. Examples. Pumps In Parallel Head Calculation.

From circuitengineeclair.z21.web.core.windows.net

Pd Pumps In Parallel Pumps In Parallel Head Calculation If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. With pumps in parallel, the flow rates are additive with a common head. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head. Pumps In Parallel Head Calculation.

From blog.hayespump.com

How to Operate Pumps in Parallel Hayes Pump Pumps In Parallel Head Calculation Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. With pumps in parallel, the flow rates are additive with a common head. H 1 =. Pumps In Parallel Head Calculation.

From www.youtube.com

PENG2011 Fluid Mechanics Pump Head Calculations Part 4 Example Pumps In Parallel Head Calculation H 1 = h 2. Examples in this book will show how to employ pumps in parallel or in series while avoiding the pitfalls that sometimes entrap a careless. See the performance curves and examples of. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. As. Pumps In Parallel Head Calculation.

From www.slideshare.net

Calculation Of Pump Head Pumps In Parallel Head Calculation The flowrate qt is split between the inlet into q1. As a general rule, always start the weaker pump first. With pumps in parallel, the flow rates are additive with a common head. The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of head which is the same. Pumps In Parallel Head Calculation.

From www.youtube.com

Combining Pumps in Series and Parallel YouTube Pumps In Parallel Head Calculation Learn how to connect pumps in parallel or serial to increase head or flow rate capacity. The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of head which is the same for both pumps, i.e. With pumps in parallel, the flow rates are additive with a common head.. Pumps In Parallel Head Calculation.

From uta.pressbooks.pub

Experiment 10 Pumps Applied Fluid Mechanics Lab Manual Pumps In Parallel Head Calculation As a general rule, always start the weaker pump first. If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. With pumps in parallel, the flow rates are additive with a common head. Determine the polynomial function for the combined performance for. Pumps In Parallel Head Calculation.

From www.pumpsandsystems.com

Calculating the Performance of Multistage Pumps Operating in Parallel Pumps In Parallel Head Calculation The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of head which is the same for both pumps, i.e. As a general rule, always start the weaker pump first. Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. With pumps in. Pumps In Parallel Head Calculation.

From www.pumpsandsystems.com

Calculating the Performance of Multistage Pumps Operating in Parallel Pumps In Parallel Head Calculation See the performance curves and examples of. H 1 = h 2. Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. As a general rule, always start the weaker pump first. Examples in this book will show how to employ pumps in parallel or in series while avoiding the pitfalls that sometimes entrap. Pumps In Parallel Head Calculation.

From www.mepengineersclub.com

Pump Calculations, Flow Rate, RPM, Head Pressure, & Impeller Diameter Pumps In Parallel Head Calculation If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. The total system performance curve for parallel pumps can. Pumps In Parallel Head Calculation.

From chemicalengineeringsite.in

Centrifugal Pump Affinity Laws Calculation Chemical Engineering Site Pumps In Parallel Head Calculation Examples in this book will show how to employ pumps in parallel or in series while avoiding the pitfalls that sometimes entrap a careless. The flowrate qt is split between the inlet into q1. If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at. Pumps In Parallel Head Calculation.

From hassanelbanhawi.com

Pumps Classification, governing Equations and Calculation Tools. Pumps In Parallel Head Calculation As a general rule, always start the weaker pump first. The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of head which is the same for both pumps, i.e. Learn how to connect pumps in parallel or serial to increase head or flow rate capacity. In pump parallel. Pumps In Parallel Head Calculation.

From hvacsimplified.in

Pump Head Calculation Sheet hvacsimplified.in Pumps In Parallel Head Calculation Examples in this book will show how to employ pumps in parallel or in series while avoiding the pitfalls that sometimes entrap a careless. H 1 = h 2. See the performance curves and examples of. The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of head which. Pumps In Parallel Head Calculation.

From www.youtube.com

NPSH Calculation pump head calculation NPSH pump calculation Pumps In Parallel Head Calculation The flowrate qt is split between the inlet into q1. H 1 = h 2. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of. Pumps In Parallel Head Calculation.

From www.eng-tips.com

head calculation in parallel pumping Pump engineering EngTips Pumps In Parallel Head Calculation If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. H 1 = h 2. Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. Learn how to connect pumps in parallel or serial to increase. Pumps In Parallel Head Calculation.

From hvacgroomingminds.blogspot.com

PUMP HEAD CALCULATION All About HVAC System HVAC Design Fire Pumps In Parallel Head Calculation Learn how to connect pumps in parallel or serial to increase head or flow rate capacity. With pumps in parallel, the flow rates are additive with a common head. The total system performance curve for parallel pumps can be determined by adding q 1 and q 2 for every value of head which is the same for both pumps, i.e.. Pumps In Parallel Head Calculation.

From www.supplywaterpumps.com

Calculation formula of pump flow and head Shenlong APK Pumps In Parallel Head Calculation Examples in this book will show how to employ pumps in parallel or in series while avoiding the pitfalls that sometimes entrap a careless. Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. As a general rule, always start the weaker pump first. The flowrate qt is split between the inlet into q1.. Pumps In Parallel Head Calculation.

From www.deppmann.com

HVAC Hydronic System Parallel Pump Operation and Curves RLD Pumps In Parallel Head Calculation If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. The flowrate qt is split between the inlet into. Pumps In Parallel Head Calculation.

From circuitengineeclair.z21.web.core.windows.net

Pd Pumps In Parallel Pumps In Parallel Head Calculation In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. With pumps in parallel, the flow rates are additive with a common head. H 1 = h 2. Determine the polynomial function for the combined performance for multiple (and identical) pumps operating in parallel. Examples in this. Pumps In Parallel Head Calculation.

From www.youtube.com

PUMP IN SERIES AND PARALLEL PUMPS CURVES COMBINATION OF PUMPS IN Pumps In Parallel Head Calculation In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. As a general rule, always start the weaker pump first. If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various. Pumps In Parallel Head Calculation.

From www.researchgate.net

8 Pump curve for 2 pumps in parallel Download Scientific Diagram Pumps In Parallel Head Calculation The flowrate qt is split between the inlet into q1. In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. See the performance curves and examples of. If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a. Pumps In Parallel Head Calculation.

From pumpfocus.com

9.6 Parallel pump operation Pumpfocus Pumps In Parallel Head Calculation Examples in this book will show how to employ pumps in parallel or in series while avoiding the pitfalls that sometimes entrap a careless. As a general rule, always start the weaker pump first. With pumps in parallel, the flow rates are additive with a common head. If the system is designed for parallel pumps, determine which pump is the. Pumps In Parallel Head Calculation.

From hvacgroomingminds.blogspot.com

PUMP HEAD CALCULATION All About HVAC System HVAC Design Fire Pumps In Parallel Head Calculation In pump parallel operation, both pump will deliver the flow they have been designed for, at the given head of the combined flow. If the system is designed for parallel pumps, determine which pump is the stronger one by running one at a time and measuring the head at various flows. Learn how to connect pumps in parallel or serial. Pumps In Parallel Head Calculation.